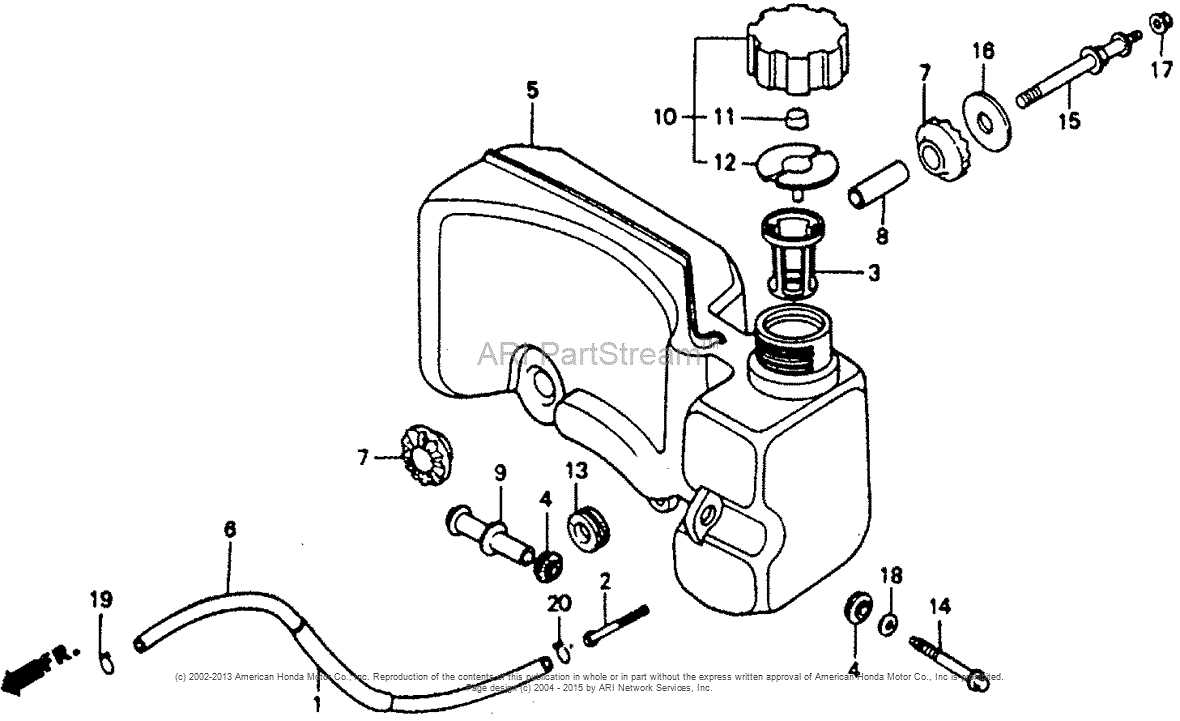

In the world of machinery, having a clear overview of the individual elements that contribute to overall functionality is essential. This section aims to provide insights into the arrangement and relationship between various components found in specific models. By grasping how each element interacts, users can enhance their understanding and improve maintenance practices.

Identifying the configuration of each segment plays a crucial role in troubleshooting and repair processes. A detailed illustration serves as a valuable reference for technicians and enthusiasts alike, enabling them to pinpoint issues effectively. Furthermore, such representations can aid in the assembly and disassembly of equipment, streamlining the workflow for any project.

By exploring the intricacies of these layouts, one can appreciate the engineering behind the machinery. A comprehensive understanding not only facilitates smoother operations but also empowers users to make informed decisions regarding upgrades and modifications. This knowledge fosters a deeper connection between the operator and the machine, leading to enhanced performance and longevity.

Importance of Accurate Parts Identification

Identifying components correctly is crucial for ensuring the efficient operation and maintenance of any system. When each element is recognized with precision, it significantly reduces the likelihood of errors during assembly or repairs. This not only streamlines processes but also enhances the overall performance and longevity of the equipment.

Understanding the correct identification of each component allows technicians to make informed decisions regarding replacements and upgrades. It minimizes the risk of using incorrect items, which can lead to malfunctions or even complete system failures. Furthermore, precise identification facilitates effective troubleshooting, enabling quicker diagnosis of issues.

In industries where precision is paramount, the ability to accurately identify individual elements can lead to cost savings and increased productivity. By investing time in understanding the specifics of each component, businesses can avoid unnecessary delays and ensure that their operations run smoothly.

Common Issues with Hrn216vka Parts

When dealing with various components of a specific machinery model, users may encounter a range of challenges that can affect performance and reliability. Identifying these issues early can lead to timely interventions and ensure the efficient operation of the equipment.

Frequent Challenges

- Wear and Tear: Continuous use may result in degradation of specific components, leading to decreased efficiency.

- Incompatibility: Some parts may not function properly with others, especially if replacements are sourced from different manufacturers.

- Assembly Errors: Improper installation can lead to malfunction, making it crucial to follow guidelines carefully.

- Maintenance Oversights: Lack of regular upkeep can lead to buildup of debris, affecting overall performance.

Symptoms to Watch For

- Unusual Noises: Strange sounds during operation may indicate a malfunctioning component.

- Decreased Efficiency: A noticeable drop in performance can signal issues with one or more parts.

- Frequent Breakdowns: If the machinery requires regular repairs, it may suggest underlying problems.

- Visual Damage: Cracks, rust, or other visible deterioration can serve as indicators of potential failures.

Steps to Read the Parts Diagram

Understanding the layout of components within a system can significantly enhance your ability to perform maintenance and repairs. This section outlines essential methods to effectively interpret the visual representation of elements, ensuring a smooth experience when working with machinery.

Familiarize Yourself with the Symbols

Before delving into the specifics, take time to understand the symbols used in the illustration. Each icon represents a different component or feature, and recognizing these can provide insights into their functions. Often, a key or legend accompanies the image, clarifying what each symbol denotes.

Identify Connections and Flow

Once you grasp the symbols, focus on the connections between components. Trace the lines that illustrate how different parts interact, as this will help you comprehend the operational flow. Pay attention to any directional indicators, as they are crucial for understanding the sequence in which elements work together.

Maintenance Tips for Hrn216vka

Regular upkeep is essential for ensuring the longevity and optimal performance of your equipment. By following a systematic maintenance routine, you can prevent potential issues and enhance the efficiency of operation. This section outlines several key strategies to keep your machinery in top shape.

Routine Inspections

Conducting frequent inspections is crucial for identifying wear and tear before they become significant problems. Here are some key aspects to monitor:

- Check for any signs of rust or corrosion on metal surfaces.

- Inspect belts and hoses for cracks or fraying.

- Examine wheels and other moving parts for smooth operation.

Cleaning and Lubrication

Keeping the components clean and well-lubricated is vital for smooth functionality. Consider the following practices:

- Clean dust and debris from all surfaces regularly.

- Apply appropriate lubricants to moving parts to reduce friction.

- Ensure that filters are replaced or cleaned as needed.

Comparing Hrn216vka with Similar Models

When evaluating various models in a specific category, it is essential to consider their features, performance, and overall design. By comparing a particular model to its counterparts, potential buyers can make informed decisions based on their specific needs and preferences.

Here are several key aspects to consider when comparing different models:

- Engine Performance: Analyze the power output and efficiency of the engines in each model. Variations in horsepower can significantly affect overall performance.

- Cutting Width: Different models offer varying cutting widths, which can impact the time required to complete tasks. A wider cutting deck may enhance productivity.

- Weight and Maneuverability: Consider the weight of each model, as it can influence ease of use and maneuverability in tight spaces.

- Durability and Build Quality: Examine the materials used in construction and any warranties offered, as these factors contribute to longevity and reliability.

- Price Range: Compare the cost of each model to ensure it fits within budget constraints while meeting performance expectations.

By focusing on these critical areas, individuals can identify the model that best aligns with their requirements, ensuring a satisfactory purchase experience.

Where to Source Replacement Parts

Finding the right components for your equipment is crucial for maintaining its efficiency and longevity. Various options exist for acquiring these essential elements, ranging from online retailers to local stores. Each source offers distinct advantages, ensuring that you can keep your machinery in optimal condition.

When looking for suitable replacements, consider exploring both specialized suppliers and general hardware stores. Additionally, online marketplaces provide a convenient platform for comparing prices and availability. Here are some recommended avenues to pursue:

| Source Type | Description | Pros | Cons |

|---|---|---|---|

| Authorized Dealers | Official vendors that specialize in specific equipment. | Genuine items, expert advice. | Higher prices, limited stock. |

| Local Hardware Stores | Neighborhood shops offering a variety of components. | Immediate availability, personalized service. | Limited selection, may lack specific items. |

| Online Retailers | Websites specializing in a wide range of tools and components. | Extensive inventory, competitive pricing. | Longer shipping times, potential for incorrect items. |

| Marketplace Platforms | Third-party sellers on large e-commerce websites. | Variety of choices, price comparison. | Variable quality, reliability concerns. |

By evaluating these sources, you can ensure that your machinery receives the best components for reliable performance. Choose wisely based on your specific needs and the availability of resources in your area.

Understanding Warranty and Service Options

When purchasing any complex equipment, it is essential to consider the protection and assistance that come with it. Warranty agreements and service provisions ensure that users have support in case of defects or operational challenges. These options not only provide peace of mind but also enhance the longevity and performance of the device.

Types of Warranty Coverage

Warranty coverage typically varies, offering different levels of protection based on the manufacturer’s policies. Commonly, warranties include full replacement, repair services, and sometimes extended support plans. It’s crucial to read the fine print to understand what is included and what might require additional fees.

Accessing Service and Support

Users should be aware of how to access support services when needed. Many manufacturers provide online resources, such as troubleshooting guides and customer service contact information. Additionally, knowing the nearest authorized service centers can expedite repairs and maintenance, ensuring optimal functionality of the equipment.

Enhancing Performance with Upgrades

Improving the efficiency and functionality of machinery can significantly impact overall performance. Upgrading various components not only enhances operational capabilities but also extends the lifespan of the equipment. Understanding which enhancements can be made allows for a more tailored approach to performance optimization.

Key Areas for Improvement

Focusing on specific areas such as engine efficiency, transmission responsiveness, and braking systems can yield substantial benefits. For instance, integrating high-performance filters can enhance airflow, leading to better combustion and increased power output. Additionally, upgrading the ignition system can ensure a more reliable start and improved fuel efficiency.

Benefits of Component Upgrades

Upgrading components results in a multitude of advantages. Enhanced durability is often observed, allowing the machinery to withstand demanding conditions. Moreover, these enhancements can lead to reduced maintenance costs, as more reliable parts require less frequent replacements. Ultimately, these modifications contribute to a smoother and more efficient operational experience.