In the realm of household maintenance, efficient devices play a pivotal role in simplifying the chore of keeping spaces pristine. A deep understanding of how these machines operate can significantly enhance their effectiveness and longevity. This article aims to provide a detailed exploration of the internal components that contribute to the functionality of a popular cleaning apparatus.

By delving into the various elements that make up this essential equipment, users can gain valuable insights into maintenance practices and troubleshooting methods. Recognizing the specific roles of each component allows for better handling and care, ultimately resulting in improved performance and durability.

In the following sections, we will break down the intricate structure of this cleaning device, offering a visual representation that aids in comprehension. Such knowledge empowers users to engage more confidently with their equipment, ensuring a seamless cleaning experience.

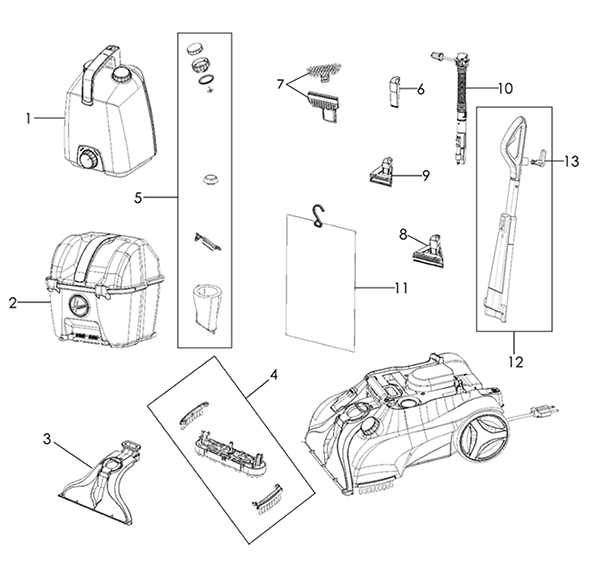

Understanding Hoover Spinscrub 50 Components

This section aims to explore the essential elements of a specific cleaning device, focusing on how each component contributes to its overall functionality. By breaking down these parts, users can gain insights into maintenance, troubleshooting, and optimization of the appliance’s performance.

Key Elements

The primary components include the motor, brushes, and water tanks. Each part plays a vital role in ensuring effective cleaning, with the motor driving the action and the brushes providing the necessary scrubbing motion. Water tanks facilitate fluid distribution, enhancing the cleaning process.

Maintenance and Care

Understanding these components is crucial for proper upkeep. Regular inspection of the motor and brushes can prevent malfunctions, while ensuring that the tanks are clean can enhance efficiency. Familiarity with these parts not only extends the lifespan of the device but also ensures optimal performance during use.

Importance of a Parts Diagram

Understanding the layout and components of any mechanical device is crucial for effective maintenance and repair. A visual representation of the individual elements helps users identify, locate, and understand the function of each piece. This clarity can significantly enhance the efficiency of troubleshooting and servicing procedures.

Facilitating Repairs

A comprehensive visual guide simplifies the repair process by providing an easy reference point. Users can quickly pinpoint the parts needing attention, reducing the time spent searching for components. This efficiency not only minimizes downtime but also decreases the likelihood of errors during reassembly.

Enhancing User Knowledge

Having a clear illustration fosters a deeper understanding of how various components interact within the system. This knowledge empowers users to make informed decisions regarding maintenance and upgrades, ultimately prolonging the lifespan of the equipment.

Key Features of Hoover Spinscrub 50

This model stands out for its exceptional cleaning capabilities and innovative design. Engineered to enhance the user experience, it offers a variety of features that cater to different cleaning needs.

- Advanced Scrubbing Technology: Utilizes dual counter-rotating brushes that work together to lift dirt and grime effectively.

- Lightweight and Portable: Designed for easy maneuverability, allowing users to clean multiple surfaces without hassle.

- Multiple Cleaning Modes: Offers various settings to tackle different types of stains and floor types, ensuring optimal results.

- Easy-to-Fill Water Tank: Features a simple filling mechanism that minimizes downtime during cleaning sessions.

- Efficient Extraction System: Capable of extracting moisture quickly, reducing drying time significantly.

These attributes not only enhance cleaning efficiency but also make the process more convenient for users, ensuring a thorough clean every time.

Common Issues and Troubleshooting Tips

When utilizing cleaning devices, users may encounter various challenges that can hinder performance. Understanding these common problems and having effective solutions at hand can significantly enhance the overall experience and ensure optimal functioning of the equipment.

Frequent Problems

Several issues may arise during operation, ranging from mechanical failures to fluid-related concerns. Identifying these problems promptly can help in taking corrective measures before they escalate.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Loss of suction | Clogged hoses or filters | Inspect and clean or replace filters; check for blockages in hoses. |

| Water leakage | Damaged seals or hoses | Examine hoses for wear; replace any damaged components. |

| Inconsistent cleaning | Dirty brushes or incorrect settings | Clean brushes thoroughly; verify settings according to surface type. |

| No power | Faulty power source or wiring issues | Check power outlet; inspect cords and connections for damage. |

Maintenance Recommendations

Regular upkeep is essential to prolong the life of the device and maintain efficiency. Simple practices can prevent many common issues from occurring.

How to Use the Parts Diagram

Understanding the visual representation of components can significantly enhance your ability to troubleshoot and maintain your cleaning equipment effectively. This guide will provide essential insights into interpreting these visuals to ensure optimal performance and longevity of your device.

Identifying Key Components

Begin by familiarizing yourself with the various sections illustrated. Each element is typically labeled, allowing you to easily recognize parts that may require attention or replacement. Pay close attention to the legends and notes that accompany the visuals; they provide crucial information regarding the function and compatibility of each piece.

Guided Repairs and Maintenance

Once you’ve grasped the layout, use the visuals as a roadmap for repairs. Consult the reference often while working to ensure you’re following the correct steps, minimizing the risk of errors. This approach will ultimately lead to a more efficient maintenance process, extending the life of your appliance.

Replacement Parts Availability and Options

Access to necessary components for maintenance is crucial for ensuring optimal performance and longevity of your cleaning device. Whether you need to replace worn-out elements or upgrade to newer versions, various sources provide options tailored to your requirements.

Sources for Components

Components can typically be found through authorized retailers, online marketplaces, or directly from manufacturers. It’s essential to verify compatibility with your specific model to avoid mismatches.

Considerations When Selecting Components

When choosing replacements, consider factors such as quality, warranty, and price. Investing in higher-quality components can enhance performance and durability.

| Source | Quality | Price Range |

|---|---|---|

| Authorized Retailers | High | $$$ |

| Online Marketplaces | Variable | $$-$$$$ |

| Direct from Manufacturer | High | $$$ |

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your cleaning equipment is essential for achieving the best results. Regular upkeep not only enhances performance but also prevents unnecessary wear and tear. By following a few simple maintenance practices, you can keep your device in top shape and extend its lifespan.

Regular Cleaning

Cleaning the various components of your equipment is crucial. Dirt and debris can accumulate and hinder functionality. Make it a habit to inspect and clean key areas after each use to maintain optimal performance.

Inspection and Replacement

Regularly check for any signs of wear or damage. Replacing worn-out components promptly will prevent more significant issues down the line. Keeping spare parts on hand can be beneficial for quick replacements when necessary.

| Task | Frequency | Notes |

|---|---|---|

| Clean filters | Every use | Ensure filters are free from blockages. |

| Check belts | Monthly | Look for signs of wear or fraying. |

| Inspect brushes | Every 3 months | Replace if bristles are worn. |

| Lubricate moving parts | Every 6 months | Use recommended lubricant for smooth operation. |

Assembly and Disassembly Instructions

Understanding the process of assembling and disassembling your cleaning device is crucial for effective maintenance and efficient operation. This section provides a step-by-step guide to help you navigate through the procedures, ensuring both safety and functionality.

Before starting, gather all necessary tools and components. Ensure you have a clear workspace to facilitate the process.

- Disassembly Steps:

- Begin by unplugging the unit to ensure safety.

- Remove the water tank by releasing the latch mechanism.

- Detach the cleaning head by locating the locking tabs and gently pressing them.

- Take out any filters or brushes as needed, following the specific instructions for removal.

- Keep all components organized for easy reassembly later.

- Assembly Steps:

- Start by placing the brushes or filters back into their designated areas.

- Reconnect the cleaning head, ensuring the locking tabs click into place securely.

- Reattach the water tank, making sure it is properly seated and locked.

- Plug the device back into the power source.

- Perform a quick check to ensure all parts are securely assembled before use.

Following these guidelines will ensure your appliance remains in optimal condition, providing reliable service for your cleaning needs.