In any complex machinery, a thorough grasp of its individual elements is essential for optimal performance and maintenance. Recognizing how each component interacts and functions together can significantly enhance the efficiency and longevity of the system. This knowledge empowers users to troubleshoot issues effectively and implement necessary repairs when needed.

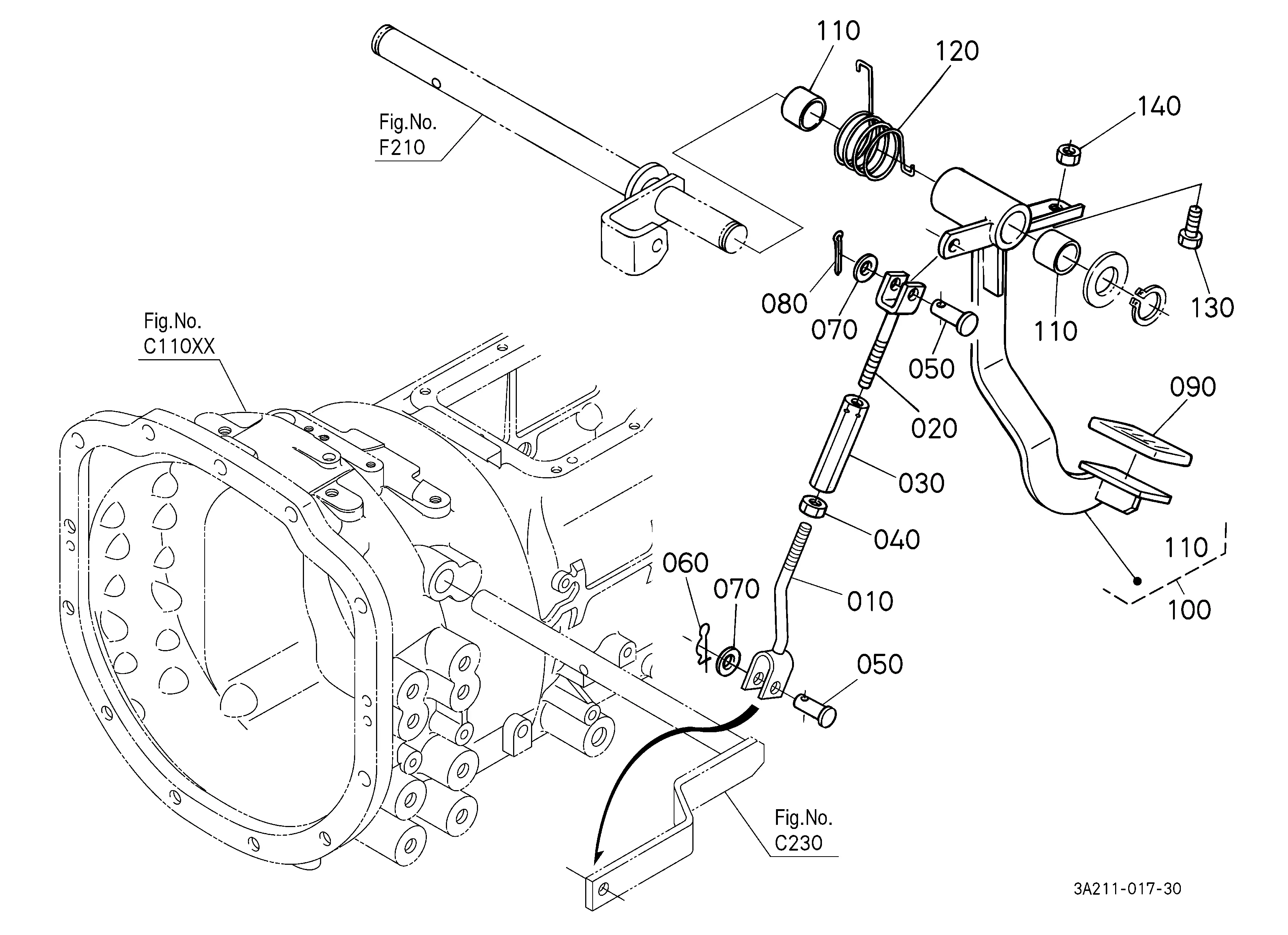

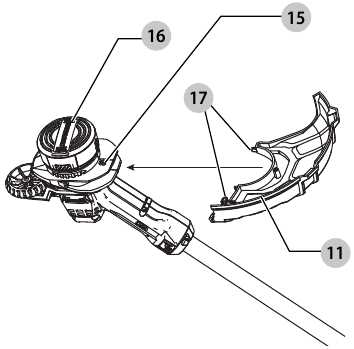

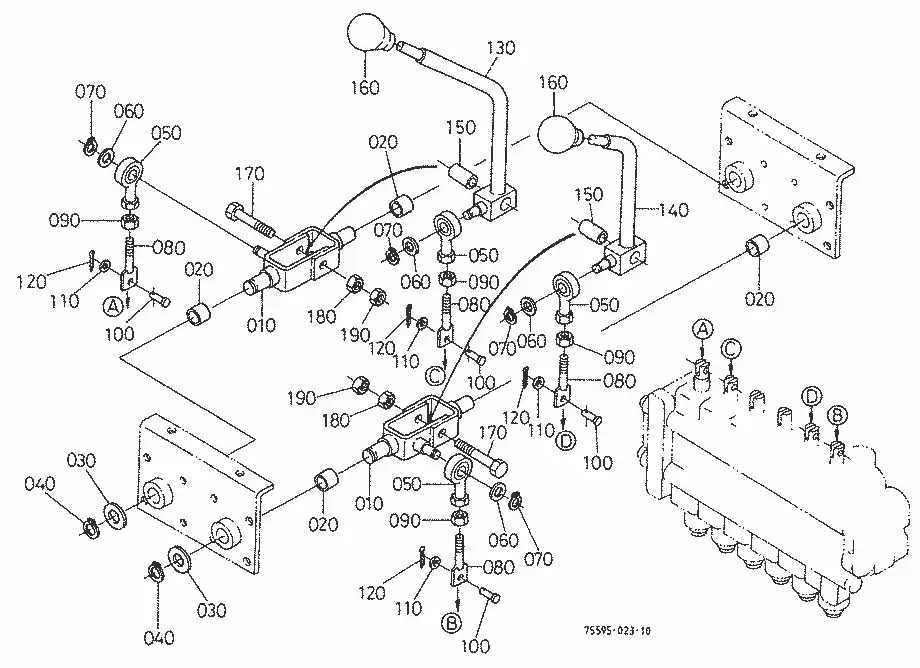

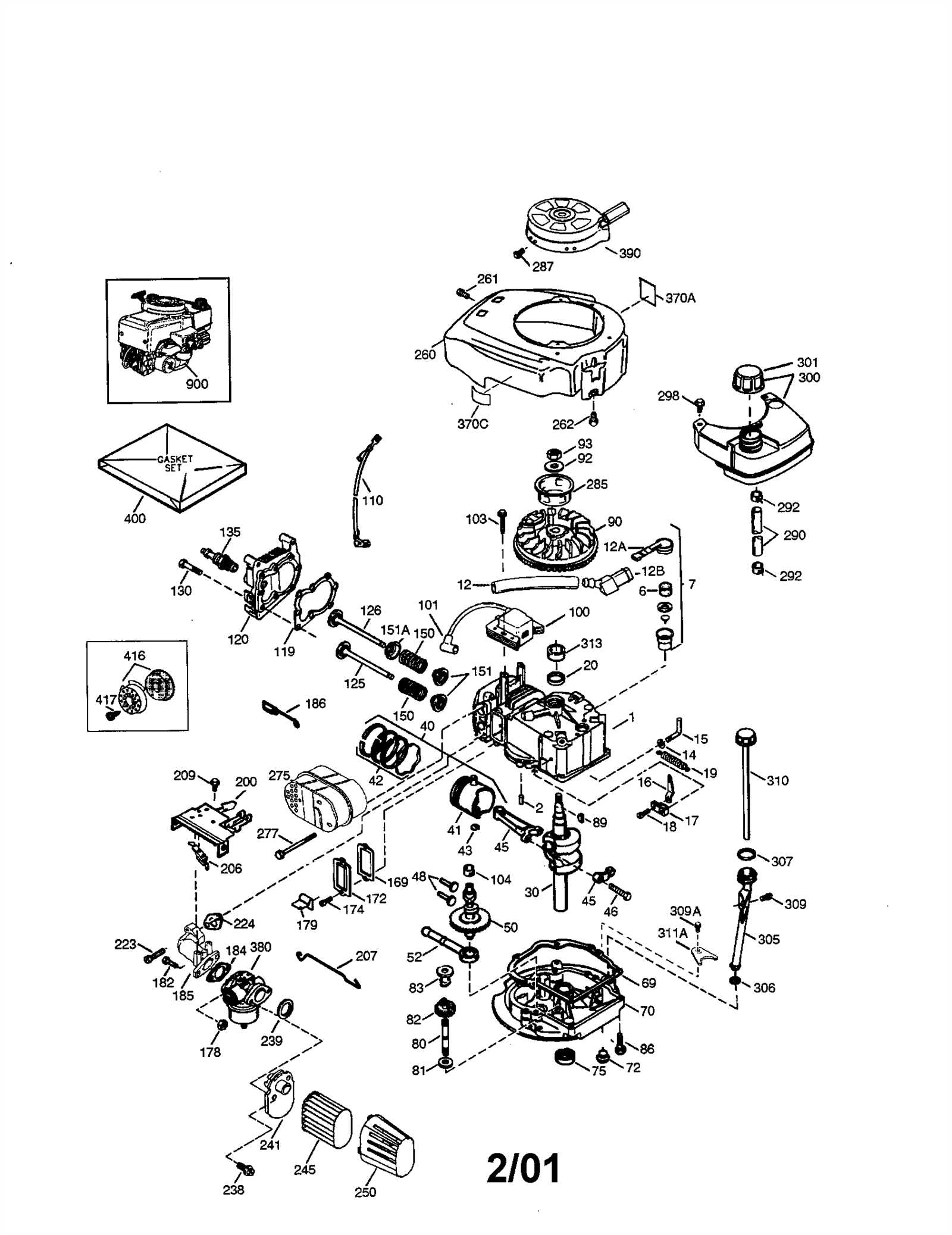

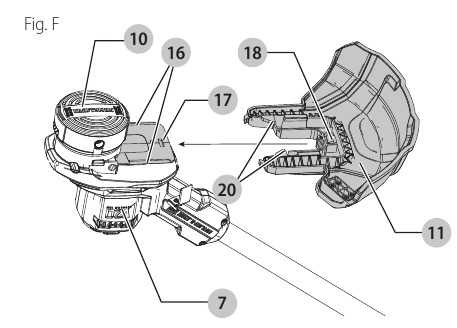

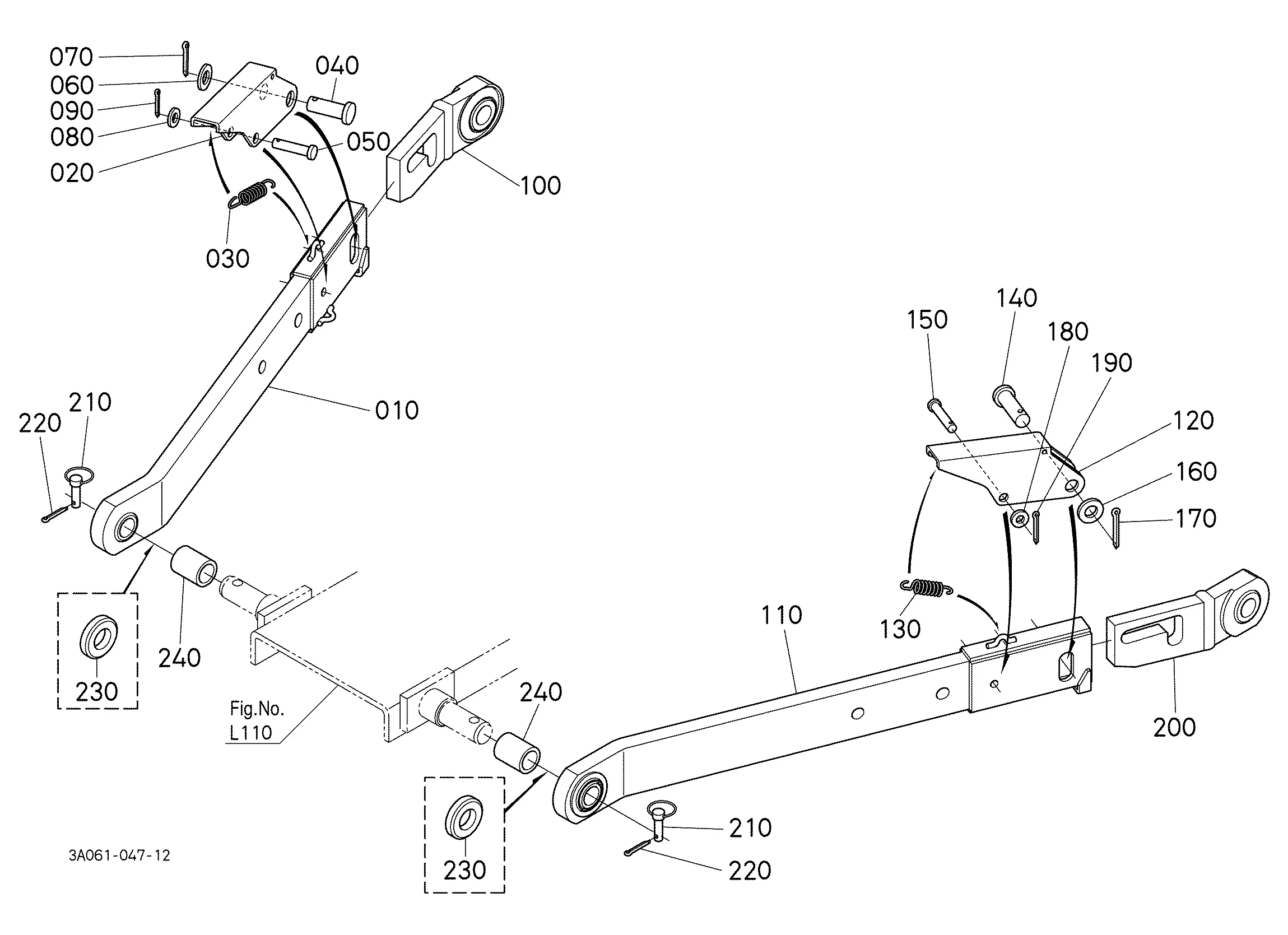

Visual representations of machinery play a crucial role in illustrating the relationships between various components. These graphical aids provide a clear overview, making it easier to identify each part’s location and function. By studying these illustrations, one can gain valuable insights into the construction and operational flow of the entire unit.

For those looking to delve deeper into their equipment’s mechanics, understanding the layout and arrangement of its components is fundamental. This exploration not only aids in effective usage but also fosters a greater appreciation for the engineering behind the design. Engaging with these visuals equips users with the knowledge to navigate maintenance tasks confidently and improve overall functionality.

Understanding Cmcst900 Parts Diagram

Comprehending the intricate layout of components is essential for anyone looking to enhance their understanding of mechanical systems. This visual representation serves as a guide, detailing each element’s role and placement, enabling users to grasp the overall structure and function of the device. By familiarizing oneself with these schematics, one can troubleshoot issues effectively and perform maintenance with confidence.

Importance of Component Layout

The arrangement of individual elements within a system plays a critical role in its efficiency and performance. Knowing how each piece interacts with others can help users identify potential points of failure and optimize functionality. This knowledge is invaluable for technicians and hobbyists alike, as it lays the foundation for successful repairs and modifications.

Interpreting the Visual Guide

Deciphering these illustrations requires attention to detail. Each symbol and line conveys important information about the relationship between components. Familiarizing oneself with the legends and annotations provided within the visual representation will enhance one’s ability to utilize the information effectively. Understanding this guide not only improves technical skills but also empowers users to make informed decisions regarding upgrades and repairs.

Key Components of Cmcst900

Understanding the essential elements of this system is crucial for optimal performance and maintenance. Each component plays a significant role in the overall functionality, ensuring seamless operation and reliability. A thorough examination of these integral parts reveals how they contribute to the device’s efficiency and effectiveness.

Core Elements

The heart of the system comprises several core elements that interact harmoniously. These include the main operational units, which are responsible for executing critical functions. Additionally, the support structures ensure stability and durability, enhancing the longevity of the entire setup.

Supporting Mechanisms

In addition to the core units, there are various supporting mechanisms that facilitate operation. These often include connectors and interfaces that allow for seamless communication between different sections. Moreover, protective components are vital for safeguarding the system from external factors, ensuring consistent performance over time.

How to Read the Diagram

Understanding a schematic representation is essential for effective maintenance and repair tasks. These visual aids provide a clear overview of components and their relationships, allowing users to grasp complex information quickly.

Start by familiarizing yourself with the legend or key that accompanies the illustration. This section usually defines symbols and colors, which are crucial for interpreting the information correctly. Pay attention to these details, as they can greatly influence your understanding of the layout.

Next, identify the main sections and how they are organized. Look for groupings of elements that serve similar functions, as this can help you navigate the representation more easily. Tracking connections between different parts can reveal how they interact within the system.

Finally, take note of any annotations or notes provided. These can offer additional insights into the purpose and functionality of various elements. By systematically analyzing each component and its placement, you can develop a comprehensive understanding of the entire assembly.

Common Issues and Solutions

In any complex machinery, various challenges can arise, affecting performance and reliability. Understanding these common problems can help users troubleshoot effectively and maintain optimal functionality. Here, we explore typical issues and their corresponding remedies.

Issue 1: Unusual Noises

Unexplained sounds may indicate mechanical wear or misalignment. Regular inspections can help identify loose components, which should be tightened or replaced to restore smooth operation.

Issue 2: Overheating

Excessive heat can lead to severe damage. Ensuring proper ventilation and checking for blockages are crucial steps. If overheating persists, consider replacing worn-out cooling elements.

Issue 3: Inconsistent Performance

Fluctuations in operation may signal underlying electrical or calibration issues. Regular maintenance and recalibration can significantly enhance reliability and consistency.

Issue 4: Leaks

Fluid leaks can compromise efficiency and safety. Identifying the source of the leak and promptly sealing or replacing affected parts is essential for preventing further damage.

By addressing these common challenges proactively, users can ensure longevity and enhance the overall effectiveness of their equipment.

Importance of Accurate Diagrams

Clear and precise visual representations are crucial in various fields, serving as essential tools for communication and understanding. They help convey complex information in an accessible format, enabling individuals to grasp intricate concepts more efficiently.

Accurate visuals offer numerous benefits:

- Enhanced Clarity: Well-crafted illustrations reduce confusion by providing a straightforward way to present information.

- Improved Efficiency: Correct representations streamline processes, saving time during troubleshooting or assembly.

- Better Training: Visual aids are invaluable in educational settings, helping learners to visualize relationships and functions.

- Effective Collaboration: Clear visuals foster better teamwork by ensuring that all members share a common understanding of the subject matter.

Inaccurate representations, on the other hand, can lead to significant challenges:

- Misinterpretation of information can result in errors that may have serious consequences.

- Wasted resources and time due to incorrect execution of tasks based on flawed visuals.

- Increased frustration among team members, hindering effective communication and collaboration.

Overall, the significance of precise visual representations cannot be overstated, as they play a vital role in promoting clarity, efficiency, and collaboration across various disciplines.

Maintenance Tips for Cmcst900

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Implementing a systematic approach to care can prevent common issues and enhance efficiency. Below are some crucial strategies to keep your device running smoothly.

1. Routine Cleaning: Dust and debris can accumulate over time, affecting functionality. Regularly clean surfaces and internal components as recommended in the user manual.

2. Lubrication: Ensure moving parts are properly lubricated to reduce friction and wear. Follow guidelines for the type of lubricant suitable for your machine.

3. Inspection: Periodically check for signs of wear or damage. Early detection can save you from more significant repairs later.

4. Calibration: Maintain accuracy by calibrating your device according to the manufacturer’s specifications. This step is vital for consistent performance.

5. Documentation: Keep a log of maintenance activities, repairs, and any issues encountered. This will help track the health of your equipment over time.

By adhering to these maintenance tips, you can ultimately extend the life of your device and ensure it operates at peak efficiency.

Parts Replacement Process Explained

Understanding the procedure for substituting components is essential for maintaining the functionality and longevity of equipment. This section outlines the systematic approach to effectively replace elements, ensuring minimal disruption and optimal performance.

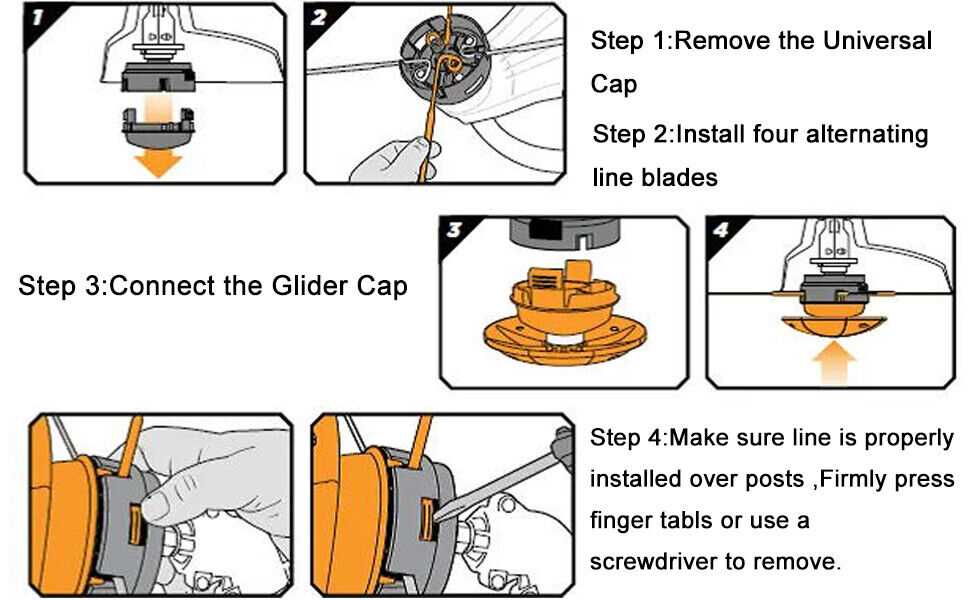

Steps for Effective Component Substitution

- Assessment: Begin by evaluating the current condition of the equipment. Identify the specific part that requires replacement and confirm its compatibility.

- Gather Tools: Assemble all necessary tools and new components before starting the replacement process. This preparation reduces downtime.

- Disassembly: Carefully remove the faulty element, following any manufacturer guidelines to avoid damaging surrounding parts.

- Installation: Position the new component in place, ensuring it fits securely. Follow any instructions regarding alignment or configuration.

- Testing: Once the new element is in place, conduct tests to verify that the equipment operates correctly and efficiently.

- Documentation: Record the replacement details, including date, parts used, and any observations during the process for future reference.

Best Practices for Replacement

- Always consult the manufacturer’s guidelines for specifications and recommendations.

- Use quality replacement items to ensure reliability and performance.

- Maintain a clean work area to prevent contamination and damage to the equipment.

- Consider regular inspections to identify potential issues before they require significant repairs.

Where to Find Quality Parts

When seeking reliable components for machinery, it’s essential to know where to look for the best options available. High-quality items can significantly enhance performance and longevity, making informed sourcing crucial for any project.

Online Marketplaces: Numerous e-commerce platforms offer a vast selection of components. Websites dedicated to industrial supplies often feature user reviews and ratings, helping you assess the quality before making a purchase. It’s wise to compare prices and specifications across different sites to ensure you’re getting the best deal.

Manufacturer Websites: Directly visiting the websites of reputable manufacturers can yield authentic and top-notch options. Many producers provide detailed information about their products, including materials used and specifications, which can aid in making an informed choice.

Local Distributors: Establishing relationships with local suppliers can be beneficial. These distributors often have a deep understanding of the products they offer and can provide insights based on regional needs and preferences. Furthermore, purchasing locally can reduce shipping times and costs.

Forums and Communities: Engaging with online forums and communities dedicated to your field can be an invaluable resource. Experienced users frequently share recommendations for trusted suppliers and brands, offering insights that may not be readily available through conventional channels.

Trade Shows: Attending industry trade shows allows for direct interaction with manufacturers and suppliers. These events provide opportunities to see products firsthand, ask questions, and often access exclusive deals. Networking at such events can also lead to recommendations for reputable sources.

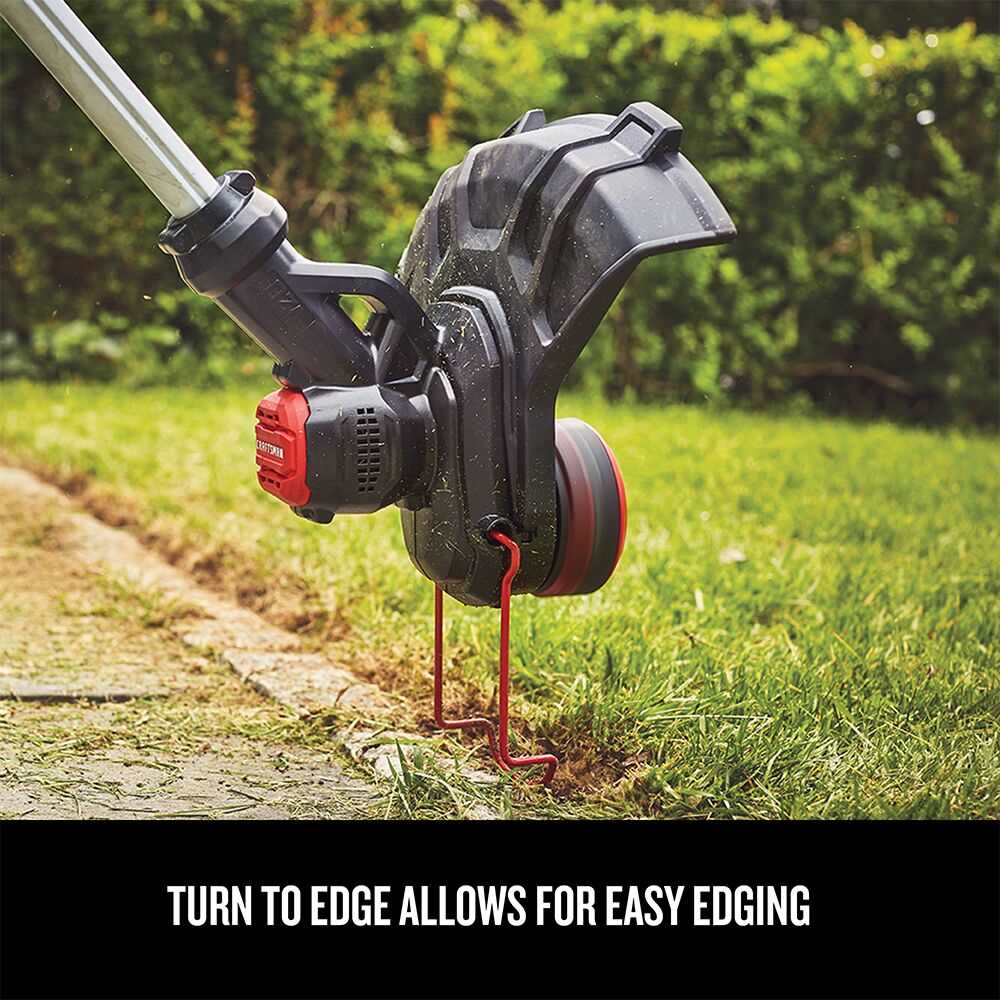

Enhancing Performance with Upgrades

Upgrading components can significantly boost the efficiency and overall functionality of your machinery. By selecting the right enhancements, users can experience improvements in speed, durability, and reliability. This section explores various ways to achieve optimal performance through thoughtful modifications.

- Engine Modifications: Upgrading the engine can lead to better power output and fuel efficiency.

- Transmission Enhancements: A refined transmission can ensure smoother gear shifts and improved acceleration.

- Suspension Improvements: Enhanced suspension systems provide better handling and ride comfort.

- Brake Upgrades: High-performance braking systems enhance stopping power and safety.

- Weight Reduction: Utilizing lighter materials can improve speed and maneuverability.

When considering upgrades, it is crucial to choose components that complement each other to avoid potential conflicts and ensure seamless integration. Regular maintenance and tuning after installation can further optimize performance.

- Assess the current setup and identify areas for improvement.

- Research compatible upgrades and their potential benefits.

- Consult with experts or communities for advice on installation and maintenance.

- Monitor performance post-upgrade to ensure desired outcomes are achieved.

Investing in the right upgrades not only enhances performance but can also extend the lifespan of your equipment, making it a worthwhile endeavor for any serious user.