The detailed breakdown of mechanical elements offers essential insights into the structure and functionality of a small engine. Understanding the arrangement of individual pieces allows for easier identification and maintenance of the machinery. This approach ensures that each component is utilized efficiently, reducing the chances of wear and tear and improving the overall performance of the system.

Knowing how to locate and recognize various elements within the system is crucial for smooth operation. Whether you are conducting routine checks or troubleshooting issues, a clear understanding of the internal layout simplifies the process. This knowledge aids in prolonging the lifespan of the equipment and ensuring optimal functionality.

By focusing on the correct positioning and connections of these components, users can gain deeper insights into how different parts of the machine interact. Such understanding is vital for both professionals and hobbyists, enabling effective repairs, adjustments, and replacements when necessary.

Understanding the Honda GXV160 Engine Structure

The internal makeup of a small motor consists of several key systems that work together to ensure efficient operation. Each component plays a vital role in transforming energy and managing the various mechanical processes. By understanding how these elements fit and interact, it becomes easier to maintain and troubleshoot the device.

Main Components Overview

- Cylinder Block – This houses the moving parts and acts as the core framework for the entire system.

- Piston and Crankshaft – These work together to convert pressure into rotational motion, powering the machine.

- Valves and Camshaft – These regulate airflow and fuel intake, maintaining balanced performance throughout operation.

Supporting Mechanisms

- Ignition System – A crucial setup that sparks the combustion process, initiating the power cycle.

- Cooling and Lubrication – These systems ensure that the components do not overheat or wear down prematurely.

- Fuel Delivery – This system provides the necessary mixture of air and fuel for efficient operation.

Main Components and Their Functions

This section explores the essential elements of a small engine and their respective roles in ensuring optimal performance. Each component plays a critical part in the overall operation, contributing to efficiency, reliability, and longevity. Understanding these elements can enhance maintenance and troubleshooting efforts.

Engine Structure

The engine consists of several key structures that house and support various mechanisms. These structures provide a framework for assembly and ensure stability during operation. The primary elements include the cylinder, crankcase, and cylinder head.

Fuel and Air Management

Effective fuel and air management is crucial for engine performance. This system regulates the intake and combustion process, ensuring the correct mixture for efficient operation. Important components in this system include the carburetor and intake manifold.

| Component | Function |

|---|---|

| Cylinder | Houses the piston and provides a space for combustion. |

| Crankcase | Encloses the crankshaft and contains oil for lubrication. |

| Cylinder Head | Seals the top of the cylinder and contains the combustion chamber. |

| Carburetor | Mixes air and fuel for combustion. |

| Intake Manifold | Distributes the air-fuel mixture to the cylinder. |

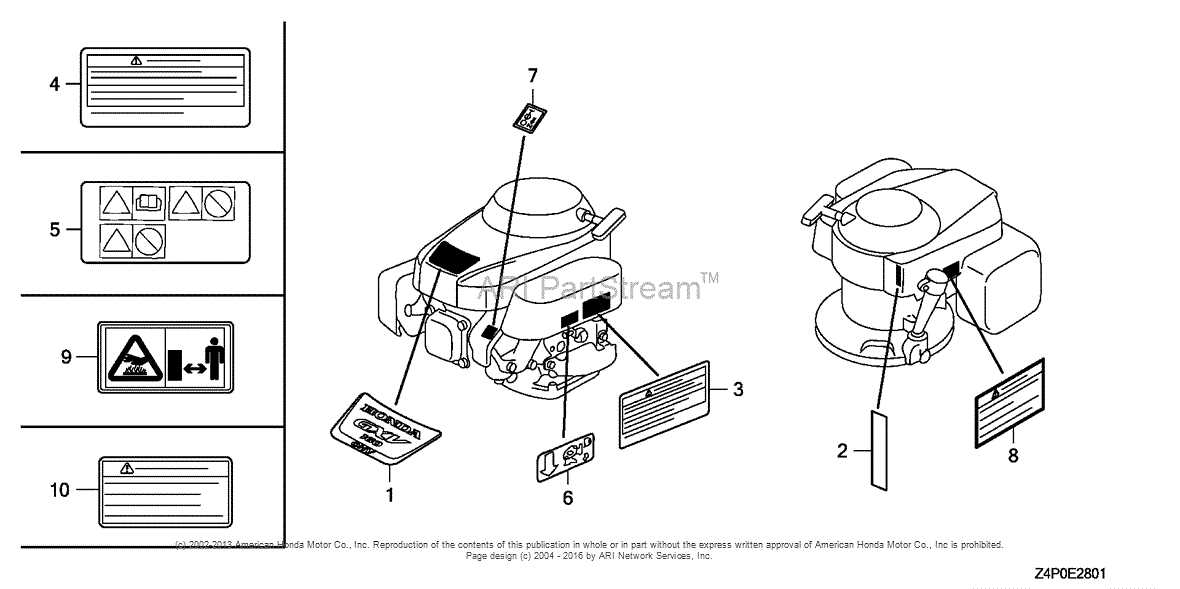

Identifying Key Engine Parts

Understanding the essential components of a small engine is crucial for effective maintenance and operation. This section highlights the primary elements that contribute to the overall functionality of the engine, enabling users to recognize and differentiate between various parts. Proper identification can aid in troubleshooting issues and ensuring optimal performance.

Main Components

- Cylinder: The core unit where fuel combustion occurs, generating power.

- Piston: A movable component within the cylinder, responsible for transferring energy.

- Crankshaft: Converts the up-and-down motion of the piston into rotational motion.

- Valves: Control the intake of air-fuel mixture and exhaust of combustion gases.

- Ignition System: Produces the spark necessary for igniting the air-fuel mixture.

Additional Elements

- Fuel Tank: Stores the fuel needed for combustion.

- Air Filter: Ensures that only clean air enters the engine, enhancing efficiency.

- Exhaust System: Directs the waste gases away from the engine, preventing buildup.

- Cooling System: Regulates the engine temperature to prevent overheating.

Detailed Overview of the Carburetor System

The carburetor system is a crucial component of small engines, playing a vital role in the air-fuel mixture necessary for efficient combustion. This system ensures that the engine receives the right proportion of fuel and air, allowing for optimal performance and smooth operation. Understanding the intricacies of the carburetor can lead to better maintenance and troubleshooting practices, ultimately enhancing the longevity of the engine.

Components of the Carburetor

The primary elements of the carburetor include the float chamber, venturi, and throttle plate. The float chamber regulates the fuel level, ensuring a steady supply for the engine. The venturi is designed to create a pressure differential that draws in air, mixing it with fuel in the correct ratio. The throttle plate controls the amount of air-fuel mixture entering the engine, influencing its speed and power output.

Functionality and Maintenance

Regular maintenance of the carburetor is essential for maintaining engine performance. This includes cleaning or replacing filters, checking for blockages, and ensuring proper sealing of all components. By keeping the carburetor in good condition, users can prevent issues such as poor fuel efficiency and starting difficulties, leading to a smoother and more reliable operation.

Air Filter Maintenance and Replacement Guide

Proper upkeep of the air filtration system is essential for optimal engine performance and longevity. Regular checks and timely replacements can prevent dirt and debris from entering the engine, ensuring smooth operation and efficiency. This section will provide guidance on how to maintain and replace the air filter effectively.

Signs of a Dirty Air Filter

Identifying a clogged or dirty filter can significantly improve performance. Here are some common indicators:

- Reduced engine power

- Increased fuel consumption

- Difficulty starting the engine

- Visible dirt or discoloration on the filter

Steps for Maintenance and Replacement

Follow these steps to ensure the air filter remains in good condition:

- Turn off the engine and allow it to cool.

- Locate the air filter housing and open it carefully.

- Remove the existing filter, taking note of its orientation.

- Inspect the filter for any damage or excessive dirt.

- If needed, clean the filter with compressed air or replace it with a new one.

- Reassemble the housing securely, ensuring a tight fit.

Regular inspection and replacement of the air filtration system contribute to better engine efficiency and extended equipment lifespan. Adhering to these maintenance practices will help in achieving optimal performance.

Fuel System Components and Diagrams

The fuel system plays a crucial role in the efficient operation of small engines. It is designed to store and deliver the necessary fuel to the engine for optimal performance. Understanding the various elements of this system helps in effective maintenance and troubleshooting.

Key components of the fuel system include:

- Fuel Tank: Stores the fuel required for operation.

- Fuel Pump: Transfers fuel from the tank to the engine.

- Fuel Filter: Removes impurities from the fuel before it reaches the engine.

- Carburetor: Mixes air and fuel for combustion.

- Fuel Lines: Transport fuel between components.

Diagrams representing these elements can enhance understanding and facilitate maintenance. They illustrate the connections and flow paths within the system, providing a visual reference for users.

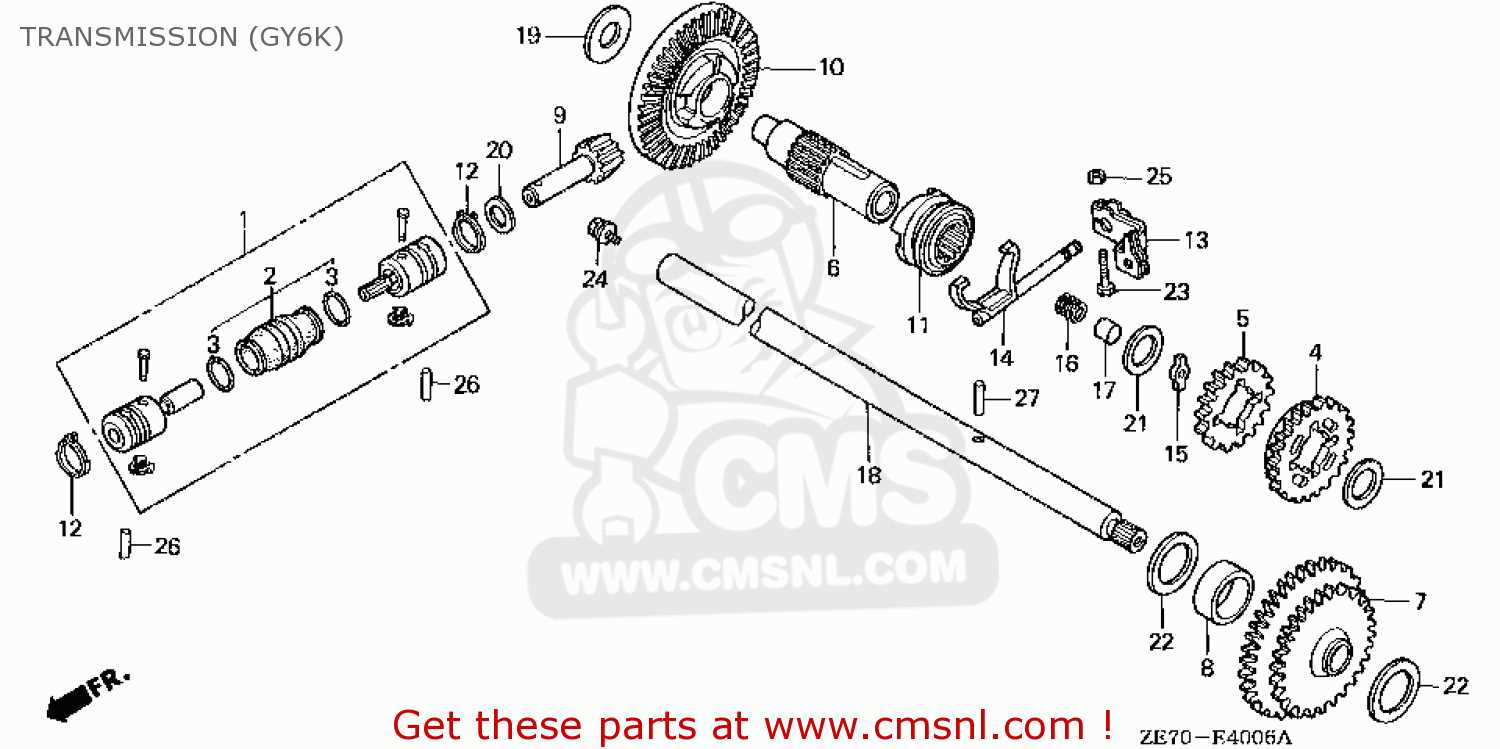

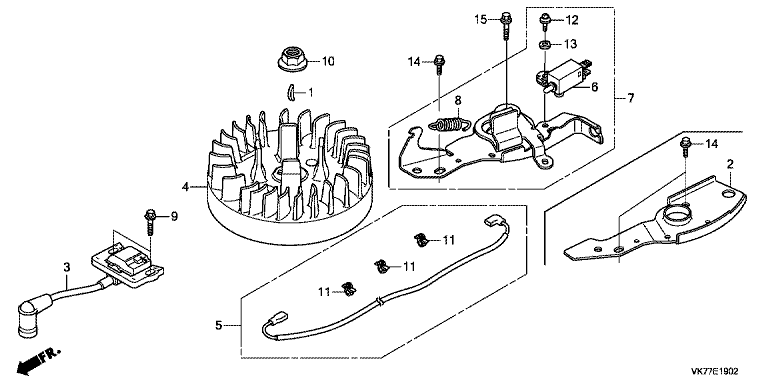

Exploring the Ignition System Layout

The ignition system is a critical component in ensuring efficient engine operation. Understanding its arrangement and function can significantly enhance performance and reliability. This section delves into the various elements that constitute the ignition setup, shedding light on their roles and interactions.

Key Components of the Ignition Setup

Several essential parts work in harmony within the ignition system. Each element contributes to the overall functionality, influencing how effectively the engine ignites the fuel-air mixture.

| Component | Function |

|---|---|

| Spark Plug | Ignites the air-fuel mixture to initiate combustion. |

| Ignition Coil | Transforms battery voltage to a higher voltage for spark generation. |

| Ignition Switch | Controls the flow of electrical current to the ignition coil. |

| Distributor | Distributes high voltage to the correct spark plug at the right time. |

Understanding System Interaction

The collaboration of these components is vital for smooth engine performance. A malfunction in any part can lead to ignition failure, resulting in poor engine performance or inability to start. Regular maintenance and inspection of the ignition system can prevent such issues, ensuring optimal operation.

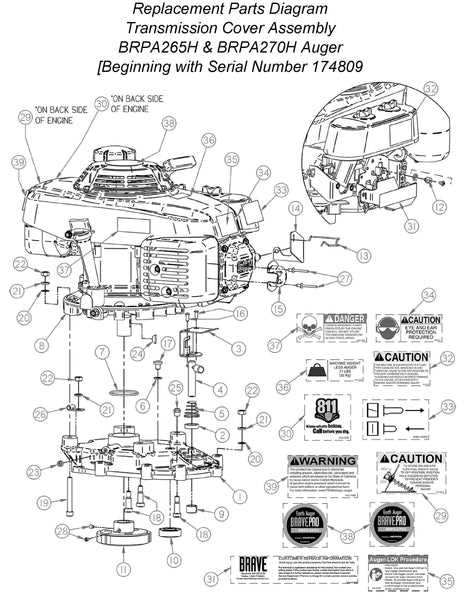

Crankcase and Piston Assembly Breakdown

The crankcase and piston assembly is a crucial component in many small engine systems. This section will explore the various elements within this assembly, detailing their functions and interconnections. Understanding these parts is essential for effective maintenance and troubleshooting.

Key components of the assembly include:

- Crankcase: The housing that encases the moving parts, providing protection and structural integrity.

- Piston: A cylindrical element that moves within the cylinder, converting pressure into mechanical work.

- Connecting Rod: Connects the piston to the crankshaft, transferring motion and force.

- Crankshaft: A rotating shaft that converts the linear motion of the piston into rotational energy.

- Gaskets and Seals: Ensure airtight closures, preventing leaks and maintaining pressure within the assembly.

Each part plays a significant role in the overall functionality of the engine. Regular inspection and maintenance of the crankcase and piston assembly are vital to ensure optimal performance and longevity of the equipment.

Genuine Replacement Parts and Availability

Access to authentic components is crucial for maintaining the performance and longevity of your equipment. Using original items ensures compatibility and reliability, which is essential for optimal operation. The significance of sourcing quality replacements cannot be overstated, as they contribute to the overall efficiency and safety of your machinery.

When seeking these genuine items, it is essential to consider various sources. Authorized dealers and certified retailers provide assurance of authenticity and support. Online platforms have also become popular for acquiring original components, often featuring extensive inventories. Checking the availability through official channels helps ensure that you receive the correct components tailored for your specific model.

Additionally, staying informed about new arrivals and restocks can significantly enhance your purchasing experience. Regularly visiting manufacturer websites or subscribing to updates can provide insights into when sought-after components become available. Prioritizing the use of genuine replacements will lead to enhanced performance and prolonged lifespan of your equipment.