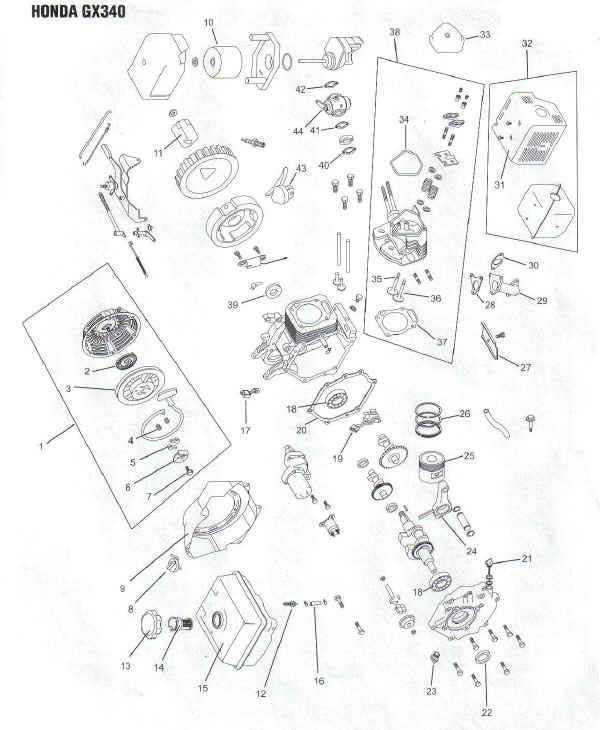

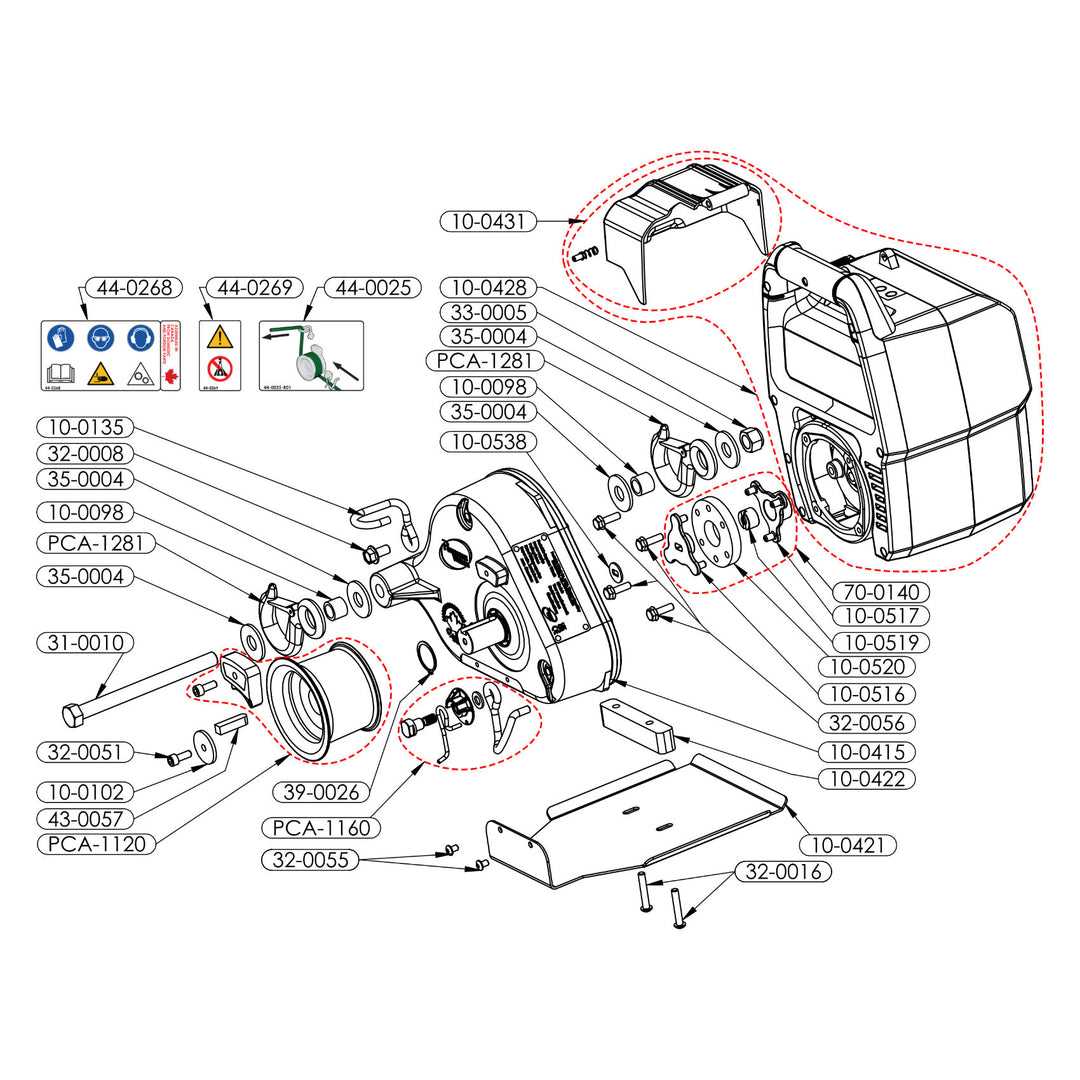

When maintaining or repairing internal combustion devices, having a clear visual representation of the components is essential. A well-organized layout allows you to pinpoint essential mechanisms, facilitating smoother repairs and enhancing your understanding of the machine’s inner workings. By examining how various elements are interconnected, you can tackle repairs with confidence and efficiency.

Each mechanical system has a unique structure, where individual sections work together to power the entire unit. Identifying key pieces and understanding their relationship to one another plays a crucial role in the upkeep and longevity of the machine. Familiarizing yourself with this layout provides a comprehensive view of the overall operation, making it easier to troubleshoot potential issues.

Overview of Key Components in Honda GX340

The mechanical structure of this engine model is made up of several critical elements that work in unison to ensure reliable performance. Each of these elements plays a unique role in the overall operation, contributing to efficiency, power output, and longevity.

Engine Block: This is the central housing where all internal functions are coordinated. It provides the foundation for the engine’s key processes, housing the cylinders and serving as the mounting point for other components.

Piston and Crankshaft: The piston moves up and down within the cylinder, transferring energy generated by combustion to the crankshaft, which then converts this motion into rotational energy, driving the system forward.

Carburetor: Essential for fuel management, this component ensures that the correct mix of air and fuel reaches the engine. Its precise operation directly impacts the motor’s efficiency and power.

Exhaust System: Responsible for expelling the by-products of combustion, the exhaust system ensures

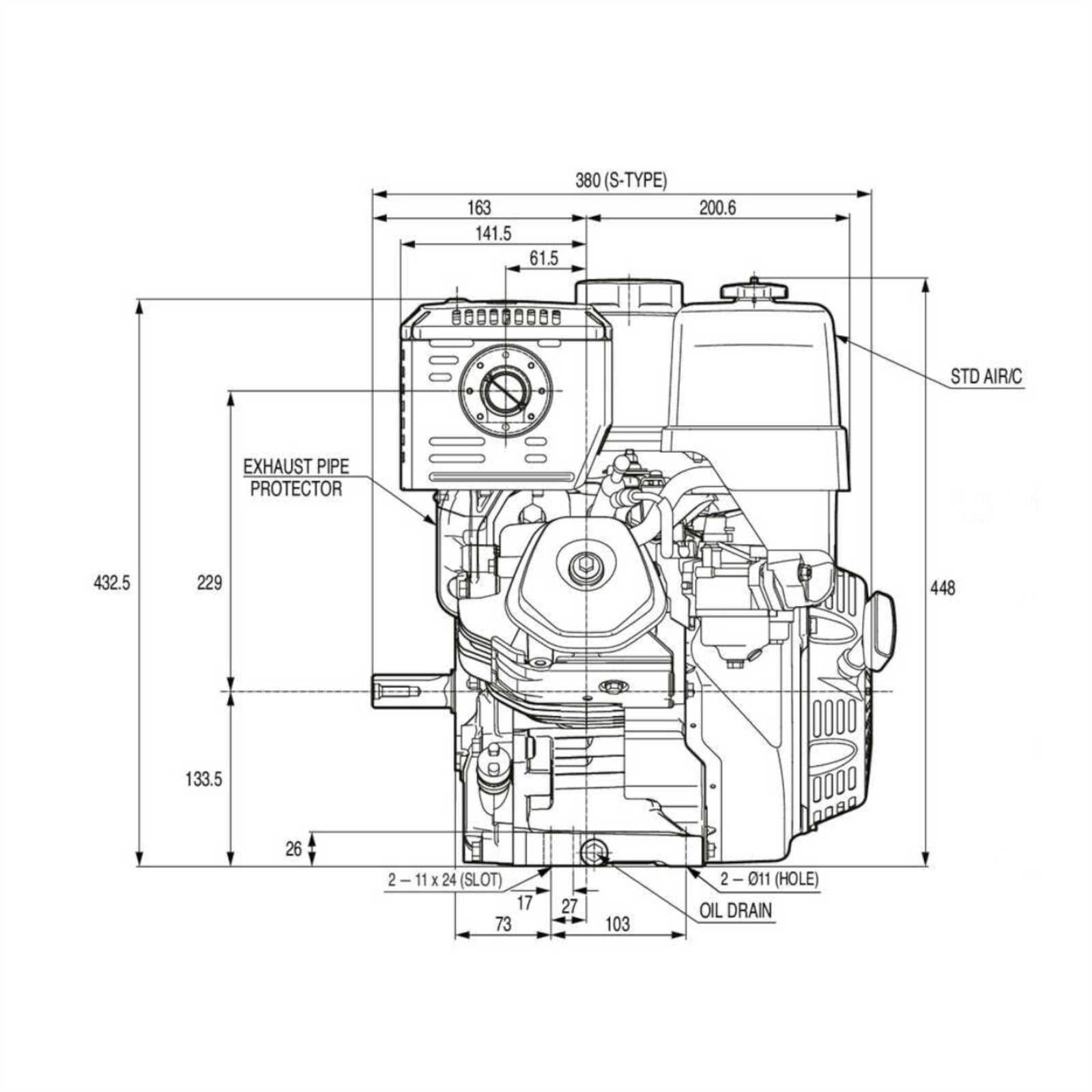

Engine Block and Cylinder Layout

The arrangement of the engine block and the positioning of the cylinder play a vital role in the overall performance and efficiency of any motor. These elements are designed to ensure optimal combustion, durability, and mechanical harmony. The structure and alignment of these components affect heat dissipation, fuel usage, and the longevity of the entire system.

Core Structure of the Engine Block

The engine block forms the backbone of the motor, providing a rigid structure for the moving parts. Its design includes multiple chambers and passages that allow the flow of coolant and oil, which are essential for maintaining proper thermal and lubrication conditions. The block is also built to withstand the high pressure generated during the power stroke, ensuring reliability over time.

Cylinder Alignment and Function

The cylinder is where the combustion process occurs, converting fuel into mechanical energy. Proper alignment of the cylinder ensures efficient combustion, smooth piston movement, and minimizes unnecessary wear. The placement of the cylinder within the block is key to achieving balanced power distribution and optimal engine performance. Furthermore, the design helps manage heat levels, which is critical for the engine’s lifespan.

Fuel System Structure and Functions

The fuel system plays a vital role in delivering the necessary energy to the engine by ensuring the precise flow of fuel. Understanding its structure and the roles of its components is essential for maintaining optimal engine performance. This section will provide an overview of how the fuel system operates, including the main elements responsible for fuel storage, delivery, and regulation.

Main Components

- Fuel Tank: This component stores the fuel required for engine operation. Its capacity and design ensure that an adequate amount of fuel is available at all times.

- Fuel Line: The conduit through which fuel travels from the tank to the engine. It is constructed to handle pressure and maintain a steady flow of fuel.

- Fuel Filter: Positioned within the line, this filter removes impurities and debris, ensuring only clean fuel reaches the engine.

Functionality Overview

- The fuel is drawn from the tank through a pump, initiating the transfer towards the engine.

- As the fuel moves through the line, the filter cleans it to prevent engine blockages and wear.

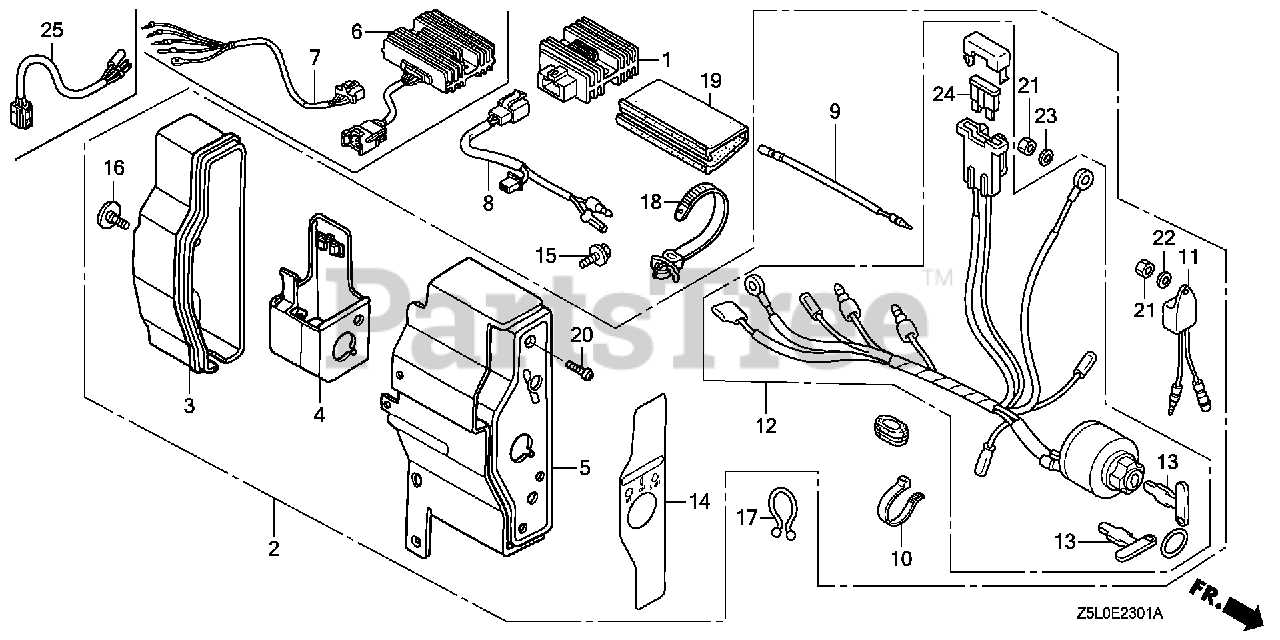

Ignition System Parts and Operation

The ignition mechanism plays a crucial role in ensuring efficient engine functionality. It governs the process by which the engine receives the necessary spark to ignite the fuel-air mixture, leading to combustion. The arrangement of components within this system is designed to deliver reliable performance under varying conditions.

- Ignition Coil: Converts low voltage from the battery into the high voltage needed to create a spark at the plug.

- Spark Plug: Creates a small, controlled explosion in the combustion chamber by generating a spark to ignite the air-fuel blend.

- Flywheel: Equipped with magnets, it passes by the coil, generating the electrical current required for the spark.

- Magneto: A small generator that helps produce electricity for the ignition process without relying on the battery.

Each of these components works in harmony, ensuring precise timing and delivery of the spark. Proper alignment and maintenance of these elements are essential for maintaining smooth engine cycles and avoiding performance issues.

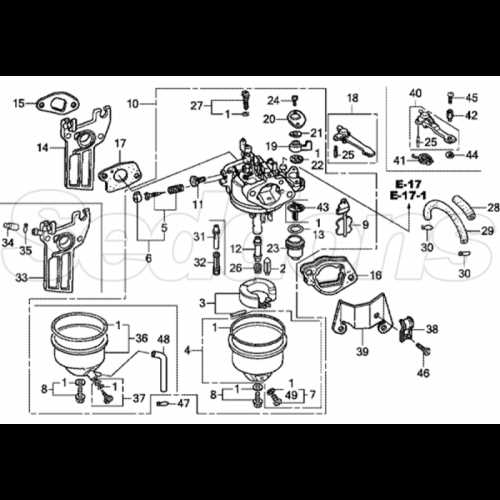

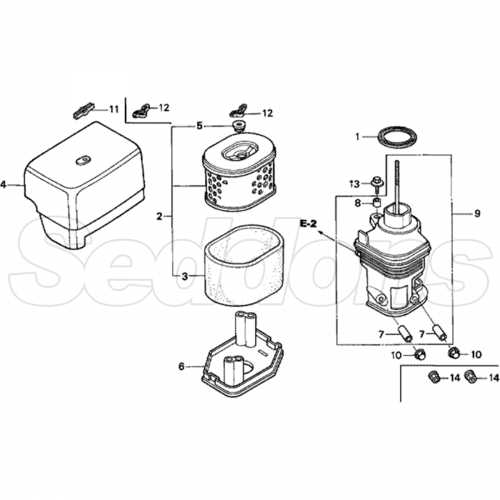

Detailed Breakdown of the Carburetor

The carburetor is a crucial component that ensures the proper mixture of air and fuel, allowing for efficient engine operation. By regulating this blend, it maintains smooth performance and optimizes combustion for various conditions. This section will explore the intricate elements that make up this vital mechanism, highlighting its key components and functionality.

Fuel Intake and Air Flow

The fuel intake system plays a pivotal role in channeling the correct amount of fuel into the combustion chamber. A precise balance is achieved with the integration of the air intake passages, which introduce the necessary airflow. Adjustments to this balance directly influence the overall efficiency of the engine.

Choke and Throttle Mechanisms

The choke lever and throttle assembly contribute to the regulation of engine speed and fuel delivery. The choke aids in starting the engine, especially in colder conditions, by enriching the fuel mixture. Meanwhile, the throttle controls the volume of air entering the system, directly affecting engine power output. Together, these components provide the fine-tuning necessary for optimal operation.

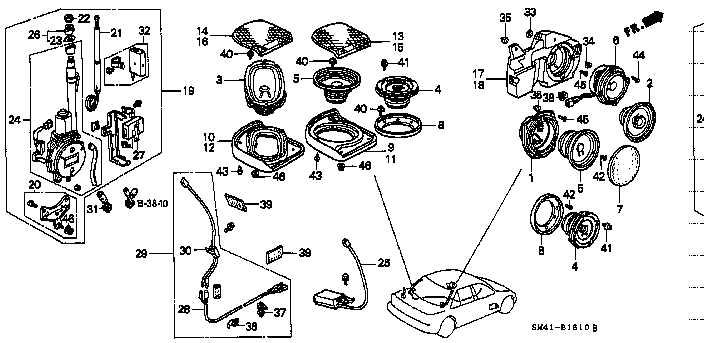

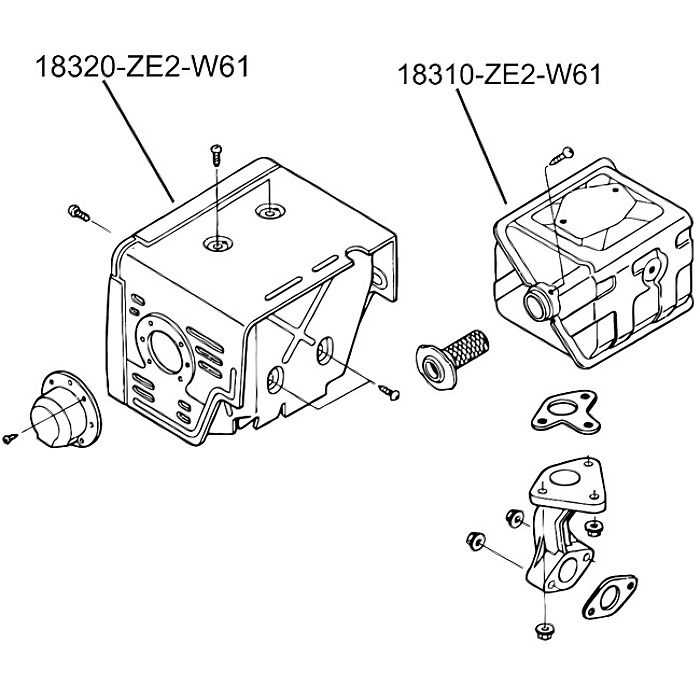

Exhaust System Components and Purpose

The exhaust system plays a crucial role in the efficient operation of an engine by directing and managing the gases produced during combustion. This assembly not only facilitates the expulsion of exhaust gases but also helps in minimizing noise and ensuring that harmful emissions are treated before being released into the atmosphere.

Understanding the various elements of the exhaust system and their functions is essential for maintaining optimal performance and compliance with environmental standards. Below is a table outlining key components and their specific roles within the exhaust assembly:

| Component | Function |

|---|---|

| Exhaust Manifold | Collects exhaust gases from the engine cylinders and channels them into the exhaust system. |

| Catalytic Converter | Converts harmful gases into less harmful emissions through chemical reactions. |

| Muffler | Reduces engine noise by dissipating sound waves produced during exhaust flow. |

| Exhaust Pipe | Guides exhaust gases from the engine through the system and out to the atmosphere. |

| Resonator | Fine-tunes sound and eliminates certain frequencies to enhance exhaust tone. |

Each component works in harmony to ensure that the exhaust system operates efficiently, contributing to the overall effectiveness of the engine while promoting a cleaner environment.

Cooling Mechanism and Airflow Components

The cooling system plays a crucial role in maintaining optimal operating temperatures within engines. Effective airflow is essential to prevent overheating and ensure efficient performance. This section explores the key elements involved in the cooling and airflow processes, highlighting their functions and significance.

Key Components

- Cooling Fan: This component enhances airflow over the engine, facilitating heat dissipation.

- Heat Exchanger: It transfers heat away from the engine, maintaining a stable temperature.

- Air Intake System: This assembly draws in fresh air, crucial for combustion and cooling.

- Shroud: This part directs airflow efficiently, optimizing the cooling fan’s effectiveness.

Airflow Management

Effective management of airflow is vital for engine performance. Properly designed airflow pathways help maintain an even temperature distribution, reducing the risk of hot spots that can lead to damage. Key practices include:

- Ensuring unobstructed air passages to maximize airflow.

- Regular maintenance of cooling components to ensure their functionality.

- Monitoring temperature levels to detect potential issues early.

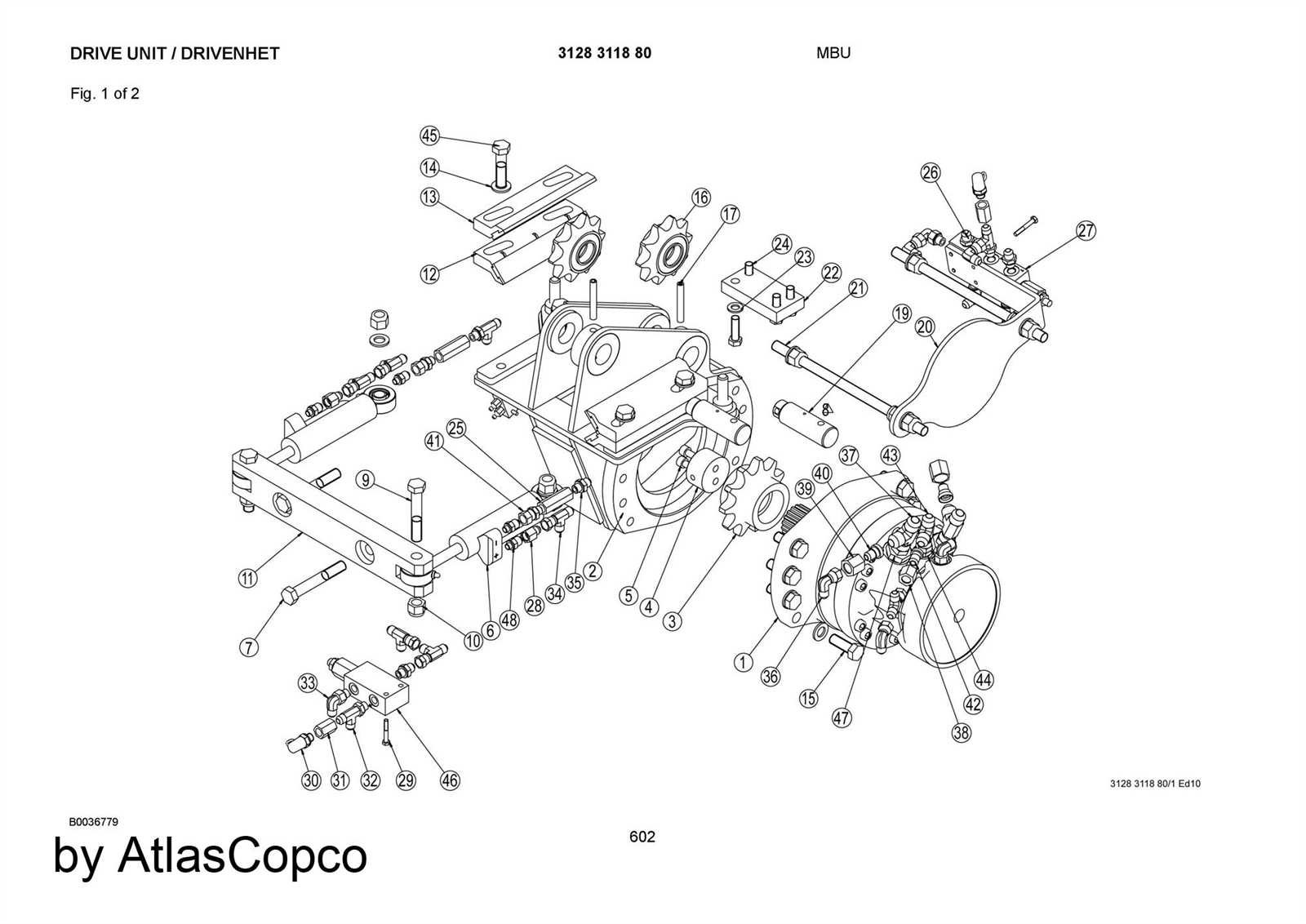

Internal Moving Components and Their Roles

Understanding the internal moving elements of an engine is crucial for recognizing how power is generated and transferred throughout the system. Each component plays a significant role in ensuring optimal performance, reliability, and efficiency. Below is a detailed overview of these vital parts and their functions.

- Piston: This cylindrical part moves up and down within the cylinder, converting the pressure from combustion into mechanical energy.

- Connecting Rod: It connects the piston to the crankshaft, transmitting the force generated by the piston’s movement.

- Crankshaft: The crankshaft converts the linear motion of the piston into rotational motion, which powers the output shaft.

- Valves: These components regulate the intake of fuel and air, as well as the expulsion of exhaust gases, ensuring efficient combustion cycles.

- Camshaft: This part controls the timing and movement of the valves, synchronizing their operation with the crankshaft’s rotation.

- Flywheel: The flywheel stores rotational energy, smoothing out the engine’s power delivery and maintaining momentum during the cycle.

Each of these elements is essential for the overall functionality of the engine, working in harmony to produce power efficiently. Understanding their roles can help in troubleshooting, maintenance, and optimizing performance.

Maintenance Tips for Optimal Engine Performance

Regular upkeep is essential for ensuring peak functionality and longevity of your engine. By adhering to a few straightforward practices, you can enhance efficiency, reduce wear, and prevent potential issues that could lead to costly repairs. This section outlines effective strategies to maintain your engine in excellent condition.

- Routine Oil Changes: Regularly replace engine oil and filters to ensure proper lubrication and remove contaminants.

- Air Filter Maintenance: Check and clean or replace the air filter periodically to allow optimal airflow and protect internal components.

- Fuel Quality: Use high-quality fuel and consider adding fuel stabilizers to prevent degradation, especially during periods of inactivity.

- Inspect Spark Plugs: Regularly examine spark plugs for wear and replace them as needed to ensure efficient ignition and fuel combustion.

- Cooling System Check: Monitor the coolant level and inspect hoses for leaks or damage to prevent overheating.

- Regular Inspections: Frequently inspect belts, hoses, and connections for signs of wear or damage to address issues before they escalate.

Implementing these maintenance practices will significantly enhance the performance and reliability of your engine, ensuring that it operates smoothly for years to come.