In the realm of small engine mechanics, comprehending the layout of essential components is crucial for efficient maintenance and repair. This section delves into the intricate arrangement of various elements that contribute to the overall functionality of these power units. A thorough understanding of this layout aids in identifying parts that may require attention or replacement, ultimately enhancing the performance of the machinery.

Every engine consists of numerous interconnected elements, each serving a specific purpose. Recognizing the relationship between these components can facilitate troubleshooting and streamline repair processes. Whether it’s examining the ignition system or analyzing fuel delivery mechanisms, having a visual reference can significantly simplify the task at hand.

By exploring the structure and positioning of these key components, individuals can develop a deeper insight into engine functionality. This knowledge empowers users to make informed decisions regarding maintenance, ensuring that their equipment operates at optimal levels. Through careful study, the intricacies of engine operation become clearer, leading to improved efficiency and longevity.

This section aims to provide insights into the essential elements that make up a specific small engine model. By breaking down the various components, readers can gain a clearer understanding of their functions and relationships within the overall system. This knowledge is crucial for effective maintenance, repair, and enhancement of the engine’s performance.

Essential Elements of the Engine

The core assembly comprises numerous parts that work in unison to ensure optimal functionality. Each component plays a vital role in the operation of the engine, contributing to its efficiency and longevity. Familiarity with these elements will empower users to troubleshoot issues and make informed decisions regarding repairs or upgrades.

Overview of Key Components

Below is a table summarizing the principal components and their corresponding functions within the engine assembly:

| Component | Function |

|---|---|

| Cylinder | Houses the piston and combustion chamber, facilitating power generation. |

| Piston | Moves within the cylinder to compress fuel and air mixture, converting chemical energy into mechanical energy. |

| Crankshaft | Transforms linear motion of the piston into rotational motion, powering the engine. |

| Fuel Tank | Stores fuel necessary for combustion. |

| Air Filter | Prevents dirt and debris from entering the combustion chamber, ensuring clean airflow. |

| Exhaust System | Channels combustion gases away from the engine, reducing noise and emissions. |

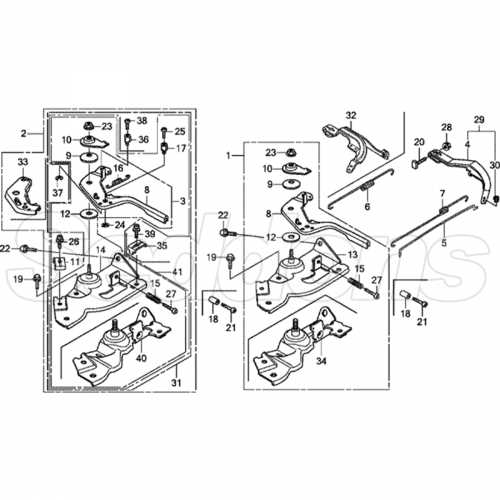

Importance of Accurate Diagrams

Precise visual representations are crucial for understanding how components interconnect and function within a system. These illustrations serve as a roadmap, guiding users through the various elements that ensure efficient operation.

Accuracy in these depictions is vital because even the smallest mistake can lead to confusion, misassembly, or malfunction. A well-crafted schematic provides clarity, making it easier to follow intricate connections and relationships between different elements.

Ultimately, detailed diagrams help in troubleshooting and maintaining systems effectively, preventing costly errors and reducing downtime.

Common Parts and Their Functions

In any engine, various essential components work together to ensure optimal performance and longevity. Understanding these elements and their individual roles is crucial for maintaining and repairing the system. Each component contributes to specific tasks that, when combined, drive the machine efficiently.

Combustion Chamber: This is where the fuel is ignited, converting chemical energy into mechanical motion. Its design and efficiency significantly affect overall engine performance.

Cylinder Head: Mounted above the combustion area, the cylinder head houses several key elements, including valves, that manage the intake and exhaust processes. It plays a critical role in regulating air and fuel flow.

Crankshaft: This vital rotating part converts the linear motion of the pistons into rotational force, which is used to drive the machine. The smooth operation of the crankshaft is essential for balanced performance.

Carburetor:

Step-by-Step Assembly Guide

In this section, we will walk through the precise steps needed to put together each component, ensuring smooth operation and long-lasting performance. Follow the instructions carefully to avoid common mistakes and ensure proper alignment and connection of each piece.

- Prepare the workspace: Clear a clean, flat surface to lay out all components. Ensure all necessary tools are easily accessible.

- Identify key components: Begin by sorting all elements into groups based on their function and size. This will help you understand where each piece fits into the overall assembly.

- Start with the base: Attach the foundational components securely, making sure to follow the appropriate alignment. Tighten all fasteners without over-tightening to avoid damage.

- Install the engine frame: Mount the engine support frame, aligning it properly to ensure stability. Use the recommended bolts and tighten them gradually.

- Connect peripheral systems: Attach fuel and exhaust systems, following the manufacturer’s guidelines for positioning and securing each part.

Maintenance Tips for Longevity

Ensuring the smooth operation and extended life of your equipment requires regular care and attention. Consistent upkeep prevents premature wear and ensures that each component continues to function at its best, avoiding costly repairs or replacements.

Regular Cleaning

Keeping mechanical systems free of dirt and debris is critical for optimal performance. Dust and grime can infiltrate moving parts, causing unnecessary friction and overheating. A periodic cleaning routine, focusing on external and internal areas, can significantly reduce the risk of damage.

Lubrication and Tightening

Maintaining the right balance of lubrication in key areas ensures smooth operation. Regularly check for any signs of dryness or excessive friction, and apply the appropriate lubricants. Additionally, inspect all fasteners and connections to ensure they are properly tightened, reducing the likelihood of loosening under strain.

Troubleshooting Common Issues

Identifying and resolving mechanical problems can be a daunting task, especially when dealing with intricate systems. By understanding the typical challenges that arise during operation, you can streamline the process of diagnosing malfunctions and restore functionality efficiently.

Frequent Operational Problems

Some typical concerns that users may face include difficulties with starting the engine, inconsistent performance, or unexpected shutdowns. These issues often stem from a variety of causes, such as fuel flow interruptions or ignition failures. Careful examination of the system can help pinpoint the root cause.

Essential Diagnostic Tips

Before diving into advanced troubleshooting, it’s crucial to inspect the core components of the machinery. Checking fuel levels, inspecting electrical connections, and reviewing air filter cleanliness can often resolve many minor issues without the need for extensive repairs.

Issue Potential Cause Solution Finding Replacement Parts Online

Locating the right components for machinery maintenance can be challenging, especially when dealing with specific mechanical systems. Online platforms offer a vast selection of alternatives, making it easier for users to find exactly what they need without leaving their workspace.

Benefits of Shopping for Components Online

- Access to a wide variety of options from multiple sellers

- Detailed specifications and user reviews to guide selection

- Convenience of comparing prices and features at any time

Key Considerations When Searching for Replacements

- Ensure compatibility by checking technical specifications carefully

- Look for trusted suppliers with positive customer feedback

- Consider delivery times and return policies before purchasing

Comparing Honda GX120 with Other Models

When analyzing different power units, it’s essential to understand how specific designs stack up against alternatives in terms of efficiency, performance, and reliability. These mechanical systems, though seemingly similar, often showcase unique strengths and limitations that suit various applications.

Engine capacity and output power are critical factors that differentiate these models. While some variants are designed for lighter, more routine tasks, others excel in handling more demanding operations, making them more appropriate for industrial or commercial use.

Additionally, fuel consumption and overall durability tend to vary across models. Smaller units may offer better fuel efficiency, while larger systems might prioritize robustness and longevity under continuous heavy use.

Customer Reviews and Experiences

Many users have shared their feedback on the reliability and performance of this equipment. Their experiences reflect the versatility and endurance of the product in various settings, from home projects to more demanding environments. These stories provide valuable insights into how the machinery holds up under different conditions.

Performance Feedback

Positive reviews often highlight the longevity and efficiency of the device. Customers appreciate its ability to consistently deliver power, even after long periods of use. Some have noted the ease of maintenance, emphasizing that regular upkeep keeps the machine running smoothly for years.

Real-Life Experiences

Many users have shared detailed accounts of how they use the device in their daily work. Whether for personal or professional purposes, the equipment has proven its reliability. Some have even described situations where it exceeded their expectations, working in harsher conditions than initially anticipated. These firsthand experiences offer a deeper understanding of its capabilities.