When it comes to maintaining small machinery, a comprehensive understanding of the internal workings is crucial. Identifying the various elements that contribute to optimal performance can significantly enhance the longevity and efficiency of the equipment. This guide delves into the essential components, their functions, and how they interconnect to ensure seamless operation.

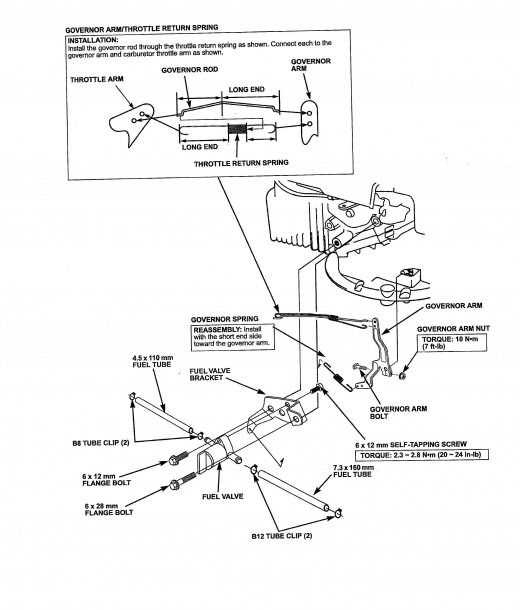

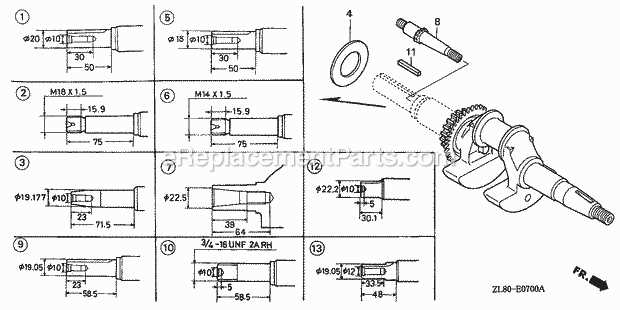

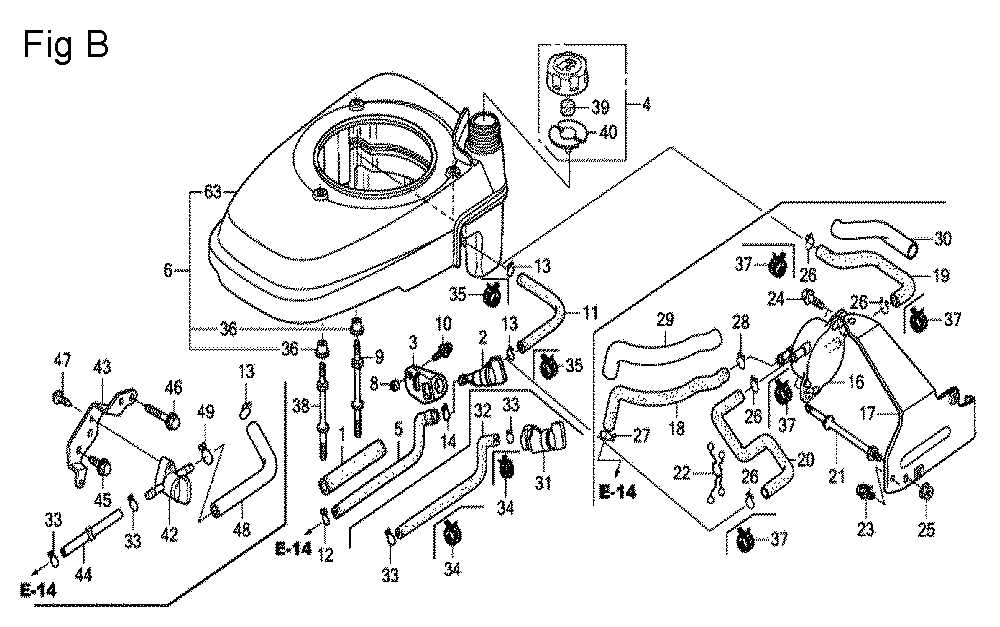

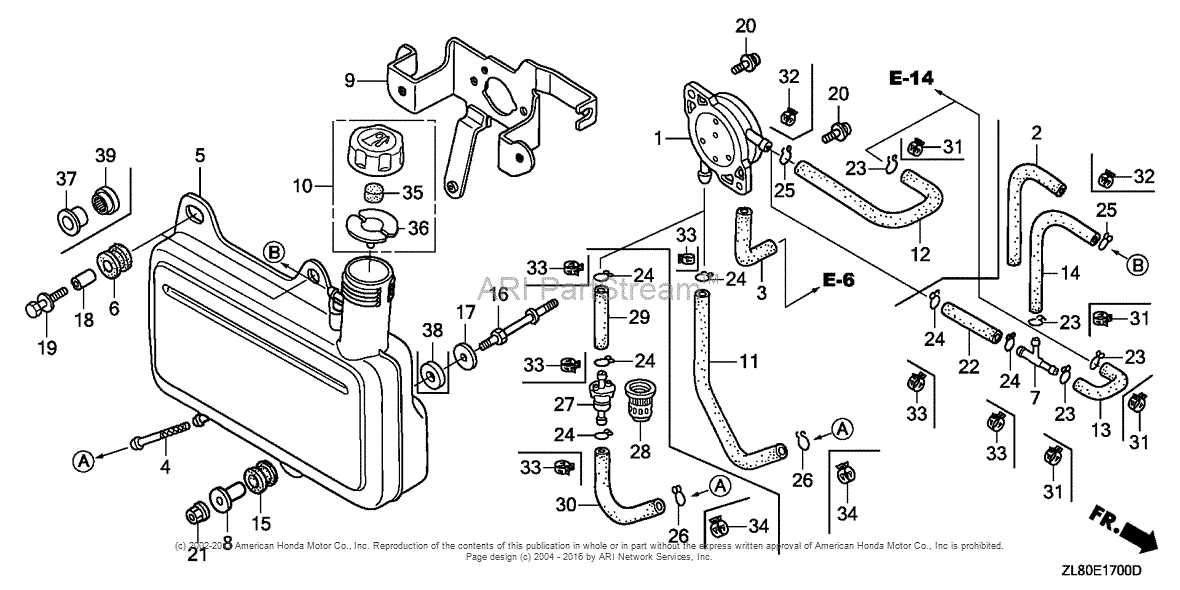

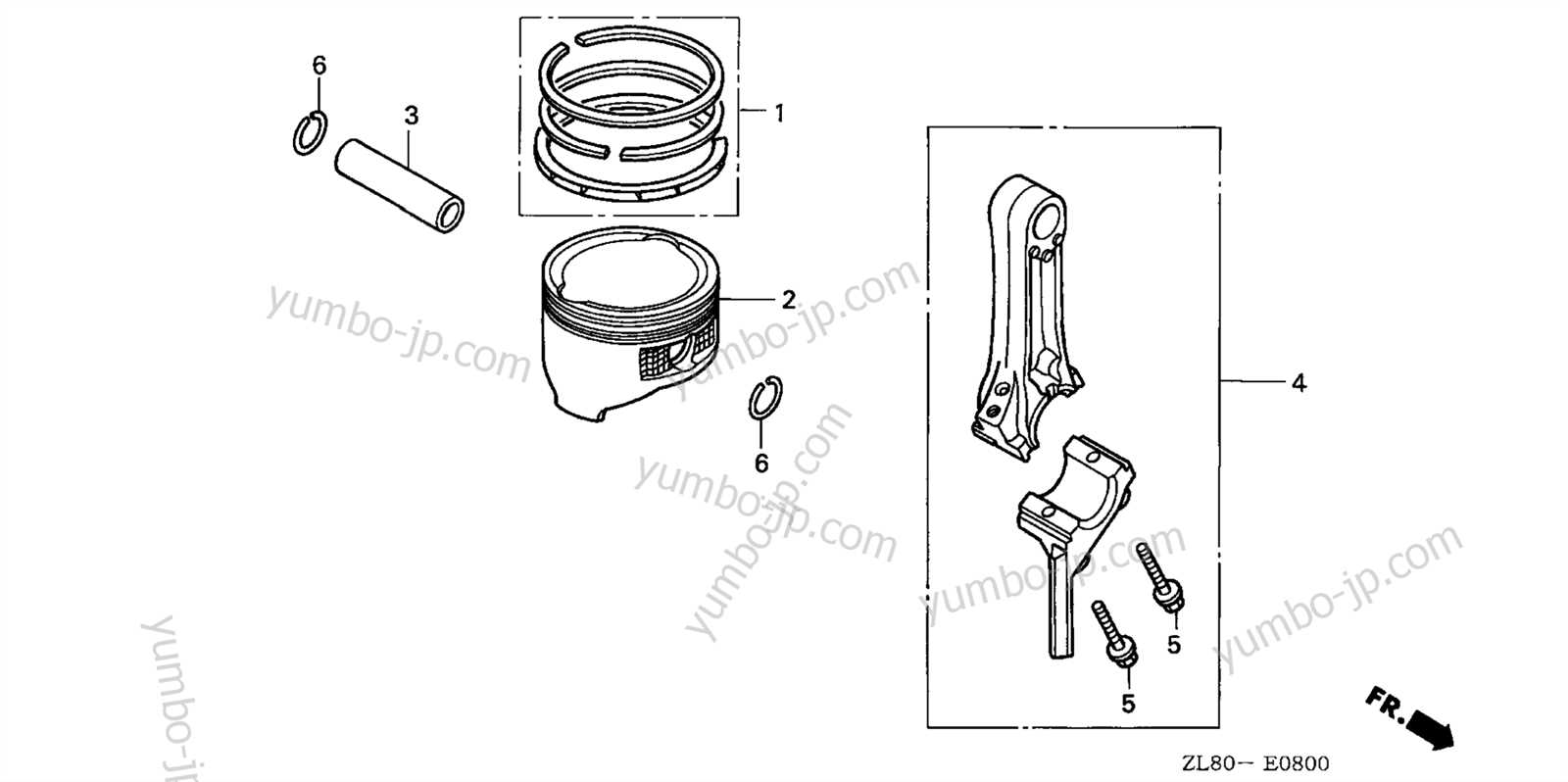

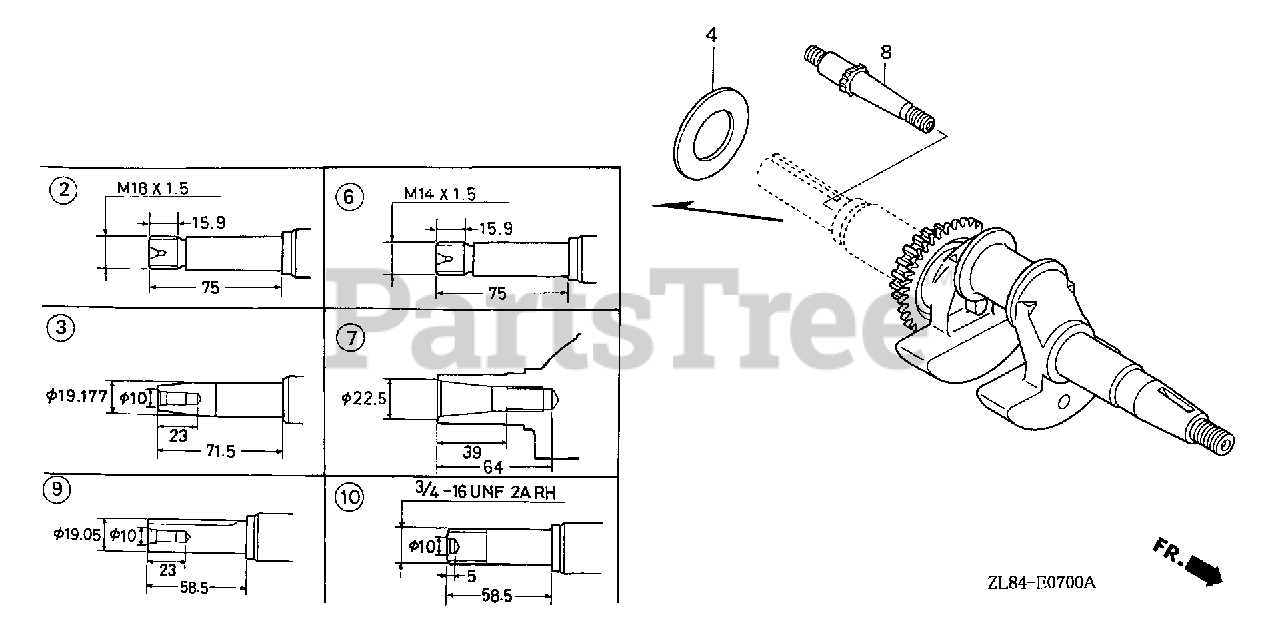

Visual representations of machinery components play a vital role in troubleshooting and repairs. They provide clarity on how parts interact and the positioning of each element within the engine assembly. By familiarizing oneself with these layouts, one can more easily identify issues and address them with confidence.

Moreover, comprehending the arrangement of engine elements not only aids in maintenance but also empowers users to make informed decisions when replacing or upgrading components. Whether you are a seasoned technician or a novice enthusiast, having access to detailed schematics can enhance your overall experience and understanding of machinery care.

Understanding the Honda GC160 Engine

This section aims to provide an insightful overview of a popular small engine, commonly used in various outdoor power equipment. By delving into its components, functionality, and maintenance, users can enhance their understanding and ensure optimal performance for their applications.

Key Components

The essential parts of this engine work together to deliver reliable power. Each component has a specific role, contributing to the overall efficiency and durability of the machine.

| Component | Description |

|---|---|

| Cylinder | Houses the piston and is crucial for combustion. |

| Piston | Moves within the cylinder, compressing the fuel-air mixture. |

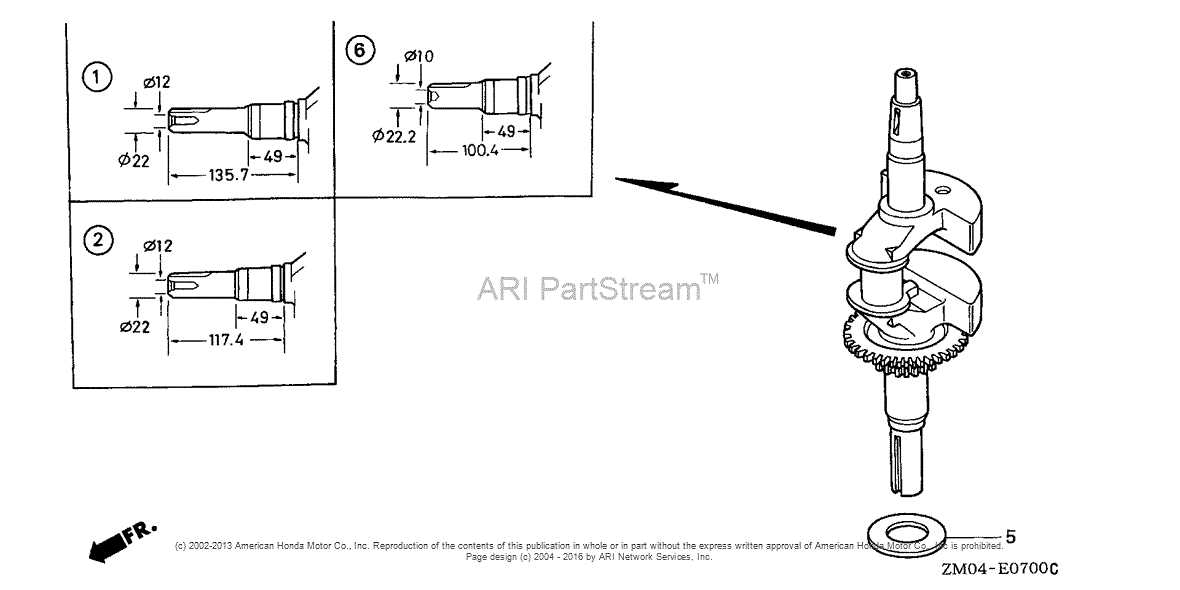

| Crankshaft | Converts the linear motion of the piston into rotational motion. |

| Fuel System | Delivers the right mixture of air and fuel to the engine. |

| Ignition System | Ignites the fuel-air mixture for combustion. |

Maintenance Tips

Regular upkeep is vital for ensuring longevity and performance. Key practices include checking the oil level, cleaning the air filter, and inspecting the spark plug. Adhering to these guidelines can prevent issues and enhance reliability.

Key Components of the GC160

Understanding the essential elements of a small engine is crucial for effective maintenance and performance optimization. Each component plays a specific role in ensuring the engine operates smoothly and efficiently. Familiarizing oneself with these parts can greatly enhance troubleshooting and repair processes.

Essential Elements

- Crankshaft: This part converts linear motion into rotational energy, enabling the engine to function.

- Piston: Moving within the cylinder, it compresses the air-fuel mixture for combustion.

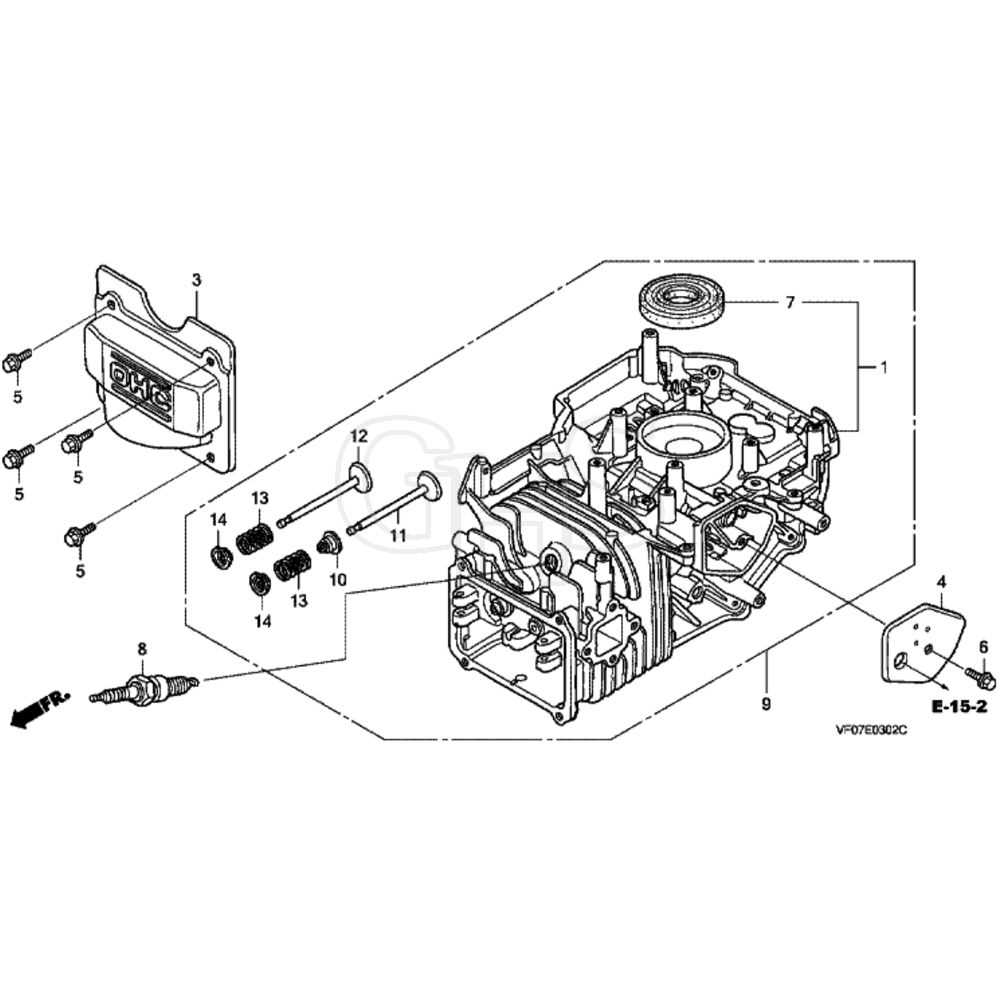

- Cylinder Head: Houses the valves and spark plug, crucial for the engine’s operation.

- Valves: Control the intake of air and fuel and the exhaust of combustion gases.

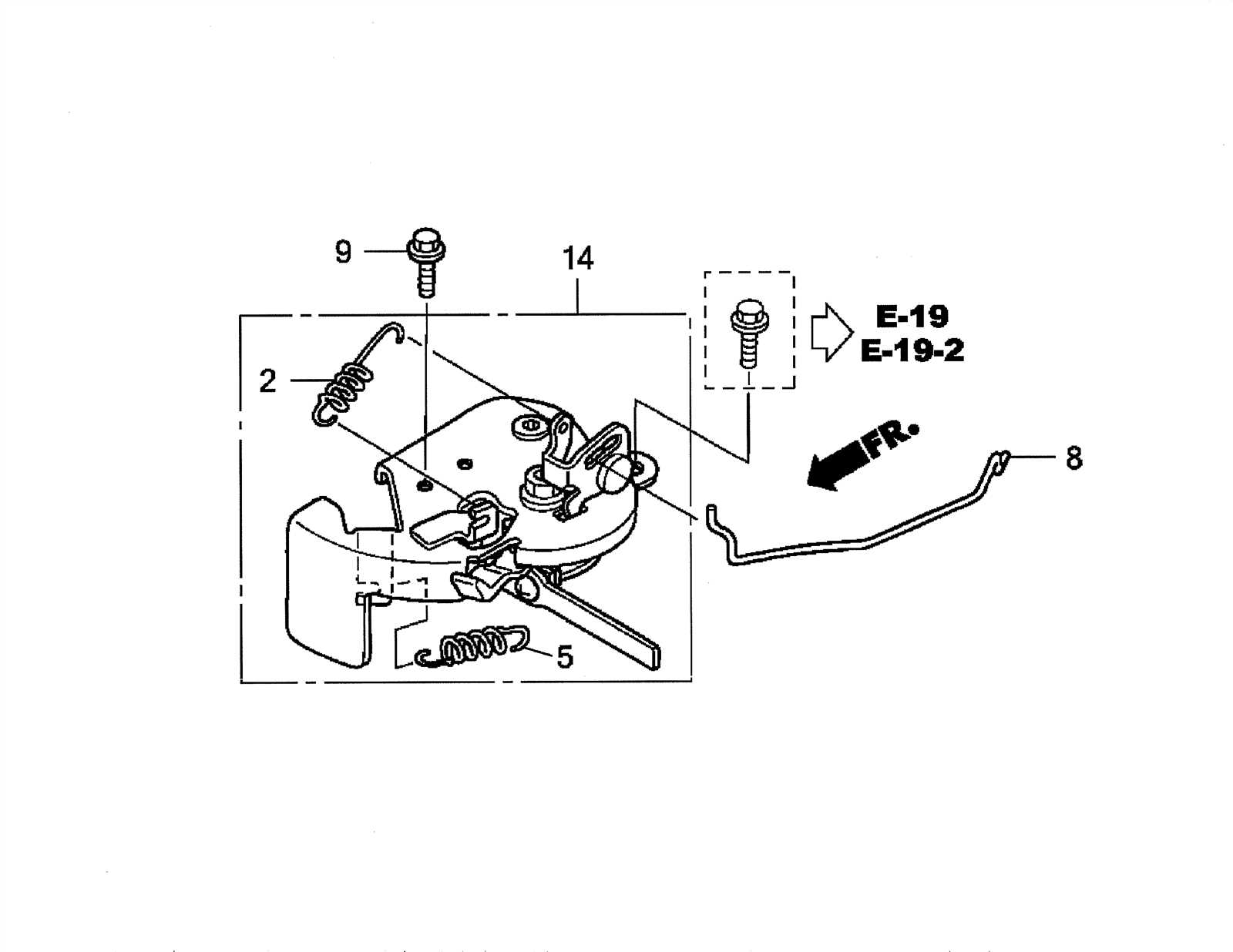

- Ignition System: Responsible for igniting the air-fuel mixture at the right moment.

Additional Features

- Fuel System: Delivers fuel to the engine, ensuring optimal combustion.

- Cooling System: Prevents overheating by dissipating excess heat.

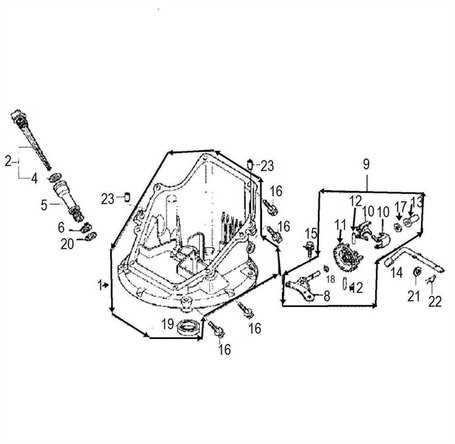

- Lubrication System: Reduces friction between moving parts, enhancing longevity.

- Air Filter: Cleans incoming air, protecting internal components from debris.

Benefits of Using OEM Parts

Choosing original equipment manufacturer components can significantly enhance the performance and longevity of your machinery. These components are specifically designed to fit seamlessly and function optimally within the system, ensuring reliability and efficiency.

- Quality Assurance: OEM components undergo rigorous testing and meet strict quality standards, providing peace of mind that you’re using a reliable product.

- Perfect Fit: These components are tailored to match the specifications of the machinery, which minimizes the risk of malfunction or damage.

- Warranty Protection: Using original components often helps maintain warranty coverage, safeguarding your investment and avoiding additional costs down the line.

- Improved Performance: OEM components are designed to work harmoniously with the existing systems, resulting in optimal performance and efficiency.

- Resale Value: Maintaining your machinery with original components can enhance its resale value, appealing to potential buyers who value quality.

In summary, investing in original components not only promotes better functionality but also supports the overall integrity of your equipment, making it a wise choice for maintenance and repairs.

Common Issues with Honda GC160

Many small engines experience a range of common problems that can hinder their performance and efficiency. Understanding these issues can help users maintain their equipment better and troubleshoot effectively when problems arise.

Fuel-Related Problems

One of the most frequent issues involves the fuel system. Contaminated or stale fuel can lead to starting difficulties and poor engine performance. Additionally, clogged fuel lines or filters can restrict flow, resulting in inconsistent operation.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Stale Fuel | Hard starting, stalling | Replace with fresh fuel |

| Clogged Fuel Line | Weak performance, sputtering | Clean or replace lines |

| Dirty Fuel Filter | Engine misfires, loss of power | Inspect and replace filter |

Mechanical Failures

Another set of challenges relates to mechanical components. Wear and tear on essential parts can lead to operational failures. Symptoms may include unusual noises or vibrations, indicating that internal components may need inspection or replacement.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Worn Piston Rings | Low compression, excessive smoke | Replace piston rings |

| Faulty Spark Plug | Engine not starting, rough idling | Replace spark plug |

| Loose or Damaged Belt | Slipping, poor power transfer | Tighten or replace belt |

How to Access the Parts Diagram

Finding the necessary visual references for components of your equipment can greatly enhance your maintenance and repair efforts. This section will guide you through the steps to locate and utilize these invaluable resources effectively.

To start, ensure you have access to a reliable internet connection. Most manufacturers provide detailed illustrations and lists of components on their official websites or through authorized dealers. Follow these steps to find the information you need:

| Step | Description |

|---|---|

| 1 | Visit the official website of the manufacturer. |

| 2 | Navigate to the ‘Support’ or ‘Resources’ section. |

| 3 | Look for the ‘Product Manuals’ or ‘Technical Information’ option. |

| 4 | Enter the model number or name of your device in the search bar. |

| 5 | Download or view the available resources related to your model. |

Utilizing these resources will facilitate a better understanding of the various elements and their configurations, ensuring a smoother repair process.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your engine requires regular attention and care. By adhering to a few essential practices, you can significantly extend the life of your machinery and maintain its efficiency. These tips focus on routine upkeep, proper handling, and timely replacements that will keep your equipment running smoothly.

Routine Check-ups

Conducting periodic inspections is crucial. Examine the oil levels and change the oil according to the manufacturer’s recommendations to prevent wear and tear. Additionally, keep an eye on air filters; a clean filter promotes better airflow and enhances performance.

Proper Storage and Handling

When not in use, store your equipment in a dry, sheltered location to protect it from environmental damage. Utilize fuel stabilizers to prevent degradation when storing fuel for extended periods. Always handle the machinery with care to avoid unnecessary strain on its components.

Regular maintenance and attention to detail can lead to a significant increase in the lifespan of your equipment. Implementing these practices will ensure your engine operates efficiently for years to come.

Where to Buy Replacement Parts

Finding quality components for maintenance or repairs can be a daunting task. However, understanding where to source these items can simplify the process and ensure you get the right items for your needs.

Online Retailers

- Specialized e-commerce sites often carry a wide selection of components, allowing you to easily compare prices and read customer reviews.

- General marketplaces like Amazon and eBay provide options from various sellers, which can be beneficial for finding specific items.

- Manufacturer websites typically have a dedicated section for accessories and replacements, ensuring authenticity.

Local Stores

- Home improvement stores frequently stock various components, providing the advantage of immediate availability.

- Automotive shops may offer specific items tailored to your machinery needs.

- Small, specialized retailers often have knowledgeable staff who can assist in finding the right components.

Upgrading Your GC160 Engine

Enhancing the performance of your small engine can significantly improve its efficiency and power output. By focusing on key components, you can unlock better capabilities and extend the lifespan of your machinery. This section will guide you through essential upgrades to optimize your engine’s performance.

Essential Upgrades to Consider

There are several modifications you can implement to achieve a noticeable increase in performance. Below are some critical areas to focus on:

| Upgrade | Description |

|---|---|

| Air Filter | Replacing the standard air filter with a high-flow option allows for better air intake, leading to improved combustion and efficiency. |

| Exhaust System | Upgrading to a performance exhaust reduces back pressure, allowing exhaust gases to exit more freely, enhancing overall power. |

| Carburetor Tuning | Adjusting the carburetor settings can optimize the fuel-air mixture, resulting in better acceleration and throttle response. |

| Ignition System | Installing a high-performance ignition coil can provide a stronger spark, improving combustion efficiency and starting reliability. |

Considerations for Upgrading

While upgrading, it’s essential to ensure compatibility with your existing setup. Research thoroughly and consult with experts if necessary to avoid potential issues. Proper installation and tuning will yield the best results and ensure your engine runs smoothly.