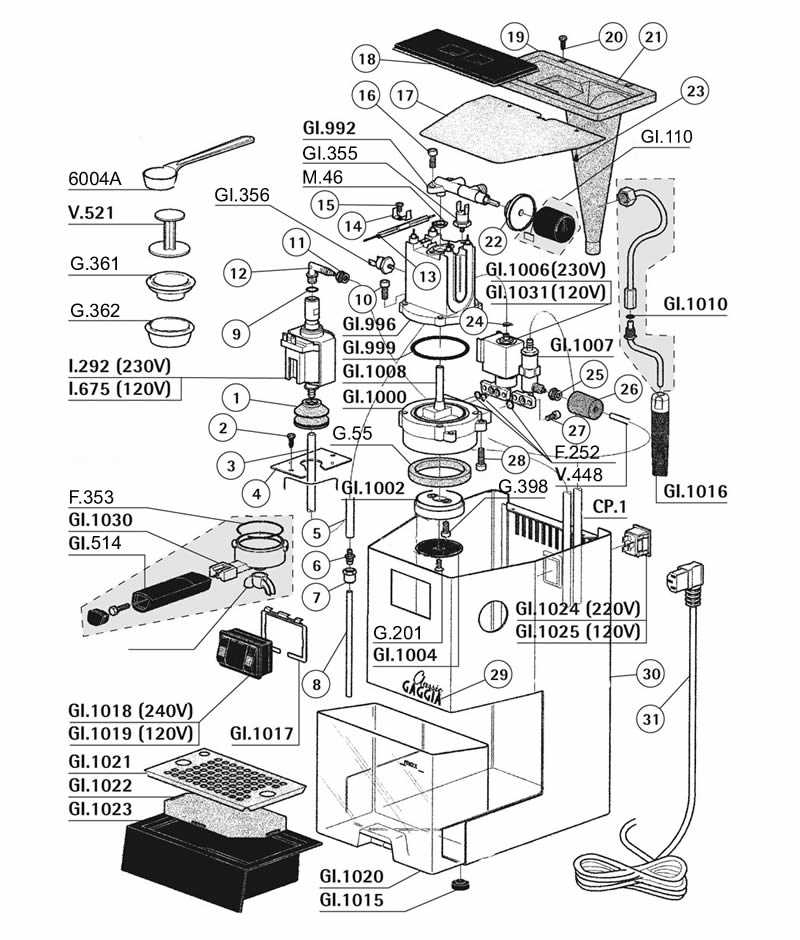

The intricacies of a coffee brewing device involve a multitude of interconnected elements that work together to craft a perfect cup. Understanding the internal structure of such a device can greatly enhance one’s appreciation of its functionality. This section provides insight into how these elements are designed to perform specific tasks within the brewing process, making the entire system operate smoothly.

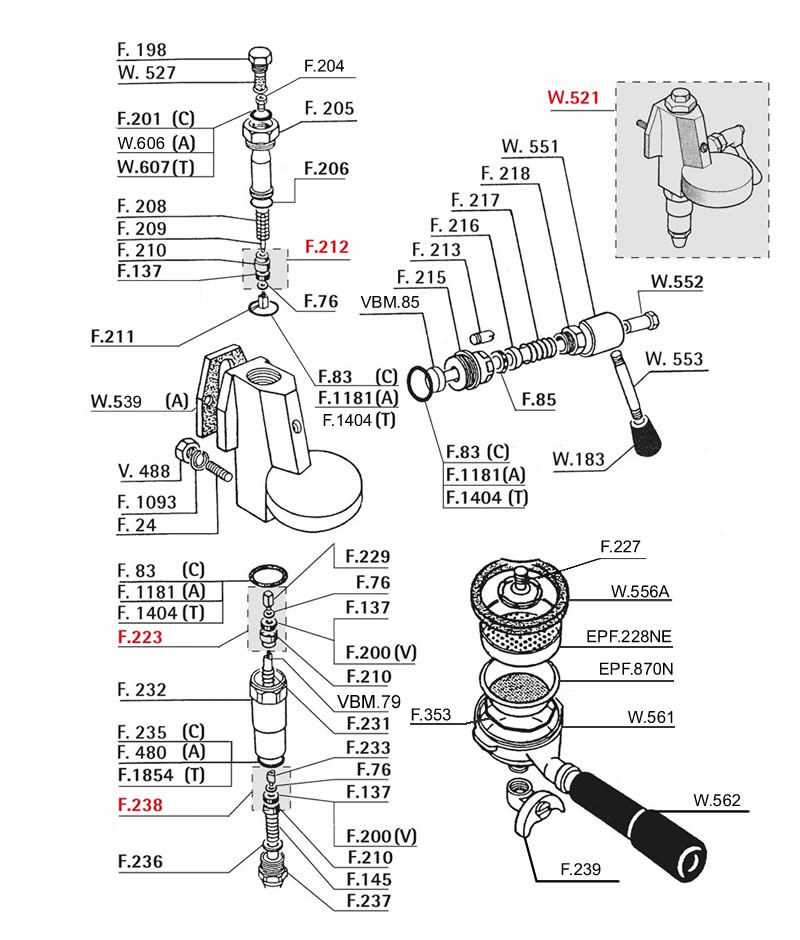

Each individual element has its own purpose, from ensuring precise water flow to maintaining optimal pressure during the brewing cycle. By exploring the design and structure of these components, users can better understand how their device operates, troubleshoot common issues, and even perform minor maintenance when necessary. Delving deeper into this knowledge enhances not only the experience but also the longevity of the equipment.

Understanding Espresso Machine Components

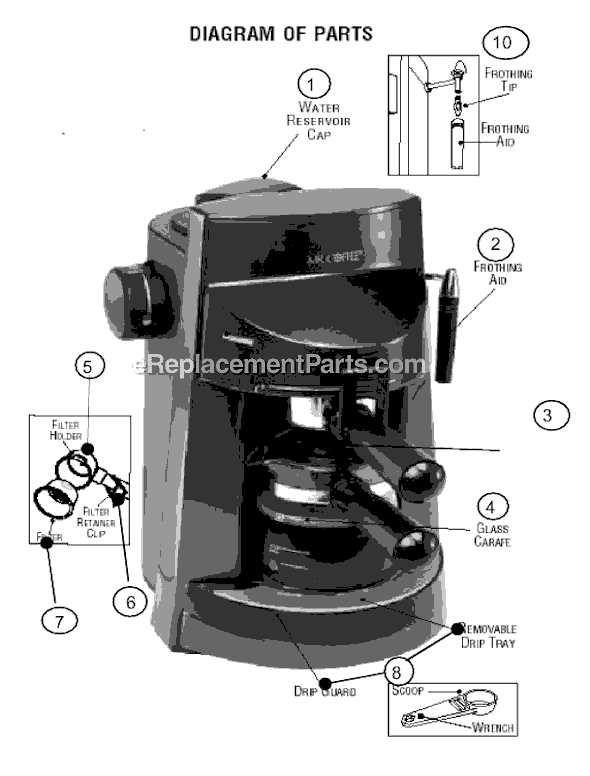

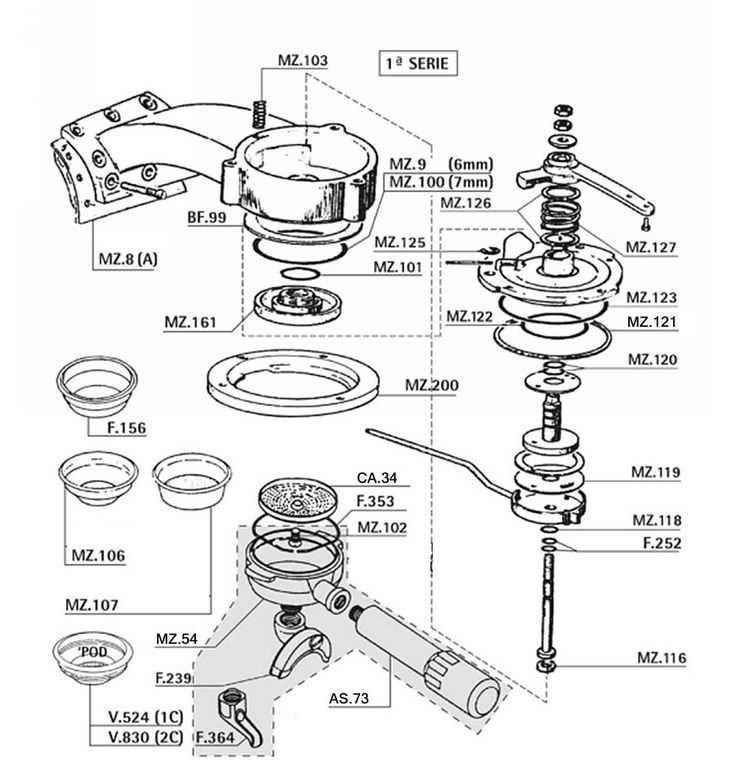

Every brewing device is made up of various elements that work together to produce a rich and flavorful drink. It’s essential to grasp how each element contributes to the brewing process and how they function in harmony. By understanding these components, one can ensure better maintenance and operation, leading to a more consistent result in every cup.

Core Elements

- Heating System: Responsible for bringing water to the optimal temperature, ensuring it’s ready for brewing.

- Pump Mechanism: Drives water through the brewing chamber at high pressure, essential for extracting flavors.

- Water Reservoir: Stores the water used for brewing, which needs to be filled regularly.

- Control Panel: Allows the user to manage brewing settings such as temperature and pressure.

Other Key Components

- Portafilter:

Internal Mechanisms of Espresso Makers

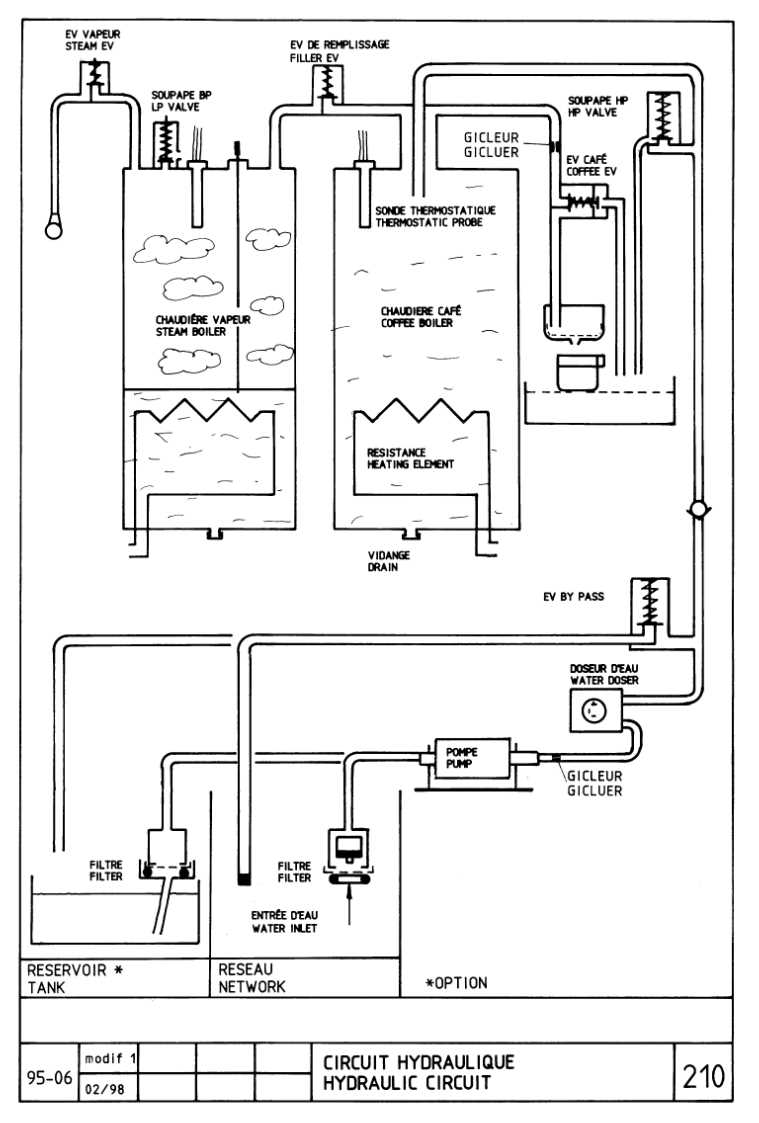

The inner workings of these brewing devices are complex yet highly efficient. Various components collaborate to produce a rich and flavorful beverage by manipulating water temperature and pressure in a precise manner. Understanding how each part functions allows users to maintain and optimize performance.

Heating Element and Water Flow

At the heart of the system is the heating unit, which is responsible for raising the temperature of water to the optimal range. This component is often paired with a pump that ensures water moves through the system at the correct pressure. Without this precise control, achieving a perfect brew would be impossible.

- Boiler or Thermoblock for heating

- Pump system to regulate flow

- Temperature sensors for consistency

Pressure and Brewing Chamber

The pressure system plays a vital role in the brewing process. By forcing hot water through a packed bed of ground beans, it extracts flavors efficiently. A pressure valve helps maintain a consistent force, which is essential for producing a well-balanced cup.

- Pressure gauge for monitoring levels

- Valves to control water release

- Chamber designed to hold the ground material

Key Parts for Brewing Efficiency

Achieving an optimal brewing process relies on several essential components working together seamlessly. The smooth operation of these elements ensures that the drink is extracted with maximum flavor and consistency. Understanding how each component contributes to the overall performance is crucial for anyone looking to enhance their brewing skills.

Water delivery systems play a vital role in ensuring the proper flow and temperature, which directly influences the final outcome of your beverage. Consistent water pressure and heat are key to unlocking the full potential of your ingredients.

Another important aspect is the grind consistency, controlled by the quality and adjustment of the grinding tool. The finer the grind, the more even the extraction, leading to a more balanced flavor profile. Regular maintenance and precise calibration of the grinding tool are essential for achieving reliable results.

Lastly, the filter mechanism is indispensable for separating the grounds from the final drink, ensuring a clean and smooth texture. Proper care and attention to the filtering system can significantly affect the efficiency and quality of the brewing process.

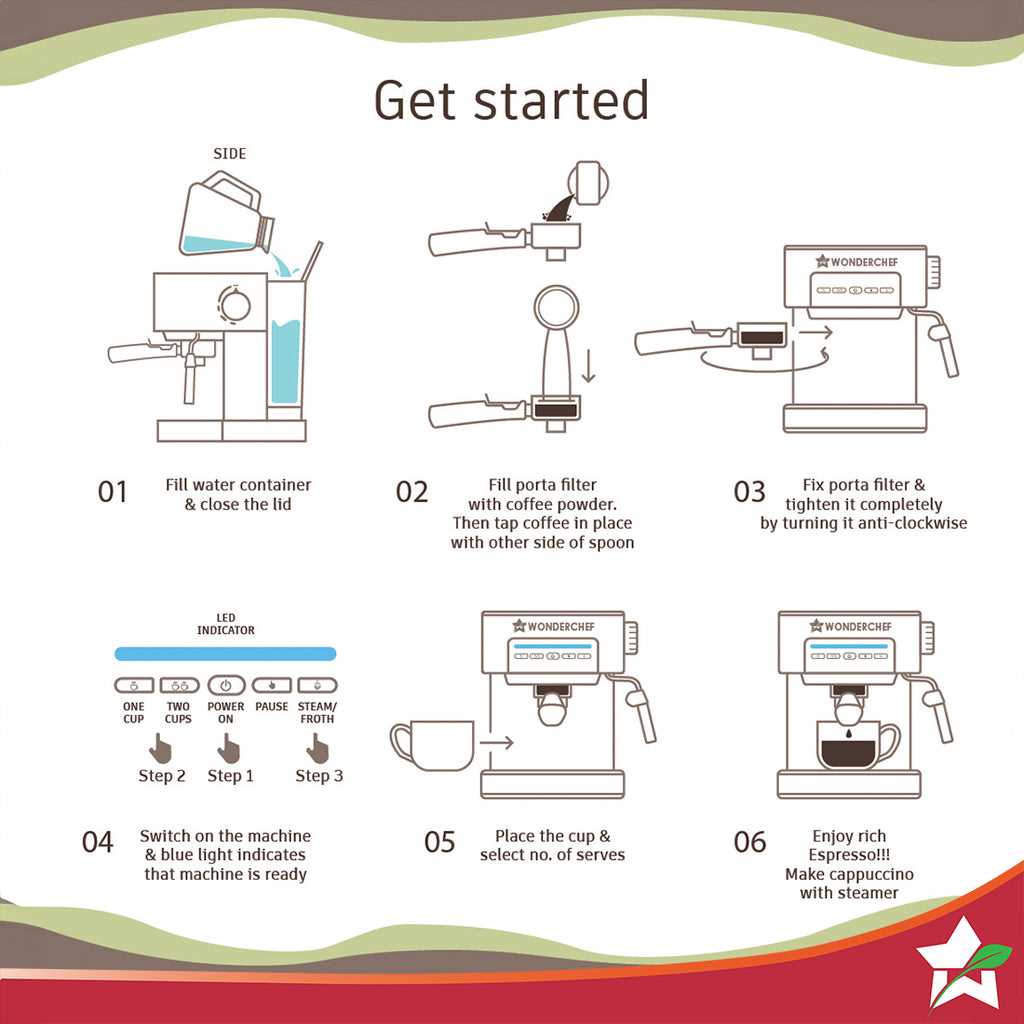

How the Pump System Works

The pump system is essential for driving water through the process, ensuring that liquid reaches the right pressure for optimal performance. The mechanism relies on precise control to generate the necessary force, enabling fluid movement through the internal pathways. By doing so, the entire flow is maintained smoothly and consistently, contributing to the overall efficiency of the process.

Pressure Generation

At the heart of the system is a powerful mechanism that creates the required pressure. This involves pushing liquid from a reservoir through tightly sealed components. The generated force ensures that the fluid is compressed and propelled forward, leading to the desired outcome.

Fluid Flow Control

The system also features specialized components that regulate the flow. These elements ensure that liquid is delivered at the right speed and volume, preventing any irregularities. By maintaining a balanced flow, the system achieves a steady and reliable operation.

Thermal Control and Heating Elements

Effective regulation of temperature is crucial in achieving optimal extraction processes, ensuring the beverage reaches its desired flavor profile. The integration of advanced thermal management technologies plays a significant role in maintaining consistent heat levels throughout the brewing cycle.

Heating components are essential for providing the necessary warmth required for brewing. These elements are designed to quickly raise the temperature of water, allowing for precise control over the brewing conditions. The materials used in these components greatly influence their efficiency and durability, which in turn affects the overall performance.

Moreover, innovative thermal control systems help mitigate temperature fluctuations, enabling users to maintain steady heat during operation. Such systems often employ sensors and automated adjustments to enhance user experience and beverage quality. Understanding these mechanisms can significantly improve one’s approach to crafting the perfect cup.

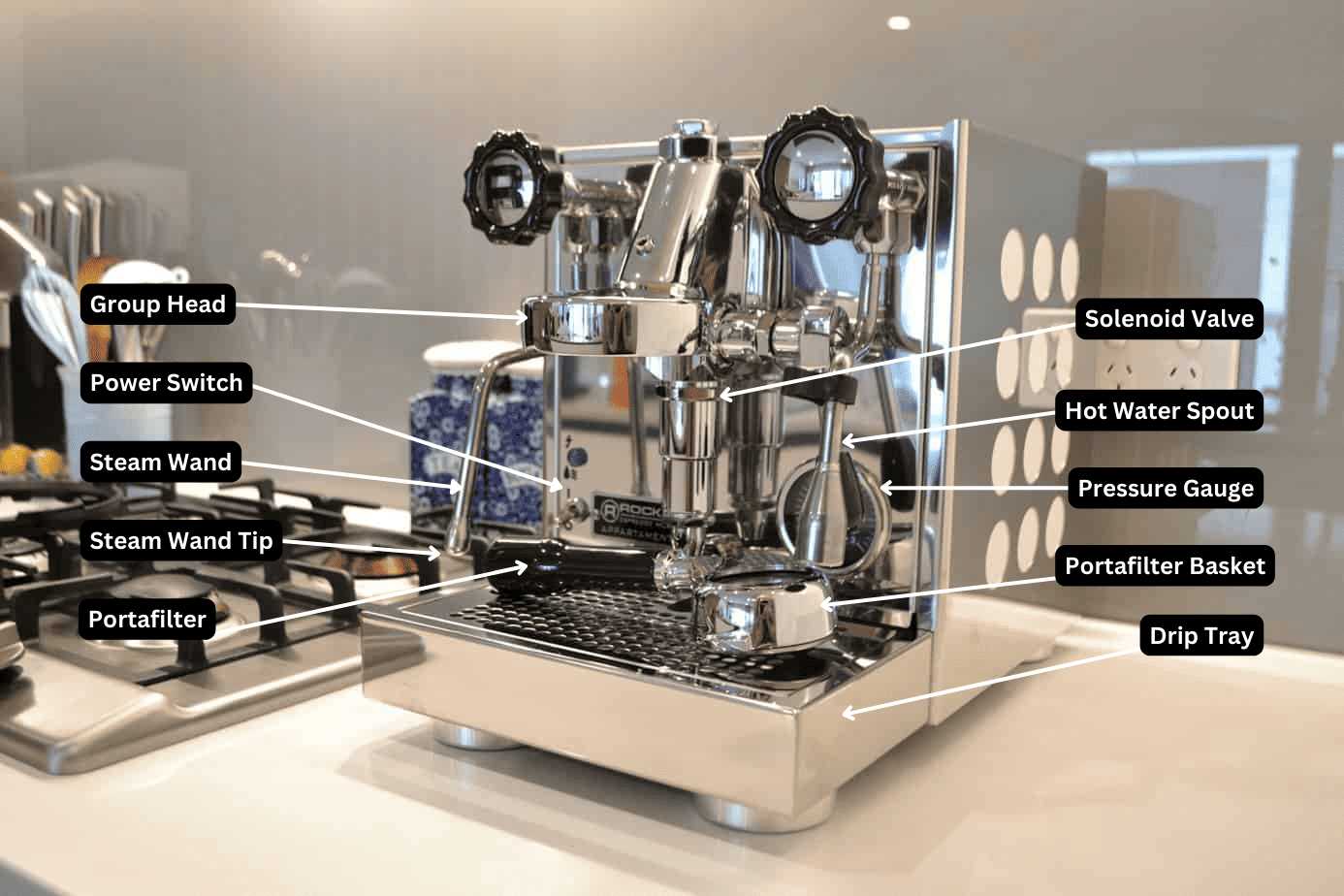

Steam Wand Functionality Explained

The steam wand is an essential tool that enhances the experience of crafting beverages. It allows users to introduce hot steam into milk or other liquids, transforming them into creamy froth or heated liquids. This functionality is crucial for those who appreciate rich textures and flavors in their drinks, offering versatility in beverage preparation.

How It Works

When activated, the wand expels steam generated from heated water. As the steam travels through the wand, it creates a whirlpool effect in the liquid. This motion incorporates air, producing microfoam that is perfect for lattes and cappuccinos. Proper technique in angling and positioning the wand is vital for achieving the desired consistency and temperature.

Maintenance and Care

To ensure optimal performance, regular cleaning and maintenance of the steam wand are necessary. Residual milk can accumulate within the nozzle, leading to blockages or contamination. Flushing the wand with steam after each use helps prevent buildup, while periodic thorough cleaning ensures that it remains functional and hygienic.

Water Reservoir and Flow Dynamics

The reservoir plays a critical role in the overall functionality of the brewing system. It serves as the primary source of liquid needed to create the perfect beverage. Understanding how water is stored and flows through the system is essential for optimal performance and flavor extraction.

Several key factors influence the dynamics of water movement:

- Capacity: The size of the reservoir determines how much liquid can be held, impacting the frequency of refills.

- Material: The type of material used in the construction affects thermal retention and durability.

- Flow Rate: The speed at which water travels from the reservoir to the brewing components influences the extraction process.

Additionally, various components work in tandem with the reservoir to ensure smooth operation:

- Water Pathways: Channels through which liquid flows must be designed to minimize resistance and maintain consistent pressure.

- Valves: Control the flow, allowing precise management of when and how much water is released.

- Filters: Help in purifying the water before it reaches the brewing area, ensuring optimal flavor.

By understanding these elements, users can enhance their experience and ensure high-quality results with each brew.

Maintaining the Grinder for Optimal Use

Regular upkeep of the grinding unit is essential for achieving the best results in beverage preparation. Ensuring that this component remains in top condition will enhance the quality of the brew and prolong its lifespan. Proper maintenance not only improves flavor extraction but also minimizes the risk of mechanical issues.

Begin by routinely cleaning the grinder to prevent the buildup of coffee residues and oils that can affect taste and functionality. Use a brush specifically designed for this purpose to remove particles from the grinding blades and interior surfaces. It is advisable to perform this cleaning after every use or at least once a week for optimal hygiene.

Additionally, checking the grind settings periodically is crucial. The coarseness or fineness of the grind can significantly impact the brewing process, so adjustments may be necessary depending on the type of beverage being prepared. Make sure to calibrate the settings according to the specific requirements of each blend.

Replacing worn-out grinding elements is another important aspect of maintenance. Over time, the blades can become dull, leading to uneven grinds and compromised extraction. Monitoring their condition and replacing them when necessary will ensure consistent performance.

Lastly, keeping the grinding unit free from moisture is vital. Excess humidity can cause clumping of coffee grounds and lead to mold growth. Store the unit in a dry place and consider using desiccants to absorb any excess moisture in the storage area.

Troubleshooting Common Component Failures

Addressing typical issues that may arise with various components is crucial for maintaining optimal performance. By understanding common malfunctions and their symptoms, users can effectively diagnose and rectify problems, ensuring a smoother experience with their device.

Identifying Symptoms

Recognizing signs of failure is the first step in troubleshooting. Below are some common indicators:

- Inconsistent temperature levels

- Unusual noises during operation

- Inadequate output or flow

- Unexpected leaks or drips

- Control panel malfunctions

Common Issues and Solutions

Once symptoms are identified, the following list provides solutions for frequently encountered problems:

- Inconsistent Temperature: Check the heating element and ensure proper calibration. If necessary, replace faulty thermostats.

- Noisy Operation: Inspect moving parts for wear and tear. Lubrication may resolve excessive friction.

- Poor Flow: Clean filters and water lines to remove any blockages that may hinder performance.

- Leaking: Examine seals and gaskets for damage. Replacing worn components can eliminate leaks.

- Control Panel Issues: Restart the unit to reset settings. If problems persist, consult the user manual for further troubleshooting steps.