In the world of gardening and agriculture, having a reliable tool for applying liquids can significantly enhance efficiency and effectiveness. This specialized device is essential for anyone looking to maintain their green spaces or crops with precision. Familiarizing yourself with the various elements of this equipment can lead to better maintenance practices and improved performance.

Identifying the different sections of this apparatus allows users to troubleshoot issues, perform regular maintenance, and optimize their usage. Each component plays a crucial role in ensuring that the application of liquids is consistent and targeted, ultimately benefiting the overall health of the plants or areas being treated.

By exploring the layout and functionality of these individual parts, users can gain insights into how to improve their techniques and enhance the longevity of their tools. Understanding the interactions between these elements can also aid in selecting the right upgrades or replacements when necessary.

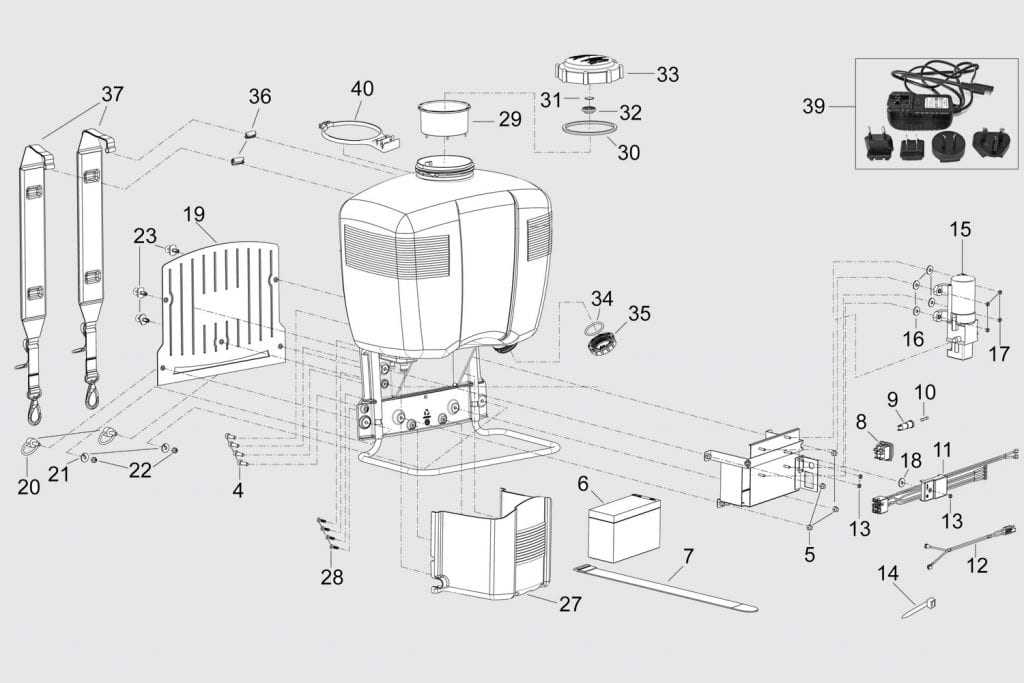

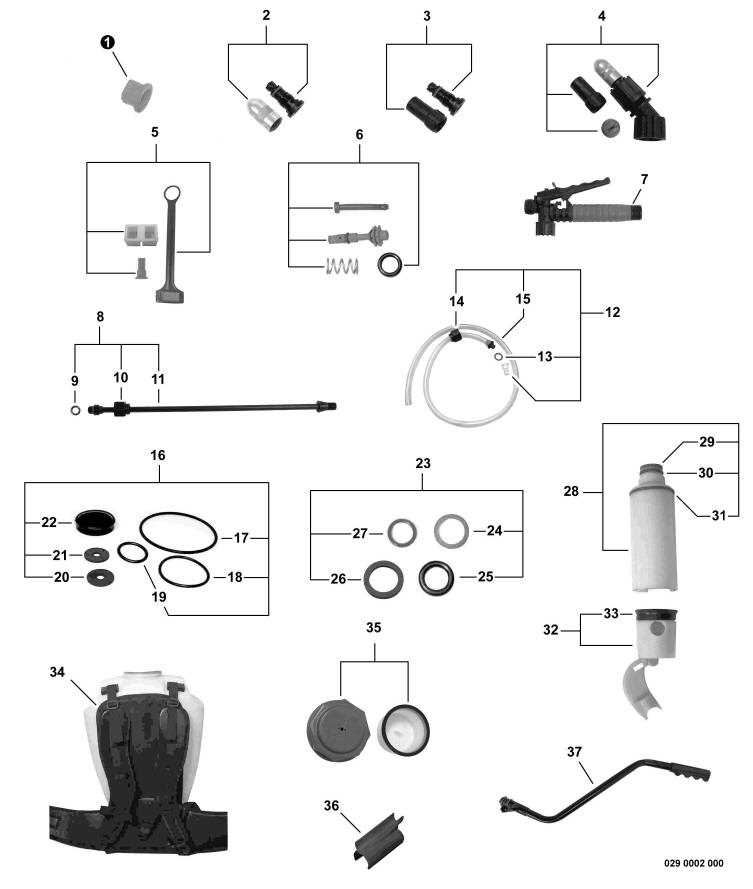

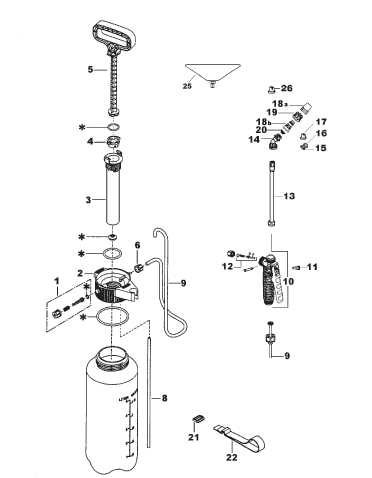

Understanding Solo Backpack Sprayers

This section delves into the essential components and functionalities of portable liquid application devices commonly used in agriculture and gardening. These tools offer an efficient means to distribute various substances, ensuring effective coverage and ease of use for operators.

Key Components

Each device is composed of several critical elements that work together to optimize performance. The reservoir holds the liquid, while the pump mechanism generates the necessary pressure. A flexible hose connects to a nozzle, allowing for adjustable spray patterns, catering to diverse applications.

Maintenance and Care

Regular upkeep is vital for longevity and efficiency. Users should periodically inspect seals, hoses, and nozzles for wear and tear. Proper cleaning after each use prevents residue build-up, ensuring that the apparatus remains functional and reliable for future tasks.

Essential Components of Backpack Sprayers

Understanding the critical elements of portable liquid application devices is vital for effective usage and maintenance. Each component plays a significant role in ensuring optimal performance, efficiency, and user comfort during operation. A comprehensive grasp of these features not only enhances the longevity of the equipment but also improves the overall application process.

Key Features

The following elements are fundamental for the effective functioning of these devices:

| Component | Description |

|---|---|

| Tank | The primary reservoir for holding the liquid, usually made from durable materials to withstand various chemicals. |

| Pump | Generates pressure to facilitate the distribution of the liquid through the nozzle, crucial for achieving the desired spray pattern. |

| Nozzle | Directs and disperses the liquid, available in various types for different application needs, ensuring effective coverage. |

| Straps | Designed for comfort, allowing the user to carry the device securely while minimizing fatigue during extended use. |

Maintenance Considerations

Regular inspection and maintenance of these components are essential to avoid malfunctions and ensure consistent performance. Keeping the tank clean, checking the pump for leaks, and replacing nozzles as needed are important practices for any user.

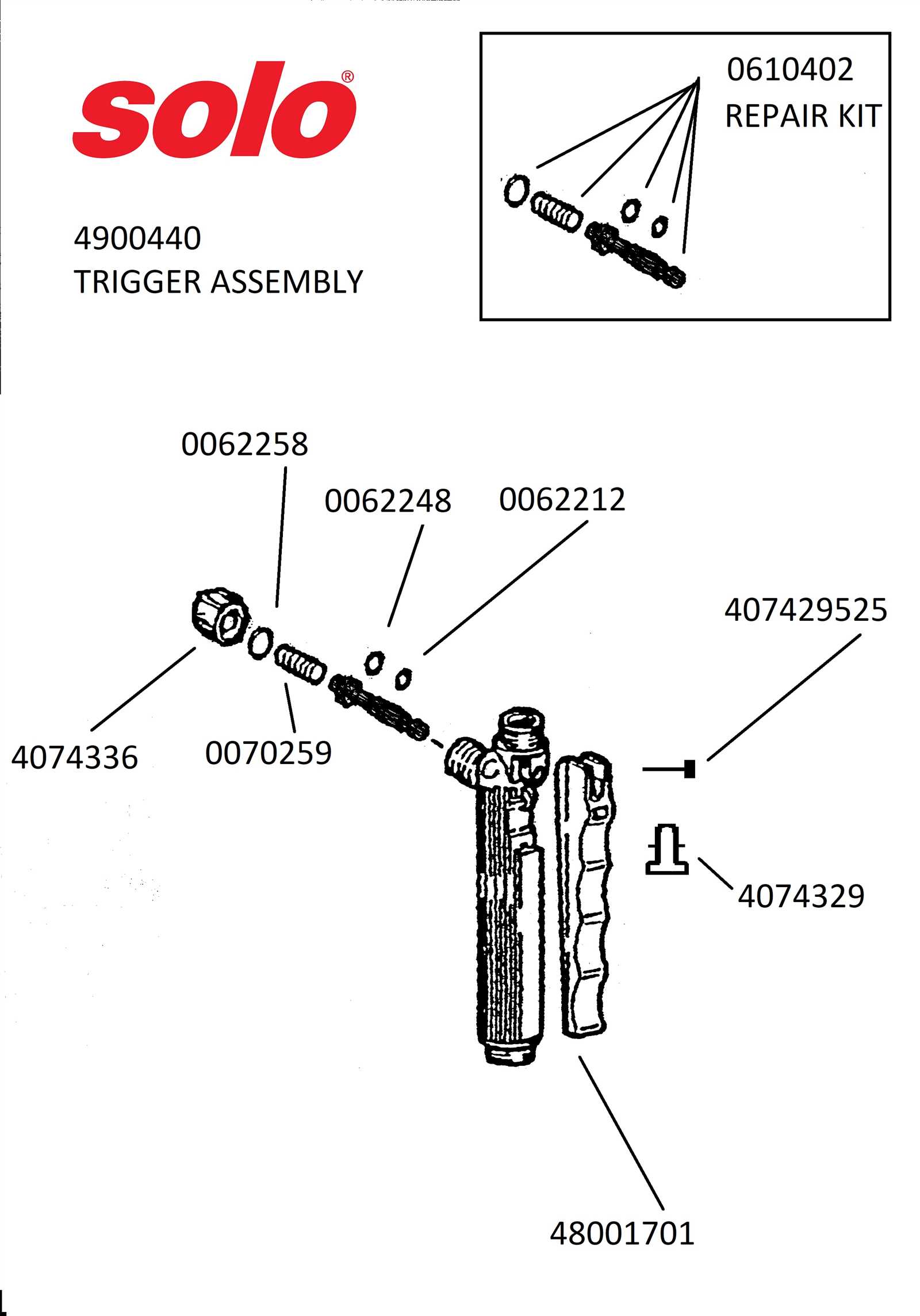

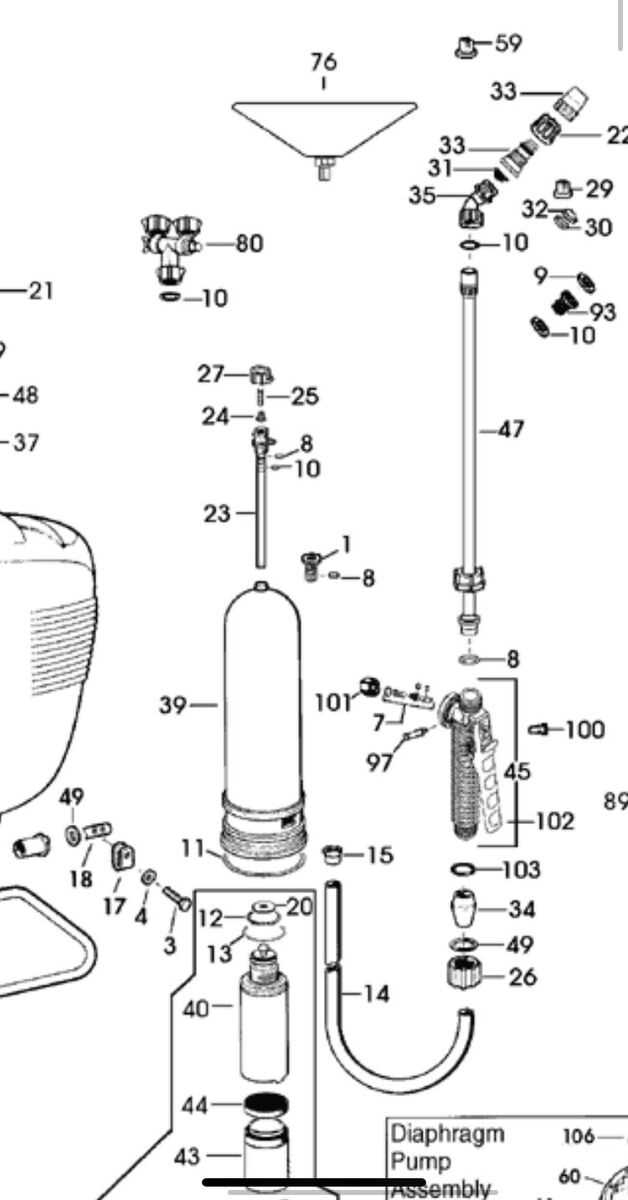

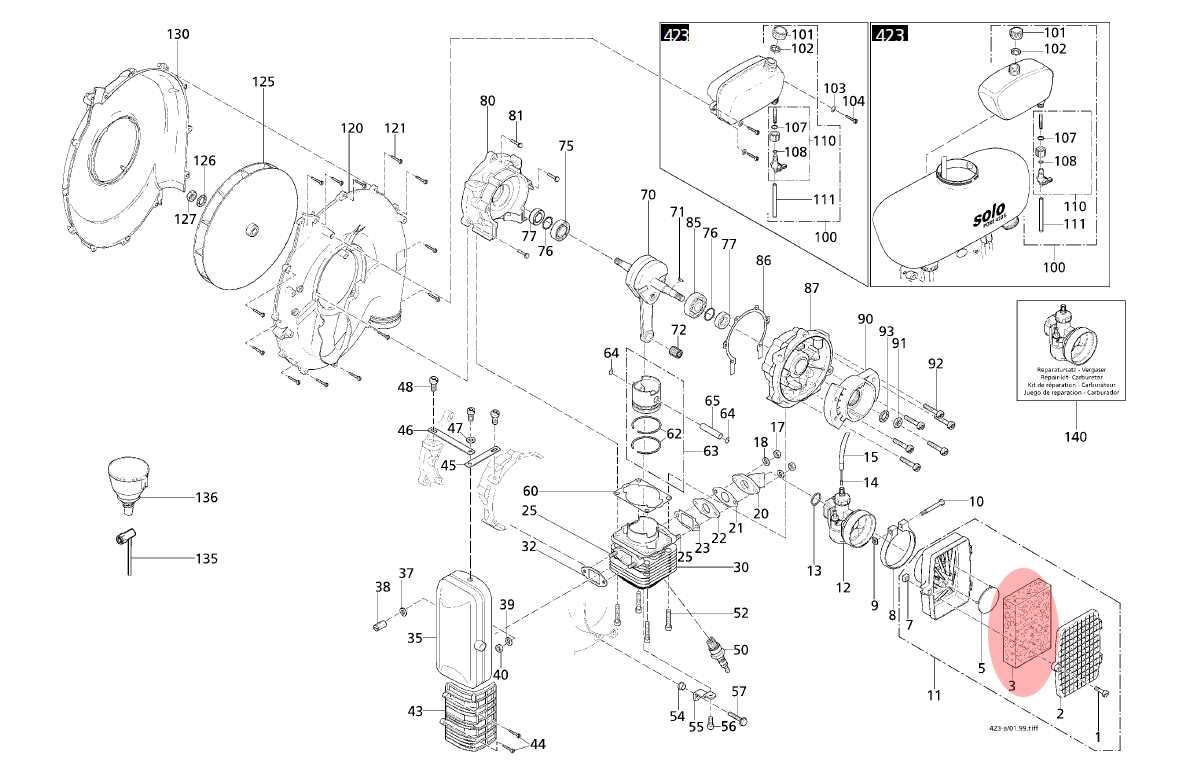

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a detailed overview, allowing users to identify individual elements and their interconnections. Mastering the art of interpreting these visuals can significantly enhance your troubleshooting skills and improve overall equipment functionality.

To begin, familiarize yourself with the key symbols and notations used in these representations. Each element is typically labeled, and the accompanying legends clarify the function of each part. Take note of any reference numbers or letters that correspond to the list of components, as these will guide you in locating replacements or additional information.

Another important aspect is the layout. Components are often arranged in a logical order, which reflects how they are assembled or how they interact with one another. Pay attention to arrows and lines indicating movement or flow; these can provide crucial insights into how the system operates. By analyzing these connections, you can better understand the role of each element in the overall mechanism.

Finally, practice makes perfect. Regularly consulting these visual aids while performing maintenance will build your familiarity and confidence. Over time, you’ll find that reading these illustrations becomes an intuitive process, empowering you to tackle repairs with greater ease and precision.

Common Issues with Backpack Sprayer Parts

Equipment designed for agricultural tasks often encounters various challenges that can hinder performance. Understanding these issues is crucial for maintaining optimal functionality and ensuring longevity. Common problems can arise from wear and tear, improper handling, or lack of maintenance, affecting the overall efficiency of the device.

Leaks and Seal Failures

One of the most frequent issues involves leaks caused by deteriorated seals or damaged connections. These leaks not only waste valuable liquids but can also create safety hazards. Regular inspection of gaskets and fittings can help identify wear early, preventing more extensive repairs.

Clogged Filters and Nozzles

Another prevalent concern is the clogging of filters and nozzles. Debris and chemicals can accumulate over time, leading to inconsistent spray patterns and reduced pressure. Routine cleaning and proper filtration can mitigate this problem, ensuring even distribution during application.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires consistent care and attention. Regular maintenance not only prolongs the lifespan of your tool but also enhances its performance. Following a few essential practices can significantly improve its reliability over time.

Routine Cleaning

After each use, it’s crucial to clean all components thoroughly. Residual chemicals can cause corrosion and clogging, affecting functionality. Use warm water and a gentle detergent to rinse all parts, ensuring that no traces of substances remain. Pay special attention to nozzles and filters, as these are prone to blockages.

Regular Inspections

Conduct periodic checks to identify any wear and tear. Look for cracks, leaks, or signs of deterioration. Inspect seals and gaskets, as these are essential for preventing leaks. Addressing minor issues promptly can prevent more significant problems down the line, saving time and money on repairs.

Choosing the Right Replacement Parts

Selecting appropriate components for your equipment is crucial for maintaining its efficiency and longevity. A thorough understanding of your device’s specifications and compatibility will help ensure optimal performance and reduce the likelihood of future issues.

Assessing Compatibility

Before acquiring new components, it’s vital to verify that they align with your equipment’s model and specifications. This involves checking dimensions, attachment methods, and material compatibility to avoid any operational challenges.

Quality vs. Cost

While it may be tempting to choose the most affordable options, investing in high-quality components can significantly enhance performance and durability. Consider balancing cost with long-term benefits to make the ultimate choice for your needs.

Assembly Process for Sprayer Components

The assembly of application equipment involves a systematic approach to ensure all elements function together seamlessly. Understanding the integration of various components is crucial for achieving optimal performance during usage. Each segment must be correctly aligned and securely attached to facilitate effective operation.

Step-by-Step Integration

Begin by gathering all necessary components, ensuring that each item is free from damage. Carefully follow the instructions provided for the assembly process. Typically, this includes:

- Connecting the main body to the handle securely.

- Attaching the pressure chamber, ensuring a tight seal to prevent leaks.

- Installing the nozzle and adjusting it for the desired spray pattern.

Final Checks and Maintenance

Once assembled, conduct a thorough inspection to verify that all connections are firm and components are correctly positioned. It is advisable to perform a test run to check for any operational issues. Regular maintenance, such as cleaning and checking for wear, will prolong the lifespan of the equipment and maintain its efficiency.

Identifying Parts by Model Number

Understanding the components of your equipment is essential for effective maintenance and repairs. Each model features unique identifiers that facilitate the selection of suitable replacements. By focusing on the specific model number, you can ensure compatibility and optimal performance.

Step 1: Locate the model number, typically found on the unit itself, often on a label or embossed area. This number serves as the key to accessing relevant resources.

Step 2: Refer to the manufacturer’s documentation or website, which often includes a comprehensive list of compatible components linked to each model number. This information allows for accurate identification.

Step 3: If available, utilize online forums or community groups dedicated to equipment discussions. These platforms can provide insights from other users who have encountered similar needs.

Step 4: Keep a record of your model number and any associated components, ensuring easier access in future maintenance or replacement scenarios. This proactive approach minimizes downtime and enhances functionality.

Safety Precautions During Repairs

When engaging in maintenance tasks, it is essential to prioritize safety to prevent accidents and ensure a smooth workflow. Adopting proper measures protects not only the individual performing the repairs but also the equipment itself.

Firstly, always wear appropriate personal protective equipment (PPE). This includes gloves, goggles, and masks to shield against potential hazards such as chemicals, sharp objects, or debris. Ensuring that your workspace is well-ventilated is equally important to minimize inhalation of harmful substances.

Secondly, before starting any repair, disconnect any power sources and release any pressurized components. This reduces the risk of unexpected discharge or electrical shocks. Familiarizing yourself with the equipment’s manual can also provide crucial insights into specific safety protocols.

Additionally, keeping your workspace organized and free from clutter is vital. This practice not only enhances efficiency but also helps to avoid tripping hazards or misplacing tools that could lead to injuries.

Lastly, if unsure about any procedure, do not hesitate to seek professional advice or assistance. Prioritizing safety ensures a successful repair process and extends the life of your equipment.