The performance and longevity of watercraft propulsion systems depend heavily on understanding their internal structures. For enthusiasts and professionals alike, knowing how these mechanisms are organized and interconnected is essential for maintenance and repairs. Identifying the various elements that make up these engines provides clarity on how to ensure smooth operation and prevent breakdowns.

Each component plays a crucial role in maintaining balance and efficiency in marine propulsion systems. Whether you’re performing routine inspections or troubleshooting specific issues, having a clear grasp of the system’s makeup is fundamental to keeping the equipment in optimal condition. This knowledge empowers you to address potential issues before they escalate into costly repairs.

To effectively maintain these systems, a detailed overview of their structure is essential. By exploring the layout and understanding how the various pieces fit together, one can significantly improve their ability to manage, repair, and enhance engine performance, ultimately ensuring a longer lifespan for the equipment.

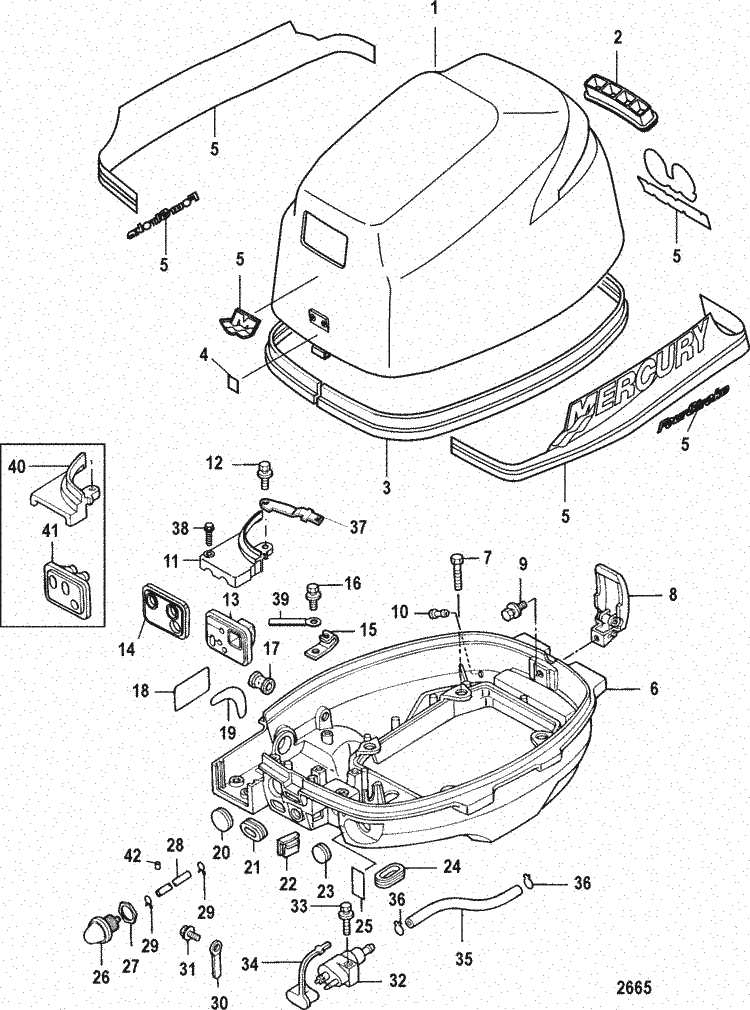

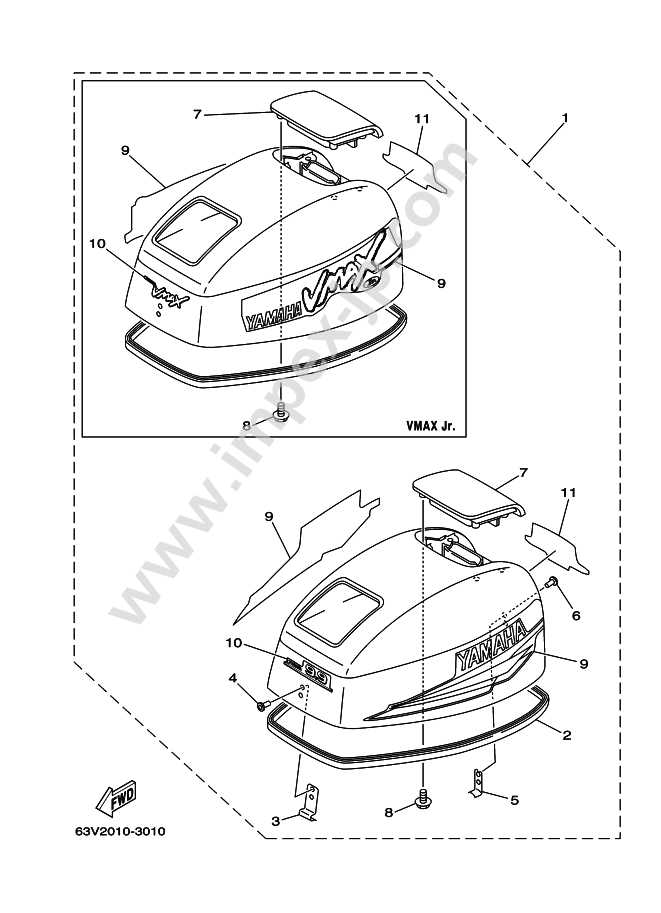

Engine Overview

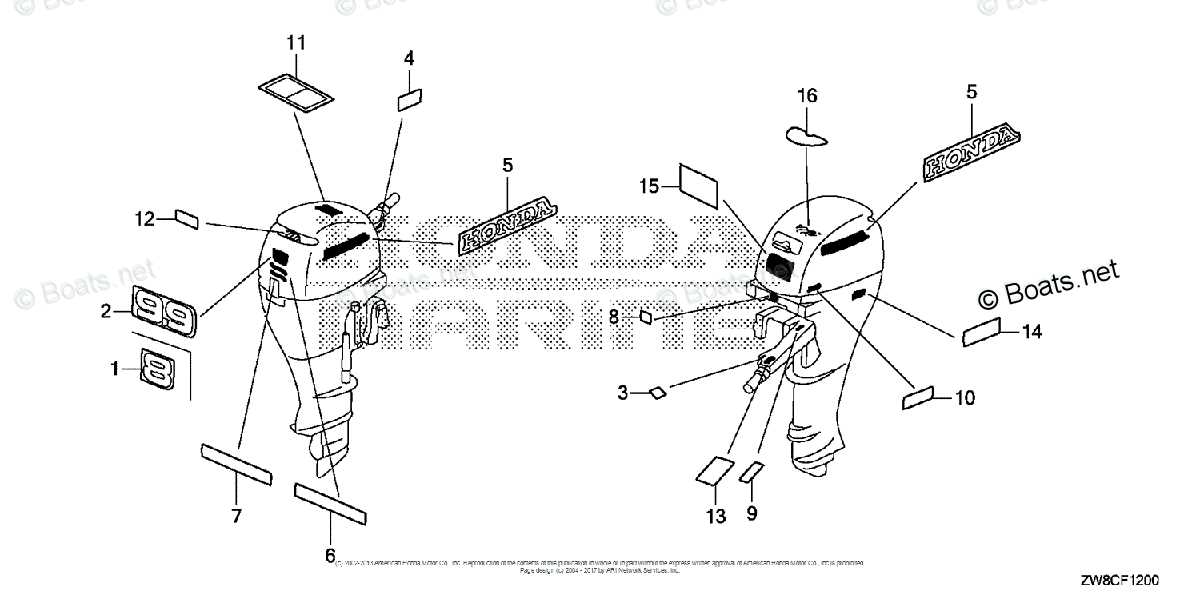

This compact propulsion system stands out for its reliability and efficiency, making it a popular choice for small to medium-sized vessels. Designed to provide smooth operation and fuel economy, the engine is engineered for those who seek consistent performance on the water. Its lightweight design ensures easy handling while maintaining enough power to handle a variety of boating activities.

Performance and Features

With a focus on delivering optimal power-to-weight ratio, this motor ensures that boats move swiftly and with precision. The system integrates advanced cooling technology to prevent overheating, which helps extend the lifespan of the engine. Additionally, the control mechanism offers smooth acceleration and easy maneuverability, giving users confidence in various conditions.

Durability and Maintenance

Built to withstand challenging marine environments, this propulsion unit is crafted from corrosion-resistant materials, ensuring longevity even with regular exposure to saltwater. Routine maintenance is simplified thanks to the easily accessible components, allowing

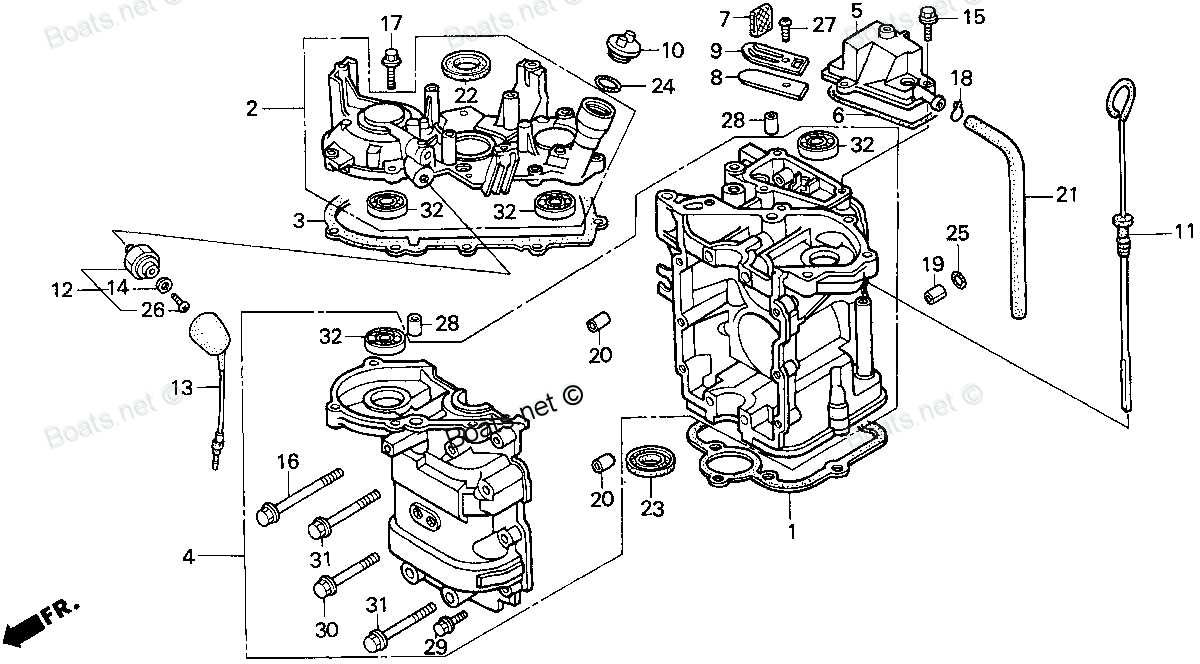

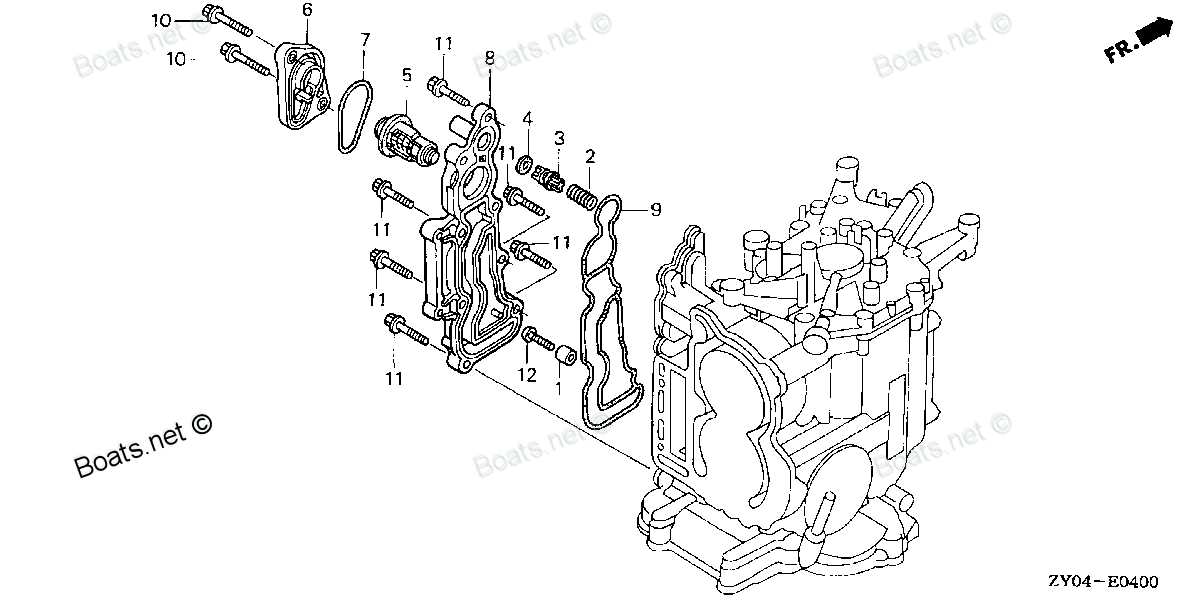

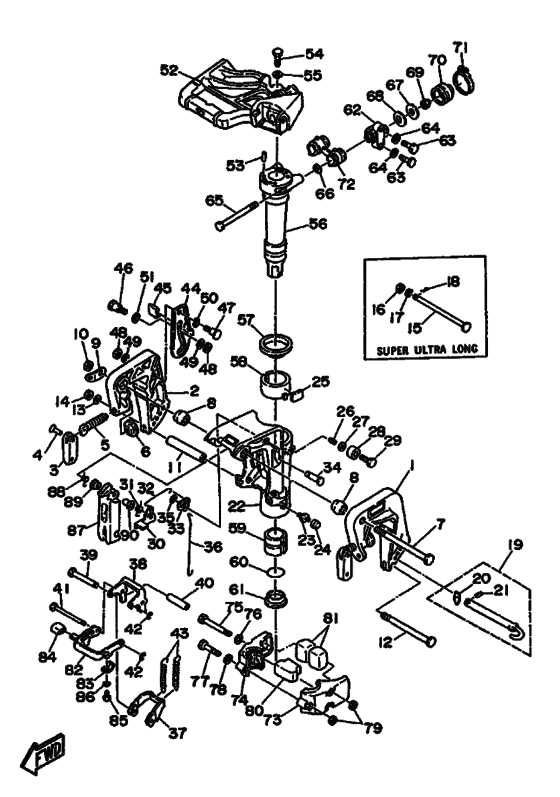

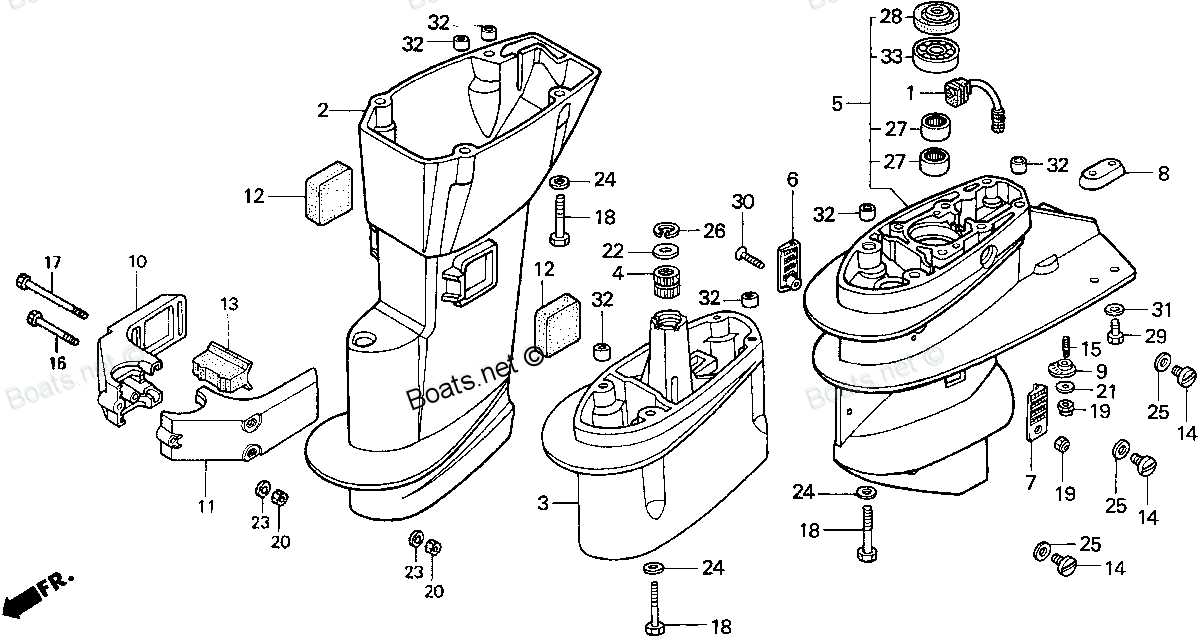

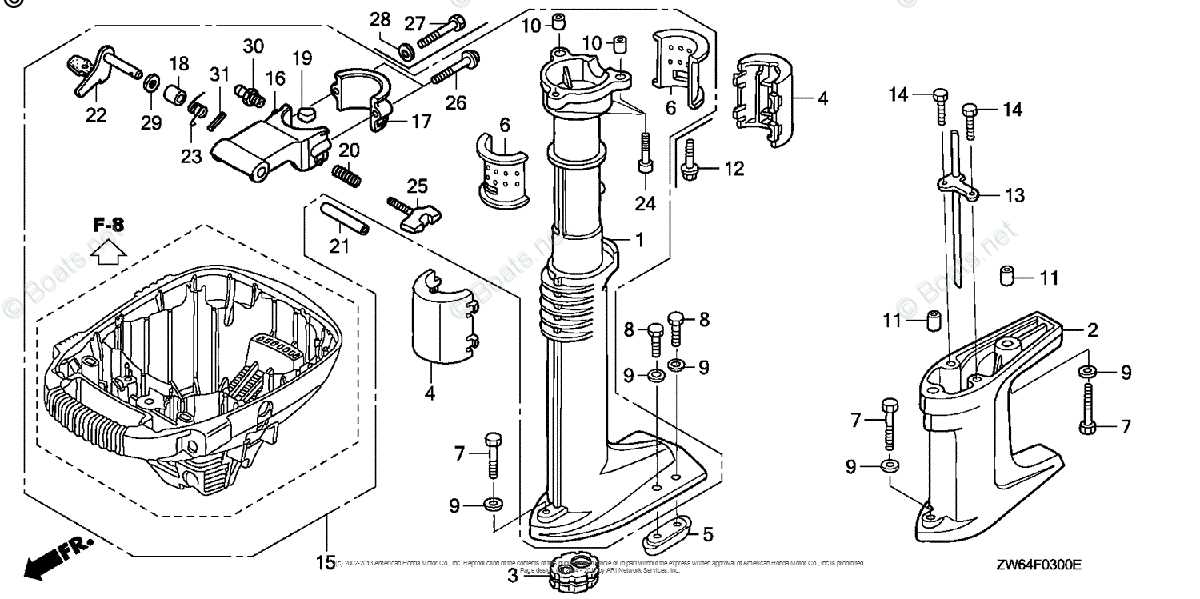

Main Components of the 9.9 HP Engine

This section outlines the key elements that make up a small, high-performance marine motor. These components work together to ensure smooth operation, durability, and efficiency. Understanding each part’s function can help with maintenance and troubleshooting.

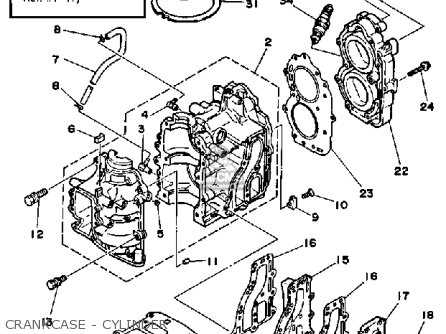

Core Engine Parts

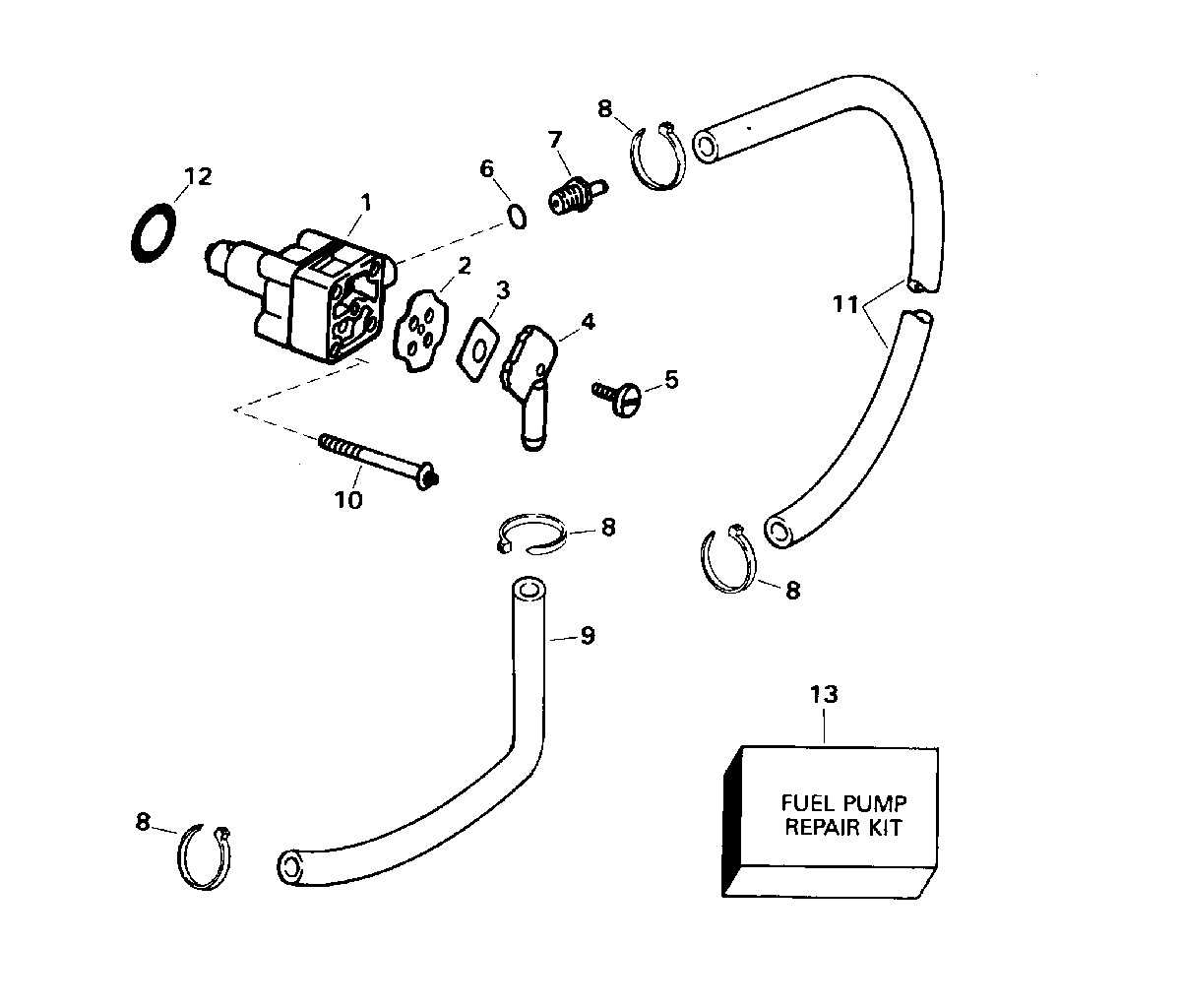

The essential elements of the engine include a combustion system, a cooling mechanism, and a fuel intake setup. These are vital for the motor’s proper performance, converting fuel into mechanical energy while maintaining the temperature and flow of the engine.

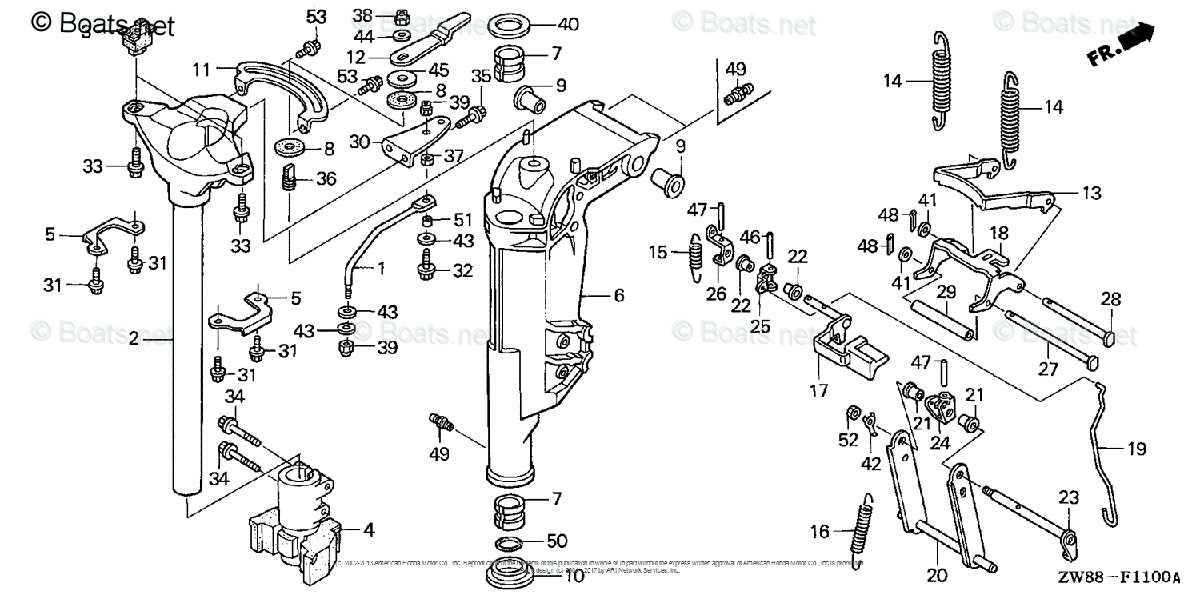

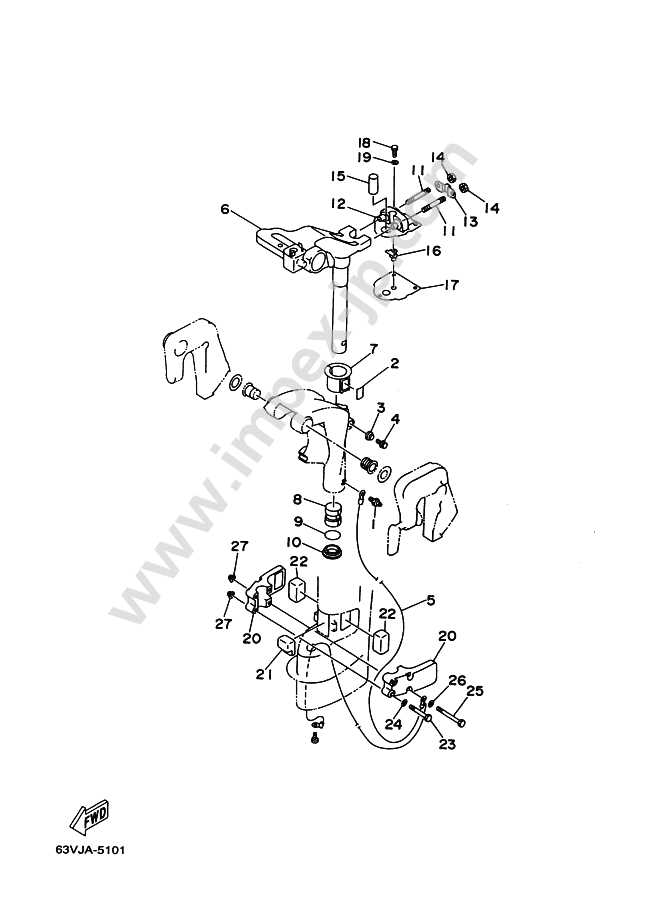

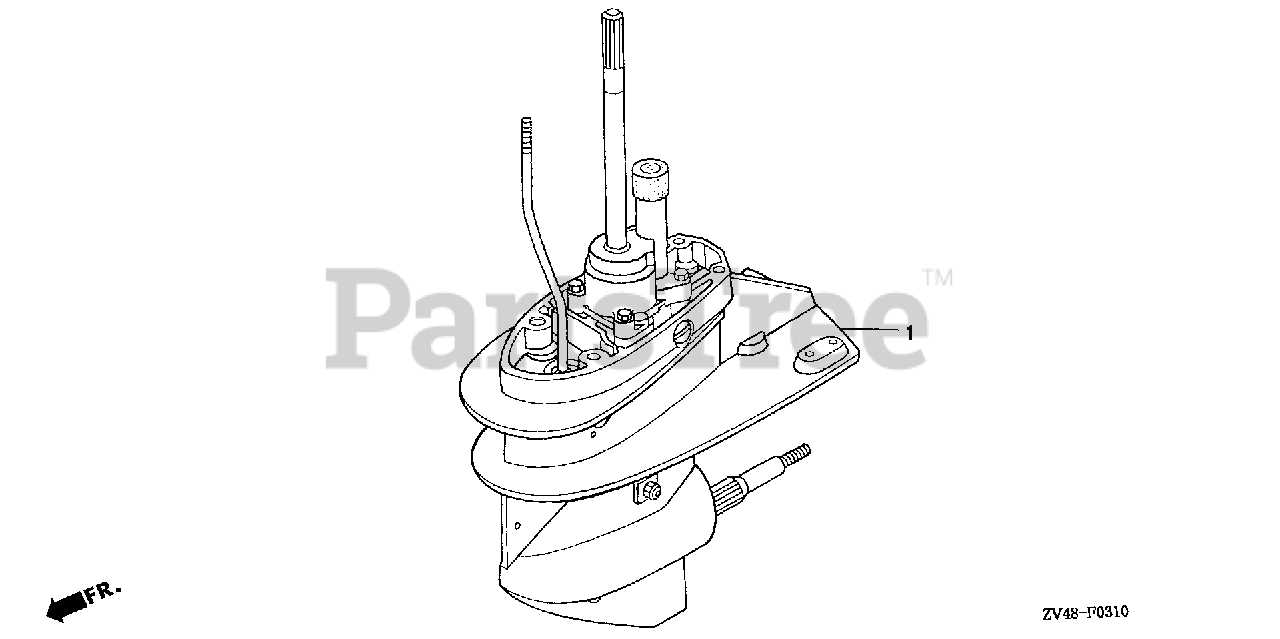

Power Transmission System

The power generated by the engine is transferred to the propeller through several critical parts. These include the driveshaft, gear system, and the propeller itself, which ensures the motor delivers force to move the watercraft efficiently.

| Component | Function |

|---|

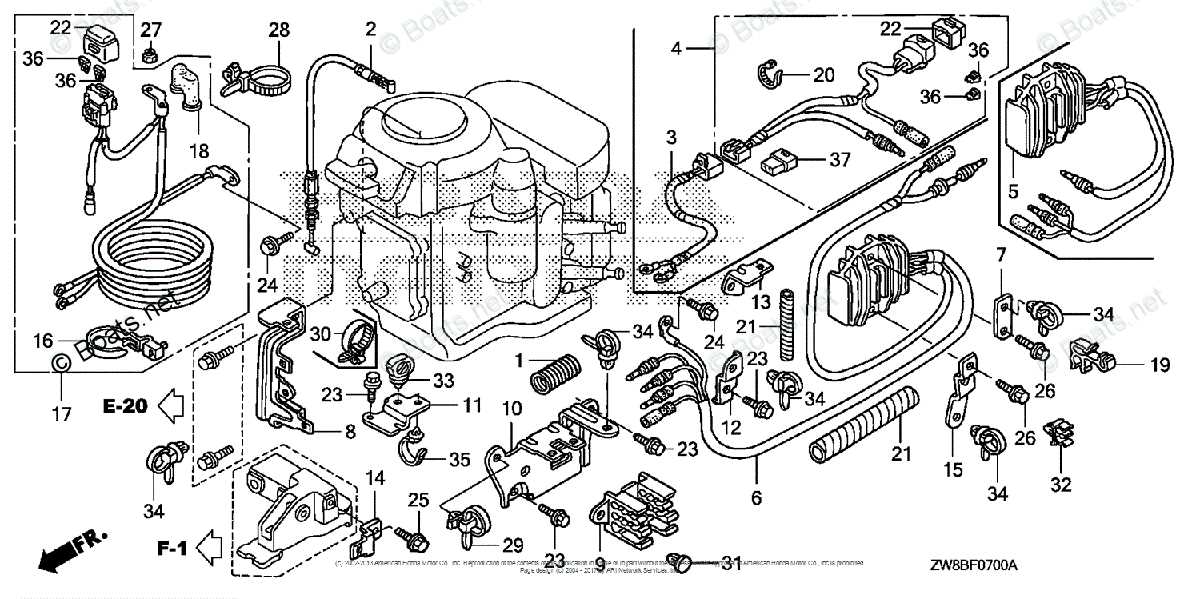

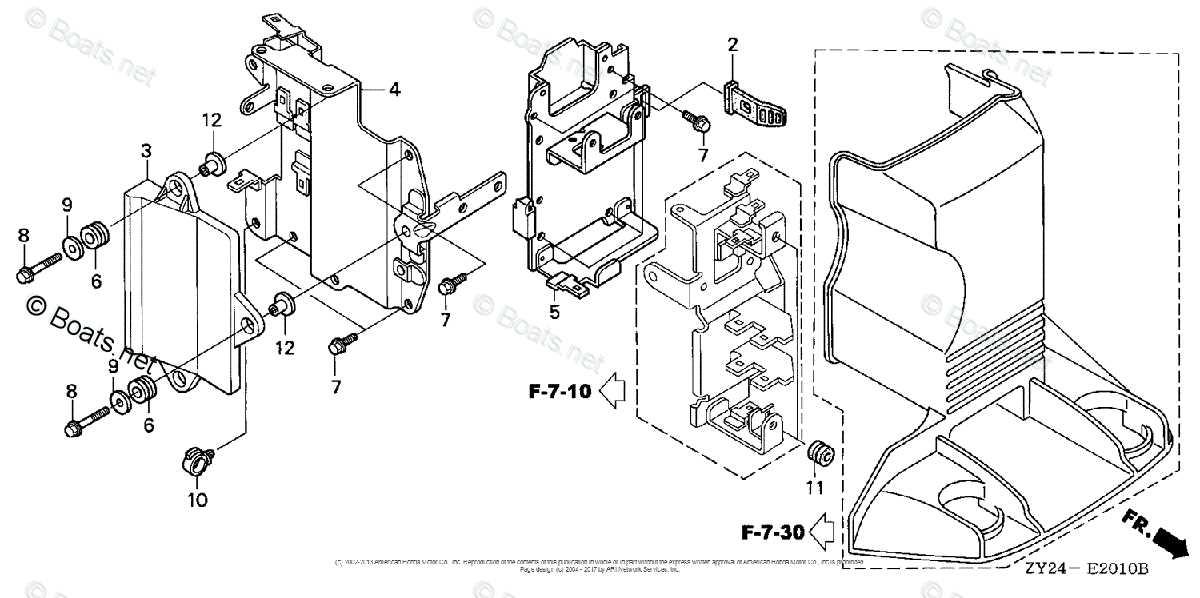

| Component | Description | Function |

|---|---|---|

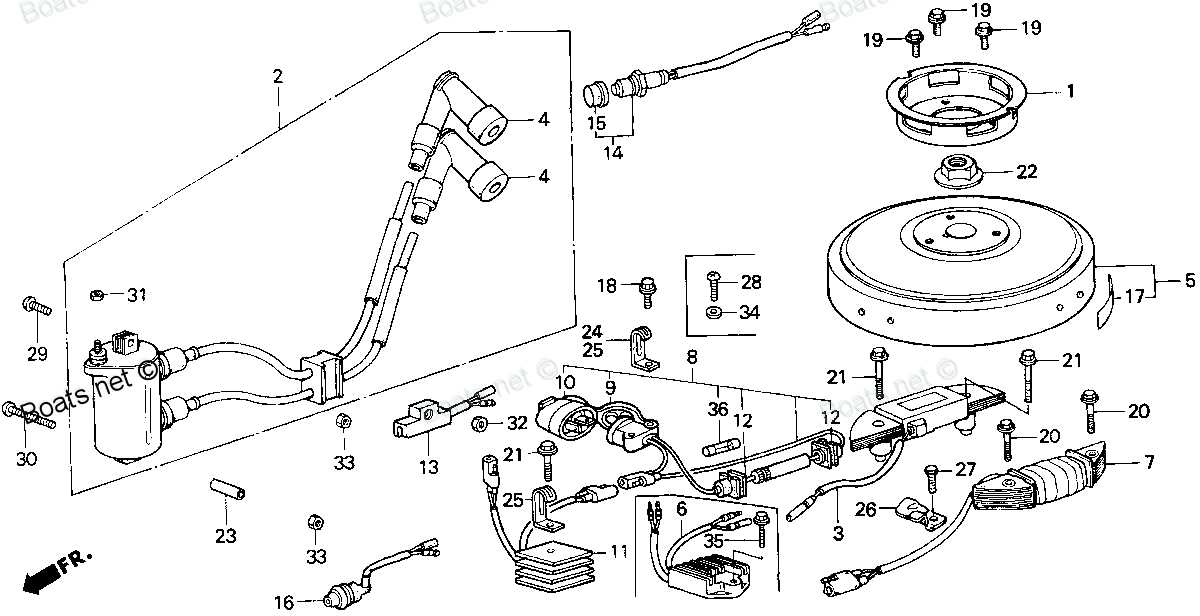

| Battery | Energy storage unit supplying power | Provides electrical energy to start the engine and power accessories |

| Ignition System | System responsible for initiating combustion | Generates sparks to ignite the fuel-air mixture in the engine cylinders |

| Wiring Harness | Network of electrical cables | Connects all electrical components, facilitating power distribution |

| Regulator/Rectifier | Device that controls voltage and converts AC to DC | Ensures a steady electrical output to charge the battery |

| Starter Motor | Electric motor used to start the engine | Cranks the engine for initial ignition |

By gaining a comprehensive understanding of these components, users can enhance the performance and longevity of their marine propulsion units. Regular inspections and maintenance of the electrical system can prevent common issues and ensure smooth operation.

Lubrication System and Maintenance Tips

The lubrication mechanism is essential for ensuring the longevity and efficiency of marine engines. Regular maintenance and proper lubrication contribute to optimal performance, reduce wear and tear, and prevent costly repairs. Understanding the components involved in this system is vital for any operator looking to enhance their engine’s reliability and lifespan.

Importance of Regular Lubrication

Maintaining adequate lubrication levels is crucial to minimize friction between moving parts. Regular checks and top-ups of lubricant ensure that the engine operates smoothly, helping to avoid overheating and other potential issues. It is recommended to consult the manufacturer’s specifications for the appropriate type of lubricant and maintenance intervals.

Maintenance Best Practices

To ensure a well-functioning lubrication system, it is advisable to perform routine inspections. Look for signs of leaks, check the quality of the lubricant, and replace it as needed. Cleaning or replacing filters can also enhance the effectiveness of the system. Following a regular maintenance schedule and keeping detailed records of service can significantly extend the operational life of the engine.

Exhaust System Configuration and Functionality

The exhaust system is a critical component in marine propulsion systems, designed to effectively manage and expel exhaust gases produced during engine operation. Its configuration plays a significant role in ensuring optimal performance and efficiency. Understanding the layout and function of this system can provide insights into its importance for both engine longevity and overall boat performance.

Key Components of the Exhaust System

The exhaust system consists of several key elements that work together to facilitate the safe and efficient removal of combustion byproducts. These components include the exhaust manifold, riser, and silencer, each serving a distinct purpose in the overall operation.

| Component | Function |

|---|---|

| Exhaust Manifold | Collects exhaust gases from the engine cylinders and directs them to the riser. |

| Exhaust Riser | Raises the exhaust gases to a safe level, preventing backflow and allowing for proper ventilation. |

| Silencer | Reduces noise produced by the engine and muffles the sound of escaping gases. |

Operational Efficiency

Efficient exhaust gas management is crucial for maintaining engine performance and minimizing environmental impact. A well-configured exhaust system reduces the risk of overheating and ensures that exhaust gases are expelled quickly and efficiently, allowing the engine to operate at optimal levels.