In the realm of agricultural machinery, having a clear understanding of various mechanisms is crucial for optimal performance and maintenance. Each machine comprises numerous elements that work in harmony to deliver efficiency and reliability. By examining the intricate layout of these components, operators can enhance their skills in troubleshooting and repairs, ensuring longevity and effectiveness in their equipment.

The exploration of each individual section reveals the complexity and engineering behind these machines. Knowledge of how parts interact not only aids in timely servicing but also empowers users to make informed decisions regarding upgrades and replacements. This comprehension is essential for anyone involved in the operation or maintenance of lawn care devices.

Whether you’re a seasoned professional or a hobbyist, familiarizing yourself with the essential building blocks of your machinery can lead to significant improvements in its functionality. By delving into the specifics of the construction and organization of these elements, you can unlock the full potential of your equipment, paving the way for successful and efficient operations.

Overview of Grasshopper 725d

This section provides an insightful look into a specific model of machinery renowned for its efficiency and versatility. Designed to cater to various tasks, this equipment stands out due to its unique features and robust construction, making it a preferred choice among professionals in the field.

Key Features

Equipped with a powerful engine and an innovative design, this model ensures optimal performance in diverse environments. Its user-friendly interface enhances operational ease, allowing users to maximize productivity while minimizing downtime.

Applications

From landscaping to agriculture, this machinery serves multiple purposes, making it an invaluable asset. Its adaptability enables it to tackle various tasks effectively, ensuring that users achieve the ultimate results in their projects.

Key Features of the Grasshopper 725d

This section outlines the prominent characteristics of a highly efficient and versatile mowing machine, designed to meet various landscaping needs. Its innovative design and advanced technology enhance both functionality and user experience, making it a valuable asset for professionals and enthusiasts alike.

Performance and Efficiency

- Powerful engine options for optimal performance.

- Exceptional fuel efficiency, allowing longer operational periods without frequent refueling.

- Advanced cutting systems that ensure a clean and precise cut on various terrains.

User-Friendly Design

- Ergonomically designed controls for ease of use and comfort during operation.

- Compact size that facilitates maneuverability in tight spaces.

- Quick and easy maintenance procedures to minimize downtime.

These features collectively contribute to a reliable and efficient machine, catering to the diverse needs of lawn care professionals.

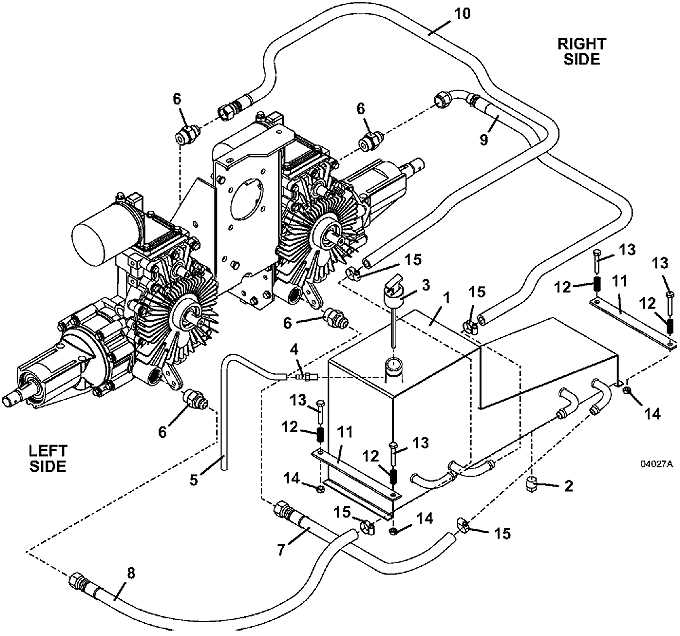

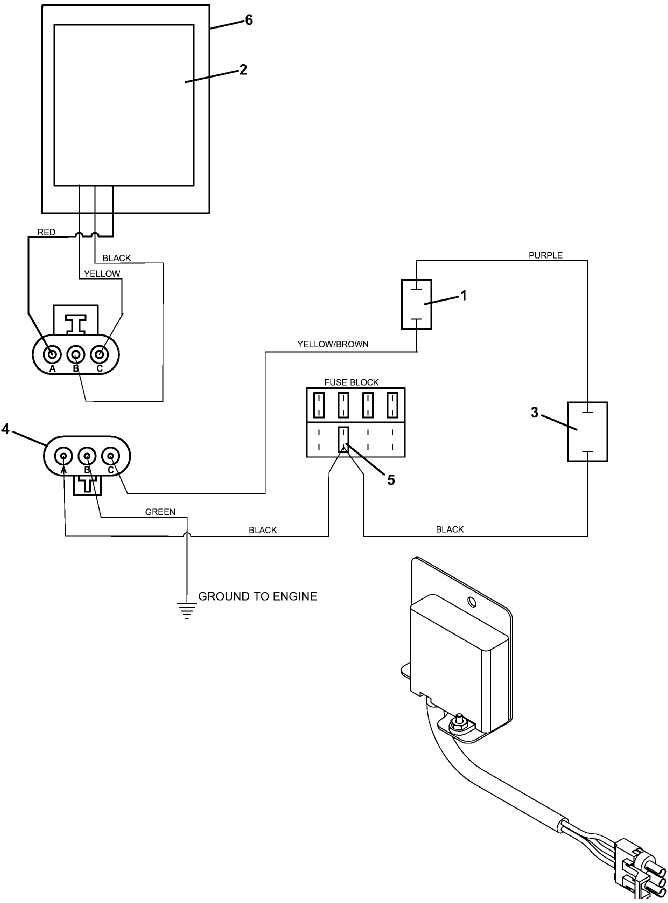

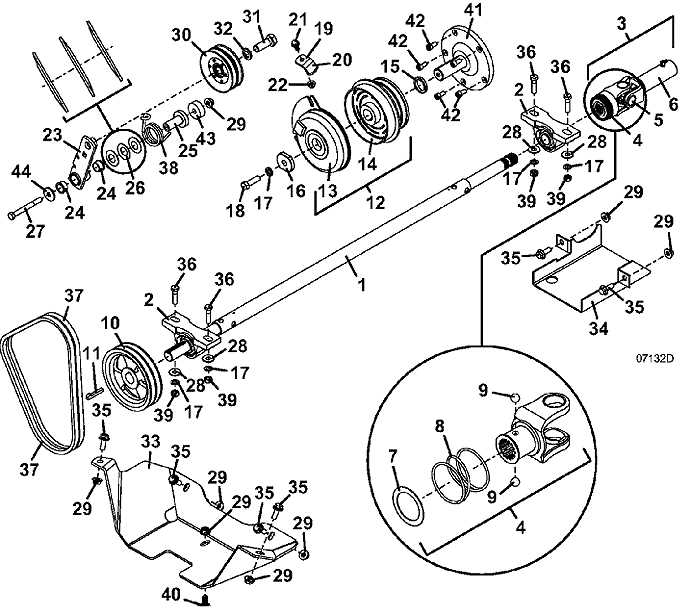

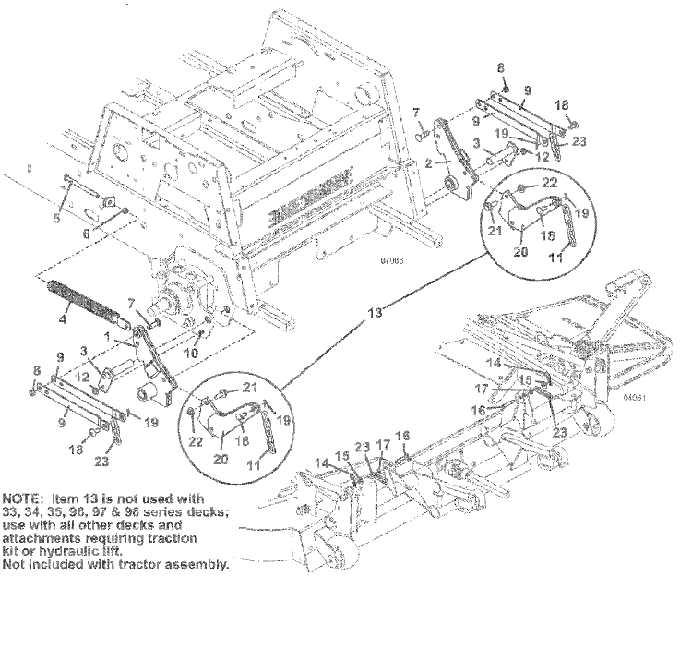

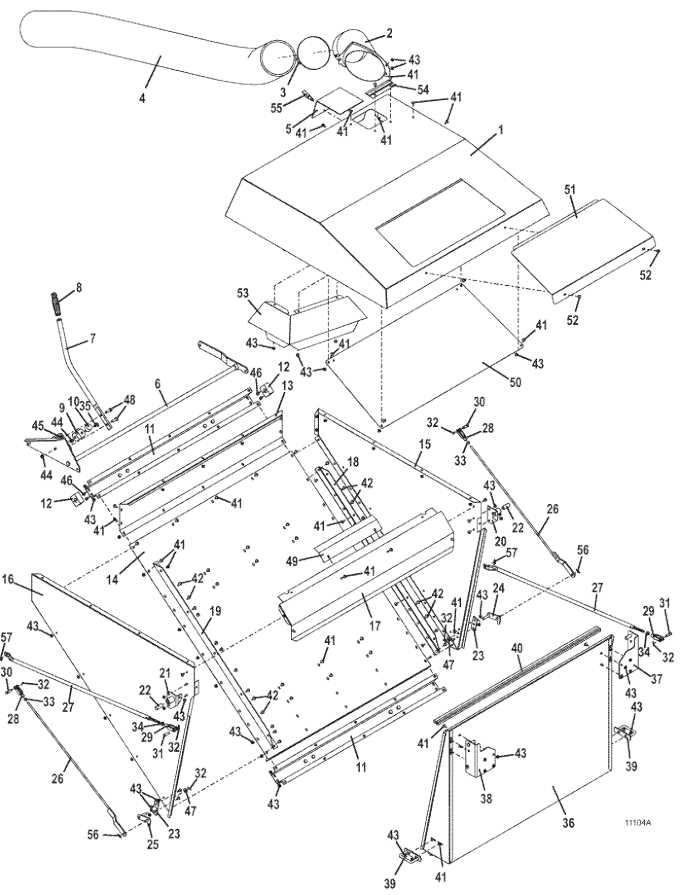

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricate workings of machinery. They serve as valuable tools for both technicians and operators, enabling efficient maintenance and repair. By providing a clear overview of individual elements, these illustrations enhance comprehension and facilitate troubleshooting processes.

Clarity and Precision: Having a visual guide allows users to easily identify specific elements, ensuring that repairs and replacements are executed accurately. This clarity reduces the risk of errors, which can lead to costly downtime or damage.

Efficient Communication: When discussing issues or required replacements, these visual aids provide a common language for all parties involved, from engineers to service personnel. This shared understanding streamlines the communication process and fosters collaboration.

Time-Saving: Quick access to detailed visual information can significantly cut down on repair time. Technicians can swiftly locate components, understand their functions, and address issues without extensive searching or guesswork.

Enhanced Training: For new employees or those unfamiliar with specific systems, these visuals serve as excellent training resources. They provide a foundational understanding that can be built upon with hands-on experience.

How to Read a Parts Diagram

Understanding a schematic representation of components is crucial for effective maintenance and repair. This guide will help you navigate these visual aids with ease.

To start, familiarize yourself with the layout:

- Identify the sections, usually categorized by function.

- Look for labels indicating specific components or assemblies.

Next, pay attention to the numbering system:

- Each item is typically assigned a unique number for easy reference.

- Cross-reference these numbers with a parts list for detailed specifications.

Finally, note any additional symbols or notes:

- Symbols may indicate special instructions or warnings.

- Annotations often provide helpful context or clarifications.

By following these steps, you can effectively interpret any schematic representation and ensure proper understanding of each component’s role.

Commonly Replaced Components

Regular maintenance often involves replacing certain parts to ensure optimal performance and longevity of equipment. Understanding which components frequently need attention can enhance reliability and efficiency.

Key Components

- Blades

- Filters

- Batteries

- Belts

- Hydraulic hoses

Signs of Wear

- Unusual noise during operation

- Decreased cutting efficiency

- Fluid leaks

- Inconsistent power output

Maintenance Tips for Grasshopper 725d

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Proper care can prevent breakdowns and extend the life of your machine, resulting in increased efficiency and reduced repair costs. Implementing a routine maintenance schedule will help keep all components in top condition.

1. Routine Inspections: Regularly check all crucial elements such as belts, blades, and filters. Look for signs of wear and tear, and address any issues promptly to avoid further damage.

2. Cleanliness: Keep the machine clean and free from debris. Accumulated grass clippings and dirt can lead to overheating and hinder performance. Regularly wash the exterior and ensure that all moving parts are free from obstructions.

3. Lubrication: Proper lubrication is vital for smooth operation. Apply the recommended lubricants to all moving components as specified in the manufacturer’s guidelines. This practice will reduce friction and wear, enhancing efficiency.

4. Fluid Checks: Regularly check and replace fluids, including oil and hydraulic fluids, as needed. Maintaining the correct fluid levels ensures that all systems operate smoothly and prevents damage due to low lubrication.

5. Blade Maintenance: Keep blades sharp and well-adjusted. Dull blades can cause unnecessary strain on the machine and lead to poor cutting performance. Sharpen or replace blades as needed for optimal results.

6. Battery Care: Inspect the battery regularly for corrosion and ensure connections are tight. A well-maintained battery can prevent starting issues and ensure reliable operation.

7. Store Properly: When not in use, store the equipment in a sheltered location to protect it from harsh weather conditions. Covering it with a tarp can help prevent dust accumulation and moisture damage.

By following these maintenance tips, you can ensure that your machinery remains in excellent working condition, maximizing its efficiency and lifespan.

Ordering Replacement Parts

Ensuring the optimal performance of your equipment often requires timely acquisition of components that may wear out or become damaged over time. Understanding how to effectively order these essential items can greatly enhance the longevity and efficiency of your machinery.

Identifying Required Components

Before placing an order, it’s crucial to accurately identify the components you need. Follow these steps:

- Consult the user manual or service guide to determine specific component numbers.

- Inspect the equipment for visible wear or damage that may require attention.

- Take note of the manufacturer’s specifications to ensure compatibility.

Where to Order

Once you’ve identified the necessary components, you have several options for procurement:

- Authorized Dealers: Purchasing from certified retailers ensures you receive genuine items.

- Online Marketplaces: Numerous websites offer a wide range of components, often at competitive prices.

- Local Supply Stores: Visit nearby shops that specialize in machinery supplies for immediate availability.

By following these guidelines, you can streamline the process of acquiring replacement components, helping to maintain the efficiency and reliability of your equipment. Remember to keep records of previous orders to simplify future purchases.

Where to Find Diagrams Online

Accessing detailed schematics and technical illustrations can be crucial for maintenance and repair tasks. Fortunately, numerous online resources provide users with the ability to locate these valuable visual aids. Whether you’re looking for user manuals, exploded views, or specific component layouts, the internet offers a variety of platforms to help you in your search.

Manufacturer Websites

Many original equipment manufacturers host comprehensive libraries of resources, including technical illustrations, manuals, and guides. By visiting the official site of the equipment, you can often find downloadable content that includes precise layouts and instructions. This is typically the most reliable source for accurate and up-to-date information.

Online Forums and Communities

Engaging with online communities and forums dedicated to machinery and equipment can yield a wealth of shared resources. Enthusiasts and professionals often upload their own collections of schematics and documents. These platforms not only provide valuable illustrations but also allow for discussions and advice from experienced users.