The intricate world of mechanical assemblies often requires a clear visual representation to grasp the various components involved. By exploring these visuals, one can gain a deeper appreciation for the functionality and design of the machinery in question.

In this section, we will examine a comprehensive overview of the individual elements that contribute to the overall operation. Each piece plays a vital role, and recognizing their interconnections is crucial for anyone interested in the mechanics of such devices.

Whether you are a seasoned technician or a curious enthusiast, delving into this illustrative guide will enhance your understanding. This ultimate resource will serve as a foundation for maintenance, repair, and further exploration of mechanical systems.

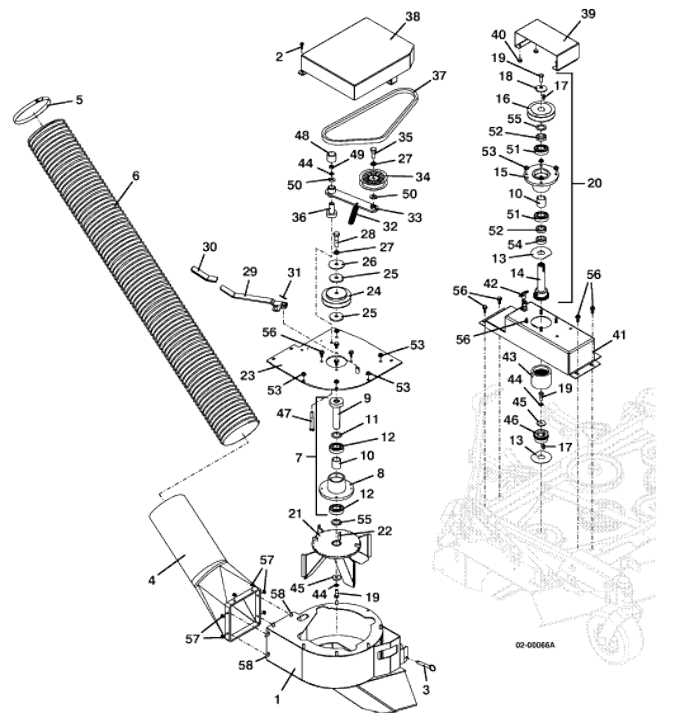

Understanding Grasshopper 223 Components

This section explores the intricate elements that make up a specific mechanical assembly. Each component plays a vital role in the overall functionality and efficiency of the system, contributing to its performance and reliability. By delving into the individual parts, one can gain insights into how they interact and support each other to achieve optimal operation.

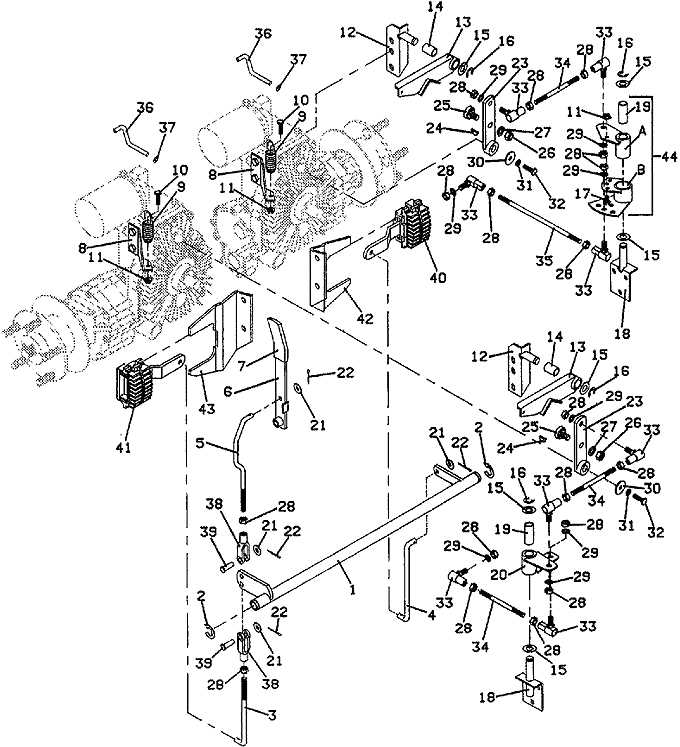

Key Elements of the Assembly

At the core of this configuration are several crucial elements that work in harmony. These include drive mechanisms, structural supports, and control systems. Each part is designed with precision to ensure seamless integration, allowing for effective movement and stability. Understanding the function of each element is essential for both maintenance and enhancement of the system.

Importance of Component Compatibility

Compatibility among the various elements is paramount for the assembly’s success. When components are designed to fit together perfectly, it reduces wear and enhances longevity. Proper alignment and synchronization are vital to prevent malfunctions and ensure smooth operation. Analyzing how these elements interact can lead to improved design and functionality in future iterations.

Overview of Grasshopper 223 Functionality

This section delves into the essential capabilities and features of a specific mechanical device designed for versatile applications. It emphasizes the intricate balance of performance, efficiency, and user-friendly design, which allows operators to achieve optimal results across various tasks. By understanding these functionalities, users can maximize the potential of the equipment and tailor its use to meet specific needs.

Key Features

The device is engineered with several standout characteristics. Its robust construction ensures durability, while the intuitive interface facilitates ease of use, even for those new to similar machinery. Additionally, the integration of advanced technology allows for seamless operation, enhancing both speed and accuracy in execution.

Applications

Versatility is a hallmark of this equipment, making it suitable for a wide range of industries. Whether employed in construction, landscaping, or agriculture, it proves to be an invaluable tool. The ability to adapt to different environments and requirements ensures that users can tackle diverse challenges effectively, resulting in improved productivity and efficiency.

Key Parts in the Grasshopper 223

This section explores the essential components of a popular agricultural machine, focusing on their roles and functionalities. Understanding these elements is crucial for maintenance, repair, and optimal operation of the equipment.

Main Components Overview

Every machine is made up of several key components, each contributing to its overall performance. Familiarity with these elements can enhance efficiency and longevity.

| Component | Description |

|---|---|

| Engine | Powers the entire system, providing necessary energy for operation. |

| Transmission | Transfers power from the engine to the wheels, enabling movement. |

| Chassis | Framework that supports all other components, ensuring structural integrity. |

| Hydraulic System | Facilitates lifting and lowering of attachments, enhancing versatility. |

Regular upkeep of these components is vital to ensure smooth functioning and prevent breakdowns. Timely inspections and servicing can lead to improved productivity and reduced downtime.

How to Access the Parts Diagram

Obtaining a visual representation of components is essential for effective maintenance and repairs. This guide will provide you with the steps necessary to access these resources, ensuring you have the information needed to work efficiently on your machinery.

Step-by-Step Guide

To begin, identify the official website or documentation source related to your specific model. Many manufacturers offer downloadable resources or online access to schematics. Look for sections labeled as “Support” or “Resources” on the homepage.

Using Online Resources

Once you are on the appropriate platform, utilize the search function to locate the relevant section. Enter keywords that describe the equipment in question. After finding the appropriate visual guide, you can download or print it for your convenience. This ensures that you have a reliable reference while working on repairs.

Importance of Accurate Parts Identification

Identifying components correctly is crucial in various industries, ensuring smooth operations and effective maintenance. Accurate recognition can prevent delays and reduce costs associated with mismanagement.

Several key reasons highlight the significance of precise identification:

- Efficiency: Correct identification streamlines workflow, allowing for faster repairs and replacements.

- Cost Savings: Avoiding incorrect purchases minimizes unnecessary expenses and optimizes budgeting.

- Safety: Ensuring the right components are used enhances operational safety and reduces the risk of accidents.

- Longevity: Using the correct items contributes to the durability of machinery, extending its lifespan.

- Quality Assurance: Proper components lead to better performance and reliability, maintaining high standards.

Ultimately, investing time in accurate identification yields significant benefits across the board, fostering a more productive and secure environment.

Common Issues with Grasshopper 223 Parts

When working with mechanical components, it’s crucial to be aware of potential problems that can arise during operation. Various elements may exhibit signs of wear or malfunction, leading to decreased efficiency or performance. Identifying these issues early can save time and resources.

Worn Components: Over time, many elements may become worn due to regular usage. This deterioration can result in misalignment or improper function, making it essential to regularly inspect and replace these items to maintain optimal performance.

Assembly Errors: Incorrect assembly can lead to significant operational challenges. Ensuring that each component is correctly fitted and secured can prevent leaks and operational failures. It’s important to follow manufacturer guidelines meticulously.

Material Fatigue: Exposure to varying conditions can cause material fatigue, resulting in cracks or fractures. Regular maintenance checks are necessary to identify such issues before they lead to complete failure.

Compatibility Issues: Using incompatible components can result in poor performance and increased wear. Always verify that all elements are compatible with each other to ensure seamless operation.

Contamination: Foreign substances can negatively impact the functioning of components. Keeping the environment clean and regularly checking for contamination will help preserve the integrity of the mechanical system.

Maintenance Tips for Grasshopper 223

Proper upkeep is essential for ensuring the longevity and efficiency of your equipment. Regular maintenance not only enhances performance but also prevents costly repairs in the future. Here are some key practices to help you maintain your machine effectively.

1. Regular Cleaning: Keep your machine free from dirt and debris. After each use, inspect and clean components to avoid buildup that can lead to operational issues.

2. Lubrication: Ensure that all moving parts are properly lubricated. This reduces friction and wear, promoting smoother operation. Use the recommended lubricants specified in the manufacturer’s guidelines.

3. Check Fluid Levels: Regularly inspect and top off fluids, including oil and fuel. Low levels can lead to performance problems and potential damage.

4. Inspect Belts and Cables: Periodically examine belts and cables for wear or damage. Replace any that show signs of fraying or cracking to avoid breakdowns.

5. Blade Maintenance: Keep cutting blades sharp and well-aligned. Dull blades not only perform poorly but can also strain the engine. Sharpen or replace blades as needed.

6. Seasonal Check-ups: At the start of each season, conduct a thorough inspection. This proactive approach can identify issues before they become serious problems.

7. Follow Manufacturer’s Recommendations: Always refer to the user manual for specific maintenance guidelines tailored to your model. Adhering to these recommendations will ensure optimal performance.

By following these maintenance tips, you can enhance the reliability and efficiency of your equipment, ensuring it serves you well for years to come.

Upgrades and Modifications Available

Exploring enhancements and alterations can significantly elevate the performance and aesthetics of your model. Whether you’re aiming for improved speed, better handling, or a more personalized look, there are various options to consider. These upgrades can transform the overall experience, making it more enjoyable and tailored to your preferences.

Popular upgrades include advanced suspension systems, high-performance motors, and lightweight components that optimize speed and maneuverability. Additionally, customizing the body with unique paint jobs or decals allows for a distinctive appearance that stands out. Don’t forget about the importance of quality tires, which can drastically improve traction and control on different terrains.

For those looking to delve deeper, electronic modifications such as upgraded batteries and controllers can provide enhanced responsiveness and longer run times. Ultimately, the right combination of enhancements will create a model that truly reflects your style and performance expectations.

Resources for Grasshopper 223 Owners

This section offers a collection of valuable materials and tools designed to assist enthusiasts in maintaining and enhancing their equipment. Access to quality resources can significantly improve performance and longevity, ensuring a rewarding experience for every owner.

| Resource Type | Description | Link |

|---|---|---|

| Manuals | Comprehensive guides for troubleshooting and maintenance. | Download Here |

| Community Forums | Interactive platforms for sharing experiences and advice. | Visit Forum |

| Parts Suppliers | Reliable sources for high-quality replacements and upgrades. | Shop Now |

| Tutorial Videos | Visual guides for assembly, disassembly, and repairs. | Watch Videos |