In the realm of gardening machinery, comprehending the intricate components is essential for efficient maintenance and optimal performance. Having a clear visualization of the various elements that constitute these machines can significantly enhance your ability to troubleshoot and repair them when necessary.

The layout of these components serves as a valuable guide for both novice and experienced users. By familiarizing yourself with the arrangement and function of each section, you empower yourself to take better care of your equipment, ultimately prolonging its lifespan and improving its functionality.

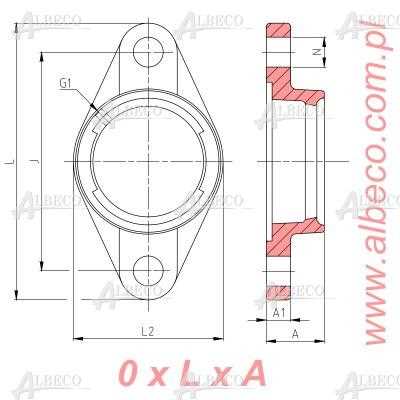

Furthermore, a thorough understanding of the mechanical intricacies allows for informed decision-making when seeking replacements or upgrades. Knowledge of specific configurations not only aids in problem-solving but also fosters a deeper appreciation for the engineering behind your tools.

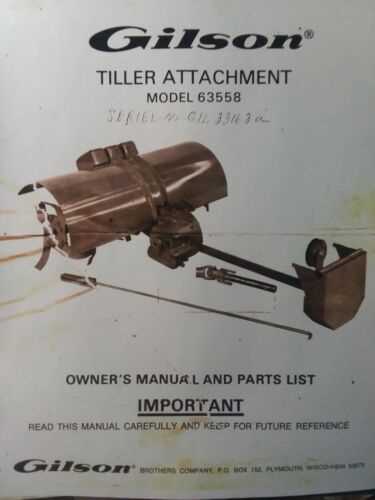

Understanding Gilson Tiller Components

Exploring the intricacies of garden cultivation machinery reveals a complex interplay of elements that contribute to its efficient operation. Each component plays a crucial role in ensuring the overall functionality, making it essential for users to familiarize themselves with these integral parts.

Main Functional Elements

The core functionality of such equipment hinges on several key components:

- Engine: The powerhouse that drives the entire system, providing the necessary energy for operation.

- Transmission: This mechanism transfers power from the engine to the working parts, allowing for smooth operation.

- Blades: Designed for soil cultivation, these cutting tools are pivotal in breaking up the ground.

- Handlebars: Essential for maneuverability, they allow the operator to guide the machine effectively.

- Wheels: Facilitating mobility, they support the machine’s movement across various terrains.

Additional Components to Consider

In addition to the main elements, several auxiliary parts enhance performance:

- Fuel System: Stores and delivers fuel to the engine, crucial for efficient operation.

- Cooling System: Prevents overheating by dissipating heat generated during operation.

- Frame: Provides structural integrity and stability, supporting all other components.

- Controls: Enable the operator to adjust speed and direction, enhancing ease of use.

- Safety Features: Essential for protecting the user during operation, including guards and emergency shut-off systems.

Understanding these components not only aids in effective maintenance but also enhances the user experience by promoting informed operation.

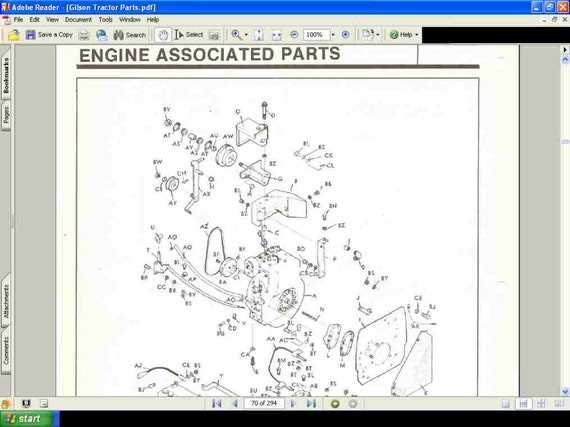

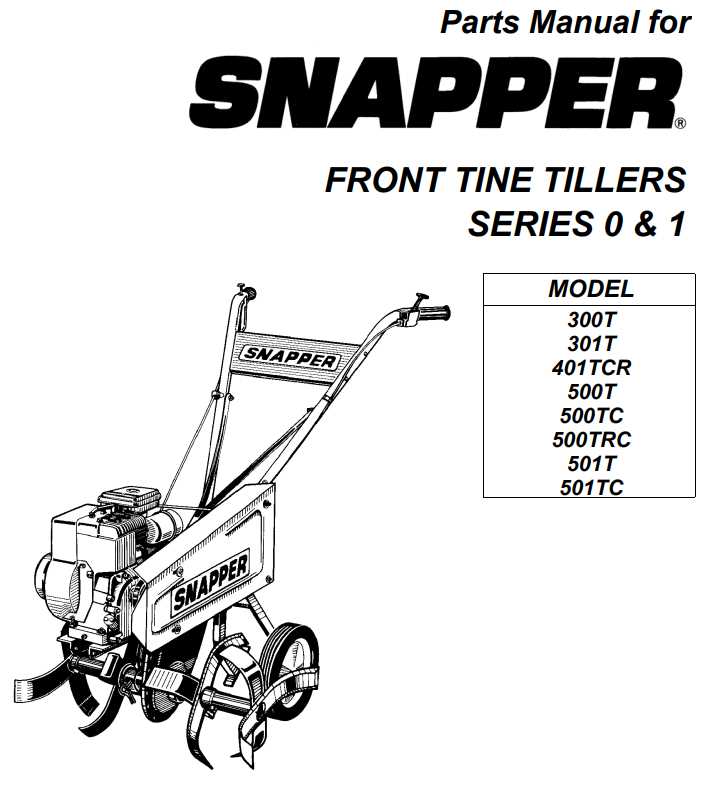

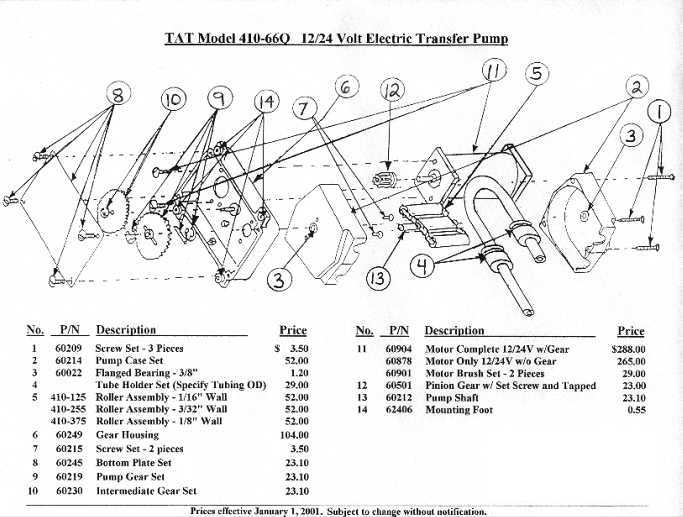

Importance of Parts Diagrams

Visual representations of components are essential tools for understanding the assembly and maintenance of machinery. They serve as guides that simplify complex structures, allowing users to identify individual elements and their relationships within the whole system. Such illustrations enhance efficiency, reduce errors, and streamline the repair or replacement process.

Benefits of Visual Guides

- Enhanced Clarity: Diagrams provide a clear visual reference that aids in comprehending intricate designs.

- Efficient Troubleshooting: Quick identification of faulty components allows for faster resolutions.

- Improved Communication: Shared visuals facilitate discussions among technicians and users, ensuring everyone is on the same page.

Application in Maintenance

- Promotes organized repairs by showing the correct order of disassembly and reassembly.

- Reduces the risk of missing parts or using incorrect replacements.

- Supports training efforts for new staff by providing clear instructional materials.

Common Gilson Tiller Models

This section provides an overview of popular cultivator variants that have garnered attention for their performance and reliability. Each model offers unique features and specifications, catering to various gardening needs and preferences.

| Model Name | Engine Type | Working Width | Weight |

|---|---|---|---|

| Model A | 4-Cycle Gas | 18 inches | 100 lbs |

| Model B | 2-Cycle Gas | 20 inches | 90 lbs |

| Model C | Electric | 16 inches | 80 lbs |

| Model D | 4-Cycle Gas | 24 inches | 120 lbs |

Understanding the specifications of these models aids in selecting the most suitable option for both novice and experienced gardeners. Each variant is designed to facilitate soil preparation and enhance gardening efficiency.

How to Read Parts Diagrams

Understanding technical illustrations can greatly enhance your ability to maintain and repair machinery. These visual representations provide a comprehensive view of components and their interrelationships, enabling users to identify what is needed for repairs or replacements. Mastering the interpretation of these visuals can save time and reduce frustration during maintenance tasks.

Familiarizing with Symbols and Labels

Each illustration typically features a variety of symbols and labels that indicate specific components and their functions. Pay attention to the key or legend, as it often explains the meaning of different markings. Recognizing common icons can help you quickly locate the parts you need and understand how they fit together.

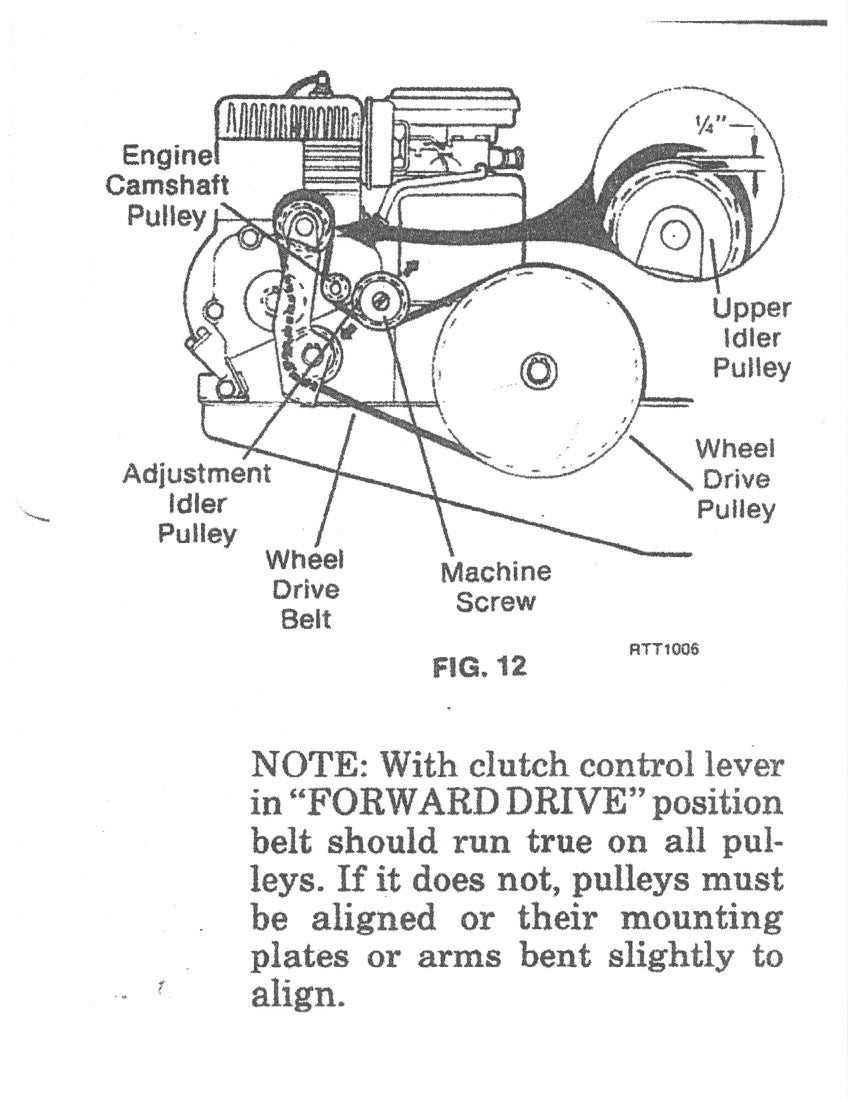

Interpreting Component Relationships

Beyond identifying individual elements, it’s essential to grasp how they connect with one another. Look for lines or arrows that indicate relationships, as they often show assembly sequences or flow directions. Understanding these connections is crucial for effective disassembly and reassembly, ensuring that everything functions properly after maintenance is complete.

Essential Replacement Parts Overview

Understanding the critical components of garden machinery is vital for maintaining efficiency and prolonging the life of your equipment. This section highlights the key elements that require attention and replacement over time, ensuring optimal performance in your gardening tasks.

Key Components to Monitor

Regular inspection of specific components can prevent breakdowns and improve functionality. The following parts are commonly subject to wear and tear, and knowing when to replace them can save you time and money in the long run.

Maintenance and Replacement Schedule

To keep your machinery running smoothly, adhering to a maintenance schedule is recommended. The table below outlines essential components and their typical lifespan, guiding you on when to check or replace each part.

| Component | Typical Lifespan | Replacement Frequency |

|---|---|---|

| Blades | 1-2 seasons | Every season |

| Drive Belts | 2-3 years | Annually |

| Air Filters | 1 year | Every season |

| Fuel Filters | 1-2 years | Every 1-2 seasons |

| Spark Plugs | 1-2 years | Every season |

Staying proactive about these essential elements can enhance performance and ensure your gardening endeavors are successful and enjoyable.

Maintenance Tips for Tiller Longevity

Proper upkeep of your gardening equipment is essential to ensure its efficiency and extend its lifespan. By following a few simple practices, you can keep your machine running smoothly and effectively for many seasons to come.

- Regular Cleaning: After each use, remove dirt, debris, and plant residue from the machine. This prevents buildup that can cause damage and decreases performance.

- Check and Change Oil: Regularly inspect the oil level and quality. Change the oil according to the manufacturer’s recommendations to maintain engine health.

- Sharpen Blades: Keep cutting edges sharp for optimal performance. Dull blades strain the engine and reduce efficiency.

- Inspect Belts and Cables: Regularly check for wear and tear. Replace any frayed or damaged components to ensure safe operation.

- Battery Care: If your equipment is battery-operated, ensure the battery is charged and connections are clean. Replace batteries as needed to avoid starting issues.

By implementing these maintenance practices, you will enhance the functionality and longevity of your gardening tools, ensuring they remain reliable companions in your outdoor endeavors.

Where to Find Genuine Parts

Locating authentic components for your equipment is crucial for maintaining optimal performance and longevity. High-quality replacements ensure that your machinery operates smoothly and reliably, reducing the likelihood of malfunctions. Here are some reliable sources to consider when searching for these essential items.

Authorized Dealers

One of the most dependable avenues is to purchase directly from authorized dealers. These outlets are often recognized by the manufacturer and provide:

- Authentic merchandise

- Expert advice

- Warranty options

Check the manufacturer’s website for a list of certified retailers in your area or online.

Online Marketplaces

Reputable online platforms also offer a wide selection of genuine merchandise. When exploring these options, ensure that you:

- Read customer reviews to gauge reliability

- Verify the seller’s credentials

- Look for return policies in case the item doesn’t meet your expectations

Using trusted sites can lead you to high-quality alternatives that match your needs perfectly.

DIY Repairs for Your Tiller

Maintaining your gardening equipment can seem daunting, but with a bit of guidance and the right tools, you can tackle many repairs on your own. Understanding the fundamental components and how they work together is crucial for effective troubleshooting and restoration. By being proactive, you can save time and money while ensuring your machine runs smoothly.

Identifying Common Issues

Start by familiarizing yourself with typical problems that might arise. These can range from engine difficulties to issues with the cutting mechanism. Often, symptoms like unusual noises, lack of power, or difficulty starting indicate that something needs attention.

Essential Tools for Repairs

Gathering the necessary tools is essential for any DIY project. Basic items like wrenches, screwdrivers, and pliers will serve you well. Additionally, a good-quality socket set can make many tasks easier, allowing for quick adjustments and replacements.

Step-by-Step Troubleshooting

When a malfunction occurs, systematically diagnosing the issue can lead to a swift resolution. Start by inspecting visible components for wear or damage. Consult your equipment manual for insights into assembly and common repair techniques. This resource can guide you through the process, ensuring you don’t miss any crucial steps.

Preventive Maintenance

Once repairs are complete, establish a routine for regular maintenance. Simple tasks such as cleaning, lubricating moving parts, and checking fluid levels can significantly extend the lifespan of your machinery. Keeping a log of maintenance activities can also help you stay organized and proactive.

With a bit of effort and the right approach, many repairs can be handled without professional help. Embrace the DIY spirit and enjoy the satisfaction that comes from fixing your equipment effectively!

Benefits of Regular Maintenance Checks

Consistent inspections and upkeep of equipment play a crucial role in ensuring longevity and optimal performance. By adhering to a routine maintenance schedule, users can identify potential issues before they escalate, ultimately saving time and resources.

One of the primary advantages of regular check-ups is the enhancement of efficiency. Well-maintained machinery operates more smoothly, reducing energy consumption and improving overall productivity. This not only leads to better results but also minimizes operational costs.

Furthermore, routine maintenance can significantly increase safety. By addressing wear and tear or malfunctions promptly, the risk of accidents is greatly diminished, protecting both the operator and the surrounding environment. This proactive approach fosters a safer working atmosphere.

Lastly, keeping equipment in good condition can lead to higher resale value. Buyers are often willing to pay a premium for machinery with a proven maintenance history, making it a wise investment for the future. In summary, regular maintenance checks are essential for efficiency, safety, and financial benefit.