In the realm of modern household conveniences, certain devices play a vital role in enhancing our daily experiences. Among these, one particular device stands out for its ability to provide refreshment in various forms. A comprehensive understanding of its inner workings is essential for both effective maintenance and optimal performance.

The intricate network of elements within this essential appliance contributes significantly to its functionality. Each component has a specific role, working harmoniously to deliver the desired outcome. Familiarity with these elements can aid users in troubleshooting issues and ensuring longevity.

By exploring the configuration and arrangement of these vital components, individuals can gain valuable insights into how to effectively manage and care for their device. Knowledge empowers users to tackle potential challenges confidently, transforming a common household appliance into a reliable partner in everyday life.

Many users encounter various challenges with their automated freezing devices. Understanding these typical problems can help in identifying solutions and maintaining optimal performance.

Here are some frequent complications that may arise:

- Insufficient Production: The unit may fail to generate enough frozen cubes, often due to a clogged water line or inadequate water supply.

- Inconsistent Freezing: Fluctuations in temperature can lead to irregular freezing patterns, often caused by a malfunctioning thermostat or blocked airflow.

- Excessive Noise: Unusual sounds might indicate mechanical issues or worn components, which can detract from the overall efficiency of the device.

- Water Leakage: Puddles around the appliance may signal a leak in the water supply line or improper installation.

- Discoloration of Cubes: If the frozen product appears cloudy or off-colored, it may be due to impurities in the water supply.

By recognizing these prevalent issues, users can take proactive steps toward troubleshooting and ensuring the long-term functionality of their freezing appliances.

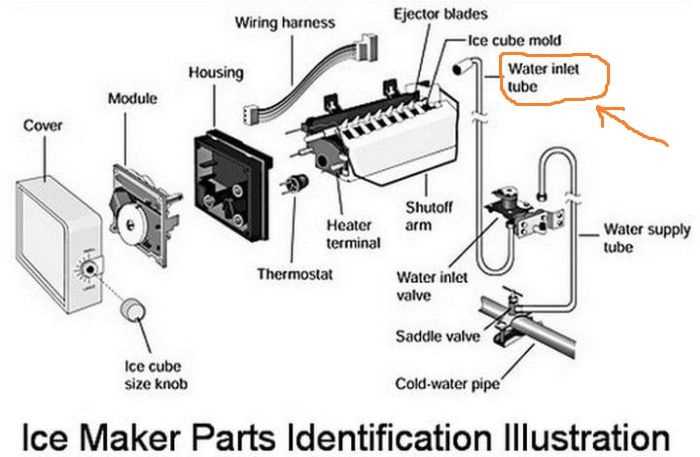

How to Identify Ice Maker Parts

Understanding the various components within a freezing appliance can significantly enhance troubleshooting and maintenance efforts. By familiarizing yourself with these elements, you can ensure optimal functionality and address any issues that may arise effectively.

Recognizing Key Components

When examining the interior of the cooling unit, look for specific items that play crucial roles in the freezing process. Common features include the water inlet, which supplies the necessary liquid, and the control mechanism, responsible for regulating the temperature. Additionally, the ejector mechanism is vital for dispensing frozen elements once they reach the desired state.

Utilizing Reference Guides

To aid in your identification efforts, consulting reference guides can be invaluable. These resources often provide visual aids and detailed descriptions of each component’s function. Identifying each element can lead to more efficient repairs and maintenance routines. Being well-informed about the inner workings of your freezing apparatus will enhance your confidence in handling any problems that may occur.

Functions of Each Ice Maker Component

Understanding the roles of various elements in a freezing apparatus is essential for effective maintenance and troubleshooting. Each component contributes to the overall functionality, ensuring that the system operates smoothly and efficiently.

- Water Supply Mechanism: This part provides the necessary liquid for the freezing process, ensuring a steady flow to produce solidified shapes.

- Freezing Chamber: Here, the temperature is lowered to facilitate the transformation of liquid into solid form, allowing for the creation of frozen units.

- Harvesting Tool: This component is responsible for releasing the frozen shapes once they have reached the desired consistency, enabling them to be collected for storage.

- Control Unit: It regulates the timing and functioning of other components, ensuring that the entire system operates in harmony and maintains the correct cycles.

- Temperature Sensor: This device monitors the internal conditions, providing feedback to the control unit to adjust settings as necessary for optimal performance.

By comprehensively understanding these roles, users can enhance their troubleshooting skills and ensure the longevity of their freezing devices.

Maintenance Tips for Ice Makers

Ensuring optimal performance of your frozen water production unit requires regular care and attention. By following a few simple maintenance practices, you can extend the lifespan of the appliance and improve its efficiency. This section outlines essential guidelines for maintaining the functionality of these devices.

Regular Cleaning: It is crucial to clean the unit frequently to prevent the buildup of mineral deposits and other contaminants. Use a soft cloth and a mixture of water and mild detergent to wipe down the exterior and interior surfaces.

Check Water Supply: Inspect the water line for any signs of leaks or blockages. A clean and unobstructed water supply is essential for the proper functioning of the device.

Monitor Temperature Settings: Keep an eye on the temperature settings to ensure they are within the recommended range. Maintaining the right temperature will help the unit operate efficiently and produce quality frozen products.

Replace Filters: If your model is equipped with a filtration system, make sure to change the filters regularly. This helps to ensure that the water used for production is clean and free from impurities.

By following these tips, you can keep your frozen water production unit in excellent condition, ensuring it continues to meet your needs effectively.

Installation Process for Ice Maker Parts

Setting up a new unit for producing frozen cubes involves several critical steps that ensure efficient operation. This procedure requires attention to detail and a clear understanding of each component’s role within the assembly. Proper installation not only guarantees functionality but also enhances longevity.

Begin by gathering all necessary tools and materials, as this will streamline the process. Identify the various components, noting their specific functions. Carefully follow the manufacturer’s instructions, making sure to connect hoses and electrical wires accurately. It is essential to secure all fittings tightly to prevent leaks and ensure optimal performance.

After assembling the unit, double-check all connections and configurations. Activate the system to test functionality, monitoring for any unusual sounds or issues. If everything operates smoothly, finalize the setup by organizing surrounding areas to maintain easy access for future maintenance.

Troubleshooting Ice Maker Problems

When experiencing difficulties with a freezing appliance, it’s essential to identify the root causes. Various issues can arise, leading to ineffective operation or complete failure. Understanding these common challenges can aid in efficient resolution and restore functionality.

Here are several common issues and their potential solutions:

- No Production of Frozen Cubes:

- Check the water supply line for kinks or blockages.

- Ensure the water valve is open and functioning properly.

- Inspect the temperature settings to confirm they are within the appropriate range.

- Slow Production Rate:

- Assess the appliance’s overall temperature settings.

- Examine for any ice build-up that may hinder performance.

- Consider external temperature influences that might affect the freezing process.

- Inconsistent Size of Frozen Cubes:

- Verify that the water level is consistent during filling cycles.

- Inspect the mold for any debris or contaminants.

- Check for irregularities in the water pressure supply.

- Unusual Noises:

- Identify the source of the noise to determine if it is a mechanical or electrical issue.

- Ensure all components are securely in place and free from obstruction.

- Monitor for signs of wear or damage that may require replacement.

By systematically examining these areas, users can effectively diagnose and rectify issues, ensuring optimal performance of their freezing appliance.

Replacement Parts for GE Ice Makers

Maintaining optimal functionality in your GE appliance often involves understanding the various components that contribute to its performance. When specific elements wear out or malfunction, it is essential to identify suitable replacements to ensure continued efficiency and reliability. This section provides insights into the different elements available for your model, helping you restore its operation effectively.

Common Components to Consider

Several crucial components play significant roles in the overall operation of your appliance. Familiarizing yourself with these elements will aid in recognizing potential issues and determining the necessary replacements. Here are some typical components you might need:

- Water Valve: Controls the flow of water to the unit.

- Control Module: Manages the various functions of the system.

- Fan Motor: Circulates air to maintain optimal temperatures.

Where to Find Quality Replacements

Finding reliable replacements is crucial for the longevity of your appliance. Authorized dealers, online retailers, and local home improvement stores often stock quality replacements. Ensure to verify compatibility with your specific model to avoid any issues during installation.

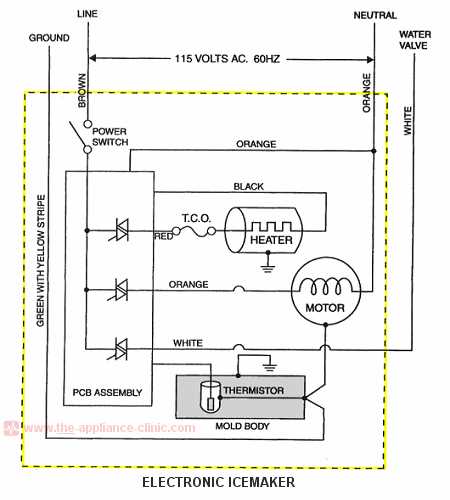

Understanding Ice Maker Wiring Diagrams

Wiring schematics serve as essential guides for comprehending the intricate connections within automated cooling systems. These visual representations simplify the complexities involved in understanding how different components interact and function together. By grasping these connections, users can better troubleshoot and maintain their appliances.

Each schematic typically illustrates the flow of electricity through various elements, highlighting key features such as power sources, switches, and sensors. Familiarizing oneself with these elements is crucial for diagnosing issues and ensuring proper functionality. A well-structured schematic can aid in identifying potential problems and facilitate the process of making necessary adjustments.

Moreover, recognizing the relationship between various components enhances overall knowledge of the system. For instance, understanding how a water inlet operates in conjunction with control modules is vital for effective maintenance. This knowledge empowers users to approach repairs with confidence, ensuring that their cooling systems operate efficiently and reliably.