When it comes to maintaining machinery, a clear understanding of its various elements is essential for effective servicing and repairs. Knowing how each part interacts and contributes to the overall functionality can greatly enhance the user experience and prolong the lifespan of the equipment. This section aims to provide insights into the intricate assembly of your device, ensuring that you have the necessary knowledge at your fingertips.

Identifying individual elements plays a crucial role in troubleshooting and repairs. With a comprehensive overview of how these components fit together, users can quickly pinpoint issues and implement effective solutions. Moreover, being familiar with the layout and organization of parts allows for more efficient maintenance, helping you avoid potential pitfalls.

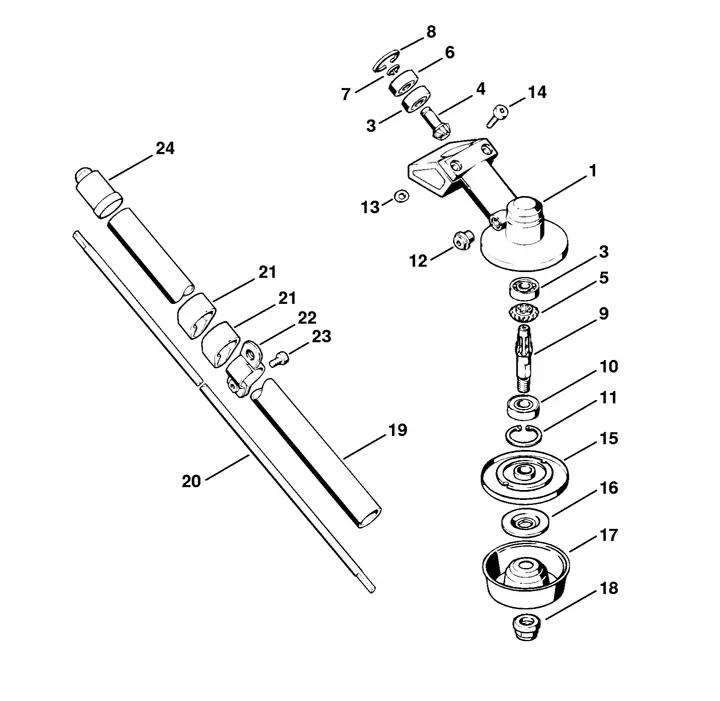

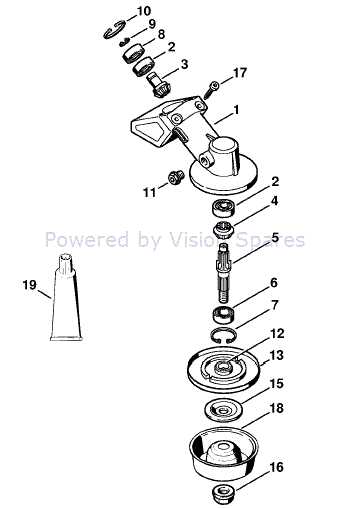

Additionally, visual aids can be instrumental in enhancing comprehension. By presenting a clear representation of the various sections and their respective functions, users can better appreciate the design and engineering that go into their equipment. This not only aids in effective repairs but also fosters a deeper appreciation for the machinery itself.

Understanding the FS90R Parts Diagram

Grasping the intricate layout of components is essential for effective maintenance and troubleshooting. A clear visual representation aids users in identifying each element’s function, ensuring smoother operation and longevity of the equipment. This guide will delve into the significance of comprehending the schematic layout, highlighting key features and their roles within the overall system.

When exploring the structure, it’s important to note the categorization of elements, which often follows a logical sequence. Each part is meticulously designed to interact with others, contributing to the overall efficiency of the machine. Below is a simplified overview of common categories found in such schematics:

| Component Category | Description |

|---|---|

| Power Supply | Generates and distributes electrical energy to various parts. |

| Drive Mechanism | Transmits energy to enable motion and operation. |

| Control Unit | Manages the operation of the system through input and feedback. |

| Safety Features | Ensures user protection and prevents operational hazards. |

| Maintenance Points | Designated areas for routine checks and servicing to enhance longevity. |

By familiarizing oneself with this structure, operators can not only optimize performance but also address issues more efficiently when they arise. Understanding the interconnectedness of these components is key to effective management and upkeep of the equipment.

Key Components of the FS90R

Understanding the essential elements of this equipment is crucial for optimal performance and maintenance. Each component plays a significant role in ensuring efficiency and durability, contributing to the overall functionality.

Engine Assembly

The heart of the machine, the engine assembly, drives its performance. It comprises various parts that work in unison to provide power, enabling the equipment to tackle demanding tasks with ease.

Cutting System

The cutting system is vital for achieving precise results. This assembly includes blades and other attachments designed for effective cutting, making it essential for users seeking high-quality output.

How to Interpret Parts Diagrams

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations provide crucial information that helps users identify and locate each element within a system. By learning to read these visuals, one can simplify the process of troubleshooting and ordering the right replacements.

Start with the Legend: Many illustrations include a legend or key that explains symbols and notations used. Familiarizing yourself with this guide is crucial as it serves as the foundation for accurate interpretation.

Focus on Labels: Each element is typically labeled, providing essential details such as part numbers and descriptions. Pay close attention to these labels, as they are vital for identifying the correct items needed for your project.

Analyze Connections: Look for lines or arrows indicating how components connect or interact with each other. Understanding these relationships can clarify assembly and disassembly processes.

Use Scale References: Some illustrations include scale references, allowing you to gauge the size of components relative to one another. This information can be useful for fitting new parts accurately.

Refer to Manufacturer Guidelines: Cross-referencing the visual guide with the manufacturer’s documentation can provide additional context and ensure that you are following best practices during maintenance.

By applying these strategies, anyone can effectively navigate these visual tools, making the repair and maintenance process more efficient and precise.

Common Issues with FS90R Parts

When maintaining a high-performance outdoor tool, users often encounter a range of common challenges. Understanding these frequent issues can help ensure that your equipment operates smoothly and efficiently. This section highlights typical problems that may arise and offers insight into potential solutions.

Frequent Problems

- Overheating: Equipment can become excessively hot during use, leading to reduced performance and potential damage.

- Difficulty Starting: Many users report issues with ignition, resulting in frustrating attempts to power up the machine.

- Fuel Leaks: Leaks can occur due to worn or damaged seals, impacting functionality and safety.

- Vibration: Excessive vibrations during operation can indicate alignment issues or worn components.

Troubleshooting Tips

- Regularly check and replace worn gaskets to prevent leaks.

- Inspect and clean the air filter to enhance airflow and starting efficiency.

- Ensure that all bolts and screws are tightened to minimize vibrations.

- Monitor fuel quality and replace old fuel to prevent starting issues.

By proactively addressing these issues, users can enhance the longevity and reliability of their outdoor equipment, ensuring it remains a valuable tool for years to come.

Importance of Genuine Replacement Parts

Using authentic components for machinery maintenance is crucial for ensuring optimal performance and longevity. These items are specifically designed to meet the original specifications set by the manufacturer, which guarantees compatibility and reliability. By opting for genuine components, users can maintain the integrity of their equipment and avoid potential issues associated with inferior alternatives.

Quality Assurance: Genuine components undergo rigorous testing and quality control processes. This ensures that they meet the necessary standards for durability and efficiency. Utilizing these high-quality items significantly reduces the risk of failure and enhances the overall functionality of the machinery.

Safety: Employing original components is essential for the safety of operators and users. Non-authentic items may not perform as expected, leading to malfunctions that could cause accidents or injuries. By choosing genuine replacements, one can have peace of mind knowing that the equipment is safe to operate.

Cost-effectiveness: Although authentic components may have a higher upfront cost, they often prove to be more economical in the long run. Their durability reduces the frequency of replacements and repairs, ultimately saving money on maintenance and downtime.

Warranty Protection: Many manufacturers provide warranties on their equipment that may be voided if non-genuine components are used. By sticking with authentic replacements, users ensure that their warranties remain valid, protecting their investment and offering additional financial security.

In conclusion, utilizing authentic components is vital for maintaining machinery performance, ensuring safety, and protecting investments. It is always wise to prioritize quality and reliability over short-term savings to achieve long-lasting results.

Maintenance Tips for FS90R Owners

Proper upkeep is essential for ensuring longevity and optimal performance of your equipment. Regular maintenance can help identify potential issues before they escalate, enhancing efficiency and reliability during use. Here are some practical recommendations to keep your machine in top shape.

Regular Inspection

Conduct frequent checks on various components, including the air filter, spark plug, and fuel lines. Cleaning or replacing these parts as needed can prevent operational disruptions and enhance performance.

Fuel Management

Use fresh, high-quality fuel and store it properly to prevent degradation. Additionally, consider adding a fuel stabilizer if the equipment will not be used for an extended period, ensuring that it starts easily when needed.

Where to Find FS90R Parts

Locating components for your equipment can significantly enhance its performance and longevity. There are several reliable sources where you can explore options to obtain these essential items.

- Authorized Dealers: Check with manufacturers’ official retailers for genuine replacements.

- Online Marketplaces: Websites like eBay or Amazon often have a wide range of aftermarket options.

- Local Repair Shops: Visit nearby service centers that specialize in maintenance and repairs.

- Forums and Communities: Join online groups dedicated to your equipment for recommendations and tips.

Each source offers distinct advantages, so consider what aligns best with your needs and preferences.

Comparing FS90R to Similar Models

When evaluating a range of tools designed for landscaping and gardening, it’s essential to consider how they stack up against each other. Different models can vary significantly in terms of performance, features, and user experience. This section provides insights into how a particular high-performance tool compares to its competitors, highlighting key similarities and differences that can inform purchasing decisions.

Performance and Efficiency

One of the most critical aspects to examine is the performance efficiency of these tools. While some models boast powerful engines capable of handling heavy-duty tasks, others may prioritize fuel efficiency and ease of use. The specific design and technology integrated into each model can affect cutting capabilities, weight, and maneuverability, making it crucial for users to assess which attributes align with their specific needs.

Features and Usability

Features play a significant role in the overall usability of any gardening equipment. Some models offer advanced functionalities such as adjustable cutting heads, ergonomic handles, and quick-start systems. Comparing these features can reveal which options are more user-friendly and adaptable for various tasks. Additionally, considering the weight and balance of each model can impact comfort during prolonged use, influencing the overall satisfaction of the operator.

Ultimately, understanding the nuances between different landscaping tools can empower users to make informed decisions that enhance their gardening experience and efficiency.

DIY Repairs Using the Parts Diagram

Performing maintenance and repairs on your equipment can be a fulfilling experience, allowing you to save money while gaining valuable skills. Utilizing a detailed schematic of components can significantly enhance your understanding of how various elements interact within your machine. This guide provides insights on how to effectively use such a visual representation for your repair tasks.

Understanding the Visual Representation

A comprehensive illustration of components is essential for any repair process. Here’s how to leverage it:

- Familiarize yourself with the different sections and their respective functions.

- Identify the specific components you need to work on, ensuring clarity on their placement.

- Note any related parts that may require attention during repairs or replacements.

Steps for Effective Repairs

Follow these steps to execute repairs efficiently:

- Gather all necessary tools and replacement items based on your visual guide.

- Carefully disassemble the unit, referring to the schematic to avoid mistakes.

- Replace or repair components as needed, ensuring compatibility and proper installation.

- Reassemble the equipment, double-checking that everything is securely fitted.

- Test the machinery to confirm that repairs were successful.

By following this approach, you can tackle repairs with confidence and improve the longevity of your equipment.