The intricate machinery utilized in warehouses and industrial environments is vital for efficient operations. Comprehending the various elements that comprise these machines can enhance safety and productivity. Each component plays a crucial role, ensuring seamless functionality and performance.

In-depth knowledge of these essential structures allows operators to maximize effectiveness while minimizing risks. Familiarity with the core functionalities of each segment equips users to address maintenance issues proactively. As we delve deeper, we uncover the ultimate significance of understanding how each element interconnects.

By exploring these mechanical systems, individuals can appreciate the engineering marvels behind their operations. This understanding not only fosters respect for the technology but also contributes to a safer working environment. Let’s take a closer look at what makes these machines operate smoothly and reliably.

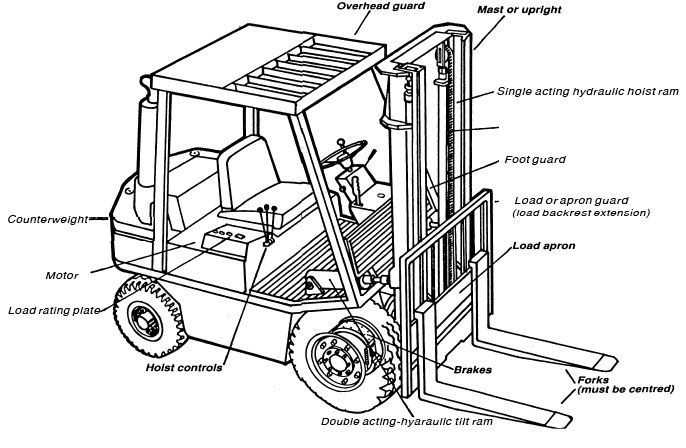

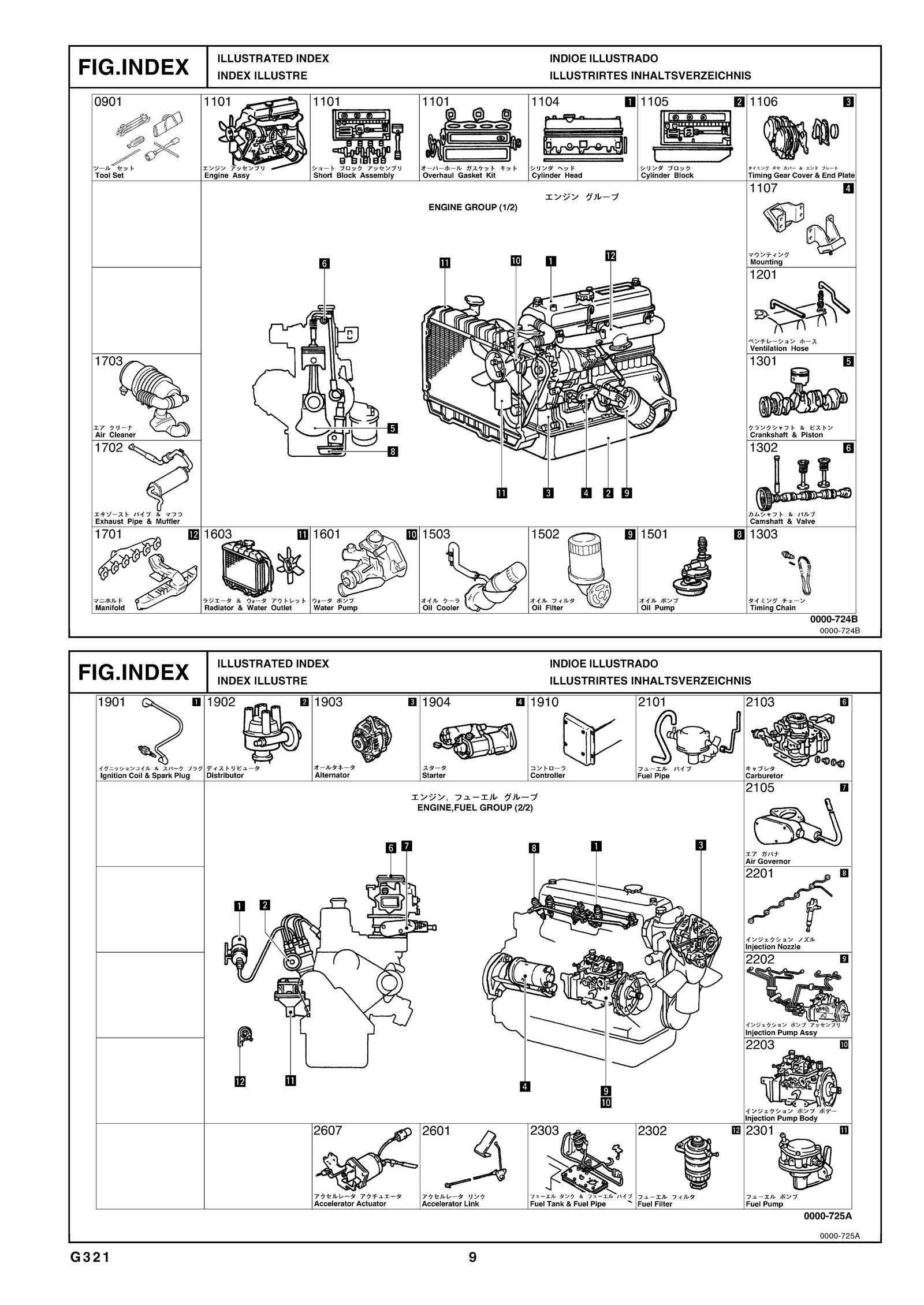

Understanding Forklift Components

This section explores the essential elements that make up industrial lifting machines, focusing on their functionality and interrelation. A solid grasp of these components is crucial for efficient operation and maintenance, enhancing both safety and productivity in various settings.

Key Elements of Lifting Equipment

The machinery consists of various sections, each playing a pivotal role in its overall performance. Familiarity with these sections allows operators to maximize the efficiency and longevity of the equipment.

| Component | Function |

|---|---|

| Mast | Supports the lifting mechanism and raises the load. |

| Forks | Engage and lift loads for transport. |

| Chassis | Provides stability and houses other components. |

| Power Unit | Drives the lifting and movement functions. |

Importance of Component Understanding

Comprehending these essential elements not only aids in effective usage but also supports troubleshooting and repair efforts. Operators equipped with knowledge about the machine’s components are better prepared to handle challenges that arise during operation.

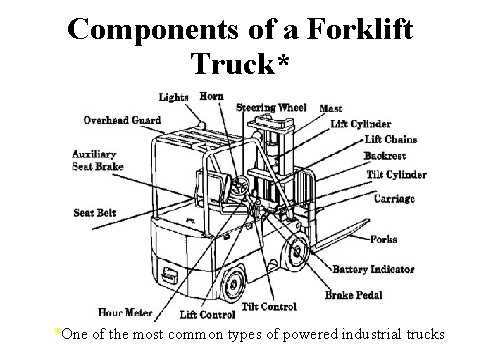

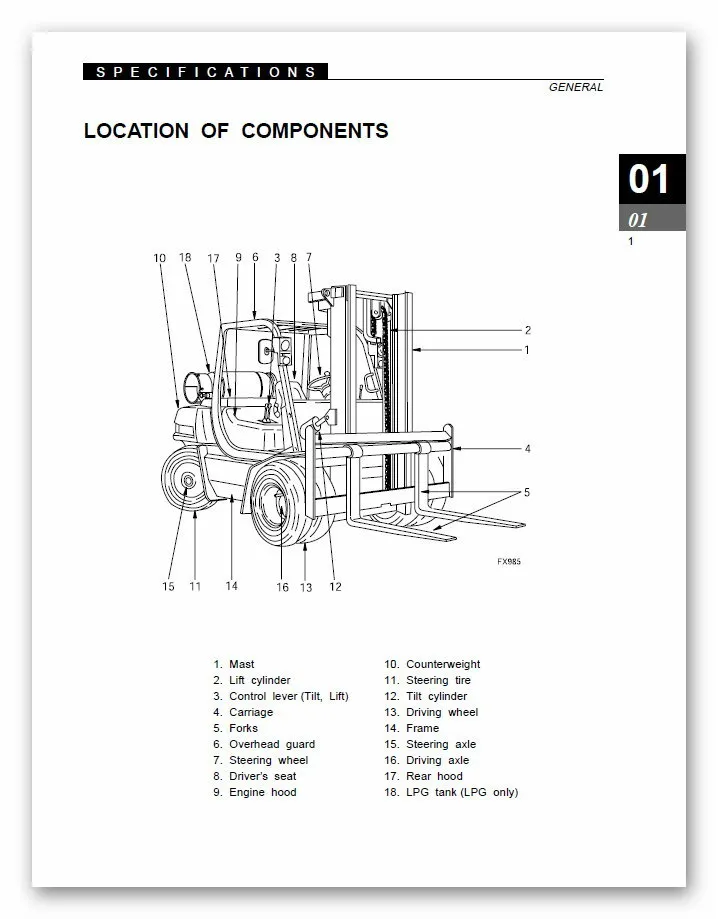

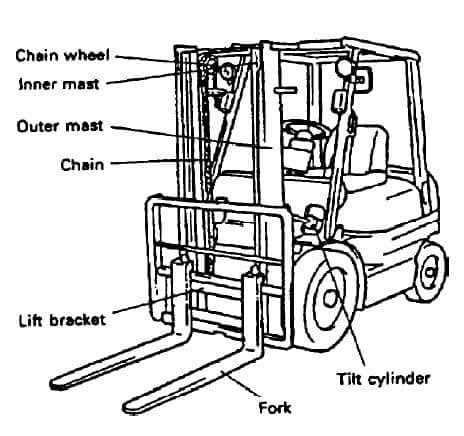

Main Parts of a Forklift

Understanding the essential components of these powerful lifting machines is crucial for their effective operation. Each element plays a significant role in ensuring safety and efficiency in material handling tasks.

Key Components

- Chassis: The foundational structure that supports the entire vehicle.

- Engine: Provides the necessary power for movement and lifting operations.

- Mast: The vertical assembly that raises and lowers the load.

- Carriage: The platform attached to the mast that holds the load.

Additional Features

- Forks: The prongs that engage with the load.

- Steering System: Allows for precise maneuvering in tight spaces.

- Controls: The interface for the operator to manage lifting and driving functions.

- Counterweight: Balances the load to prevent tipping during operation.

How Forklift Systems Function Together

The efficient operation of industrial lifting vehicles relies on a series of interconnected components that work in harmony. Each element plays a crucial role, ensuring that the entire mechanism functions smoothly and effectively. Understanding how these systems interact can enhance both safety and performance in the workplace.

At the core of this machinery are various systems that contribute to lifting, steering, and stability. The interplay between these systems is essential for achieving optimal functionality. Below is a summary of key systems and their roles:

| System | Function |

|---|---|

| Powertrain | Provides the necessary energy for movement and lifting operations. |

| Hydraulic System | Enables lifting and lowering of heavy loads through fluid pressure. |

| Steering Mechanism | Facilitates directional control, allowing for precise navigation. |

| Stability Features | Ensures balance during operation, preventing tip-overs and enhancing safety. |

When these systems function together seamlessly, operators can achieve high levels of efficiency and safety in material handling tasks. Continuous maintenance and understanding of these interdependencies are vital for long-term operational success.

Importance of Safety Features

In any industrial environment, the presence of safety mechanisms is crucial for ensuring the well-being of operators and preventing accidents. These features play a vital role in enhancing operational efficiency while minimizing risks associated with heavy machinery. Understanding their significance can lead to a safer workplace and improved productivity.

Several key benefits highlight the importance of incorporating safety features:

- Accident Prevention: Effective safety measures reduce the likelihood of mishaps, protecting both personnel and equipment.

- Enhanced Operator Confidence: When operators are aware of the protective systems in place, they are more likely to perform their tasks with assurance.

- Compliance with Regulations: Adhering to safety standards not only avoids legal repercussions but also promotes a culture of safety within the organization.

- Minimized Downtime: Fewer accidents translate to less disruption, ensuring that operations run smoothly and efficiently.

- Cost Savings: Investing in safety features can lead to long-term financial benefits by reducing costs associated with injuries and equipment damage.

To maximize the advantages of these safety features, it is essential to regularly inspect and maintain them. Training personnel on their usage further amplifies their effectiveness, creating a comprehensive safety culture that benefits everyone involved.

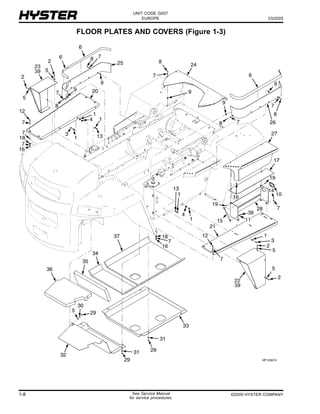

Maintenance Tips for Forklift Parts

Regular upkeep is essential for ensuring optimal performance and longevity of your heavy machinery. Proper care not only enhances efficiency but also minimizes the risk of unexpected breakdowns. By focusing on key components, you can maintain smooth operations and reduce overall costs.

First, routinely inspect the hydraulic system for leaks or wear. Ensure that the fluids are at appropriate levels and replace them as needed. Additionally, check seals and hoses for signs of damage.

Next, pay attention to the battery. Regularly clean terminals and ensure connections are secure. This helps prevent electrical issues and prolongs battery life.

Tires are crucial for stability and safety. Regularly examine them for wear and proper inflation. Replace tires that show signs of excessive damage or wear to ensure optimal traction.

Finally, maintain the lifting mechanism by lubricating moving parts and checking for wear. This helps ensure smooth operation and extends the life of the equipment. Keeping a maintenance log can also aid in tracking issues and scheduling timely service.

Common Issues with Forklift Components

Understanding the frequent challenges associated with material handling machinery is crucial for maintaining operational efficiency. These issues can range from mechanical failures to electrical malfunctions, each affecting performance and safety.

One common problem involves wear and tear on mechanical elements, such as bearings and lift chains. Regular inspections are essential to identify signs of fatigue before they lead to more serious complications.

Another frequent issue is related to hydraulic systems. Leaks or low fluid levels can drastically impair lifting capabilities, making it vital to check these systems routinely.

Electrical faults also pose significant risks. Malfunctions in batteries or wiring can result in unexpected downtime. Ensuring all connections are secure and components are in good condition can help mitigate these risks.

Ultimately, proactive maintenance and a keen awareness of these common issues will enhance reliability and safety in material handling operations.

Upgrading Forklift Parts Effectively

Enhancing the components of your heavy machinery is essential for improving performance and safety. By strategically selecting upgrades, you can ensure that your equipment remains efficient and reliable in various operational conditions.

Key Considerations for Upgrades

When planning enhancements, it’s important to assess the specific needs of your operations. Consider factors such as durability, compatibility, and technological advancements that can contribute to improved functionality.

Benefits of Upgrading

Upgrading can lead to increased productivity, reduced downtime, and enhanced safety measures. By investing in quality components, you also prolong the lifespan of your equipment.

| Upgrade Type | Benefits | Considerations |

|---|---|---|

| Powertrain Enhancements | Improved efficiency and torque | Compatibility with existing systems |

| Brake Systems | Enhanced safety and response | Regular maintenance requirements |

| Control Systems | Increased precision and ease of use | Training for operators |

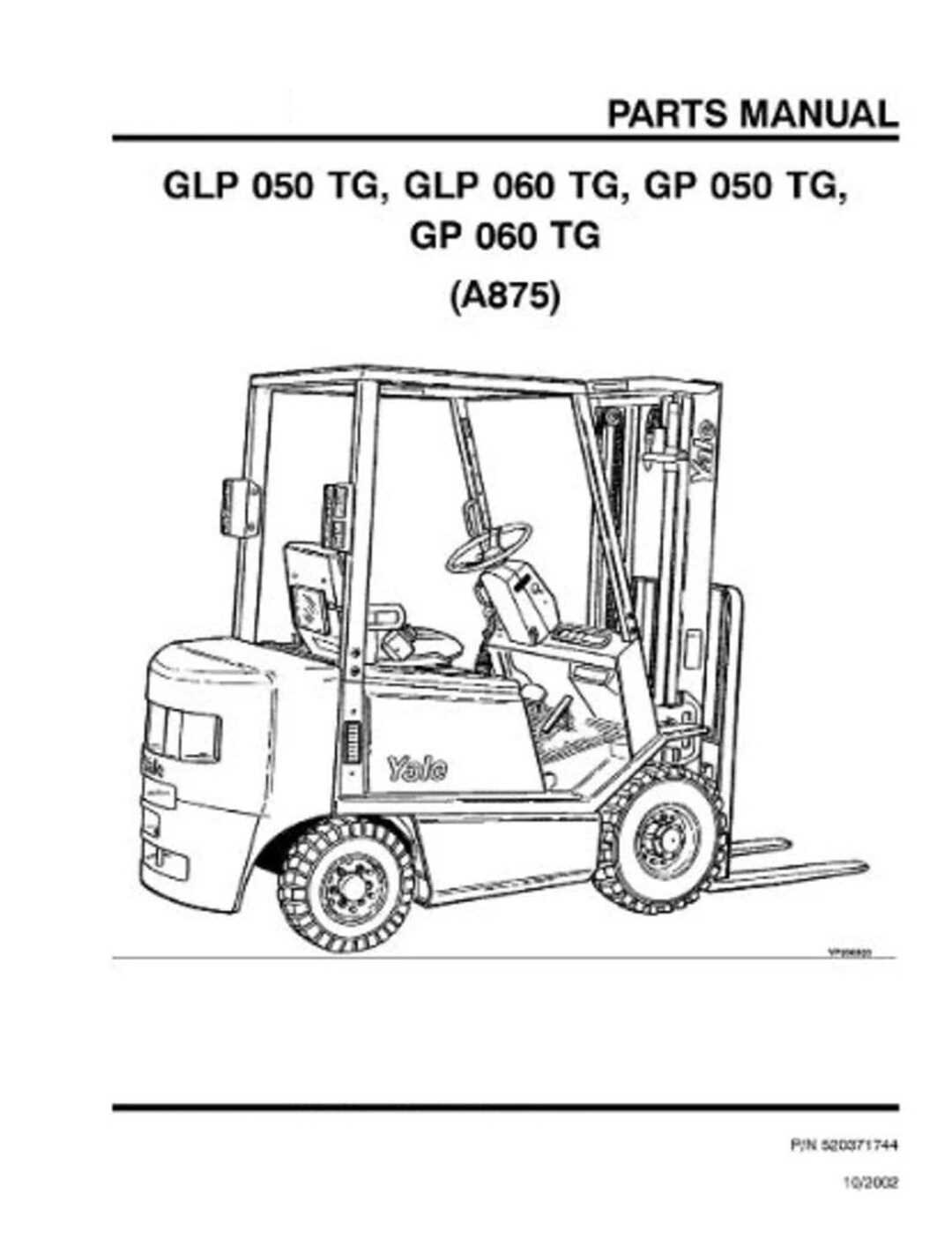

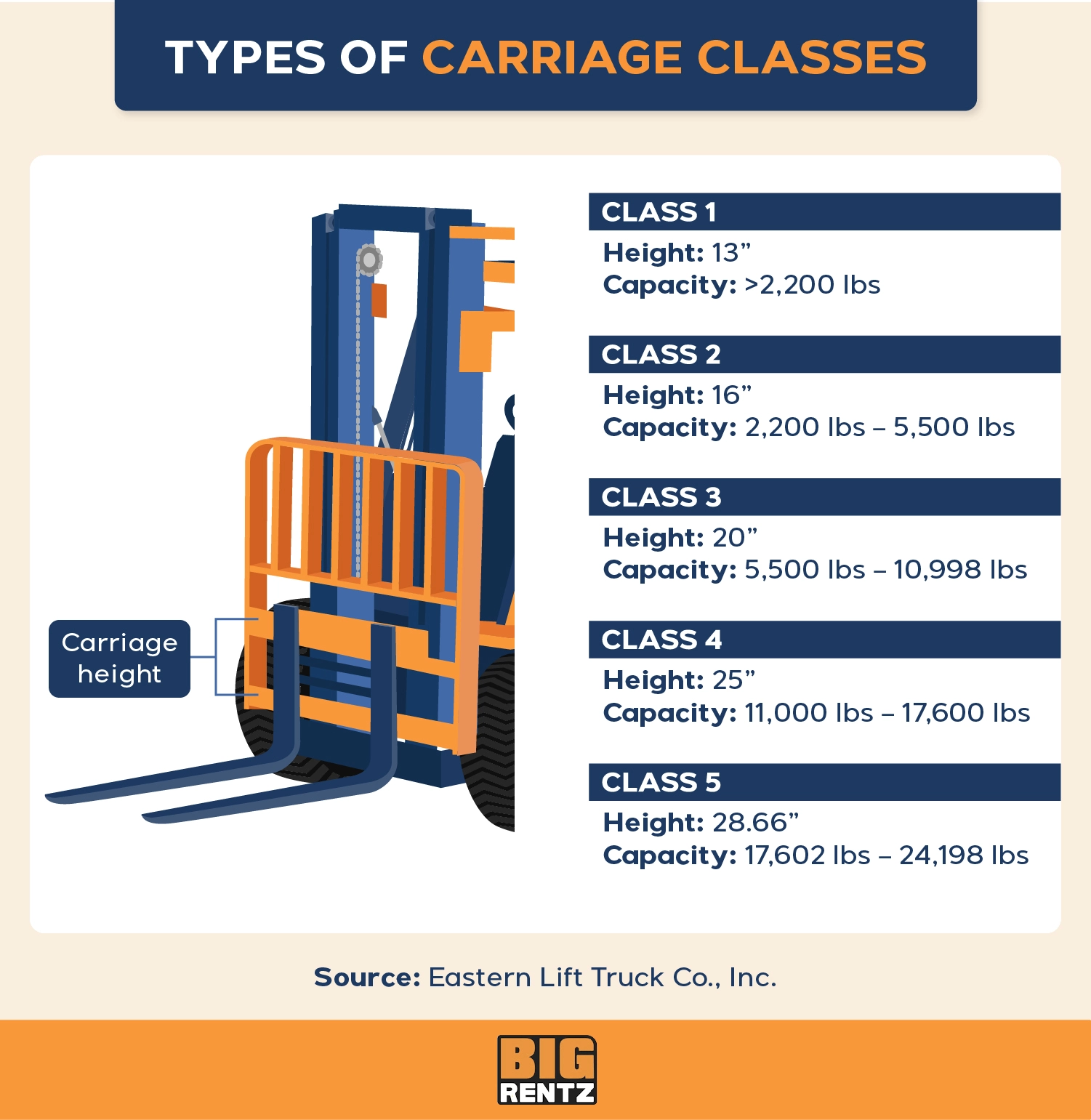

Choosing the Right Forklift for Your Needs

Selecting the appropriate lifting equipment for your operations is crucial for maximizing efficiency and safety. Various factors play a significant role in ensuring that the machinery aligns with your specific requirements, including the type of loads, operating environment, and frequency of use.

Capacity is a fundamental consideration; knowing the maximum weight you need to handle will guide your choice. Additionally, the design of the equipment should suit the space where it will operate, especially if navigating tight aisles or outdoor conditions. Power sources, whether electric, gas, or diesel, can also affect both performance and cost-effectiveness.

Lastly, evaluating your budget and potential for future growth is essential. Investing in the right machinery can ultimately enhance productivity and reduce operational costs in the long run.

Future Trends in Forklift Design

The evolution of material handling vehicles is set to transform industries, driven by advancements in technology, sustainability, and efficiency. As businesses seek innovative solutions to meet rising demands, the focus will shift towards smarter, more versatile machines that enhance productivity while minimizing environmental impact.

Integration of Automation and AI

One of the ultimate trends is the incorporation of automation and artificial intelligence. These technologies will enable vehicles to operate autonomously, optimizing routing and load management, ultimately reducing operational costs. Smart sensors will enhance safety and efficiency, allowing for real-time monitoring of performance.

Sustainability and Eco-Friendly Solutions

The push for greener practices will drive the development of electric and hybrid models, which produce less emissions and lower energy costs. Renewable energy sources will also play a crucial role, making the machinery more sustainable in the long run. This shift not only benefits the environment but also aligns with corporate social responsibility initiatives.