Every tool designed for maintaining outdoor spaces relies on various interconnected elements. These mechanisms work in harmony to ensure the equipment performs efficiently, delivering clean results. Understanding how these individual components function together can help users maintain and troubleshoot their tools more effectively.

Whether you are a seasoned gardener or a beginner, familiarizing yourself with the key elements of such tools is essential for proper upkeep. From cutting mechanisms to guiding structures, each piece plays a significant role in ensuring the precision and durability of the equipment.

By learning more about these core elements, users can gain a deeper understanding of how to replace or repair specific parts when necessary, improving both the lifespan and performance of their gardening equipment.

Mclane Edger Components Overview

The machinery designed for precision in lawn care consists of various essential elements that work together to maintain edges and borders of walkways and gardens. Understanding how these individual pieces function can help ensure the equipment operates efficiently and stays durable over time.

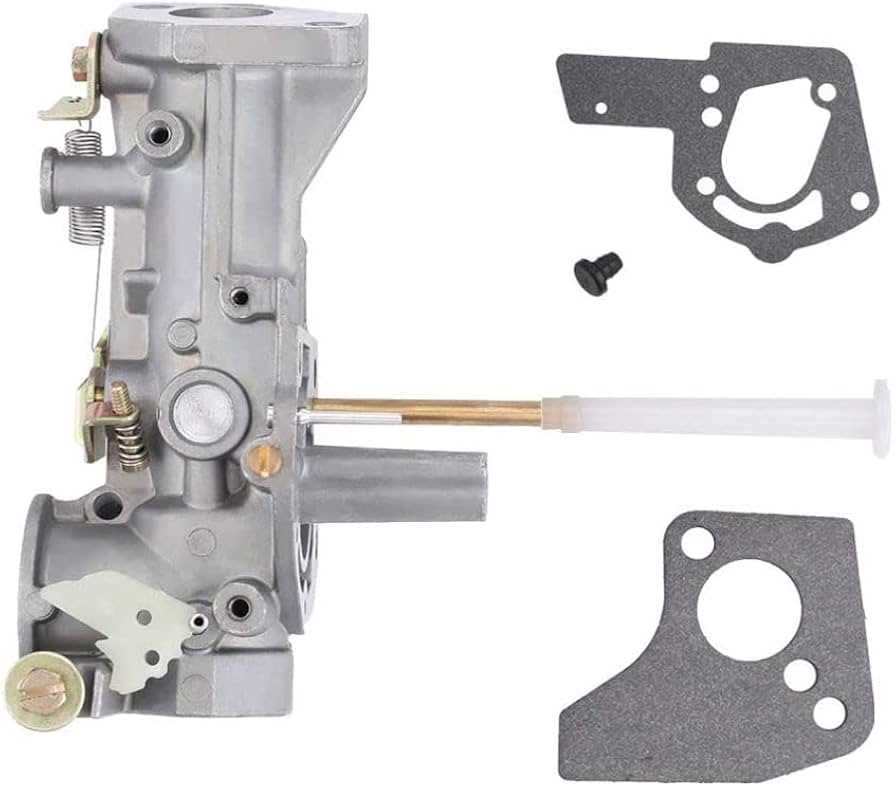

Engine and Power Source

The core of the device relies on a robust power source, often fueled by gas or electricity, which drives the cutting mechanism. This section includes components responsible for transferring energy to the blades, ensuring consistent performance.

Cutting Mechanism and Blades

A sharp set of rotating or fixed blades forms the key cutting mechanism, slicing through overgrown areas. Proper maintenance of these blades is crucial to keeping the equipment effective and ensuring clean, precise lines with each use.

Additional Components such as wheels, levers, and handles provide control and stability, allowing for accurate maneuvering while in operation. These elements ensure the tool can handle different terrains and cutting angles with ease.

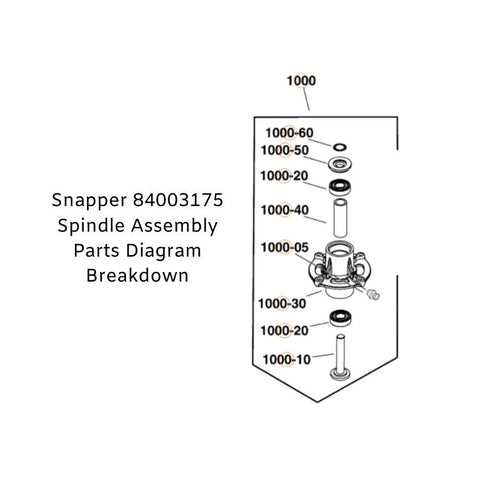

Blade Assembly and Its Function

The blade assembly plays a crucial role in maintaining the efficiency and precision of cutting tasks. It is designed to ensure smooth and accurate performance, working in harmony with other components to deliver consistent results. Understanding how this system operates is essential for achieving optimal performance and longevity of the tool.

The main purpose of the blade assembly is to provide clean and sharp cuts, ensuring a precise operation. This mechanism is carefully engineered to withstand wear and tear, allowing the tool to perform under demanding conditions. Its structure consists of multiple interconnected elements that contribute to a balanced and efficient function.

| Component | Function | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Blade | Responsible for cutting through material with sharp and clean edges. | ||||||||||||||||

| Component | Function | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Handle Grips | Provides comfortable and secure grip for the user | ||||||||||||

| Adjustment Mechanism | Allows the handle to

Throttle Cable and Adjustment TipsThe throttle cable is a crucial component in ensuring smooth operation and optimal performance of your equipment. Proper adjustment of this cable is essential for maintaining responsiveness and efficiency during use. This section will provide insights into cable management and offer practical tips for achieving the best results. Here are some essential tips for managing and adjusting the throttle cable:

By following these guidelines, you can maintain the efficiency and reliability of your equipment, ensuring it operates smoothly when you need it most. Edger Frame and Structure Breakdown

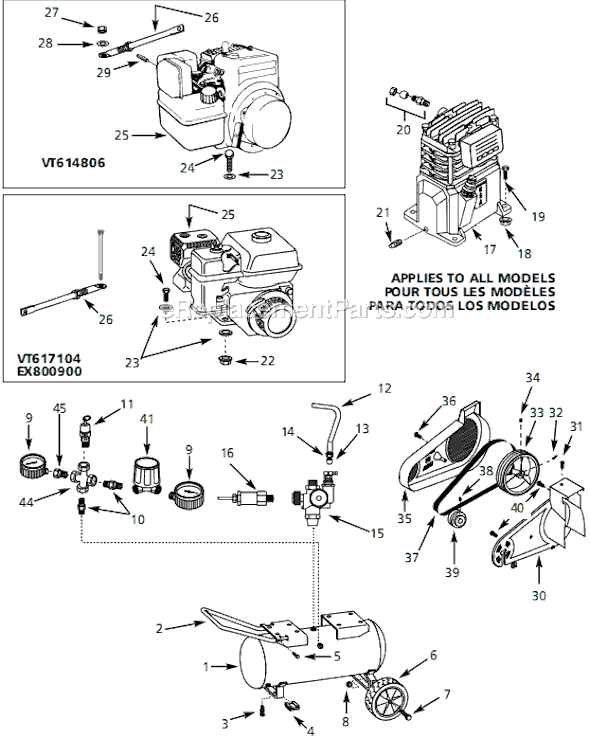

The framework and composition of a landscaping tool are essential for its functionality and durability. Understanding the various components that contribute to its overall design allows users to appreciate the engineering behind these machines. This section delves into the main elements that form the core structure, emphasizing their roles and interconnections.

Replacement Guide for Belt and PulleyWhen maintaining your equipment, understanding how to replace essential components like belts and pulleys is crucial. These parts are vital for optimal performance, and regular checks can prevent more significant issues down the line. This guide aims to provide clear steps for successfully replacing these elements, ensuring your machine runs efficiently. Identifying the Correct ComponentsBefore beginning the replacement process, it is essential to identify the correct belts and pulleys for your specific model. Consult your user manual or an online resource that outlines compatible components. Ensuring you have the right parts will facilitate a smoother replacement process and help maintain the longevity of your equipment. Step-by-Step Replacement ProcessStart by disconnecting the power supply to ensure safety. Next, remove any protective covers to access the belt and pulley system. Carefully detach the old belt, noting the routing for the new one. Replace the pulley if needed, ensuring it aligns correctly. Finally, install the new belt, following the original path, and secure all components before restoring power. Testing the system after replacement is crucial to verify proper functionality. Maintenance Tips for Long-Lasting PerformanceProper upkeep is essential for ensuring optimal functionality and extending the lifespan of your gardening equipment. By following a few straightforward guidelines, you can enhance performance and reduce the likelihood of unexpected breakdowns. Regular InspectionFrequent checks can help identify potential issues before they escalate. Here are key areas to focus on:

Cleaning and LubricationKeeping your equipment clean and well-lubricated is crucial for efficient operation. Consider these practices:

By implementing these maintenance strategies, you can significantly improve the performance and longevity of your gardening tools. |