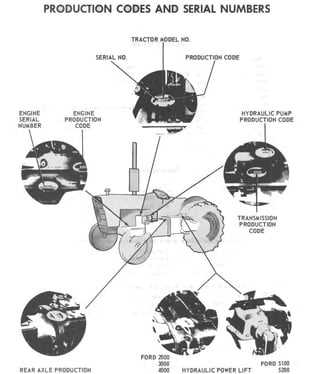

When working with heavy machinery, comprehending the arrangement and functionality of various elements is crucial for maintenance and operation. Each section plays a pivotal role, ensuring that the entire system functions smoothly and efficiently. Familiarity with these components not only enhances performance but also aids in troubleshooting potential issues.

In this exploration, we will delve into the intricacies of specific machinery, focusing on the layout and relationships between different units. By visualizing these assemblies, operators and technicians can better understand how each component interacts with others, facilitating effective repairs and replacements. A thorough knowledge of these systems is essential for anyone involved in the upkeep or operation of such equipment.

Furthermore, gaining insights into the specific configurations allows for informed decision-making regarding modifications or upgrades. Understanding the unique characteristics of these assemblies enables users to maximize the potential of their machinery, ensuring that it meets the demands of various tasks with reliability and precision.

Proper upkeep and timely repairs of heavy machinery require a selection of specialized instruments. Utilizing the right tools not only enhances the quality of work but also increases productivity and safety on the job site. Here’s a breakdown of essential equipment that can make the repair process more efficient.

- Wrenches: A variety of sizes, including adjustable and socket types, are crucial for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for working with different fasteners.

- Pliers: Needle-nose and slip-joint pliers help grip, twist, and cut wires or other materials.

- Hammer: A heavy-duty hammer or sledgehammer is essential for driving or removing components.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage from over-tightening.

In addition to basic hand tools, some power equipment can significantly speed up the repair process:

- Impact Wrench: This tool provides high torque output, making it easier to remove stubborn fasteners.

- Drill: A heavy-duty drill is useful for creating holes or driving screws with speed and efficiency.

- Cutting Tools: Angle grinders or saws are valuable for cutting through metal or other materials that may need replacement.

Having the right assortment of tools not only streamlines the repair process but also minimizes downtime. Investing in quality equipment ensures that machinery remains in optimal working condition.

Common Issues and Solutions

Understanding typical challenges that arise with heavy machinery can significantly enhance maintenance and operational efficiency. By recognizing common faults and implementing appropriate remedies, operators can ensure optimal performance and prolong the lifespan of their equipment.

Hydraulic System Problems

Hydraulic systems are critical for the efficient operation of construction machinery. Frequent issues include fluid leaks, erratic movements, and decreased power. Addressing these concerns promptly is essential to prevent more severe damage.

| Issue | Possible Cause | Recommended Solution |

|---|---|---|

| Fluid leaks | Worn seals or hoses | Inspect and replace damaged components |

| Erratic movements | Air in the system | Bleed the hydraulic lines to remove trapped air |

| Decreased power | Low fluid levels | Check fluid levels and top up as necessary |

Engine Performance Issues

Engine-related complications can lead to significant downtimes and reduced efficiency. Identifying symptoms such as stalling, poor acceleration, or unusual noises is crucial for timely intervention.

| Issue | Possible Cause | Recommended Solution |

|---|---|---|

| Stalling | Clogged fuel filter | Replace the fuel filter and check fuel lines |

| Poor acceleration | Dirty air filter | Inspect and clean or replace the air filter |

| Unusual noises | Loose components | Tighten bolts and inspect for damaged parts |

Resources for Parts Replacement

Finding reliable sources for component exchange can significantly enhance the efficiency of any machinery. Whether you are maintaining, upgrading, or repairing equipment, knowing where to acquire quality replacements is crucial. This section highlights various resources that can assist in sourcing the necessary components to ensure optimal functionality and longevity.

Online Marketplaces

Numerous online platforms offer a wide range of alternatives for mechanical replacements. These marketplaces provide users with access to new and refurbished items at competitive prices. When selecting a platform, consider factors such as user reviews, return policies, and shipping options to ensure a satisfactory purchasing experience.

Local Distributors and Dealers

Visiting local distributors can be advantageous for obtaining components quickly. Authorized dealers often have extensive knowledge about specific equipment and can offer personalized service. They might also provide warranties on their products, which adds an extra layer of assurance.

| Resource Type | Description | Advantages |

|---|---|---|

| Online Marketplaces | Websites specializing in selling various components. | Convenient access, price comparison, extensive selection. |

| Local Dealers | Authorized distributors providing specific components. | Expert guidance, immediate availability, warranty options. |

| Manufacturer Websites | Official websites offering original replacements. | Guaranteed compatibility, high quality, direct support. |

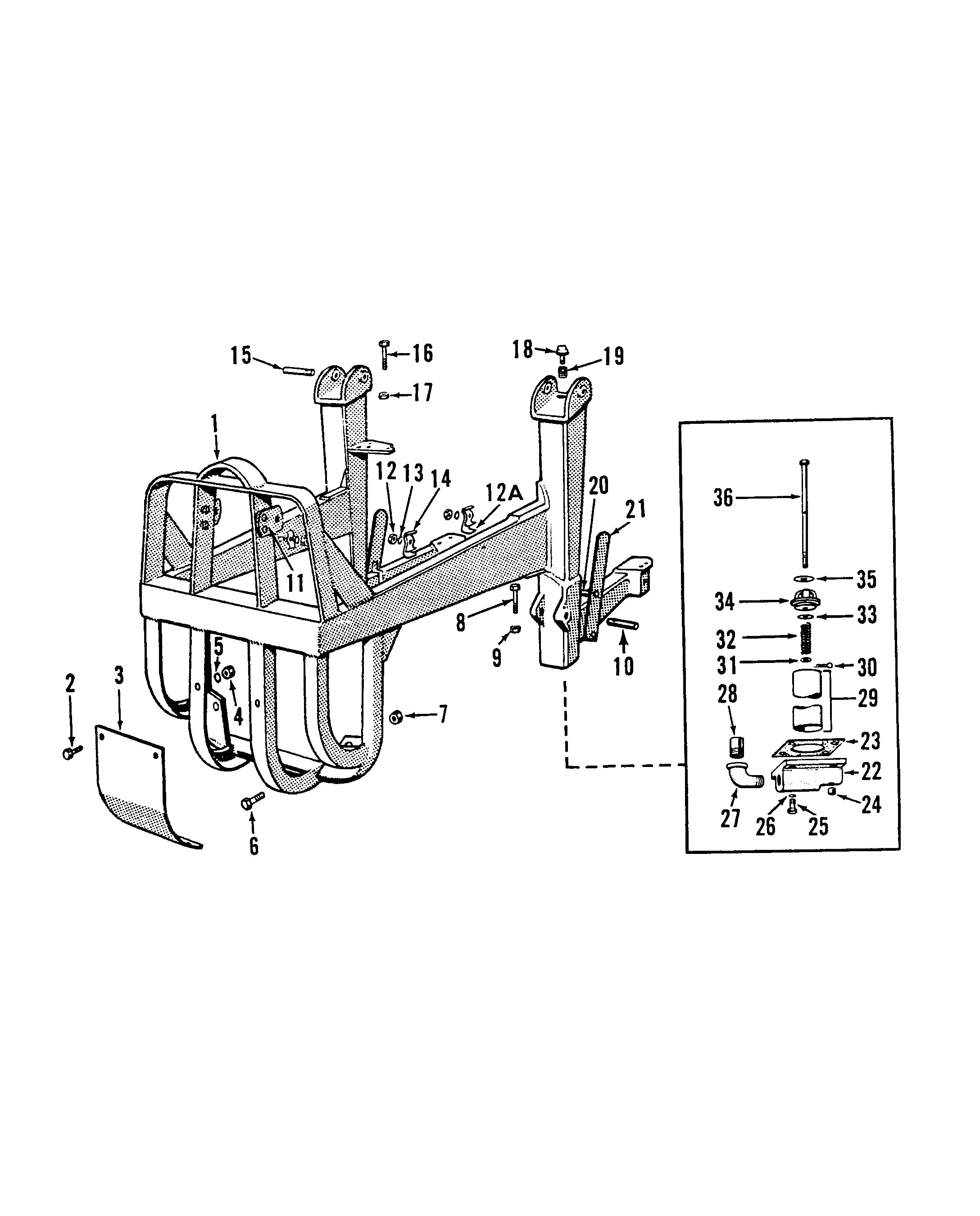

Illustrated Diagrams and Guides

Visual representations and instructional materials play a crucial role in understanding the components and functionality of machinery. These resources provide users with clear insights into the assembly, maintenance, and operation of various equipment, enhancing their ability to troubleshoot and perform repairs efficiently.

Benefits of Visual Resources

Utilizing pictorial aids simplifies complex concepts, making it easier for users to identify specific elements and their relationships. This approach not only aids in comprehension but also serves as a valuable reference during hands-on tasks, ensuring that procedures are followed accurately and safely.

Types of Visual Aids Available

A variety of visual tools are accessible, ranging from detailed sketches to comprehensive manuals. These resources often include labeled images and step-by-step instructions, which cater to both novice and experienced users. By leveraging these materials, individuals can gain a deeper understanding of machinery, ultimately leading to improved performance and longevity of the equipment.