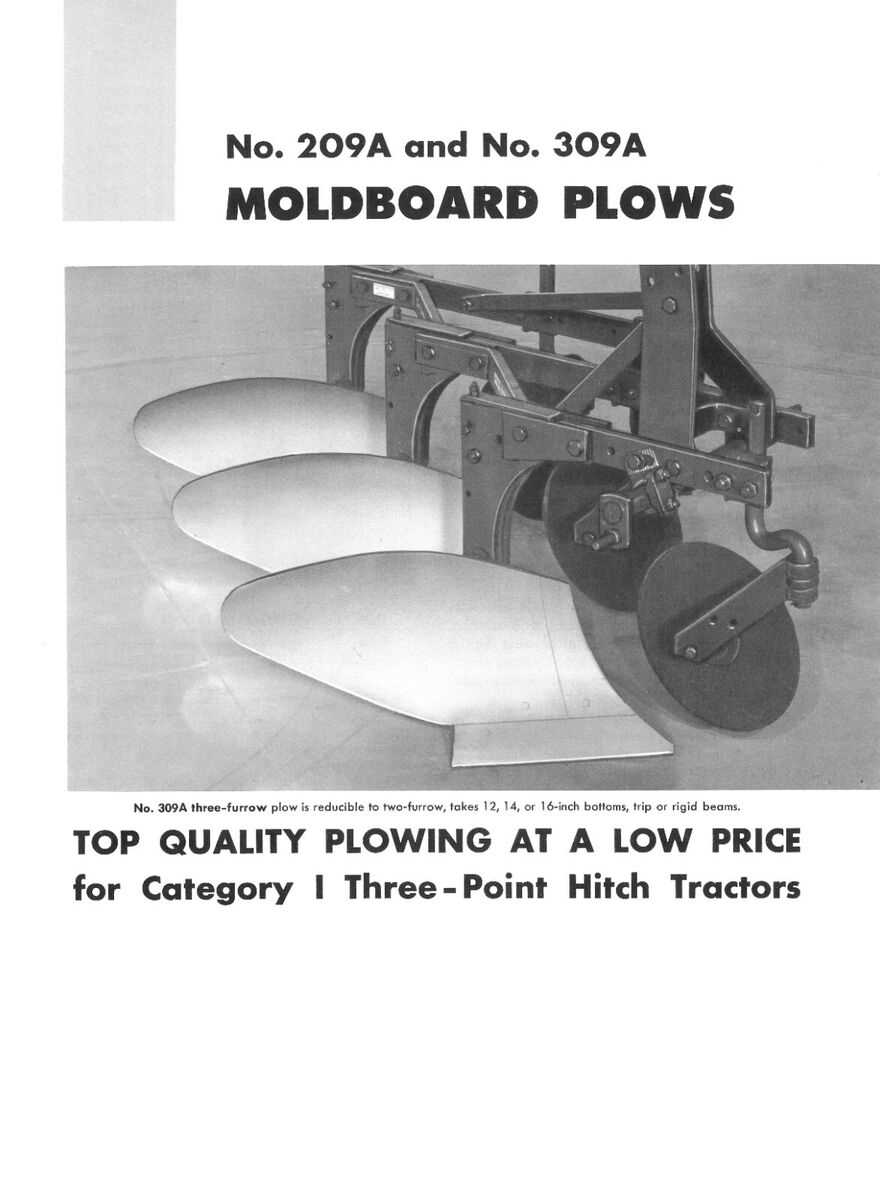

In the realm of agricultural machinery, having a comprehensive grasp of the various elements that constitute essential tools can significantly enhance their functionality and efficiency. This knowledge not only empowers operators to make informed decisions regarding maintenance and upgrades but also ensures optimal performance during critical tasks.

For those engaged in land cultivation and management, familiarity with the intricate arrangement of implements can be invaluable. By delving into the specifics of each component, users can identify potential issues, facilitate repairs, and customize their machinery to better suit their unique requirements.

This guide aims to illuminate the essential constituents of a popular cultivation tool, providing insights that will aid users in their quest for operational excellence. With a clear understanding of the mechanisms involved, individuals can navigate challenges more effectively and maximize their productivity in the field.

Understanding Ford 101 Plow Components

Gaining insight into the elements that make up this agricultural implement is essential for effective operation and maintenance. Each component plays a vital role in ensuring that the equipment functions efficiently, allowing users to achieve optimal performance in various soil conditions. Familiarity with these parts can enhance usability and facilitate repairs when necessary.

Key Elements of the Equipment

The implement consists of several crucial elements, each contributing to its overall functionality. Understanding their roles helps in recognizing how they interact and affect the equipment’s performance.

| Component | Description |

|---|---|

| Frame | The structural backbone that supports all other components, providing stability and durability. |

| Share | A sharp blade that cuts through soil, facilitating efficient tillage and cultivation. |

| Heel | Located at the rear of the share, this element helps to turn and mix the soil as it is disturbed. |

| Skimmers | These components prevent debris from accumulating and ensure a clean working surface. |

Maintenance Considerations

Key Features of Ford 101 Plow

This section explores the essential characteristics of a renowned agricultural implement, focusing on its design and functionality that enhance soil cultivation. The robust structure and thoughtful engineering contribute to its effectiveness in various farming tasks.

- Durability: Constructed from high-quality materials, ensuring longevity and resilience in tough field conditions.

- Adjustability: Features adjustable components that allow operators to customize settings for different soil types and conditions.

- Ease of Use: Designed for simple operation, reducing the learning curve for new users while maximizing efficiency for experienced operators.

- Compatibility: Easily attachable to a wide range of tractors, making it versatile for various farming setups.

- Maintenance: Engineered for low maintenance, with easily replaceable parts that ensure minimal downtime.

The combination of these attributes makes this implement a preferred choice among farmers, significantly improving productivity and effectiveness in soil preparation tasks.

Importance of Proper Maintenance

Regular upkeep of agricultural equipment is crucial for ensuring optimal performance and longevity. Neglecting maintenance can lead to a range of issues that not only affect functionality but also incur higher costs over time. Adopting a proactive approach to care can significantly enhance the efficiency of machinery and minimize the risk of unexpected failures.

- Improved Efficiency: Well-maintained equipment operates more smoothly, resulting in better fuel efficiency and increased productivity.

- Extended Lifespan: Routine inspections and servicing can prevent wear and tear, extending the useful life of the machinery.

- Cost Savings: Investing in maintenance reduces the likelihood of costly repairs and downtime, allowing for more predictable budgeting.

- Safety: Regular checks ensure that all safety features function correctly, protecting operators and workers on-site.

- Enhanced Performance: Keeping machinery in top condition allows it to perform at its best, meeting the demands of various tasks efficiently.

To maximize the benefits of maintenance, operators should adhere to a systematic schedule, which includes cleaning, lubricating, and replacing worn components. Documentation of all maintenance activities can also help track the history and performance of the equipment, making it easier to identify any recurring issues.

Identifying Common Wear Parts

Understanding the components that frequently experience degradation is crucial for maintaining efficiency and performance. Regular inspection of these elements can prevent unexpected breakdowns and extend the lifespan of the machinery.

| Component | Description | Signs of Wear |

|---|---|---|

| Shovel | The primary tool for digging and moving soil. | Cracks, chips, or thinning edges. |

| Blade | Essential for cutting through tough surfaces. | Worn down surface, irregular edges. |

| Fasteners | Secures various components together. | Looseness, rust, or visible damage. |

| Bearings | Facilitates smooth movement of moving parts. | Unusual noise, rough rotation. |

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers several significant advantages that enhance the performance and longevity of machinery. These components are designed specifically for compatibility and optimal functioning within a particular system, ensuring a seamless integration that aftermarket alternatives may not provide.

- Quality Assurance: OEM components are subject to rigorous testing and quality control standards, ensuring they meet high performance and durability requirements.

- Exact Fit: These components are crafted to fit perfectly with the existing machinery, reducing the risk of installation issues and operational problems.

- Extended Lifespan: Using manufacturer-recommended components can lead to improved lifespan of the machinery, minimizing the frequency of replacements.

- Warranty Protection: Many warranties are maintained when using original components, protecting your investment and providing peace of mind.

- Enhanced Performance: OEM components are engineered to work optimally with the equipment, ensuring consistent performance under various conditions.

Choosing original components ultimately supports the overall health of the machinery and contributes to efficient operations, making it a wise decision for maintenance and repair needs.

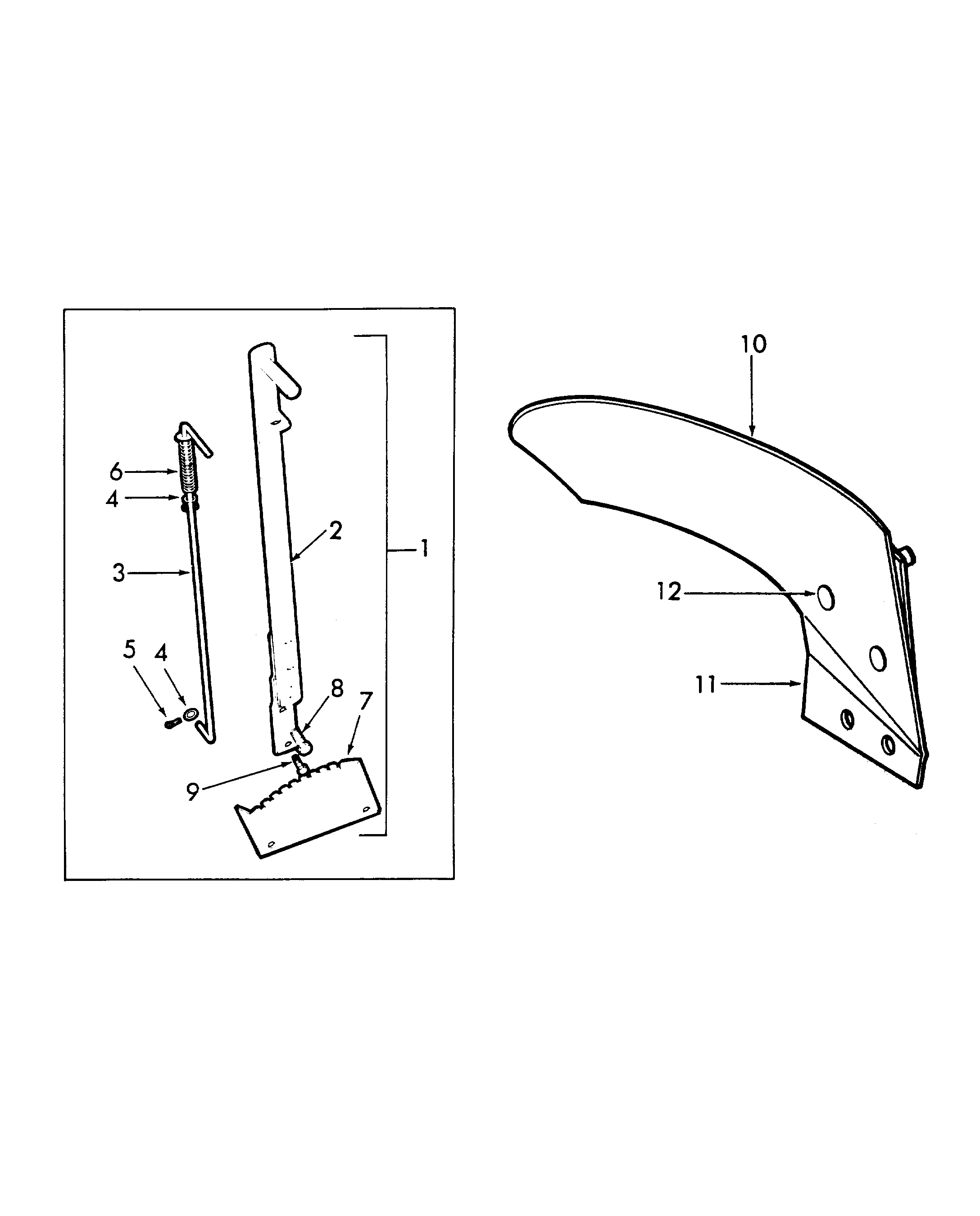

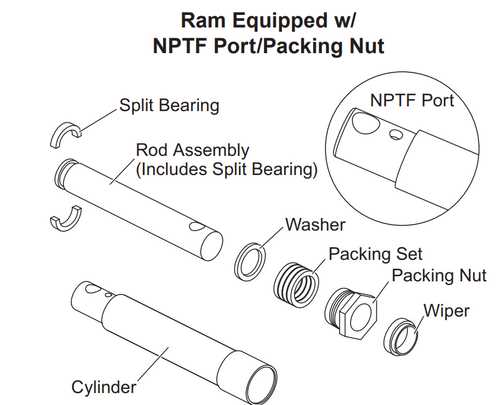

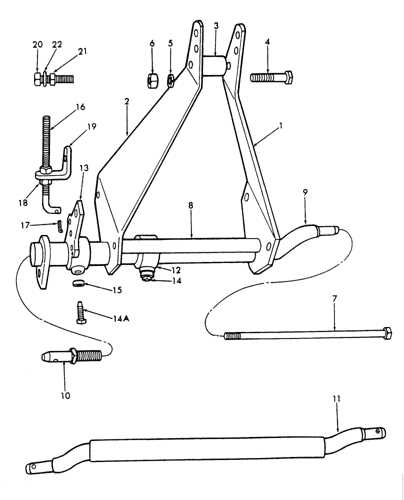

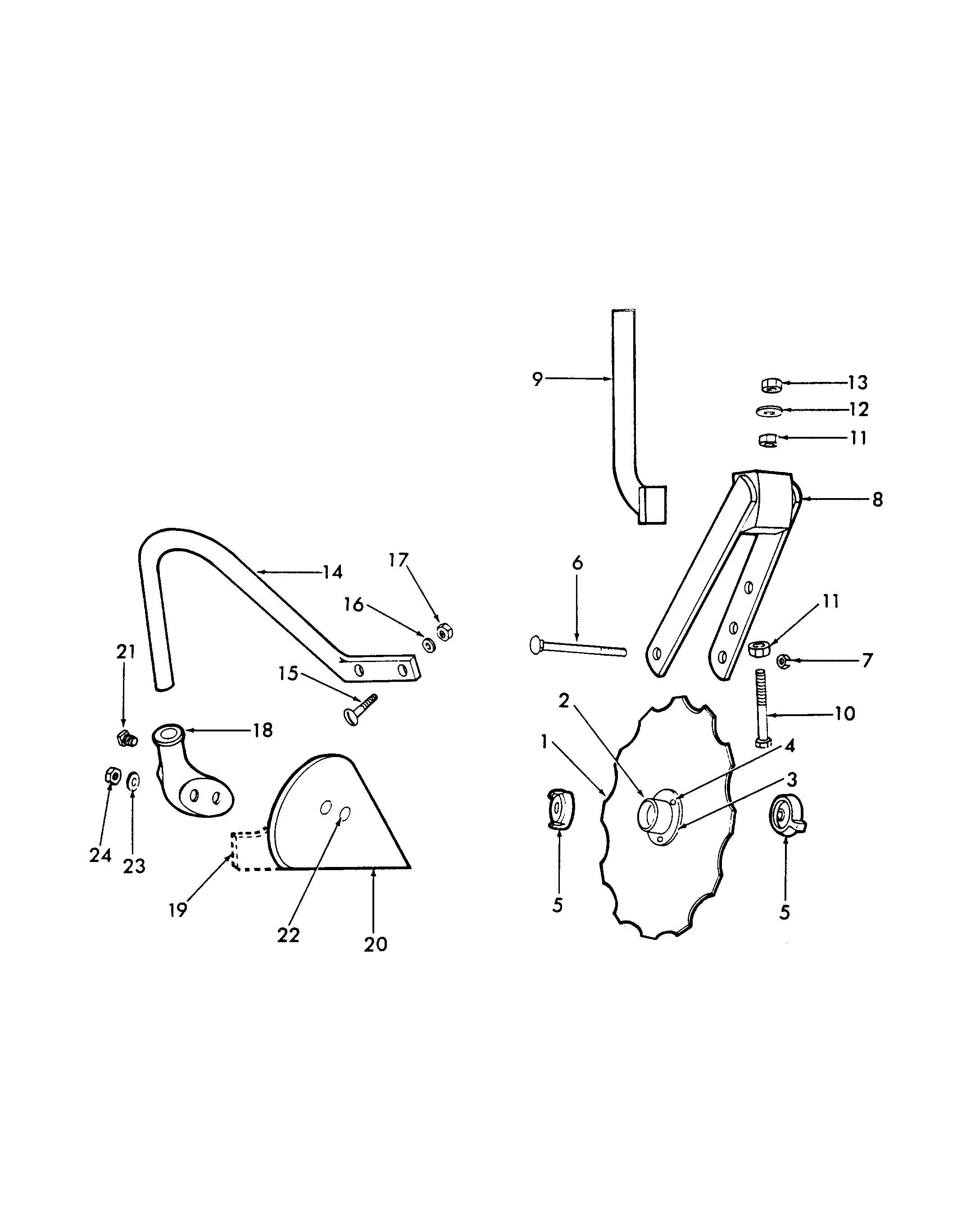

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repairs. This guide will help you navigate through these illustrations, allowing you to identify various elements and their relationships. By familiarizing yourself with the layout, you can enhance your troubleshooting skills and streamline your repair processes.

Key Components of the Illustration

Typically, these visual guides include a variety of symbols and notations that indicate different pieces. Familiarize yourself with the legend or key, which usually explains what each symbol represents. Numbers often correlate with a list of items, making it easier to locate specific elements. Additionally, look for arrows or lines that connect parts, as they indicate the arrangement or assembly order.

Interpreting Connections and Relationships

Beyond identifying individual components, understanding how they fit together is crucial. Pay attention to the orientation and positioning in the illustration; this information can clarify how each part interacts with others. Recognizing these connections will aid you in assembling or disassembling the entire system efficiently.

Troubleshooting Common Issues

When operating agricultural equipment, encountering difficulties can be frustrating. Understanding common problems and their potential solutions is essential for maintaining efficiency and effectiveness in the field. This section aims to guide users through typical malfunctions, helping to pinpoint the source of the issue and offering practical remedies.

1. Uneven Performance: If the implement is not operating uniformly, check for worn components or improper adjustments. Ensure all settings are calibrated correctly and that any attachments are securely fastened.

2. Hydraulic Failures: Low fluid levels or leaks can lead to inadequate power. Inspect hydraulic lines for signs of wear or damage and verify that fluid levels are optimal.

3. Steering Issues: Difficulty in steering may indicate mechanical wear or alignment problems. Regularly inspect the steering linkage for damage and ensure proper lubrication is applied.

4. Noise Problems: Unusual sounds often signal mechanical issues. Identify the source of the noise by examining gears and bearings for wear, and address any irregularities promptly.

5. Electrical Malfunctions: If electrical components fail, check for loose connections or blown fuses. A systematic inspection of the wiring can help isolate the problem.

Upgrading Your Plow System

Enhancing your agricultural equipment can significantly improve efficiency and effectiveness during fieldwork. By integrating advanced components, you can optimize performance, reduce wear and tear, and ensure that your machinery operates at its best in various conditions.

Benefits of Modern Components

Investing in new technology offers numerous advantages, including improved durability, increased productivity, and enhanced versatility. Upgraded elements can provide better adaptability to different soil types and weather conditions, making your tasks easier and more efficient.

Essential Upgrades to Consider

When planning enhancements, focus on components that will yield the most significant improvements. Below is a table outlining some key upgrades to consider:

| Upgrade Type | Description | Benefits |

|---|---|---|

| Blade Materials | Switching to high-strength alloys or composite materials | Increased durability and longer service life |

| Height Adjustment Mechanisms | Installing automatic height control systems | Improved precision and reduced operator fatigue |

| Attachment Systems | Using quick-connect attachments for versatility | Faster swaps between implements and increased functionality |

By carefully selecting and implementing these upgrades, you can ensure your equipment meets the demands of modern agriculture, ultimately leading to more successful operations and greater yields.

Resources for Parts and Support

Finding reliable sources for components and assistance can significantly enhance the maintenance and functionality of your equipment. Whether you are looking for specific items or seeking expert guidance, a variety of options are available to ensure you have what you need.

Here are some valuable resources to consider:

- Online Retailers:

- Many e-commerce platforms offer a wide range of components and accessories.

- Specialized websites focus on agricultural machinery and related tools.

- Manufacturer Websites:

- Official sites often provide comprehensive catalogs of available items.

- Access to technical support and warranty information is typically available.

- Local Dealers:

- Authorized dealers can offer personalized assistance and expert advice.

- They may also have exclusive deals on specific items.

- Forums and Community Groups:

- Online communities can be great for sharing experiences and tips.

- Members often exchange information about sourcing hard-to-find components.

- Repair Manuals and Guides:

- Access to detailed guides can aid in the identification of necessary components.

- These resources often include troubleshooting tips and maintenance advice.

Utilizing these resources can help streamline your search for components and support, ensuring your equipment remains in optimal condition.