In the realm of machinery and appliances, the efficient circulation of air plays a critical role in maintaining optimal performance. This section aims to explore the intricate components that contribute to the functionality of these essential systems, providing insights into their design and operational mechanisms.

Every component has a purpose, and understanding their relationships enhances our knowledge of how airflow is managed. By examining the assembly and interaction of these elements, we can delve deeper into their significance in various applications, from household devices to industrial equipment.

Ultimately, grasping the layout and arrangement of these systems equips users with the knowledge to troubleshoot issues effectively and ensure longevity. This exploration not only fosters a deeper appreciation for engineering but also empowers individuals to make informed decisions regarding maintenance and upgrades.

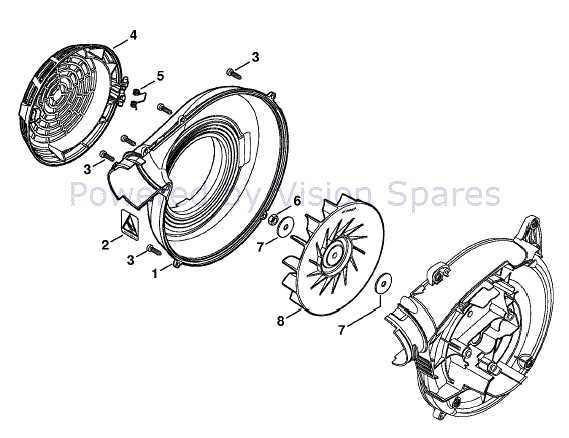

Understanding Fan Parts Diagrams

Grasping the components of a ventilation system is crucial for effective maintenance and troubleshooting. Such visual representations serve as a roadmap, allowing users to navigate through various elements, facilitating a deeper comprehension of functionality and interactions.

Importance of Visual Representation

Clarity is essential when dealing with complex machinery. Visual aids break down intricate structures into manageable sections, enabling quick identification of each segment’s role. This approach not only enhances understanding but also improves efficiency in repairs and upgrades.

Key Elements to Note

When examining these illustrations, focus on labels, connections, and assembly order. Recognizing how each element interacts within the system can ultimately lead to better performance and longevity of the equipment.

Importance of Accurate Diagrams

Precision in technical representations plays a crucial role in various industries. When components are illustrated clearly and accurately, it facilitates better understanding, efficient troubleshooting, and effective communication among professionals. This clarity is essential for maintaining high standards in production and maintenance processes.

Enhancing Understanding

Accurate representations aid technicians and engineers in grasping the relationships and functions of different elements. By providing a clear visual reference, these illustrations minimize confusion and ensure that everyone involved has a unified perspective on the system being examined.

Facilitating Maintenance and Repairs

When it comes to servicing equipment, having a reliable visual reference streamlines the repair process. Technicians can quickly identify necessary components, understand their arrangements, and execute repairs with confidence, reducing downtime and enhancing overall efficiency.

| Benefits of Accurate Representations | Description |

|---|---|

| Improved Clarity | Reduces ambiguity in understanding complex systems. |

| Efficient Communication | Facilitates discussions among team members and stakeholders. |

| Faster Troubleshooting | Enables quick identification of issues and solutions. |

| Better Training | Serves as an effective tool for educating new staff. |

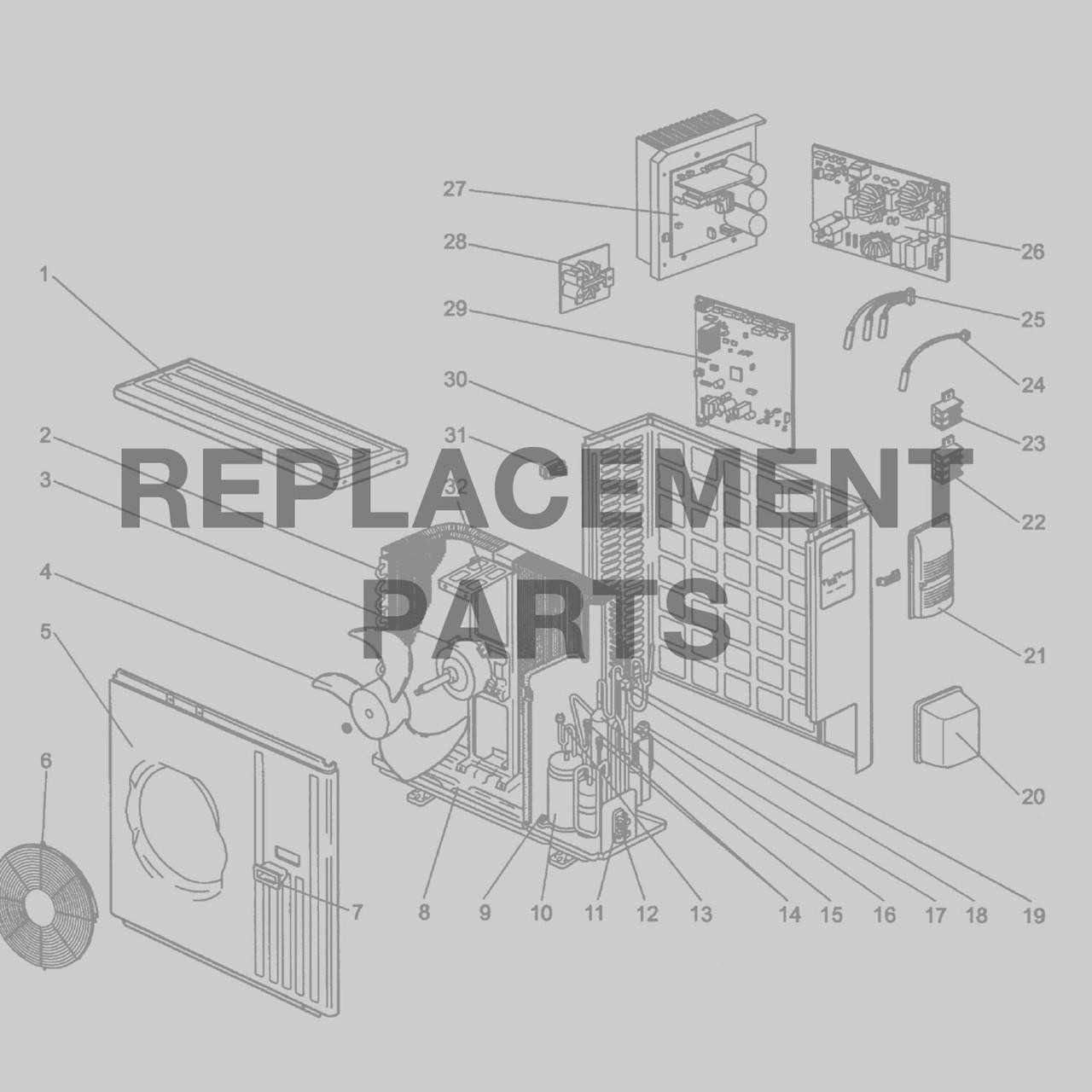

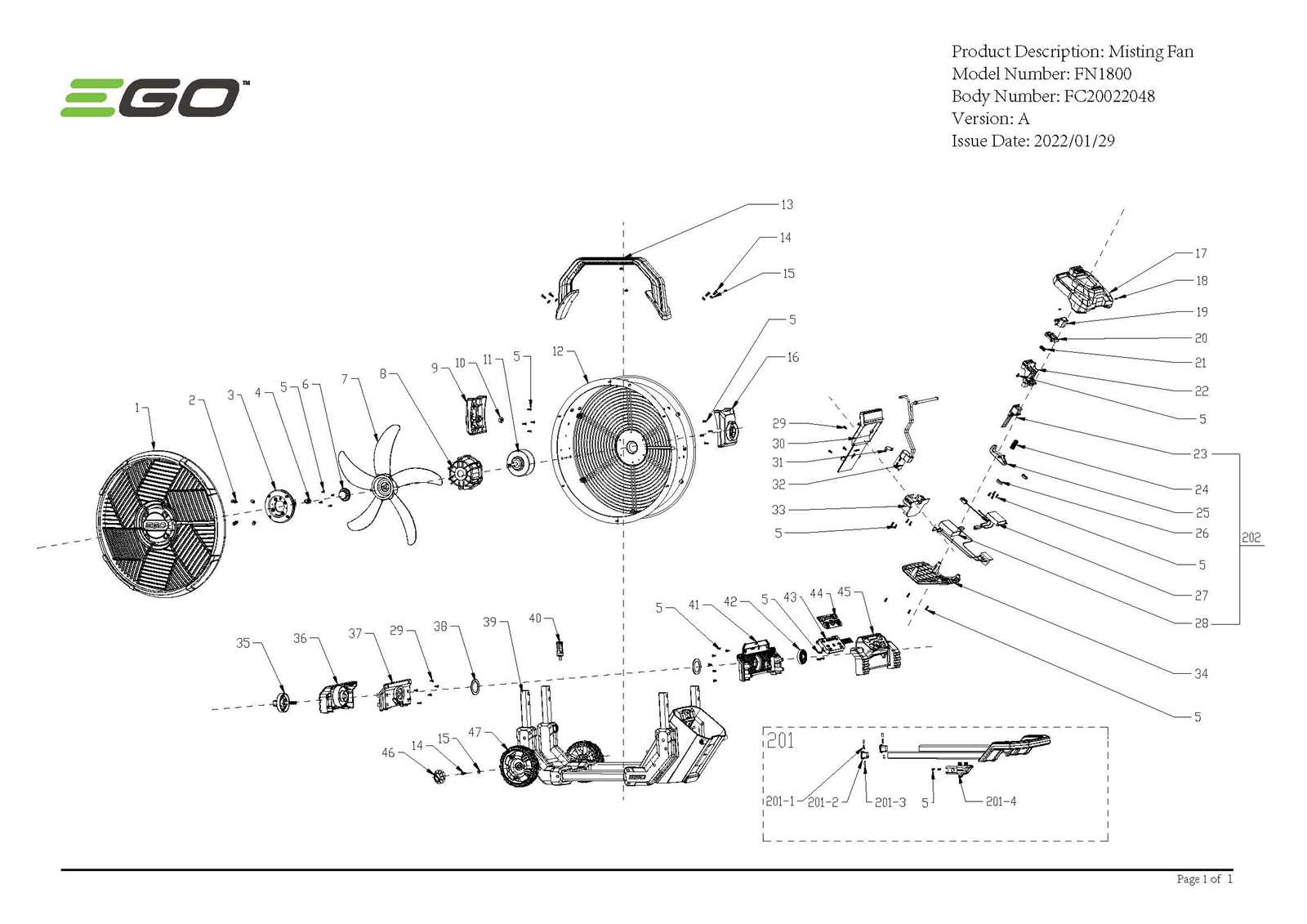

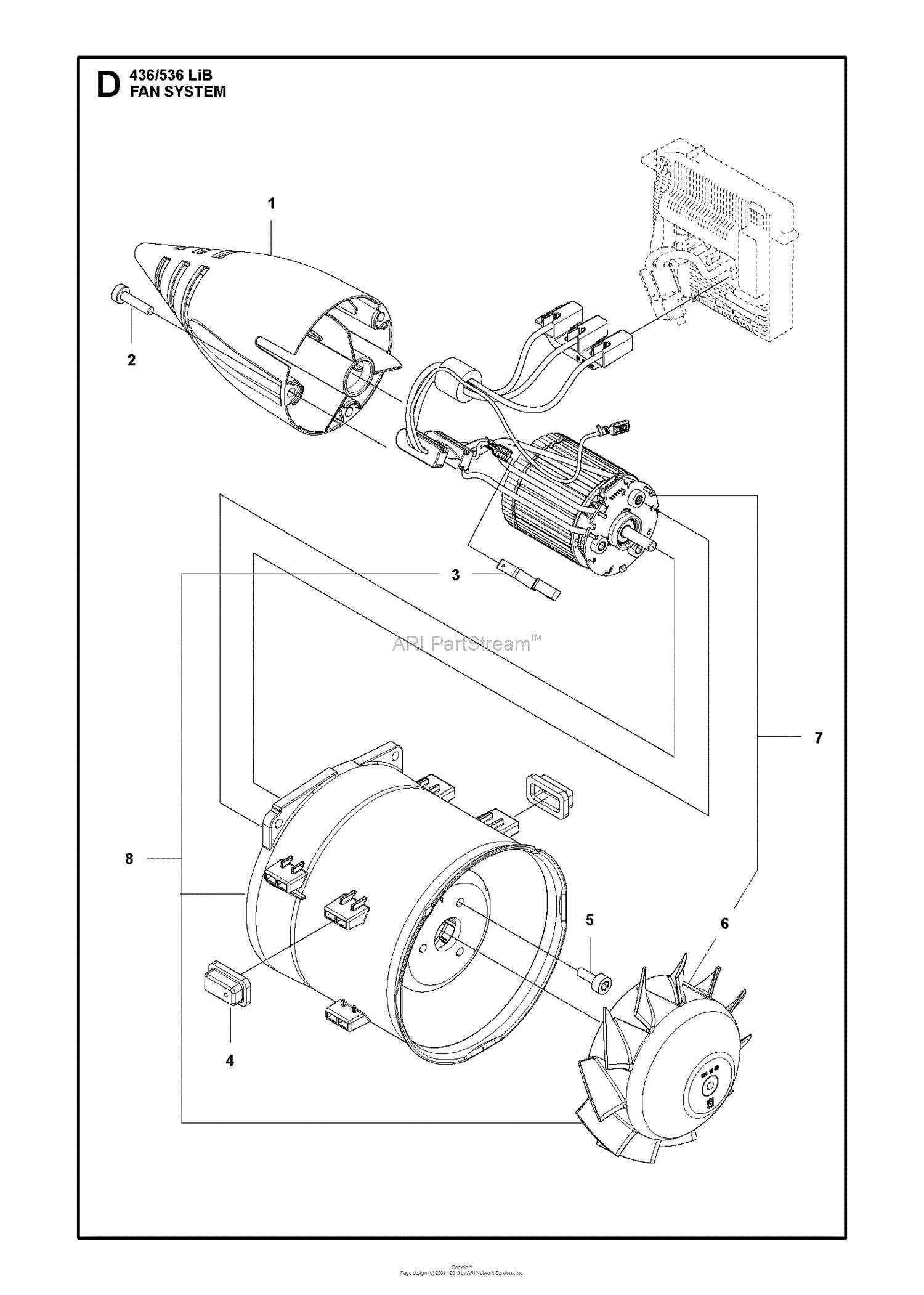

Common Components of Fan Systems

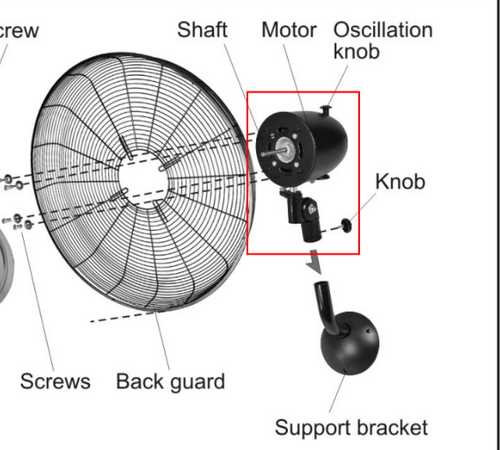

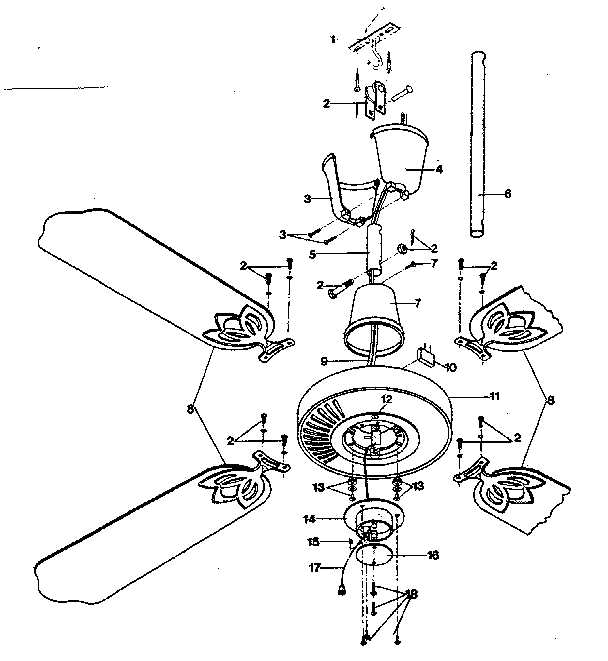

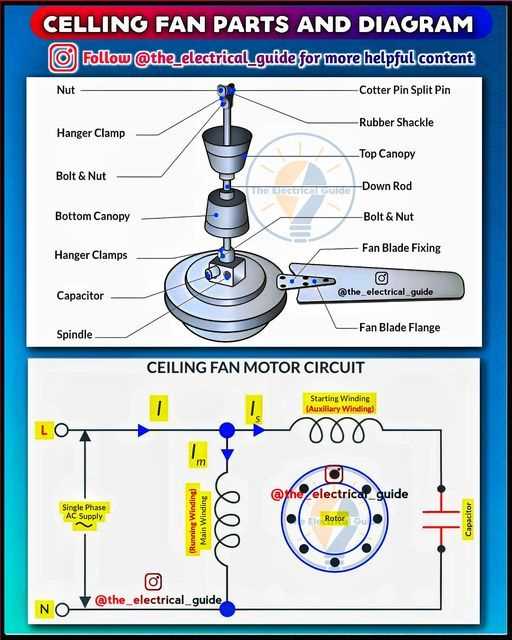

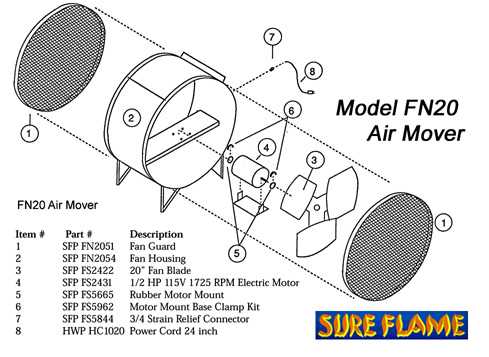

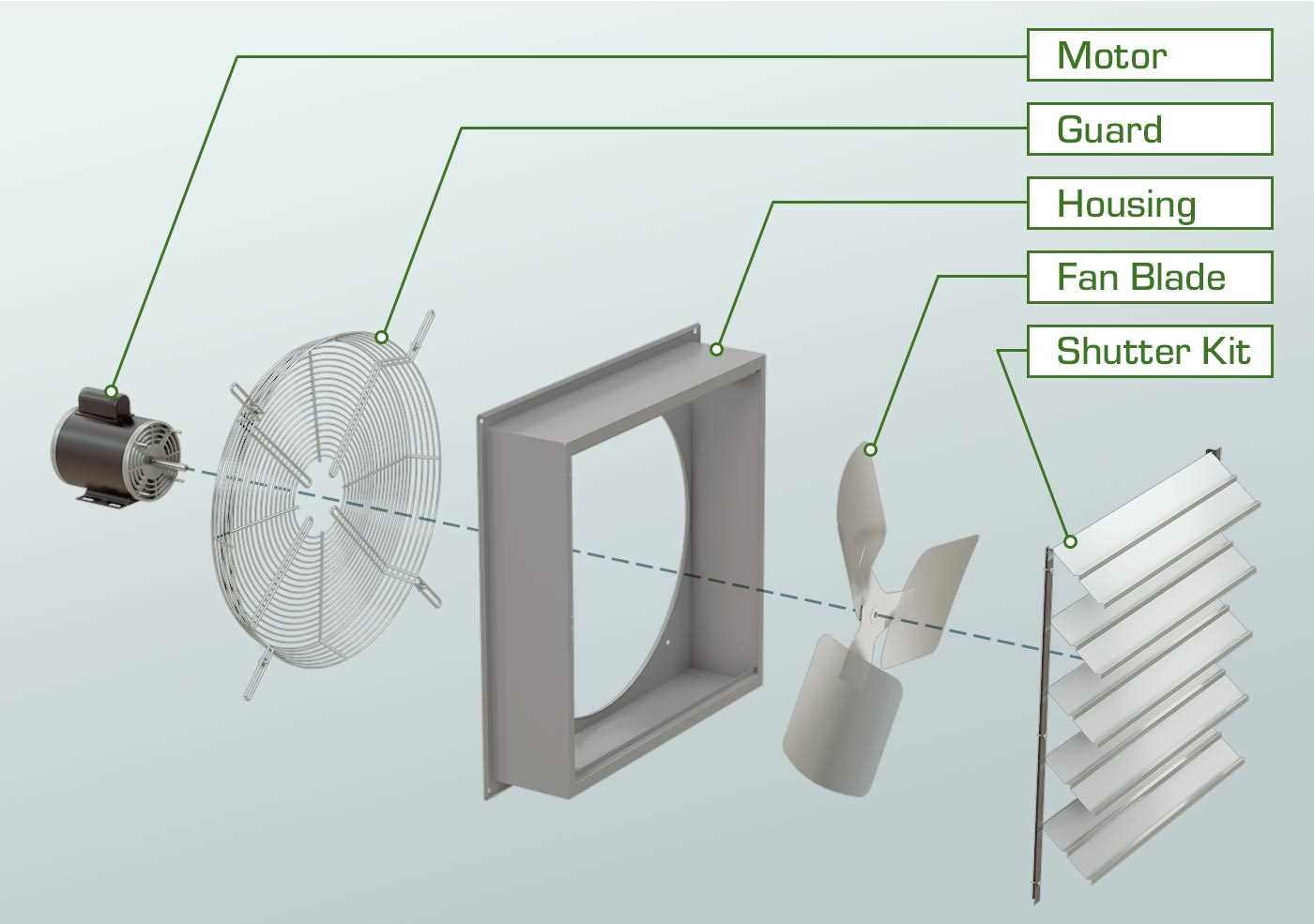

Understanding the essential elements that make up air circulation mechanisms is crucial for effective design and maintenance. These systems are composed of various components that work together to ensure optimal airflow and efficiency, each playing a specific role in the overall functionality.

Key Elements

The core components typically include motors, blades, housing, and control systems. The motor powers the mechanism, while the blades are designed to move air effectively. The housing protects the internal elements and directs airflow, whereas control systems regulate operation based on demand and environmental conditions.

Supportive Accessories

In addition to the primary components, several supportive accessories enhance performance. These may include dampers, filters, and speed controllers, which help optimize airflow, reduce noise, and improve energy efficiency, ultimately leading to a more effective system.

How to Read a Fan Diagram

Understanding technical illustrations is essential for effectively navigating and servicing equipment. These visual guides provide detailed representations, helping users identify components and their relationships. Here’s a structured approach to interpreting these visuals.

Begin by familiarizing yourself with the layout:

- Orientation: Note the overall orientation and scale, which can provide context for the representation.

- Labels: Pay close attention to the labels associated with each element. They often indicate specific functions or specifications.

- Symbols: Different shapes and icons are utilized to represent various components. Understanding these symbols is crucial.

Next, analyze the connections:

- Lines: Solid lines typically denote physical connections, while dashed lines may indicate optional or theoretical links.

- Arrows: Directional arrows indicate the flow of energy or air, guiding your understanding of movement within the system.

Lastly, cross-reference:

- Documentation: Always consult accompanying manuals or guides to confirm your interpretations.

- Expert Insight: If uncertain, seek advice from professionals or forums specializing in this field.

By applying these strategies, you’ll enhance your ability to decipher and utilize these technical illustrations effectively.

Types of Fan Designs Explained

In the realm of airflow mechanisms, various configurations serve distinct purposes, optimizing performance based on specific requirements. Understanding these variations is essential for selecting the most suitable option for a given application.

Centrifugal systems utilize a spinning impeller to draw air in and expel it at a right angle. This design is particularly effective for high-pressure applications, making it ideal for industrial uses where air must be moved through ductwork.

Axial designs, in contrast, move air parallel to the axis of the blades. This configuration is typically employed in situations requiring high volume flow rates but lower pressure, such as cooling systems and ventilation in residential and commercial settings.

Mixed-flow units combine elements of both centrifugal and axial types, offering a compromise between pressure and volume. These versatile models are often used in specialized applications, providing efficient airflow management without sacrificing performance.

Diaphragm styles are characterized by their unique operation, where a flexible membrane oscillates to create airflow. This design is commonly found in small-scale applications, such as electronics cooling and portable devices.

Each configuration has its strengths, making it crucial to analyze the specific needs of a project. By understanding these various designs, one can make informed decisions to enhance efficiency and effectiveness in airflow management.

Maintenance Tips for Fan Parts

Proper upkeep of mechanical devices is essential for ensuring their longevity and optimal performance. Regular care not only enhances functionality but also prevents unexpected breakdowns. Here are some practical tips to keep your equipment running smoothly.

- Regular Cleaning: Dust and debris can accumulate over time, affecting efficiency. Use a soft cloth or a brush to clean surfaces regularly.

- Check for Wear: Inspect components for signs of wear and tear. Look for frayed edges, cracks, or any irregularities that may require replacement.

- Lubrication: Apply appropriate lubricants to moving elements to reduce friction and wear. Follow manufacturer guidelines for the best results.

- Ensure Proper Alignment: Misalignment can lead to excessive noise and vibration. Regularly check and adjust as necessary to maintain balance.

Adopting these maintenance practices can significantly extend the life of your equipment, enhancing both safety and efficiency.

Identifying Faulty Components Easily

Recognizing defective elements within a system is crucial for maintaining optimal performance. A systematic approach can simplify the troubleshooting process, enabling efficient identification of issues.

To streamline the identification process, consider the following steps:

- Examine symptoms: Note any irregularities or unusual behavior.

- Utilize testing tools: Employ multimeters or diagnostic software to assess functionality.

- Check connections: Ensure all links are secure and free from corrosion or damage.

- Review specifications: Compare current performance against manufacturer guidelines.

By following these guidelines, individuals can delve into the troubleshooting process, ultimately enhancing the reliability of the system.

Applications of Fan Systems in Industry

In various sectors, the effective movement of air and gases plays a crucial role in optimizing processes and ensuring safety. The integration of these systems enhances operational efficiency and contributes to maintaining desired environmental conditions.

Key Industrial Applications

- Ventilation in manufacturing plants to improve air quality and worker comfort.

- Cooling systems in data centers to regulate temperature and prevent equipment overheating.

- Dust and fume extraction in workshops to ensure compliance with health regulations.

- Process drying in food and pharmaceutical industries to enhance product quality.

Benefits of Utilizing These Systems

- Increased energy efficiency through optimal airflow management.

- Improved safety by reducing the risk of fire and harmful gas accumulation.

- Enhanced productivity due to a better working environment.

- Flexibility in design to meet specific operational needs.

Resources for Fan Parts Information

Understanding the components of air circulation devices is essential for effective maintenance and repair. This section provides a variety of sources to help enthusiasts and professionals alike find detailed information about these essential mechanical elements.

| Resource Type | Description | Link |

|---|---|---|

| Manufacturer Websites | Official sites often provide detailed specifications and manuals. | Visit |

| Online Forums | Communities where users share experiences and troubleshooting tips. | Visit |

| DIY Guides | Step-by-step instructions for assembly and repairs. | Visit |

| Technical Journals | Academic papers and articles covering innovations and studies. | Visit |

| Retailers | Online shops that provide descriptions and compatibility information. | Visit |