The intricate machinery involved in maintaining lush greenery requires a clear understanding of its various elements. Knowing how each component interacts not only enhances efficiency but also simplifies the maintenance process. This section aims to shed light on the essential parts of these machines, providing clarity for both seasoned users and newcomers alike.

By delving into the layout and functionality of different components, users can gain valuable insights into the operation of their equipment. This knowledge is crucial for troubleshooting issues and ensuring optimal performance. Whether it’s for routine upkeep or specific repairs, understanding the arrangement of parts contributes significantly to effective management.

Familiarizing oneself with the structural design facilitates better decision-making when it comes to replacements and upgrades. With a solid grasp of the various elements at play, users can approach their equipment with confidence, ensuring longevity and reliability. The exploration of these crucial components lays the groundwork for proficient operation and maintenance.

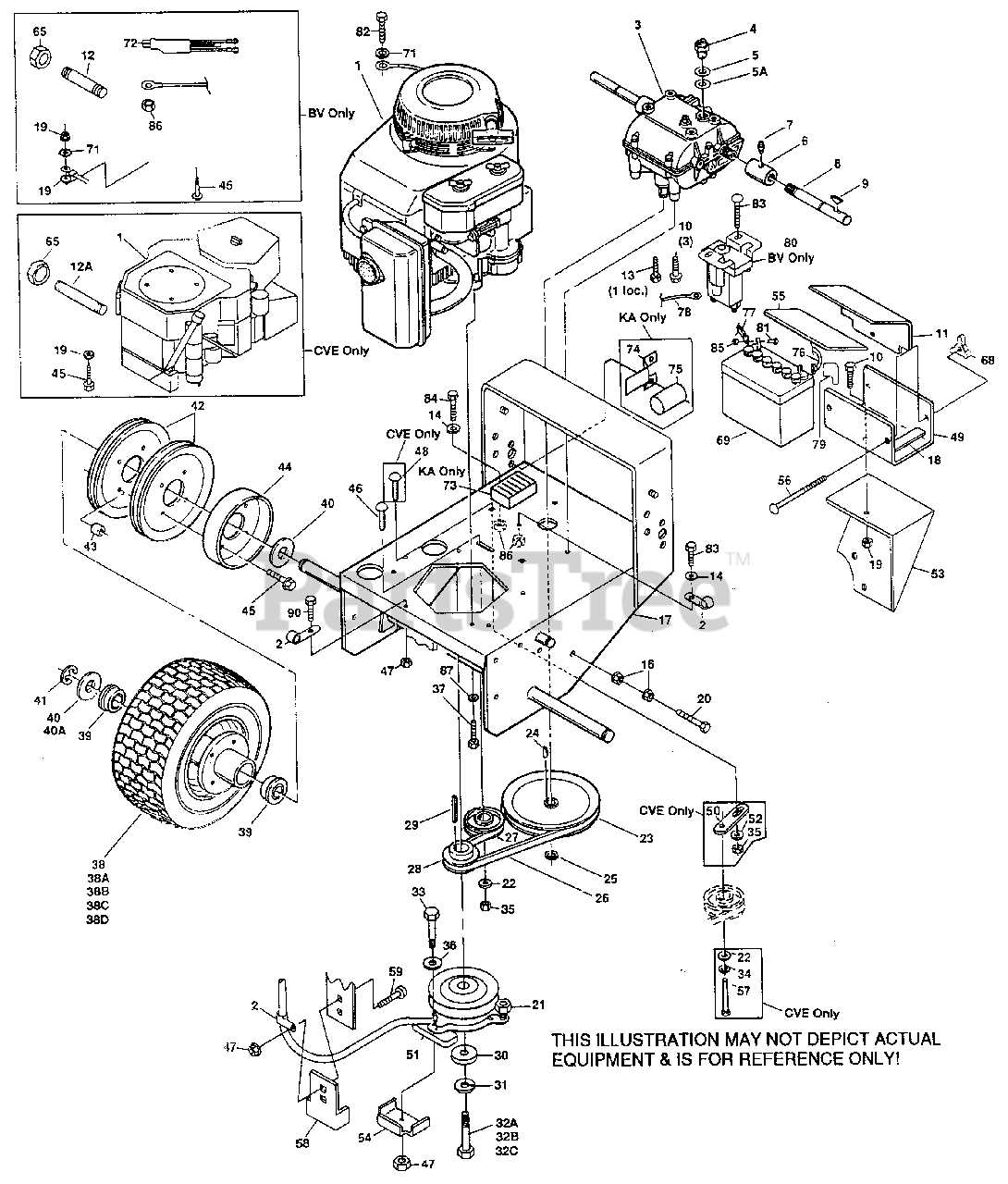

Understanding Encore Mower Parts

This section aims to explore the essential components of a lawn care machine, providing insights into their functions and importance. Recognizing these elements enhances maintenance and troubleshooting, ensuring optimal performance and longevity of the equipment.

Main Components

- Engine: The power source, responsible for driving the entire system.

- Deck: The housing that protects and supports the cutting mechanism.

- Blades: Sharp elements that perform the cutting task, crucial for achieving an even trim.

- Wheels: Facilitate movement and maneuverability across various terrains.

Maintenance Tips

- Regularly check the oil levels to ensure the engine runs smoothly.

- Inspect and sharpen the cutting blades for effective performance.

- Clean the deck to prevent grass buildup, which can affect cutting efficiency.

- Examine the wheels for wear and tear, replacing them as needed.

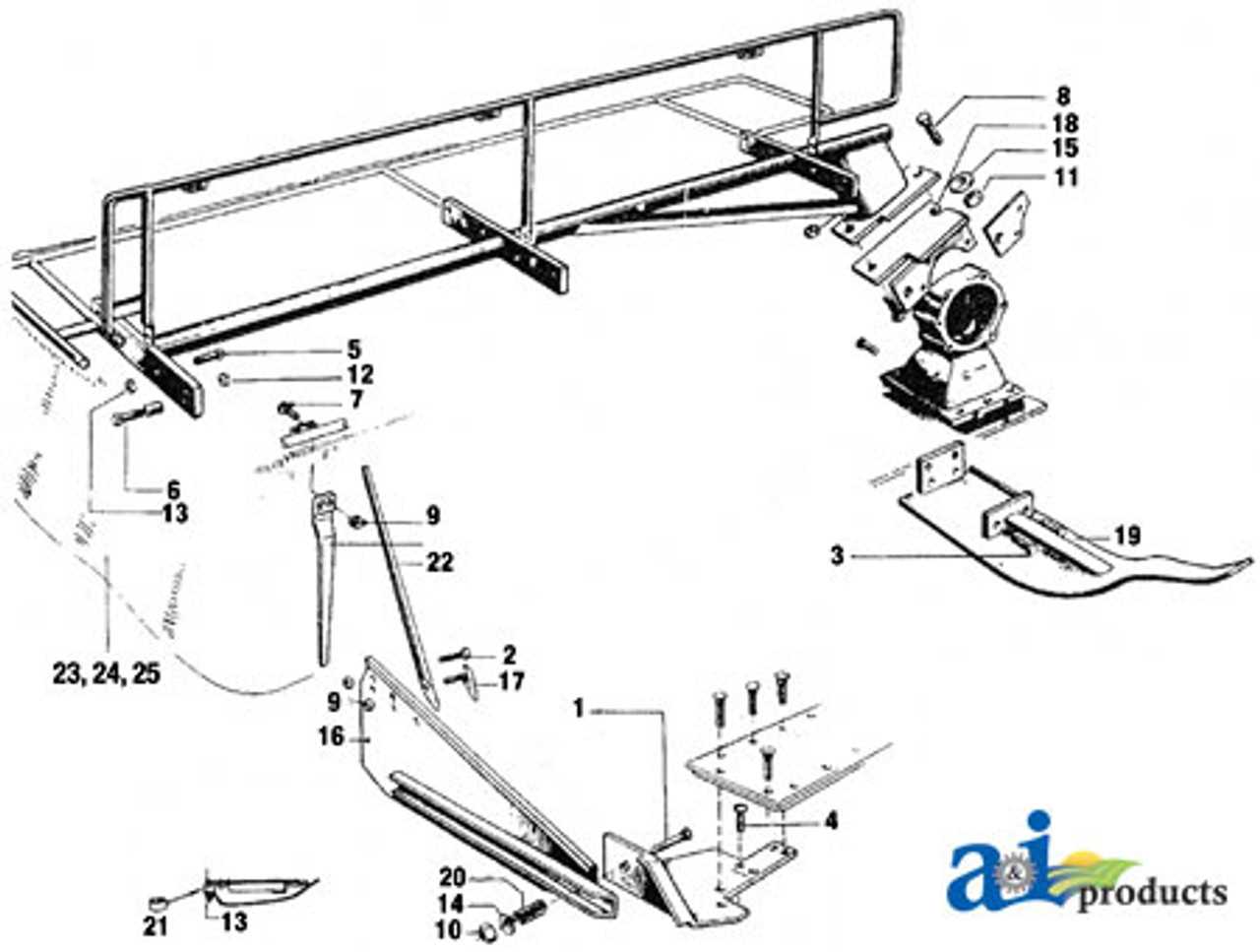

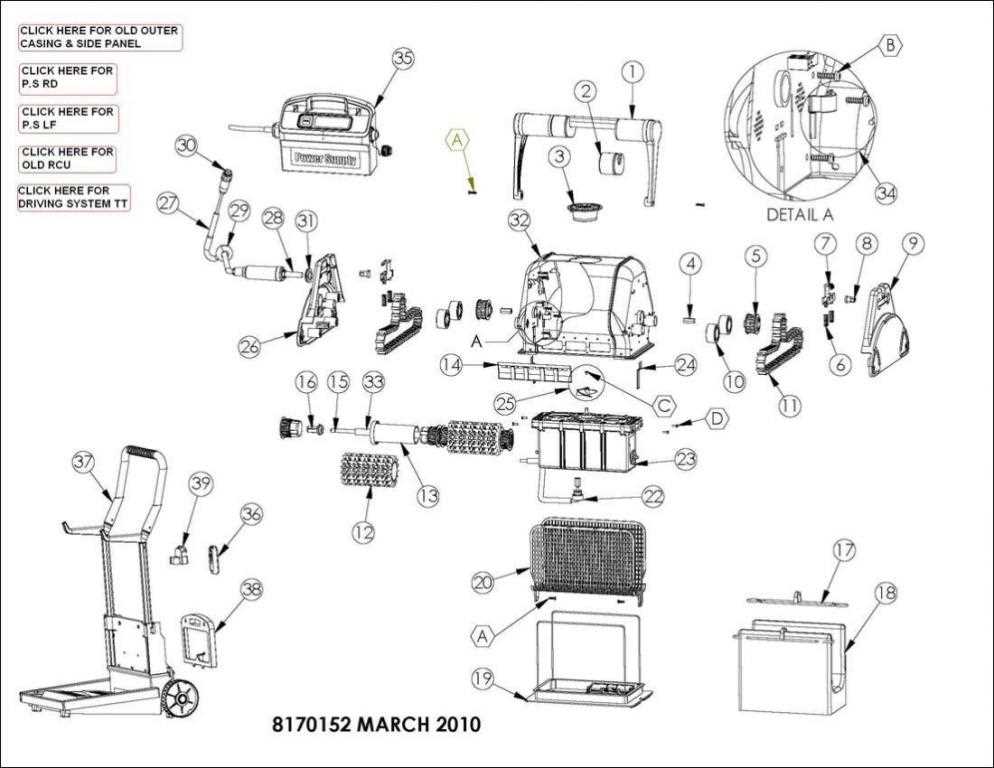

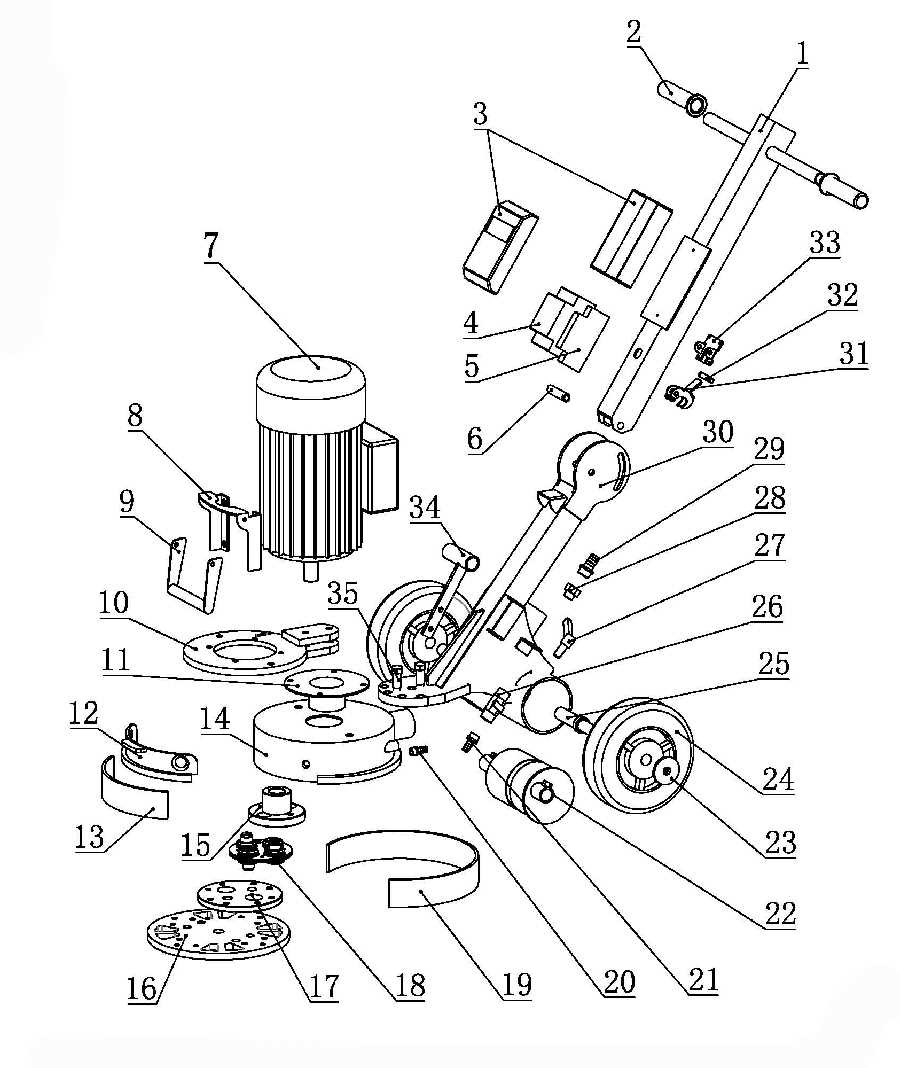

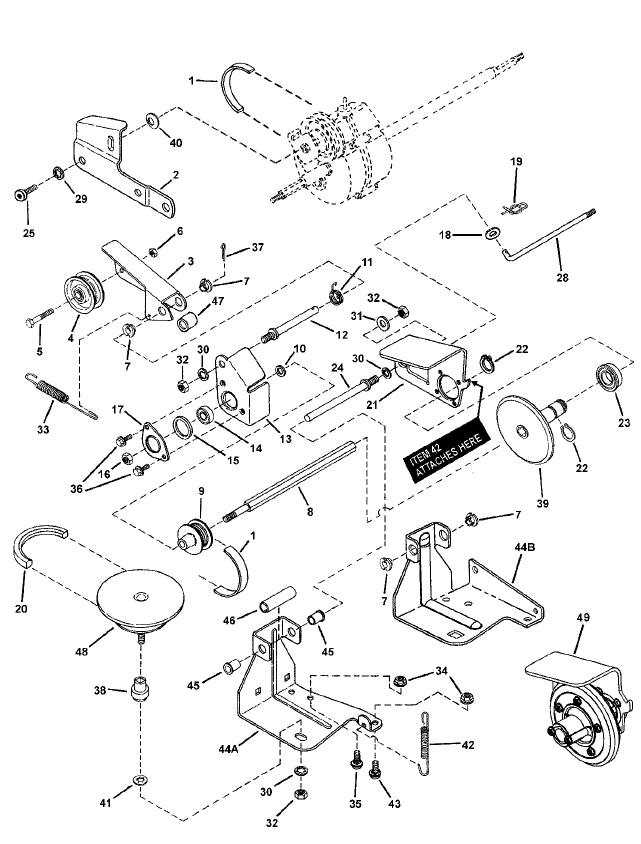

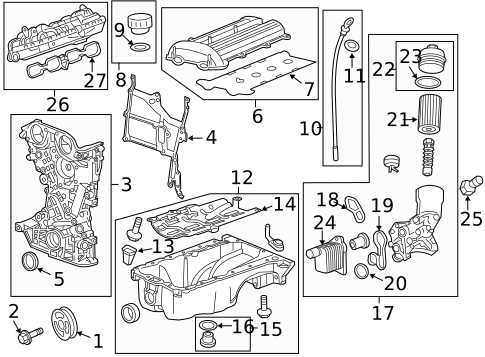

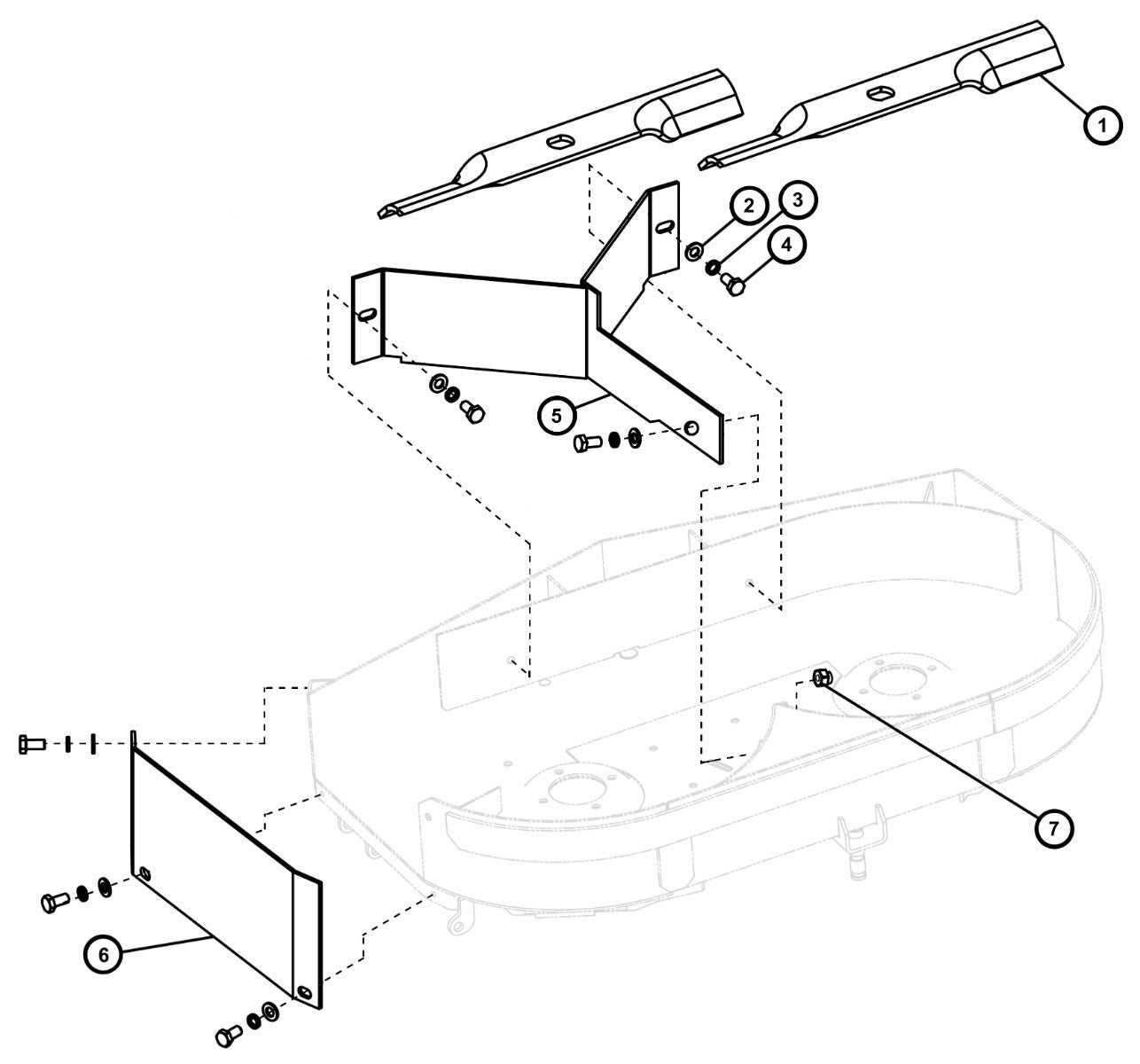

Importance of Accurate Diagrams

Clear and precise visual representations play a crucial role in understanding and maintaining equipment efficiently. Accurate diagrams serve as essential tools for technicians and users alike, providing detailed insights into the intricate workings of machinery.

These diagrams not only enhance comprehension but also facilitate quicker troubleshooting and part identification. They enable precise communication between stakeholders involved in maintenance and repairs, ensuring that tasks are performed with precision and effectiveness.

By relying on well-constructed diagrams, individuals can navigate through complex assemblies with confidence, minimizing errors and optimizing the overall efficiency of equipment servicing. Therefore, the meticulous creation and use of accurate diagrams are paramount in achieving operational excellence and prolonging the lifespan of machinery.

Common Issues with Mower Components

Maintenance of outdoor equipment often involves identifying wear and tear in essential mechanisms. Regular use, environmental factors, and improper handling can lead to malfunctions that reduce performance and shorten the lifespan of individual elements.

Blades may become dull or chipped, impacting the quality of the cut. Exposure to rocks and debris can accelerate this process, requiring timely sharpening or replacement to maintain functionality.

Belts are prone to stretching or cracking over time. A loose belt can slip, leading to inefficient power transmission, while a broken one can halt operation entirely. Inspecting them periodically helps avoid unexpected breakdowns.

Another frequent issue is with wheels and bearings. Dirt buildup and rust can hinder movement, making it harder to maneuver the equipment smoothly. Cleaning and lubricating these areas ensures effortless operation and extends their service life.

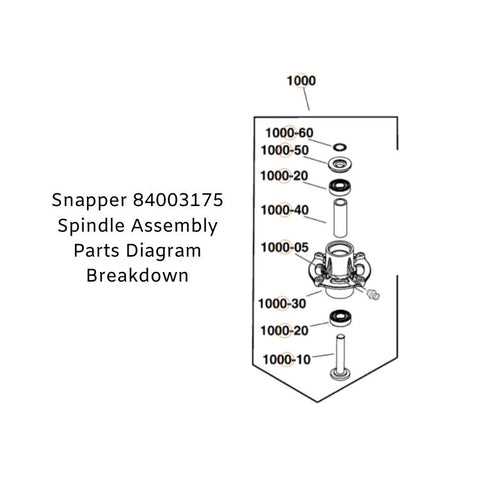

Lastly, spindles

How to Read Parts Diagrams

Understanding technical illustrations helps in identifying individual components and their relationships within a system. These visual tools provide a clear overview of how different elements fit together, ensuring smooth assembly, maintenance, or troubleshooting.

Key Symbols and Indicators

- Numbers and Labels: Each element is usually marked with a unique identifier, aiding quick reference in manuals or spare lists.

- Arrows and Lines: Arrows indicate movement or direction, while lines connect related components.

- Shading and Outlines: Shaded areas often represent groups or sections that need to be handled together.

Steps to Interpret the Layout

- Identify the legend or key to understand symbols used across the diagram.

- Locate the main sections or assemblies, often marked in larger or bolder text.

Essential Tools for Mower Maintenance

Proper upkeep of lawn equipment requires specific tools that ensure smooth operation and longevity. Routine care helps prevent wear, improves efficiency, and reduces the risk of unexpected breakdowns. Having the right instruments on hand allows for timely inspections and adjustments.

A set of wrenches in various sizes is vital for tightening bolts and securing components. Screwdrivers with both flat and Phillips heads come in handy for disassembling smaller sections during inspections. Additionally, pliers are useful for handling cables or hard-to-reach elements that need realignment.

Lubricants and cleaning agents play a crucial role in minimizing friction and keeping moving parts in good condition. A grease gun simplifies the application of lubrication in narrow areas. Brushes and compressed air are effective for clearing debris from critical sections.

Safety is paramount, so wearing gloves and protective glasses prevents injuries during maintenance. For blade sharpening, a metal file or grinder ensures precise edge restoration, promoting efficient performance. Lastly, a well-organized toolbox keeps everything easily accessible for future servicing needs.

Replacing Worn-Out Mower Parts

Over time, essential components of outdoor machinery experience natural wear and tear, leading to reduced performance. Timely replacement ensures the equipment remains reliable and efficient, preventing more significant mechanical issues down the road.

Identifying Key Areas for Replacement

Regular inspection helps detect signs of deterioration, such as cracked belts, dull blades, or loose fasteners. Paying close attention to these elements ensures smooth operation and minimizes unexpected breakdowns during use.

Choosing Compatible Components

When selecting replacements, it is crucial to find options that match the original specifications to maintain optimal functionality. Using high-quality substitutes extends the equipment’s lifespan and enhances overall performance. Additionally, proper installation ensures that each element works in harmony with the rest of the system.

Where to Find OEM Parts

Finding high-quality original components ensures the optimal performance and longevity of equipment. Choosing certified replacements minimizes the risk of compatibility issues and helps maintain warranties. It’s crucial to explore reliable sources that guarantee genuine products to avoid potential malfunctions.

Authorized Distributors

Certified suppliers offer direct access to original components from manufacturers, often with technical support and guarantees. These outlets specialize in authentic solutions tailored for specific models, ensuring seamless integration during repairs or replacements.

Online Marketplaces and Manufacturer Sites

Many original components are available through official online platforms, providing convenience and direct shipping options. Some manufacturers also offer part lookup tools, making it easy to identify and order the right item without intermediaries.

Tips for Efficient Lawn Care

Maintaining a lush and healthy lawn requires thoughtful planning and consistent upkeep. Proper care ensures not only visual appeal but also promotes the growth of resilient grass that can withstand changing weather conditions.

Watering at the Right Time is essential to prevent evaporation and ensure moisture reaches the roots. Early mornings are ideal for irrigation, as cooler temperatures reduce water loss.

Regular trimming encourages even growth and helps avoid patches. Adjusting the blade height seasonally ensures the grass remains at an optimal length, promoting deeper root development.

It’s also important to rotate tasks such as fertilizing, aerating, and seeding. These activities improve soil quality and ensure uniform coverage, keeping the lawn healthy year-round.

Finally, being mindful of seasonal needs ensures the lawn remains vibrant. Shifting techniques based on the weather and grass type helps maintain consistency and prevent issues like overgrowth or dehydration.

Preventative Maintenance for Longevity

Proactive care ensures that mechanical tools remain reliable over time. Regular inspections and upkeep reduce unexpected breakdowns, improving performance and extending service life.

Key Areas to Monitor

- Inspect belts and fasteners for wear or looseness.

- Lubricate moving components to prevent friction damage.

- Monitor fluid levels, such as oils, to maintain smooth operation.

Routine Tasks for Optimal Performance

- Clean filters to avoid blockages that impair functionality.

- Check blades or cutting mechanisms regularly for sharpness.

- Store equipment in a dry place to prevent rust and corrosion.

Following a consistent maintenance schedule reduces repair costs and maximizes operational efficiency over the years.