When it comes to machinery, grasping the arrangement and functionality of various elements is crucial for effective maintenance and operation. Each component plays a vital role in ensuring the overall system performs efficiently. By visualizing how these pieces interconnect, users can enhance their understanding and troubleshooting capabilities.

Detailed illustrations showcasing the configuration of essential elements can serve as a valuable reference for both beginners and seasoned professionals. Such resources not only simplify complex systems but also aid in identifying potential issues before they escalate. Familiarity with the structure facilitates informed decisions during repairs or upgrades.

Moreover, comprehending the layout of these mechanisms can significantly extend their lifespan. By recognizing the purpose of each element, individuals can implement preventative measures that minimize wear and tear. This knowledge empowers users to take proactive steps, ultimately leading to improved performance and reliability.

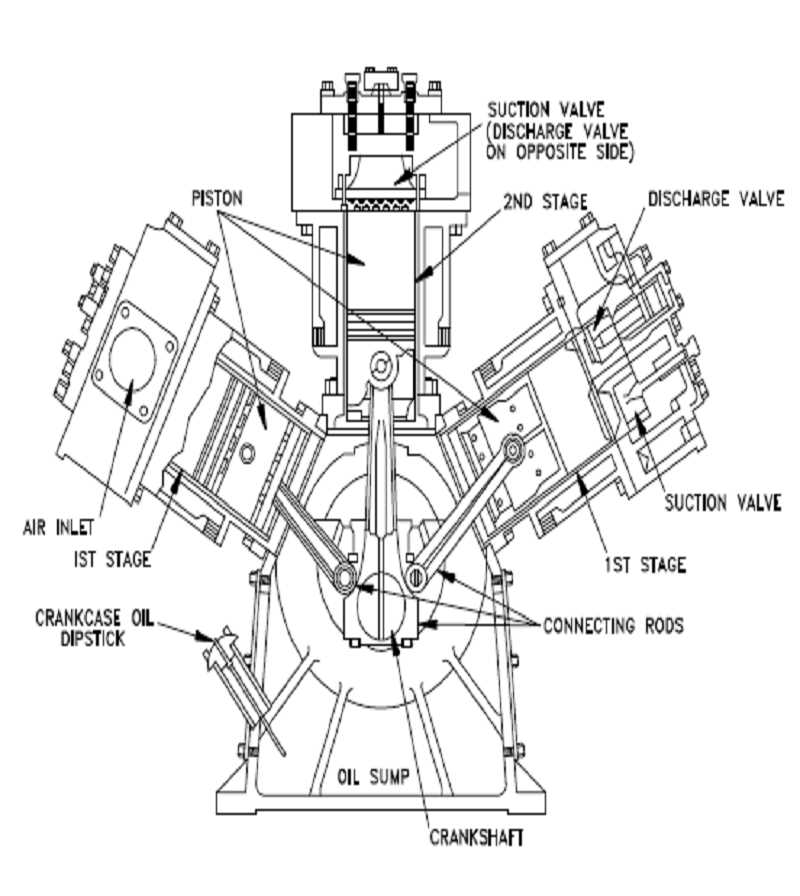

This section will provide a comprehensive overview of the essential elements that make up a specific mechanical device designed for compressing gases. Understanding these components is crucial for effective maintenance and troubleshooting. Each part plays a vital role in the overall functionality and efficiency of the equipment.

Key Elements of the Mechanism

- Power Source: The primary energy supply that drives the system.

- Pressure Vessel: The container that holds the compressed gas for various applications.

- Regulating Device: Ensures the pressure remains within safe limits during operation.

- Connecting Tubes: Facilitate the movement of gases between different components.

- Control Panel: The interface for operating and monitoring the system.

Benefits of Understanding Each Component

- Enhanced Maintenance: Knowing each part aids in regular upkeep and prolongs the equipment’s lifespan.

- Effective Troubleshooting: Identifying issues becomes easier when one understands the function of each element.

- Improved Performance: Regularly checking components ensures optimal operation and energy efficiency.

- Safety Assurance: Familiarity with the structure helps in recognizing potential hazards and implementing safety measures.

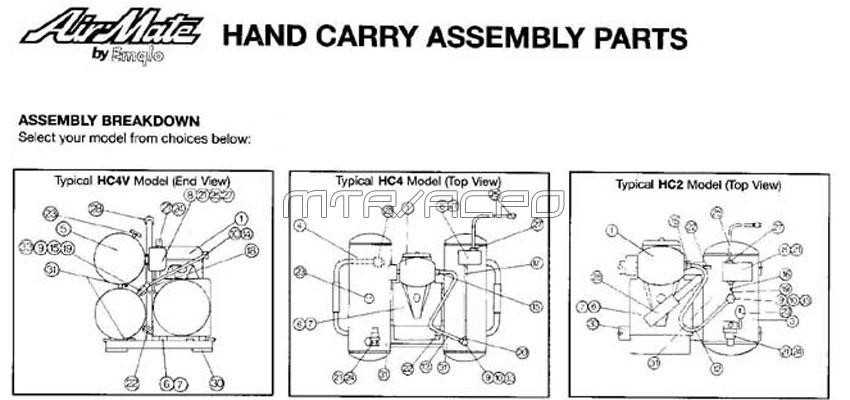

Key Parts of Emglo Compressors

This section delves into the essential components that contribute to the functionality of these machines. Understanding these elements is crucial for maintaining optimal performance and ensuring longevity.

Core Components Overview

Various critical elements work in unison to facilitate effective operation. Each part plays a unique role, impacting efficiency and reliability.

| Component | Function |

|---|---|

| Pump Assembly | Responsible for drawing in and compressing the gas, raising its pressure. |

| Pressure Switch | Monitors and controls the pressure levels, ensuring safety and efficiency. |

| Motor | Drives the pump, converting electrical energy into mechanical force. |

| Tank | Stores the compressed gas, providing a reservoir for consistent pressure delivery. |

Maintenance Tips

Regular checks and timely replacements of these key elements are vital for maintaining peak performance. Routine inspections can prevent unexpected breakdowns and enhance durability.

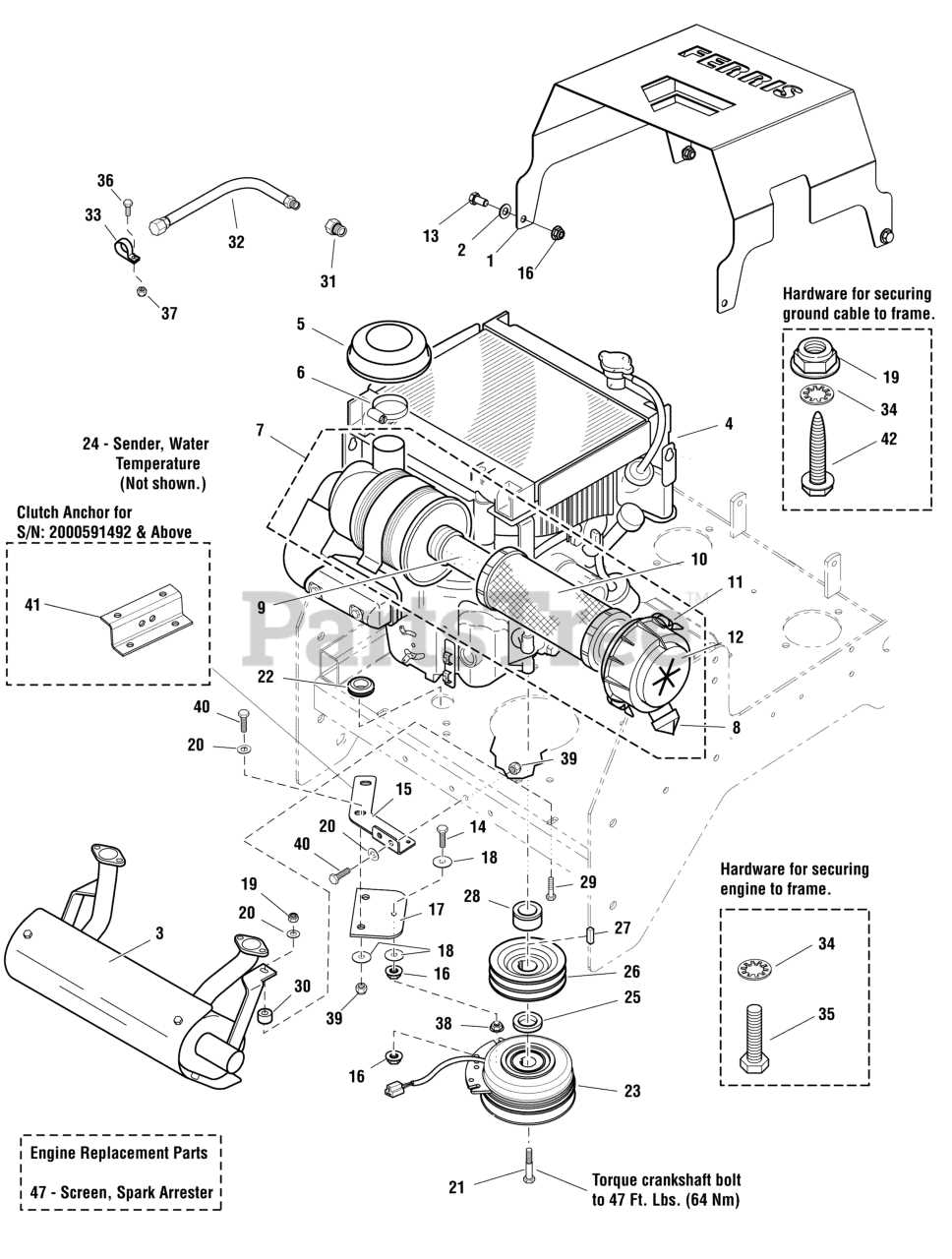

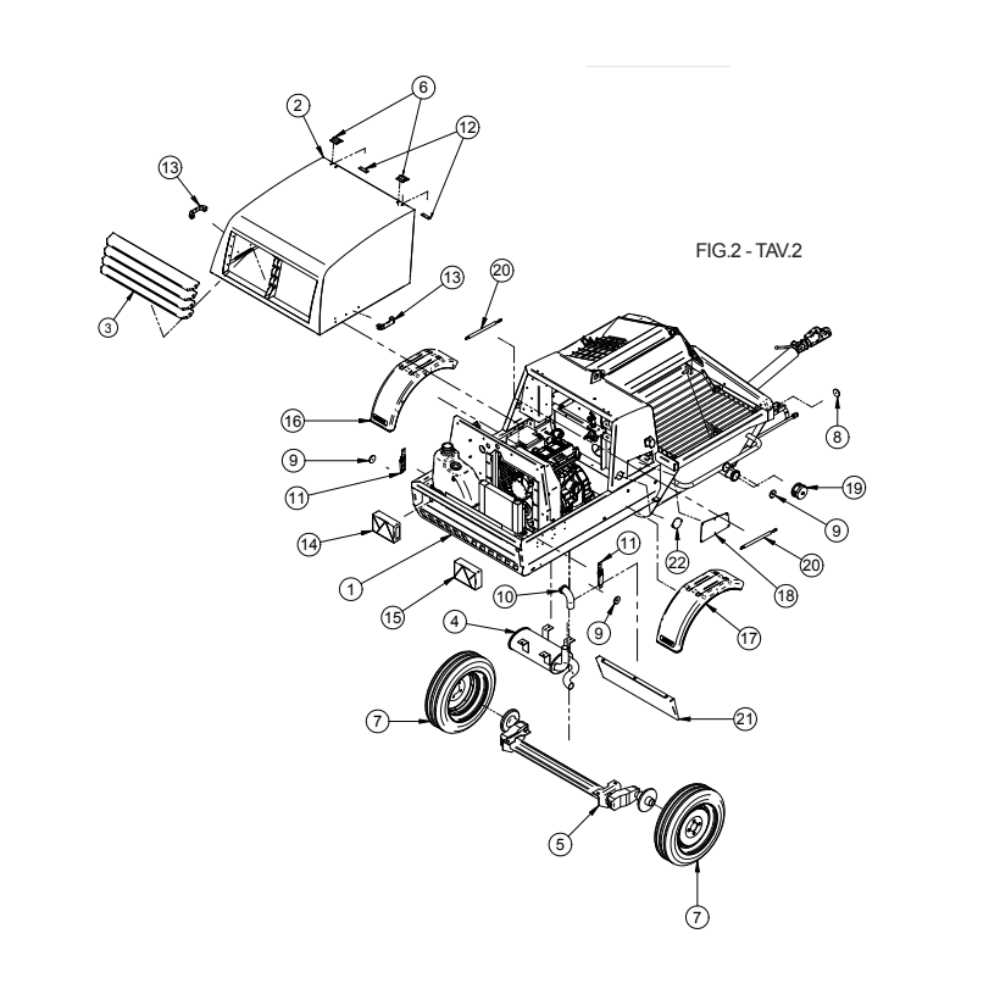

How to Read the Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. These illustrations provide a visual guide, allowing users to identify various elements and their relationships. By familiarizing yourself with this visual language, you can streamline troubleshooting and enhance your repair skills.

Begin by examining the layout; most diagrams are organized logically, often grouping related components together. Look for labels or numbers next to each element, which typically correspond to a list of descriptions or specifications. This reference will assist in recognizing each component’s function and importance.

Next, pay attention to the connections shown in the representation. Lines or arrows may indicate how parts interact or fit together. Understanding these links is crucial for proper assembly or disassembly. Lastly, take note of any legend or key included with the illustration, as it often clarifies symbols and terminologies specific to the schematic.

Common Issues with Compressor Parts

Equipment failures can often stem from various components malfunctioning or becoming worn over time. Understanding these common issues is crucial for maintaining optimal performance and ensuring longevity. Proper identification of symptoms and timely intervention can help avoid more severe complications.

Worn Seals and Gaskets

Seals and gaskets play a vital role in maintaining pressure and preventing leaks. Over time, exposure to heat and vibrations can lead to wear, resulting in diminished efficiency. Signs of wear include audible hissing or a noticeable drop in performance.

Clogged Filters

Filters are essential for keeping debris out of the system. A buildup of contaminants can restrict airflow, leading to overheating and reduced functionality. Regular inspections and replacements are necessary to ensure that these components remain effective and to prolong the equipment’s lifespan.

Maintenance Tips for Air Compressors

Ensuring optimal performance and longevity of your equipment requires regular upkeep and attention. Proper maintenance can prevent breakdowns, enhance efficiency, and prolong the lifespan of machinery.

Regular Inspections: Frequent examinations of your device can help identify potential issues before they escalate. Check for leaks, unusual noises, or vibrations that may indicate underlying problems.

Cleaning Filters: Keeping filters clean is crucial for maintaining airflow and performance. Regularly remove and clean or replace filters according to the manufacturer’s recommendations to avoid blockages.

Lubrication: Proper lubrication of moving components minimizes friction and wear. Use the recommended lubricant and apply it as needed to ensure smooth operation.

Draining Condensation: Moisture buildup can lead to rust and corrosion. Periodically drain any accumulated water from the storage tank to prevent damage and maintain performance.

Monitoring Operating Pressure: Keeping an eye on the pressure levels is essential for efficiency. Ensure that the settings are within the manufacturer’s specifications to optimize functionality.

Professional Servicing: Consider scheduling regular professional maintenance to address complex issues and perform thorough inspections. Experienced technicians can provide valuable insights and service to keep your equipment running smoothly.

Replacement Parts for Emglo Models

For those seeking to maintain or repair specific models, understanding the available components is essential. Quality replacements ensure optimal performance and longevity of the equipment. Identifying compatible pieces not only enhances functionality but also guarantees safety during operation.

Types of Available Components

Several types of components are commonly needed for effective maintenance. These items can range from mechanical to electrical, catering to various operational needs. Each component plays a crucial role in the overall efficiency and reliability of the machine.

Component Compatibility

When selecting replacements, compatibility with existing models is paramount. Using the right specifications prevents operational issues and extends the lifespan of the device. It’s advisable to consult detailed specifications or guides to ensure proper fit.

| Component Type | Description | Compatibility Notes |

|---|---|---|

| Pistons | Essential for compression; available in various sizes. | Check model specifications for size. |

| Valves | Regulate airflow; critical for performance. | Ensure they match the original design. |

| Filters | Prevent debris from entering the system. | Regular replacement is recommended. |

| Seals | Prevent leaks; available in various materials. | Choose based on operational conditions. |

Upgrading Your Emglo Compressor

Enhancing your machinery can significantly improve its efficiency and extend its lifespan. By incorporating modern components, you can achieve better performance and reliability. This process often involves selecting high-quality elements that are compatible with your existing setup, ensuring seamless integration.

Consider evaluating the current functionality of your equipment to identify any areas that may benefit from enhancement. Upgrades can range from increasing power output to improving overall durability. Investing in superior materials or innovative technologies can lead to remarkable advancements in operation.

Additionally, it’s essential to research the latest options available on the market. Reading reviews and comparing specifications can provide valuable insights into which upgrades will best suit your needs. Always prioritize components that offer a balance between quality and affordability, as this can lead to long-term satisfaction.

Resources for Finding Diagrams

Locating detailed schematics for machinery can significantly enhance repair and maintenance efforts. Various avenues exist for obtaining these valuable illustrations, each catering to different needs and preferences.

Online forums and communities dedicated to technical enthusiasts often provide a wealth of information, including user-uploaded visuals and discussions that can guide individuals in their search. Manufacturers’ websites may also feature downloadable resources, making them a reliable option for accessing accurate representations of equipment layouts.

Furthermore, technical manuals and guides, available in both print and digital formats, frequently include comprehensive illustrations that can assist users in understanding complex systems. Local libraries and specialized bookstores can be excellent resources for finding such literature, often containing archived documents that are not readily available online.

Finally, social media platforms can serve as a dynamic source of information, where groups and pages dedicated to machinery discussions share resources and advice on locating specific visuals. Engaging with these communities can provide not only the needed diagrams but also support from fellow enthusiasts.

Safety Precautions When Servicing

Maintaining equipment safely is crucial to prevent accidents and ensure optimal performance. Proper precautions must be taken to protect oneself and others during maintenance activities. Understanding the necessary safety measures not only minimizes risks but also enhances the effectiveness of the service performed.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and ear protection. These items safeguard against potential hazards, including noise, debris, and contact with harmful substances. Ensuring that all PPE fits well and is in good condition is essential for effective protection.

Work Environment and Tools

Maintain a clean and organized workspace to avoid accidents. Ensure that tools are in proper working condition and suitable for the tasks at hand. Properly storing tools when not in use can prevent tripping hazards and help keep the workspace efficient.