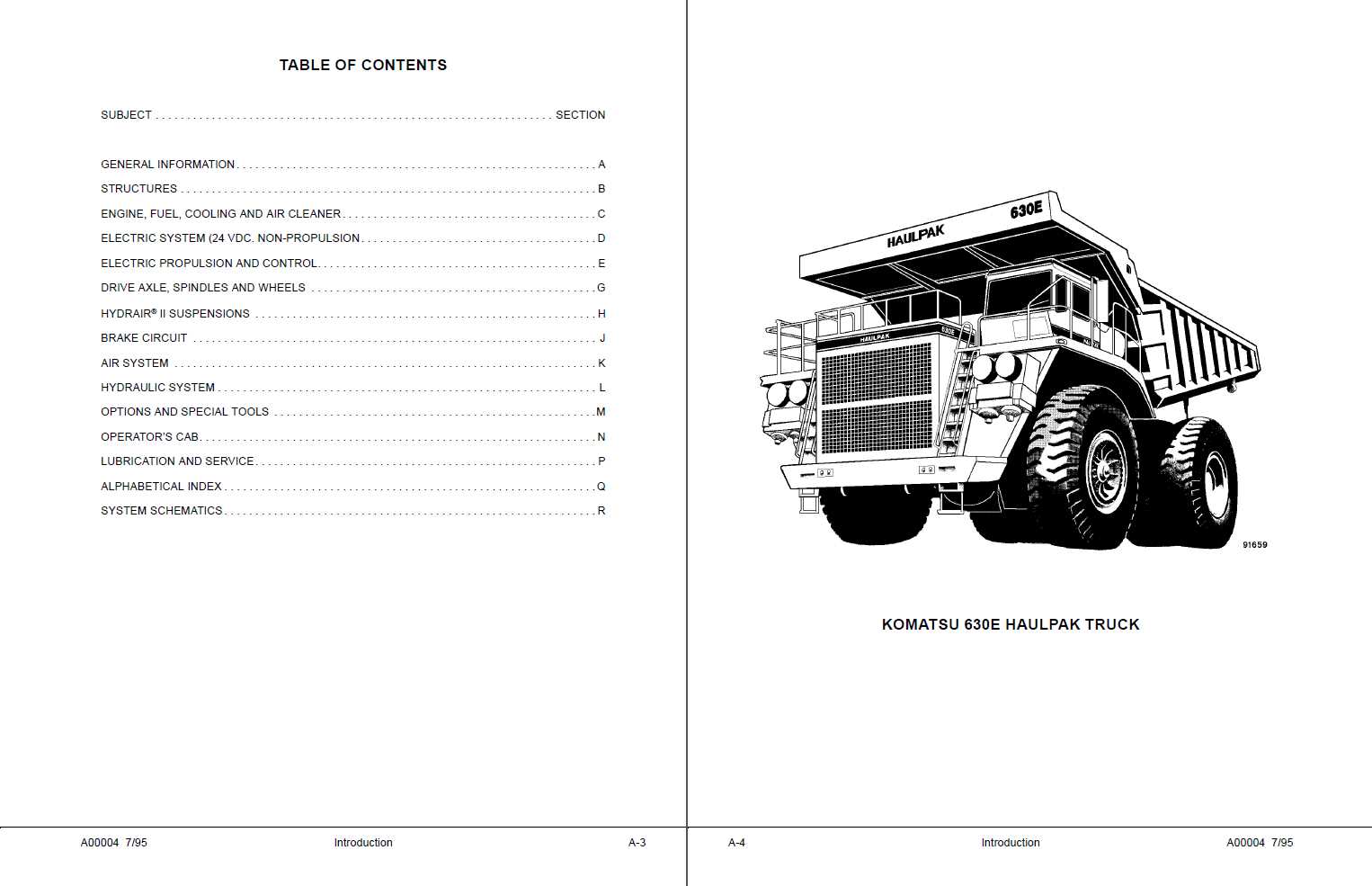

In the world of construction and transport, the intricate machinery that aids in moving materials is essential. Each segment of these powerful vehicles plays a crucial role in ensuring efficiency and safety. Understanding the various elements can significantly enhance operational knowledge and maintenance practices.

Exploring the layout of these mechanisms provides insights into their functionality and interconnections. With a comprehensive grasp of how each component interacts, operators can better troubleshoot issues and perform necessary repairs.

Furthermore, visual representations of these systems serve as valuable tools for both novices and seasoned professionals. By delving into these illustrations, one can grasp the ultimate design and engineering behind such robust machinery, paving the way for improved performance and longevity.

Understanding Dump Truck Components

The effective operation of heavy-duty vehicles relies on a variety of essential elements that work together harmoniously. Each component plays a specific role, contributing to the overall functionality and efficiency of these powerful machines. Gaining insight into these individual sections can enhance comprehension of their operations and maintenance needs.

Key Elements of Heavy-Duty Vehicles

These robust machines consist of several critical sections, each designed for a specific function. Understanding these sections helps operators maximize performance and extend the lifespan of the vehicle.

| Component | Function |

|---|---|

| Chassis | Provides the main structural framework. |

| Hydraulic System | Controls lifting and lowering mechanisms. |

| Engine | Generates the power necessary for movement. |

| Bed | Holds and transports materials. |

| Tires | Ensure mobility and stability on various terrains. |

Importance of Regular Maintenance

Maintaining the functionality of these essential sections is crucial for safe and efficient operation. Regular inspections and servicing can prevent malfunctions and extend the lifespan of the vehicle, ultimately saving time and resources.

Essential Parts of a Dump Truck

Understanding the key components of heavy-duty vehicles is crucial for their effective operation and maintenance. Each element plays a significant role in ensuring optimal performance, safety, and efficiency. Here, we explore the vital sections that contribute to the functionality of these robust machines.

| Component | Description |

|---|---|

| Chassis | The base frame that supports the entire structure and houses other essential systems. |

| Hydraulic System | A mechanism responsible for lifting and tilting the cargo bed, allowing for easy unloading. |

| Cargo Bed | The container that carries materials, designed to withstand heavy loads and harsh conditions. |

| Axles | Support the weight of the vehicle and facilitate movement by connecting the wheels. |

| Engine | The powerhouse that provides the necessary energy for movement and operation of various systems. |

| Braking System | Ensures safe stopping capabilities, crucial for managing heavy loads on inclines. |

| Wheels and Tires | Designed to support heavy weights while providing traction on different terrains. |

Functions of Each Component

The various elements of a heavy-duty vehicle work in unison to achieve optimal performance and efficiency. Each segment plays a distinct role, contributing to the overall functionality and reliability of the machine. Understanding the purpose of these components can help in maintenance and troubleshooting, ensuring longevity and effective operation.

The chassis serves as the foundation, providing structural integrity and support for the entire assembly. It bears the weight and absorbs stress, enabling smooth operation on different terrains. The engine, a critical powerhouse, converts fuel into mechanical energy, driving the entire system forward. Its performance directly influences the vehicle’s capabilities.

The hydraulic system is essential for lifting and maneuvering heavy loads. It utilizes fluid pressure to operate various functions, ensuring ease of use and precision. Additionally, the braking mechanism is crucial for safety, allowing for controlled stopping and stability under various conditions.

Other key components, such as the transmission and axles, facilitate the transfer of power from the engine to the wheels, optimizing speed and torque. Each element, from the smallest bolt to the largest assembly, plays an integral role in maintaining the efficiency and reliability of the vehicle, highlighting the importance of understanding their functions in the overall system.

Common Issues with Dump Truck Parts

When it comes to heavy machinery, certain components often experience wear and tear, leading to performance issues. Understanding these common challenges can help operators maintain optimal functionality and extend the lifespan of their equipment.

Frequent Mechanical Failures

Mechanical components can encounter various failures due to heavy usage and environmental conditions. Regular inspections are crucial to identify potential problems before they escalate.

Hydraulic System Complications

The hydraulic system is vital for lifting and lowering mechanisms. Common issues include leaks, blockages, and pressure loss, which can severely impact performance.

| Issue | Description | Possible Solutions |

|---|---|---|

| Wear and Tear | Excessive friction can lead to component degradation. | Regular maintenance and lubrication. |

| Fluid Leaks | Loss of hydraulic fluid can reduce efficiency. | Inspect seals and hoses regularly. |

| Electrical Failures | Wiring issues can disrupt functionality. | Conduct routine electrical checks and repairs. |

Maintenance Tips for Longevity

Ensuring the durability of heavy machinery requires a proactive approach to upkeep and care. Regular maintenance not only enhances performance but also significantly extends the lifespan of equipment. Adopting effective practices is crucial for optimal functionality and reliability.

To achieve lasting efficiency, consider the following essential maintenance strategies:

| Tip | Description |

|---|---|

| Regular Inspections | Conduct thorough assessments to identify wear and tear before issues escalate. |

| Fluid Checks | Monitor and replace hydraulic and lubrication fluids as needed to prevent damage. |

| Filter Replacement | Change air and oil filters regularly to ensure clean operation and prevent contaminants. |

| Tire Maintenance | Inspect and maintain proper tire pressure and tread depth to ensure safety and efficiency. |

| Component Cleaning | Keep all moving parts free of debris and buildup to maintain smooth operation. |

| Scheduled Servicing | Adhere to a regular service schedule as recommended by the manufacturer for peak performance. |

Implementing these guidelines will promote longevity and reliability, ensuring that your machinery operates efficiently for years to come.

How to Identify Damaged Parts

Recognizing wear and tear in machinery components is crucial for maintaining optimal performance and safety. Regular inspections can help spot signs of deterioration, enabling timely repairs and preventing more significant issues down the line.

Visual Inspection

Begin with a thorough visual examination. Look for cracks, deformations, or unusual wear on surfaces. Pay attention to any discoloration or rust, as these can indicate exposure to harmful elements or excessive stress. Bright spots or shiny areas on metal components may suggest friction or inadequate lubrication.

Performance Monitoring

Another method involves monitoring the equipment’s performance. If you notice unusual vibrations, noises, or changes in operational efficiency, it may signal underlying issues. Consistent performance drops can be linked to specific components that require further inspection. Regularly documenting these observations can help establish patterns that pinpoint potential problems before they escalate.

Choosing Quality Replacement Components

Selecting high-quality replacement components is crucial for maintaining the efficiency and longevity of your heavy machinery. The reliability of your equipment often hinges on the quality of the components used. Making informed choices can prevent frequent repairs and ensure optimal performance in demanding conditions.

Factors to Consider

- Material Quality: Look for components made from durable materials that can withstand harsh environments.

- Manufacturer Reputation: Choose suppliers known for their commitment to quality and customer satisfaction.

- Compatibility: Ensure that the replacement parts are designed to fit your specific machinery model.

- Warranty and Support: Consider products that come with a warranty and reliable customer support.

Where to Find Quality Components

- Authorized Dealers: Purchase from manufacturers or authorized distributors for peace of mind.

- Online Marketplaces: Research reviews and ratings on platforms that specialize in heavy equipment.

- Industry Trade Shows: Attend events to meet suppliers and compare products directly.

- Recommendations: Seek advice from industry professionals or peers who have experience with specific brands.

Impact of Parts on Performance

The efficiency and effectiveness of heavy machinery largely depend on the individual components that constitute the overall system. Each element plays a vital role in ensuring that operations run smoothly and optimally. Understanding how these components interact can lead to improved functionality and longevity of the machinery.

Key Components Influencing Performance

Several crucial elements directly affect the overall capability of the machinery. Below is a summary of how specific components contribute to performance:

| Component | Impact on Performance |

|---|---|

| Engine | Determines power output and efficiency. |

| Transmission | Influences speed and torque delivery. |

| Hydraulic System | Controls lifting and maneuvering capabilities. |

| Chassis | Affects stability and weight distribution. |

| Tires | Impact traction and overall mobility. |

Optimizing Performance through Maintenance

Regular upkeep of these critical components is essential for maintaining high performance levels. Routine inspections and timely replacements can prevent breakdowns and enhance operational efficiency, ensuring that the machinery remains reliable and effective over time.

Innovations in Dump Truck Design

Recent advancements in heavy vehicle engineering have led to transformative changes in design and functionality. These innovations not only enhance efficiency but also improve safety and environmental sustainability. The integration of cutting-edge technologies is paving the way for a new era in construction and logistics.

Smart Technologies

Automation and sensor integration are at the forefront of modern vehicle design. Features such as GPS tracking, load monitoring, and automated driving systems significantly increase operational effectiveness, allowing for real-time data analysis and decision-making.

Eco-Friendly Materials

The shift towards sustainable practices has resulted in the use of lightweight composites and recycled materials in vehicle construction. These choices reduce overall weight, enhancing fuel efficiency and minimizing carbon footprints, contributing to greener construction sites.