The effective functioning of a portable application tool relies on its various integral elements. Each component plays a crucial role in ensuring optimal performance and efficiency. By familiarizing oneself with these essential features, users can better understand the device’s operation and maintenance.

From the mechanisms that control fluid delivery to the elements that enhance user comfort, the significance of each part cannot be overstated. Knowing how these components interact can lead to improved usage and longevity of the equipment. This knowledge empowers users to make informed decisions regarding maintenance and troubleshooting, ultimately enhancing their experience with the device.

Essential Features of Sprayer Design

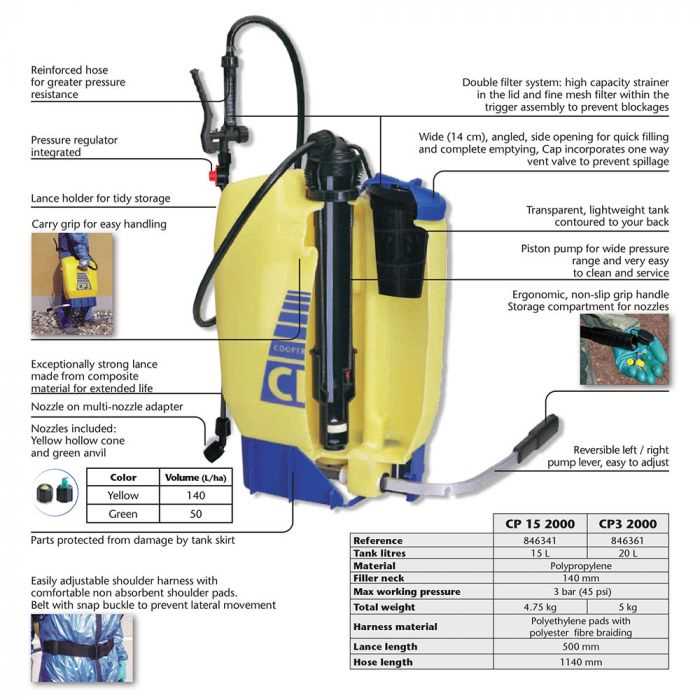

The construction of an effective liquid distribution device incorporates several fundamental characteristics that enhance its functionality and user experience. A well-designed apparatus ensures efficiency in application, ease of handling, and adaptability to various tasks.

Key aspects that contribute to the overall performance include:

| Feature | Description |

|---|---|

| Capacity | Refers to the volume of liquid the container can hold, influencing the frequency of refills. |

| Weight | Lightweight materials facilitate maneuverability and reduce fatigue during use. |

| Nozzle Type | Diverse nozzle options allow for customizable spray patterns and droplet sizes, enhancing application precision. |

| Ergonomics | Design considerations such as grip and balance improve user comfort and control. |

| Durability | Materials and construction methods that resist wear and environmental factors prolong the lifespan of the device. |

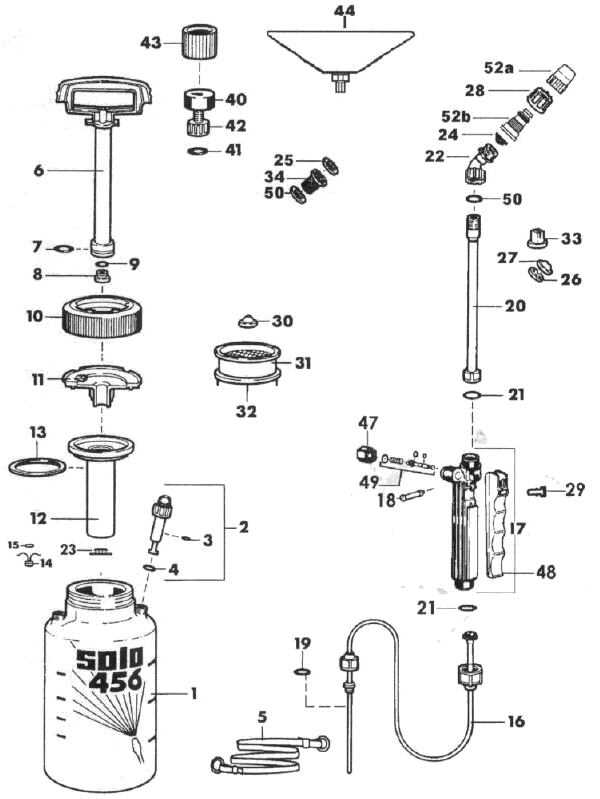

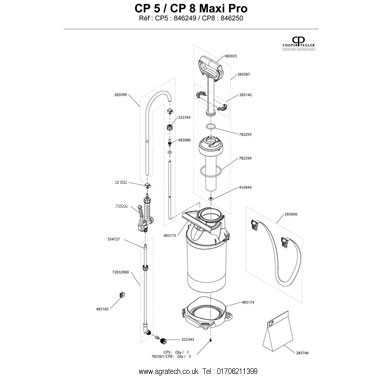

Functionality of Key Parts Explained

This section delves into the essential components of a portable liquid application device, highlighting their roles and interrelationships. Understanding how these elements work together enhances the efficiency of usage and maintenance, leading to better outcomes in various tasks.

Pump Mechanism

The pump is a vital component that generates pressure within the system, enabling the efficient distribution of the liquid. By converting manual or mechanical energy into fluid movement, it ensures a steady flow, allowing for precise application during operations.

Storage Container

The storage container serves as the reservoir for the liquid, designed to hold substantial amounts while ensuring easy access. Its construction often includes features that prevent leakage and contamination, safeguarding the quality of the contents and facilitating straightforward refilling.

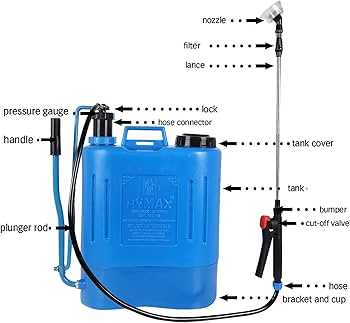

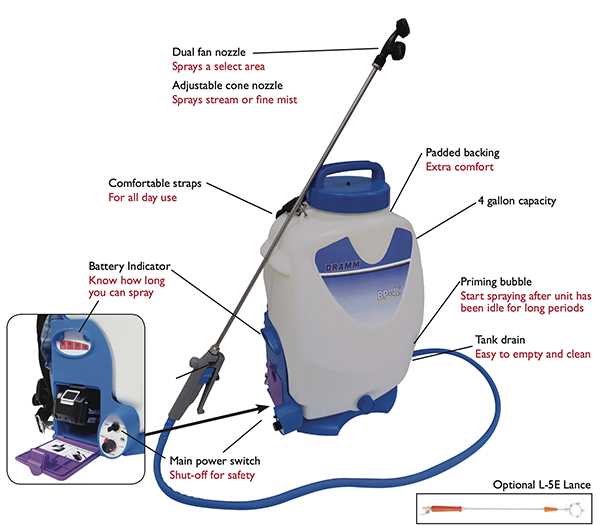

Understanding the Nozzle Mechanism

The nozzle mechanism plays a crucial role in the effective distribution of liquids in various applications. By controlling the flow and spray pattern, it significantly impacts performance and efficiency. A thorough comprehension of its components and functionality is essential for optimal usage.

This mechanism consists of several key elements that work together harmoniously. Understanding these elements can enhance both the user experience and the overall effectiveness of the device. Here are the main components:

- Outlet Opening: The point where the liquid exits, influencing the droplet size and spray pattern.

- Flow Rate Control: Adjusts the volume of liquid released, ensuring the desired application rate.

- Material Composition: The nozzle can be made from various materials, affecting durability and compatibility with different liquids.

Moreover, the design of the nozzle can vary to suit specific needs. Common designs include:

- Flat Fan: Ideal for broad coverage, suitable for larger areas.

- Conical: Provides a concentrated spray, effective for targeted applications.

- Adjustable: Offers versatility by allowing users to modify the spray pattern and flow rate according to requirements.

In summary, grasping the intricacies of the nozzle mechanism can lead to improved outcomes in application processes. Proper maintenance and understanding of its operation can maximize efficiency and effectiveness.

Importance of the Pump System

The pump system plays a crucial role in the overall functionality of any fluid application device. Its efficiency directly influences the effectiveness of the entire operation, ensuring that the required liquid is delivered at the appropriate pressure and volume.

Here are some key reasons highlighting the significance of the pump system:

- Fluid Delivery: The pump is responsible for transporting liquid from the source to the target area, ensuring even distribution.

- Pressure Regulation: It maintains the necessary pressure to achieve optimal performance, which is essential for effective application.

- Durability: A well-designed pump system enhances the longevity of the device, reducing the need for frequent replacements or repairs.

- Energy Efficiency: An efficient pump system minimizes energy consumption, leading to cost savings over time.

- Operational Versatility: It allows for adjustments in flow rates and pressures, making the device adaptable to various tasks.

In conclusion, the pump system is an integral component that significantly impacts performance and efficiency. Investing in a high-quality pump not only improves functionality but also ensures reliable operation over time.

Role of the Hose and Connections

The hose and its connections play a crucial role in ensuring effective functionality and fluid transfer in various applications. They serve as the primary conduits for transporting liquids, allowing users to achieve desired results in tasks such as agricultural spraying or maintenance. Understanding their significance is essential for optimizing performance and ensuring longevity.

Importance of Quality Hoses

Quality hoses are designed to withstand pressure and environmental factors, ensuring that the fluid remains contained without leaks. Durability and flexibility are key attributes that enhance usability, allowing for smooth operation during various tasks. Using high-quality materials can significantly impact the overall efficiency of the system.

Connection Integrity

Connections between the hose and other components are critical for maintaining a secure and leak-free system. Proper sealing and fitting are necessary to prevent fluid loss, which can lead to inefficiencies and increased operational costs. Regular inspections of these connections help identify wear and tear, ensuring that replacements can be made before any major issues arise.

Maintenance Tips for Sprayer Parts

Regular upkeep of your equipment is essential for ensuring optimal performance and longevity. By following a few key guidelines, users can prevent common issues and enhance the efficiency of their devices. This section provides practical advice on maintaining various components to achieve reliable functionality.

Regular Cleaning

Cleaning is a fundamental aspect of maintenance. Residues from previous applications can lead to clogs and malfunctions. Consider the following steps:

- Rinse all components with clean water after each use.

- Use a soft brush to remove any stubborn deposits.

- Check filters and clean or replace them as needed.

Inspection and Replacement

Routine inspections help identify wear and tear early on, allowing for timely replacements. Pay attention to:

- Seals and gaskets for any signs of damage.

- Hoses for cracks or leaks.

- Nozzles to ensure they are not clogged or worn.

By adhering to these maintenance practices, users can significantly enhance the reliability and effectiveness of their equipment, ensuring it operates smoothly for an extended period.

Common Issues with Sprayer Components

Understanding the typical challenges associated with the various elements of application equipment is essential for ensuring effective operation. These complications can lead to inefficient performance and reduced longevity of the apparatus. Below are some frequent concerns that users encounter.

- Clogged Nozzles: Blockages can prevent fluid from passing through, affecting the distribution.

- Leakage: Seals or joints may degrade over time, causing unwanted fluid escape.

- Inconsistent Pressure: Fluctuations can result from pump malfunctions, impacting application accuracy.

- Worn Hoses: Aging hoses may crack or rupture, leading to fluid loss.

Addressing these issues promptly can enhance the efficiency and reliability of the equipment. Regular maintenance and inspections are crucial in preventing these common problems.

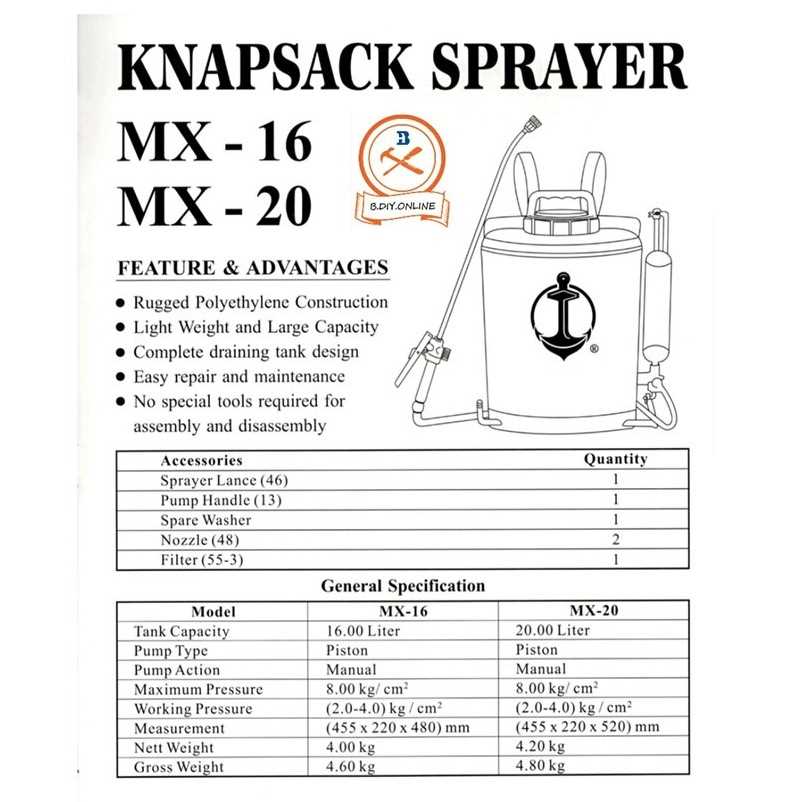

Upgrades and Accessories for Efficiency

Enhancing productivity and performance in various applications can be achieved through strategic improvements and supplementary tools. These modifications not only streamline operations but also contribute to better results and user experience. Exploring innovative solutions can significantly elevate overall effectiveness.

Performance Enhancements

Investing in performance upgrades can lead to more efficient operations. Consider the following options:

- High-capacity tanks for extended usage without frequent refills

- Improved nozzles that ensure even distribution

- Durable hoses designed to withstand wear and tear

Convenience Accessories

Incorporating convenient accessories can simplify tasks and enhance usability. Some noteworthy additions include:

- Carrying straps for improved portability

- Pressure regulators for consistent application

- Extension wands for reaching difficult areas