In the realm of industrial equipment, the intricate design and functionality of cutting devices play a crucial role in efficiency and precision. A thorough comprehension of these mechanisms is essential for anyone involved in maintenance, operation, or improvement of such tools. By breaking down the elements that constitute these machines, one can gain valuable insights into their performance and reliability.

Exploring the various segments of these devices reveals a complex interplay of parts that work in unison to achieve optimal results. Each component, from the driving mechanism to the guiding structures, contributes significantly to the overall effectiveness of the system. Understanding how these elements interact can enhance operational skills and promote better troubleshooting techniques.

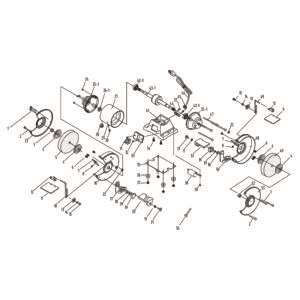

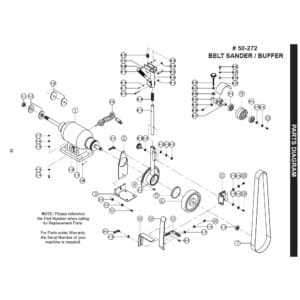

Moreover, visual representations of these components can serve as a useful reference for both novices and seasoned professionals alike. By familiarizing oneself with the arrangement and function of each part, users can ensure proper care and efficient use of their cutting tools, ultimately leading to improved outcomes in their projects.

Understanding Band Saw Functionality

The operation of cutting tools relies on a combination of elements that work together to achieve precision and efficiency. Each component plays a vital role in ensuring the overall effectiveness of the equipment, enabling smooth and accurate slicing through various materials. By grasping how these elements interact, one can appreciate the intricacies of the mechanism and enhance their usage experience.

Key Components of a Band Saw

Understanding the fundamental elements of a cutting device is essential for optimal performance and maintenance. Each component plays a vital role in the overall function, contributing to efficiency and precision during operation. Below are the crucial elements that make up this sophisticated tool.

Main Elements

- Frame: The robust structure that supports all other components, ensuring stability during use.

- Blade: The critical element responsible for cutting, available in various sizes and materials to suit different tasks.

- Table: The surface where material is placed, often adjustable for angled cuts.

- Motor: Powers the blade, providing the necessary force for cutting through various materials.

Additional Features

- Tensioning System: Maintains the correct tightness of the blade for improved cutting accuracy.

- Guides: Help stabilize the blade and keep it aligned during operation.

- Track: The pathway that ensures the blade moves smoothly and safely.

- Dust Collection: A feature that minimizes debris, promoting a cleaner workspace.

Importance of Maintenance for Longevity

Regular upkeep is essential for ensuring the extended life of any mechanical device. Proper care not only enhances performance but also minimizes the risk of unexpected failures. By adhering to a systematic maintenance routine, operators can significantly improve reliability and efficiency.

Neglecting maintenance can lead to wear and tear, ultimately resulting in costly repairs and downtime. A proactive approach fosters an environment where equipment operates smoothly, maintaining optimal functionality and safety. This section outlines key benefits of regular maintenance.

| Benefits | Description |

|---|---|

| Increased Lifespan | Regular maintenance extends the operational life of machinery by preventing early degradation. |

| Improved Performance | Consistent care ensures that all components function at their best, leading to higher productivity. |

| Cost Savings | Investing in maintenance can reduce the frequency and severity of repairs, saving money over time. |

| Enhanced Safety | Well-maintained equipment reduces the likelihood of accidents and injuries in the workplace. |

Common Issues in Band Saw Operation

Understanding frequent challenges encountered during operation is crucial for ensuring efficiency and safety. Addressing these problems not only improves performance but also prolongs the life of the equipment.

- Blade Misalignment: Incorrect positioning can lead to uneven cuts and excessive wear.

- Blade Breakage: Factors such as dullness or improper tension often result in fractures.

- Inconsistent Feed Rate: Variability in material feeding can affect cut quality.

- Vibration: Excessive shaking can indicate wear and may compromise accuracy.

- Overheating: Insufficient lubrication may cause components to heat excessively.

Regular maintenance and proper setup can significantly reduce these issues, enhancing overall functionality.

How to Read a Parts Diagram

Understanding an illustration that outlines various components of a mechanical device is crucial for effective maintenance and repair. Such representations serve as visual guides, simplifying the identification and organization of individual elements within a system. This knowledge enhances both troubleshooting and assembly processes, making it essential for anyone working with complex machinery.

Begin by familiarizing yourself with the overall layout. Each section typically highlights specific assemblies and subassemblies, which can provide context for how the components interact with one another. Pay attention to the labels accompanying each item, as these often include reference numbers or codes that correlate with detailed descriptions in accompanying documentation.

Next, examine the relationships between the elements. Lines and arrows frequently indicate connections, movements, or flow paths, which are vital for grasping how the system operates as a whole. Understanding these dynamics allows for a clearer picture of functionality and potential issues that may arise.

Finally, refer to the legend or key, if available. This will clarify any symbols or shorthand used within the illustration, ensuring accurate interpretation of the information presented. By taking the time to analyze these elements carefully, one can gain valuable insights into the operation and maintenance of the equipment.

Choosing Quality Replacement Parts

Selecting high-grade components for equipment maintenance is crucial for ensuring optimal performance and longevity. The right choices not only enhance functionality but also reduce the risk of malfunctions and costly downtime. When seeking alternatives, it’s essential to prioritize durability, compatibility, and reliability.

Understanding Material Quality

One of the primary considerations is the material used in the manufacturing of the components. Premium materials often result in greater resistance to wear and tear, thus extending the life of your machinery. It’s advisable to look for manufacturers who specify the materials and provide evidence of their durability through testing.

Compatibility and Performance

Another significant aspect is ensuring that the selected components are compatible with existing equipment. Incompatibility can lead to inefficiencies and potential hazards. Always consult the manufacturer’s specifications and guidelines to confirm that the replacements will meet performance standards and work seamlessly with your setup.

Safety Tips for Band Saw Usage

When working with cutting tools, ensuring safety is paramount. Proper precautions can significantly reduce the risk of accidents and injuries. This section outlines essential practices to maintain a secure environment while utilizing these powerful devices.

- Always wear appropriate personal protective equipment, including safety goggles, gloves, and ear protection.

- Keep the workspace clean and organized to prevent trips and falls.

- Ensure all safety guards and devices are in place and functioning correctly before operation.

Prior to starting any cutting task, familiarize yourself with the equipment and its features. Understanding how the device operates is crucial for safe usage.

- Check that the blade is sharp and properly aligned to avoid binding and unexpected kickback.

- Make sure to use the correct type of material and thickness for the intended operation.

- Always secure workpieces properly before making any cuts to prevent movement.

In case of any malfunction or unusual noise, stop the equipment immediately and investigate the issue. Regular maintenance checks will also help in identifying potential hazards early on.

- Never wear loose clothing or jewelry that could get caught in the equipment.

- Keep hands and other body parts away from the cutting area while the tool is in operation.

- Be aware of your surroundings and ensure that others are at a safe distance during operation.

By following these safety guidelines, operators can help create a safer working environment, ultimately enhancing productivity and reducing the likelihood of accidents.

Innovations in Band Saw Technology

The evolution of cutting tools has led to remarkable advancements in design and functionality, greatly enhancing performance and efficiency in various applications. These innovations are reshaping industries by introducing enhanced precision, safety, and user-friendly features.

- Advanced Blade Materials: Modern blades are crafted from high-performance alloys and coated with specialized materials, providing increased durability and reduced wear.

- Smart Technology Integration: Incorporating sensors and IoT technology allows for real-time monitoring of operational parameters, improving accuracy and minimizing downtime.

- Improved Power Systems: Innovations in motor technology offer better energy efficiency and more powerful cutting capabilities, enabling operators to tackle thicker materials with ease.

- Enhanced Safety Features: New designs include automatic shut-off systems and blade guards that significantly reduce the risk of accidents during operation.

- User-Centric Controls: Ergonomic interfaces and programmable settings facilitate easier operation, allowing users to adjust configurations quickly and efficiently.

These developments not only enhance performance but also contribute to a more sustainable approach by reducing waste and energy consumption in the cutting process.