The functionality of any fluid management system heavily relies on its core elements. These components work in unison to ensure efficient operation and longevity. A thorough comprehension of their arrangement and individual roles can significantly enhance maintenance practices and troubleshooting efforts.

Every system has unique configurations that determine its performance. Recognizing how these integral pieces interconnect helps users identify potential issues before they escalate. By delving into a visual representation of these elements, one can gain insights into the overall mechanics and operational flow.

In this exploration, we will dissect the various segments that constitute a typical circulation unit. This knowledge empowers operators to undertake informed repairs and optimizations, ultimately leading to improved efficiency and reduced downtime. Understanding these critical components lays the groundwork for mastering system management.

Understanding Hayward Super II Pump Basics

This section delves into the essential components and functions of a crucial device in aquatic maintenance. By exploring its operational principles and parts, users can enhance their knowledge and troubleshoot effectively. Familiarity with these fundamentals leads to improved performance and longevity of the system.

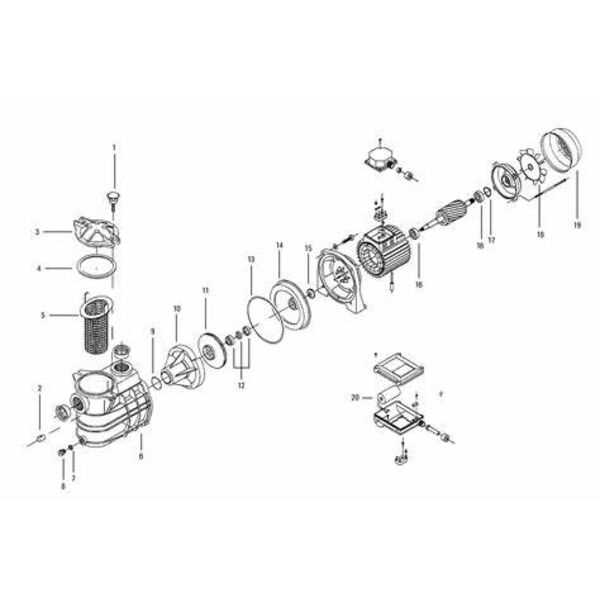

At its core, this device serves to facilitate water circulation, ensuring cleanliness and clarity in the aquatic environment. Each element plays a vital role, from the motor that powers the mechanism to the filtration system that purifies the water. Understanding the interplay between these components can significantly influence the efficiency of the overall system.

| Component | Function |

|---|---|

| Motor | Powers the entire operation, driving the impeller. |

| Impeller | Creates water flow by moving liquid through the system. |

| Strainer | Prevents debris from entering the system and damaging components. |

| Volute | Directs the flow of water from the impeller to the discharge port. |

| Seal | Prevents leaks and maintains pressure within the unit. |

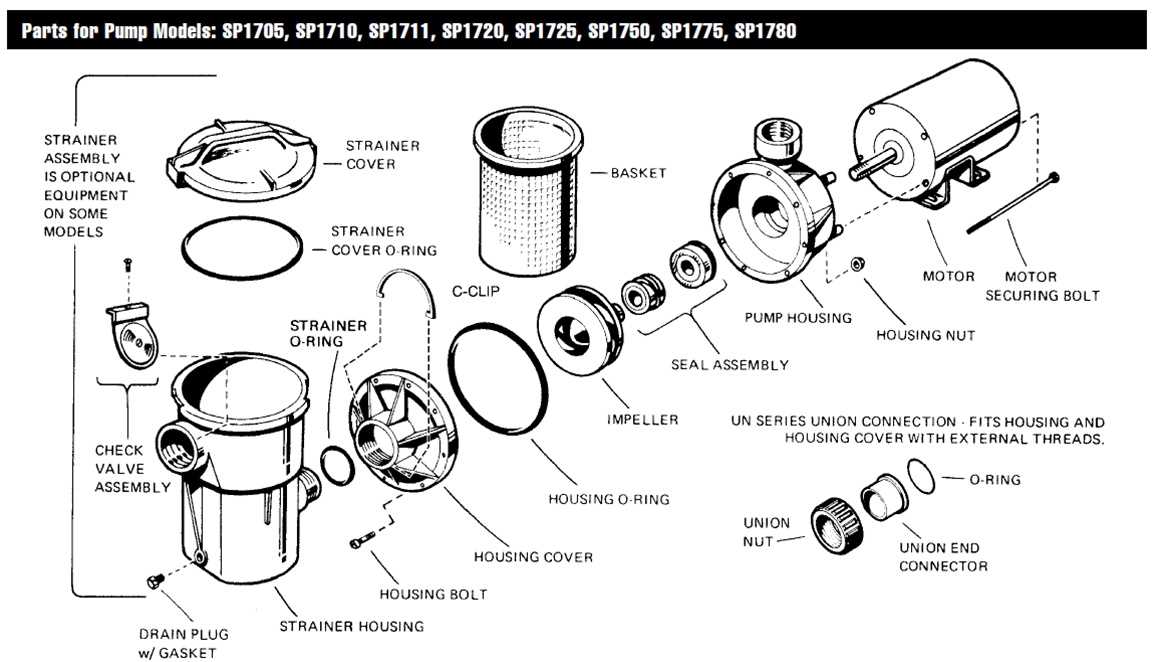

Essential Components of the Pump

Understanding the crucial elements of a circulation system is vital for effective operation and maintenance. Each component plays a significant role in ensuring optimal performance and longevity, contributing to the ultimate efficiency of the entire setup.

Motor: The driving force behind circulation, this element powers the entire assembly, ensuring that fluid moves as required.

Impeller: This rotating part is responsible for generating flow and pressure, pushing the liquid through the system.

Volute: Serving as a casing, it helps to convert kinetic energy from the impeller into pressure, guiding the flow effectively.

Strainer: Positioned at the intake, this component filters out debris and particles, protecting the internal mechanisms from damage.

Seal: Vital for preventing leaks, this part ensures that the system remains pressurized and efficient during operation.

Base: The foundational element provides stability and support, securing all components in place during operation.

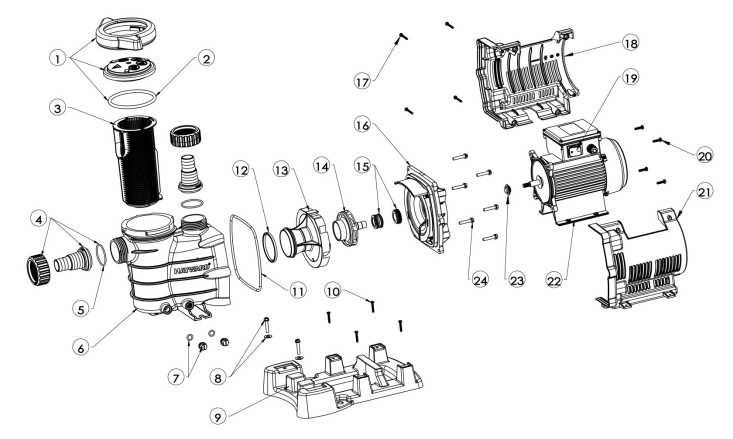

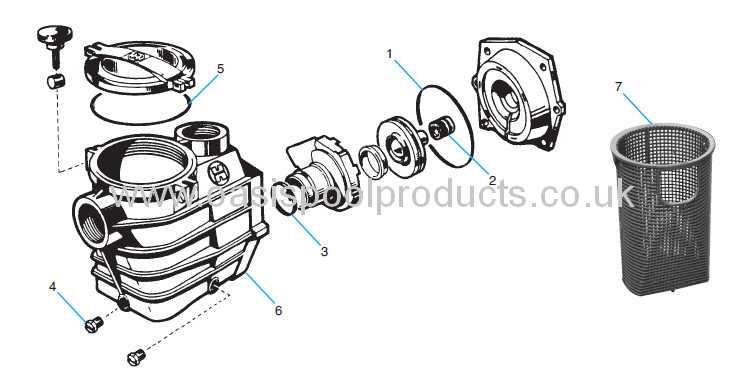

How to Read the Parts Diagram

Understanding a component illustration is essential for effective maintenance and repair of your equipment. These visual representations provide crucial information about the various elements involved, their arrangement, and how they interact within the system. Familiarizing yourself with the layout and symbols used can significantly enhance your troubleshooting skills and streamline the repair process.

Start by identifying the key sections of the illustration. Each area typically represents a specific function or component type. Labels are often used to indicate part names or numbers, which are critical for ordering replacements. Pay close attention to legend keys, as they explain any symbols or color codes that may be present, making it easier to understand the information conveyed.

Next, follow the flow of the system as depicted in the illustration. Components are often shown in a logical sequence, illustrating how they connect and operate together. This understanding is vital for diagnosing issues and ensuring that all parts are functioning correctly. Remember, a thorough grasp of the illustration can save you time and effort during maintenance tasks.

Common Issues and Troubleshooting Tips

This section addresses frequent problems encountered with water circulation equipment and provides practical solutions to resolve them effectively. Understanding these common challenges can significantly enhance performance and longevity.

| Issue | Description | Troubleshooting Steps |

|---|---|---|

| Low Flow Rate | Insufficient water movement can indicate blockages or equipment failure. | Check for debris in filters, ensure valves are open, and inspect hoses for kinks. |

| Noisy Operation | Unusual sounds may suggest loose components or air leaks. | Tighten loose fittings, check for air in the system, and inspect bearings. |

| Overheating | Excessive heat can lead to premature failure. | Inspect for obstructions in cooling vents and ensure the motor is not overloaded. |

| Frequent Cycling | Rapid on/off cycles may indicate pressure issues. | Check for clogs in the intake and ensure the pressure settings are correct. |

Replacement Parts Availability and Options

When it comes to maintaining essential equipment, the accessibility of components is crucial for ensuring optimal functionality. A variety of alternatives exist for users seeking to restore their systems efficiently. Understanding the landscape of available options can greatly enhance performance and extend the lifespan of your equipment.

Various retailers offer an extensive selection of components, ranging from OEM to aftermarket choices. Each type presents unique advantages, including cost-effectiveness and availability. Depending on specific needs, users can choose the most suitable option that aligns with their requirements.

Additionally, online platforms have made it easier than ever to find components. Many websites provide detailed catalogs and user reviews, enabling informed decisions. It’s advisable to consider factors such as warranty and compatibility when selecting replacements.

Maintenance Best Practices for Longevity

Ensuring the long-lasting performance of your equipment requires regular upkeep and attention to detail. By following a few essential practices, you can significantly extend the lifespan and efficiency of your system. Below are key recommendations to maintain optimal functionality.

- Regular Cleaning: Keep the exterior and interior components free from debris and dirt. This prevents blockages and promotes efficient operation.

- Inspect Seals and Gaskets: Routinely check for wear and tear. Replacing damaged seals prevents leaks and ensures a tight fit.

- Monitor Fluid Levels: Ensure that the operational fluids are at recommended levels. Low fluid levels can lead to overheating and damage.

- Check Electrical Connections: Inspect wiring and connections for corrosion or wear. Secure connections help maintain performance and safety.

- Lubricate Moving Parts: Apply appropriate lubricants to all moving components as per the manufacturer’s guidelines to reduce friction and wear.

By implementing these practices, you can maintain the reliability and effectiveness of your system, reducing the likelihood of unexpected breakdowns.

Consider scheduling regular professional inspections to catch potential issues early and keep your equipment running smoothly for years to come.

Benefits of Using Genuine Parts

Utilizing authentic components in maintenance and repairs offers numerous advantages that enhance performance and longevity. These original items are specifically designed to meet the highest standards, ensuring optimal functionality and reliability.

- Quality Assurance: Genuine components undergo rigorous testing to guarantee superior durability.

- Perfect Fit: Designed for specific models, ensuring seamless installation and operation.

- Enhanced Performance: Original parts contribute to improved efficiency and effectiveness.

- Long-term Savings: Investing in genuine items reduces the likelihood of frequent replacements and repairs.

- Warranty Protection: Using authentic components often preserves warranty coverage, providing peace of mind.

In summary, opting for original items not only safeguards your investment but also elevates overall performance and reliability.

Upgrades and Modifications for Performance

Enhancing the efficiency and functionality of your water circulation system can significantly improve its overall performance. By integrating advanced components and making thoughtful modifications, you can achieve better flow rates, energy savings, and extended equipment lifespan. This section explores various upgrade options that can elevate your system’s effectiveness.

Energy-Efficient Motors are a primary upgrade to consider. Transitioning to a variable-speed motor not only reduces energy consumption but also allows for customizable flow rates, adapting to different operational needs. This flexibility is essential for optimizing performance during peak usage times.

High-Performance Impellers are another modification that can lead to substantial improvements. Upgrading to a more efficient impeller design can enhance water flow while minimizing turbulence, ultimately resulting in a smoother operation and increased pressure output.

Incorporating better filtration systems can also play a crucial role in maintaining performance. Advanced filters can remove smaller particles, ensuring that the water remains clean and clear, which in turn reduces wear and tear on the circulation components.

Finally, regular maintenance and routine inspections are vital. By keeping an eye on wear and proactively replacing outdated or damaged parts, you can ensure that your system runs at peak efficiency for years to come.