In the realm of automotive maintenance, the tools that facilitate lifting and supporting heavy machinery are essential. A clear comprehension of the various components that contribute to the function of these mechanisms enhances both efficiency and safety during vehicle servicing. This knowledge is invaluable for anyone involved in maintenance or repair work.

Visual representations of these mechanisms play a crucial role in grasping how each element interacts within the system. By exploring the intricacies of these mechanisms, one can appreciate the engineering behind their design and functionality. Each component serves a specific purpose, ensuring that the entire system operates smoothly and effectively.

Moreover, understanding these systems not only aids in effective troubleshooting but also empowers individuals to perform routine maintenance with confidence. Familiarity with the layout and function of each element allows for a deeper appreciation of the mechanics at play, ultimately leading to improved performance and longevity of the tools used.

Understanding the Car Jack Mechanism

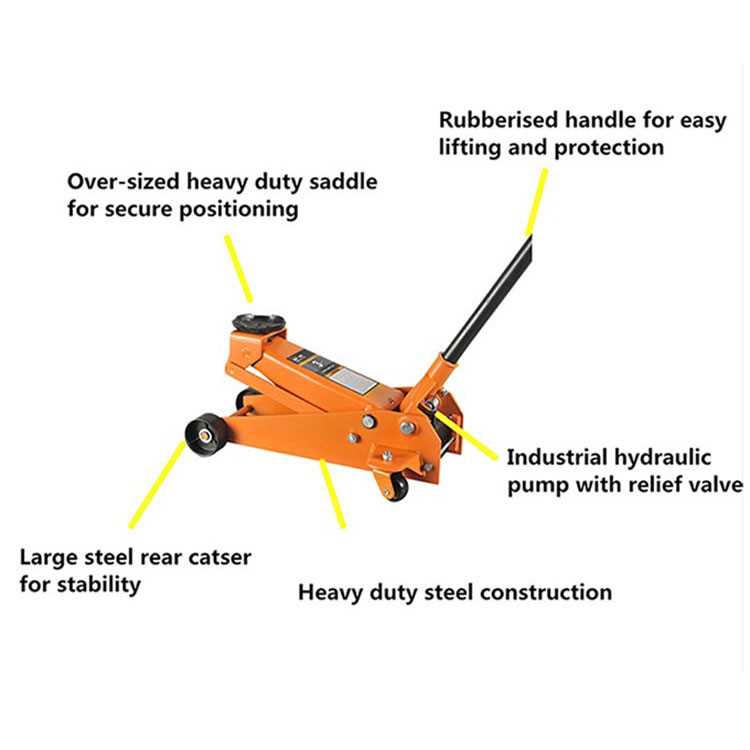

The mechanism used for elevating heavy objects is a fascinating blend of engineering principles that allows for efficient lifting and stability. This tool is designed to facilitate the safe and convenient raising of vehicles, making it an essential component for maintenance tasks. By employing mechanical advantage, it enables users to exert a small amount of force to lift substantial weights, highlighting the importance of leverage in practical applications.

Principles of Operation

At the core of this elevating device lies a system that translates human effort into mechanical force. Utilizing a combination of levers and gears, the device enhances the input force applied by the user. When a handle is turned or pushed, it activates a piston or screw mechanism that raises the platform, effectively lifting the load above the ground. This efficient transformation of energy allows for the safe handling of significant weights without the need for excessive physical strength.

Components and Their Functions

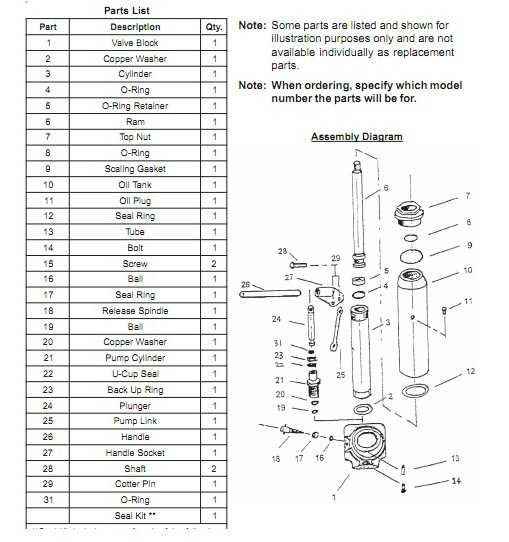

Each element of this lifting tool serves a distinct purpose, contributing to the overall functionality. The base provides stability and support, while the lifting mechanism–often a hydraulic cylinder or screw–raises the platform. The handle allows for user engagement, translating manual effort into lifting power. Understanding the role of each component is crucial for safe operation and maintenance, ensuring that the tool performs reliably when needed most.

Essential Components of a Car Jack

Understanding the crucial elements that make up a lifting device is essential for anyone looking to perform maintenance or repairs on their vehicle. Each component plays a significant role in ensuring the effectiveness and safety of the mechanism, allowing users to elevate heavy loads with ease and reliability. Familiarity with these elements can enhance your overall experience and efficiency when utilizing such tools.

Hydraulic Mechanism

The hydraulic system serves as the heart of this lifting apparatus. It utilizes fluid pressure to amplify force, enabling the user to raise substantial weights with minimal effort. This mechanism is typically designed with a pump and cylinder arrangement, where the pump compresses hydraulic fluid, transferring it to the cylinder. This action generates the necessary power to lift heavy objects effortlessly.

Support Frame

The support structure provides stability and strength during operation. Constructed from durable materials, it is engineered to withstand significant stress while ensuring that the entire assembly remains balanced. A well-designed frame is crucial for maintaining safety and preventing accidents, as it keeps the device securely in place when lifting loads.

Types of Car Jacks Explained

In the realm of vehicle maintenance, various lifting devices serve distinct purposes and offer unique advantages. Understanding the different styles available can enhance efficiency and safety during repairs or inspections. This section delves into the major categories that are commonly utilized.

Hydraulic Models

Hydraulic devices operate based on fluid mechanics, allowing for significant lifting power with minimal effort. They are often preferred for their stability and ease of use.

Mechanical Options

Mechanical alternatives rely on physical mechanisms, such as screw systems, to elevate vehicles. They are typically more compact and can be advantageous in tight spaces.

| Type | Advantages | Disadvantages |

|---|---|---|

| Hydraulic | High lifting capacity, user-friendly | Heavier, can leak fluid |

| Mechanical | Compact, no fluid issues | Requires more effort, slower operation |

How to Use a Car Jack Safely

Using lifting equipment correctly is crucial for ensuring safety while performing maintenance tasks on vehicles. Proper techniques and precautions can prevent accidents and injuries. Follow these guidelines to ensure a secure lifting process.

Preparation Steps

- Choose a flat, stable surface to work on.

- Ensure the vehicle is in park or gear, and engage the parking brake.

- Gather necessary safety equipment, such as gloves and safety glasses.

Lifting Procedure

- Locate the designated lifting points on the vehicle.

- Position the lifting equipment under the vehicle at the specified location.

- Begin lifting slowly, checking stability as the vehicle rises.

- Once elevated, place jack stands securely to provide additional support.

- Never work underneath a vehicle supported only by lifting equipment.

By adhering to these practices, you can perform maintenance tasks safely and effectively.

Common Issues with Car Jacks

Understanding the frequent problems associated with lifting mechanisms is essential for maintaining safety and functionality. These devices can face a range of issues that may affect their performance, leading to potential hazards during use. Identifying and addressing these challenges is crucial for ensuring effective operation and user safety.

Frequent Problems Encountered

Many users report specific complications that arise during the operation of lifting equipment. Below is a summary of the most common issues:

| Issue | Description |

|---|---|

| Hydraulic Fluid Leaks | Fluid loss can result in diminished lifting capacity, making the device unreliable. |

| Worn-out Seals | Seals may deteriorate over time, leading to inefficiency and potential failure during use. |

| Corrosion | Exposure to moisture can lead to rust and degradation, compromising structural integrity. |

| Improper Use | Exceeding weight limits or incorrect positioning can result in malfunction or damage. |

Prevention and Maintenance Tips

To minimize the risk of encountering these issues, regular inspection and proper maintenance are vital. Users should ensure that lifting equipment is stored in a dry environment, routinely check for fluid levels, and replace worn components as needed. Following these practices will enhance the longevity and reliability of the equipment.

Maintenance Tips for Car Jacks

Regular upkeep is essential to ensure the longevity and reliability of lifting equipment. Proper care not only enhances performance but also promotes safety during usage. By following a few simple guidelines, users can maximize the efficiency and lifespan of their lifting tools.

First, inspect the device frequently for signs of wear or damage. Look for cracks, rust, or any fluid leaks that could indicate potential failures. Keeping the equipment clean is equally important; wipe down any dirt or grime that may accumulate after each use. This prevents corrosion and ensures smooth operation.

Lubrication of moving parts is vital for optimal performance. Use the recommended lubricant on all joints and hinges to facilitate easy movement. Additionally, store the equipment in a dry, cool location to protect it from environmental factors that can lead to deterioration.

Lastly, always adhere to the manufacturer’s guidelines regarding weight limits and usage instructions. Overloading or improper use can lead to serious accidents and damage. Regular maintenance and mindful operation are key to achieving the best results from your lifting tools.

Choosing the Right Car Jack

Selecting an appropriate lifting device for your vehicle is essential for ensuring safety and efficiency during maintenance tasks. The right equipment can significantly enhance your ability to perform repairs or tire changes, making the experience smoother and more manageable. Various factors come into play, including weight capacity, design, and intended use, which must all align with your specific needs.

Types of Lifting Devices

Understanding the different types of lifting tools available can help you make an informed decision. Each type serves distinct purposes and has unique characteristics that cater to various situations.

| Type | Description | Ideal Use |

|---|---|---|

| Floor Model | These are low-profile and feature a hydraulic mechanism for easy lifting. | Regular maintenance and heavier vehicles. |

| Scissor Style | This compact option uses a scissor mechanism and is often lightweight. | Light vehicles and tight spaces. |

| Bottle Style | Featuring a vertical design, this type is highly portable and can lift heavy loads. | High-lift applications and heavier loads. |

| Electric | Powered by electricity, these devices offer convenience and ease of use. | Users seeking minimal physical effort. |

Factors to Consider

When selecting the right lifting device, several key considerations can help guide your choice. It’s crucial to assess the weight of your vehicle, the height needed for effective service, and your personal comfort with operating the equipment.

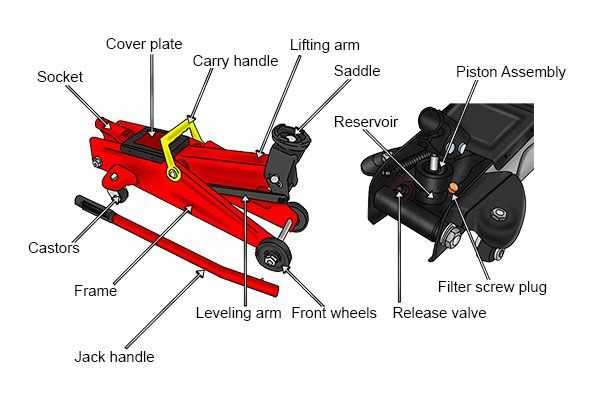

Diagram: Car Jack Parts Overview

This section provides a comprehensive examination of the essential components involved in the lifting mechanism commonly utilized for vehicles. Understanding these elements is crucial for effective operation and maintenance.

Key Components

The primary elements include the lifting mechanism, support structure, and actuation system. Each part plays a vital role in ensuring stability and efficiency during use.

Functionality and Maintenance

Regular maintenance of these components is critical to achieving optimal performance. Familiarity with the functionality of each section enhances safety and reliability.