In the world of agricultural equipment, comprehending the intricate elements that contribute to a machine’s performance is vital. A thorough understanding of these essential components enables operators to maintain efficiency and extend the lifespan of their equipment.

Every piece of machinery has its unique set of elements, each serving a specific purpose. By exploring the configurations and interactions of these components, users can better appreciate the overall functionality and reliability of their devices.

Delving into the specifics of machinery arrangements not only enhances operational knowledge but also aids in troubleshooting. Grasping the ultimate arrangement of these parts fosters an informed approach to maintenance and repairs, ensuring optimal performance throughout the equipment’s life cycle.

Understanding Bush Hog SQ600 Components

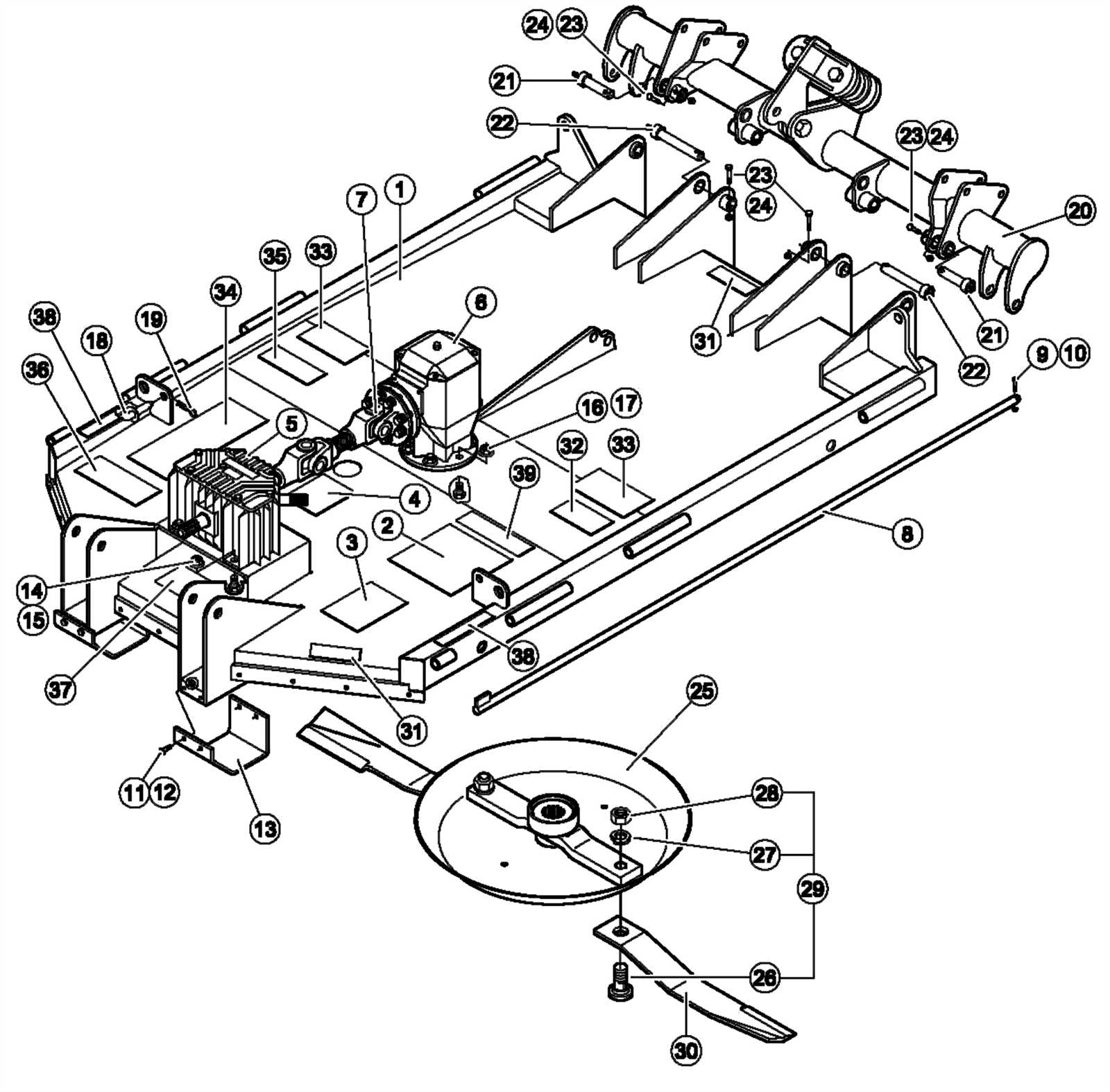

Gaining insight into the various elements that make up this agricultural implement is essential for optimal performance and maintenance. Each component plays a crucial role in the functionality and efficiency of the machine, contributing to its overall effectiveness in managing landscape tasks.

Key elements include the cutting blades, which are vital for achieving a clean and precise cut. These sharp tools are designed to withstand tough conditions and should be inspected regularly for wear and damage.

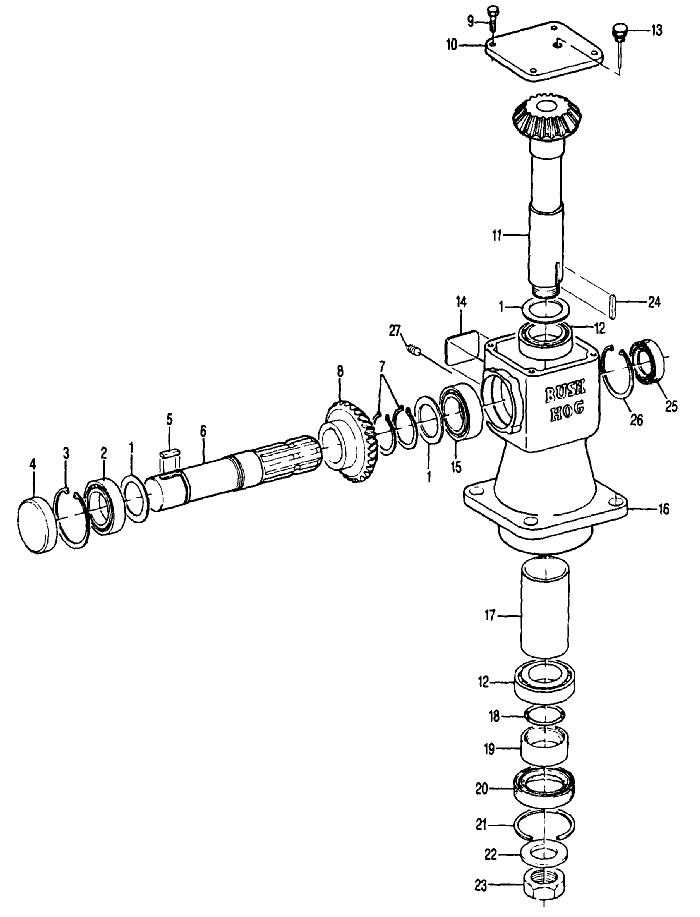

The gearbox serves as another fundamental piece, ensuring that power is transmitted efficiently from the tractor to the cutting mechanism. A well-functioning gearbox is crucial for the smooth operation of the implement, and regular lubrication can prevent unnecessary wear.

Additionally, the frame provides structural integrity, supporting all other components during use. A sturdy frame is essential for maintaining stability and ensuring that the implement can handle various terrains without compromise.

Finally, understanding the hydraulic system is important for controlling the height and angle of the cutting deck. Proper adjustment allows for versatility in different mowing conditions, enhancing productivity.

Overall, familiarity with these components can lead to improved maintenance practices and extended lifespan, ensuring that the equipment remains an invaluable asset for land management tasks.

Importance of Maintenance for Bush Hog

Regular upkeep is essential for ensuring optimal performance and longevity of any machinery. Neglecting maintenance can lead to decreased efficiency, increased repair costs, and potential safety hazards. By implementing a consistent maintenance schedule, operators can enhance the reliability and functionality of their equipment, ultimately leading to better results in the field.

Benefits of Regular Upkeep

Consistent maintenance offers several advantages that contribute to the overall effectiveness of machinery. Firstly, it helps identify and rectify minor issues before they escalate into significant problems. Secondly, routine checks can improve the equipment’s performance, resulting in smoother operation and enhanced productivity.

Key Maintenance Tasks

| Task | Frequency | Description |

|---|---|---|

| Lubrication | Weekly | Ensure all moving parts are adequately lubricated to prevent wear and tear. |

| Blade Inspection | Monthly | Check blades for sharpness and damage; sharpen or replace as necessary. |

| Belts and Cables | Monthly | Inspect for signs of wear and replace frayed components to maintain safety. |

| Fluid Levels | Weekly | Monitor oil and hydraulic fluid levels; top off as needed. |

| General Cleanliness | After Each Use | Clean debris and dirt from equipment to prevent corrosion and maintain efficiency. |

By adhering to these maintenance practices, operators can significantly extend the lifespan of their machinery while maximizing operational efficiency. Regular attention to maintenance not only preserves the equipment but also enhances safety for all users involved.

Common Issues with SQ600 Parts

When working with agricultural machinery, certain components may experience wear and tear over time. Identifying and addressing these common concerns can enhance performance and prolong the lifespan of the equipment. Below are typical problems that users might encounter with various components.

- Wear and Tear: Continuous use can lead to deterioration, particularly in high-friction areas.

- Corrosion: Exposure to moisture can result in rust, affecting the integrity of metal components.

- Alignment Issues: Improper installation or damage can cause misalignment, leading to uneven operation.

Regular maintenance and timely replacement of affected components are crucial. Here are some specific issues to monitor:

- Blades:

- Chipping and dullness can reduce cutting efficiency.

- Ensure blades are sharpened regularly to maintain optimal performance.

- Belts:

- Signs of fraying or cracking indicate a need for replacement.

- Check tension to prevent slipping.

- Hydraulic Systems:

- Leaking fluids can compromise functionality and safety.

- Inspect hoses and connections for any signs of damage.

Addressing these issues promptly can significantly improve the efficiency and reliability of the machinery in use.

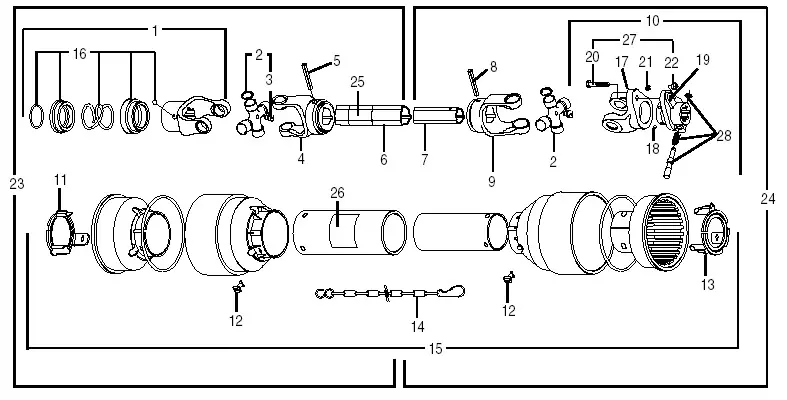

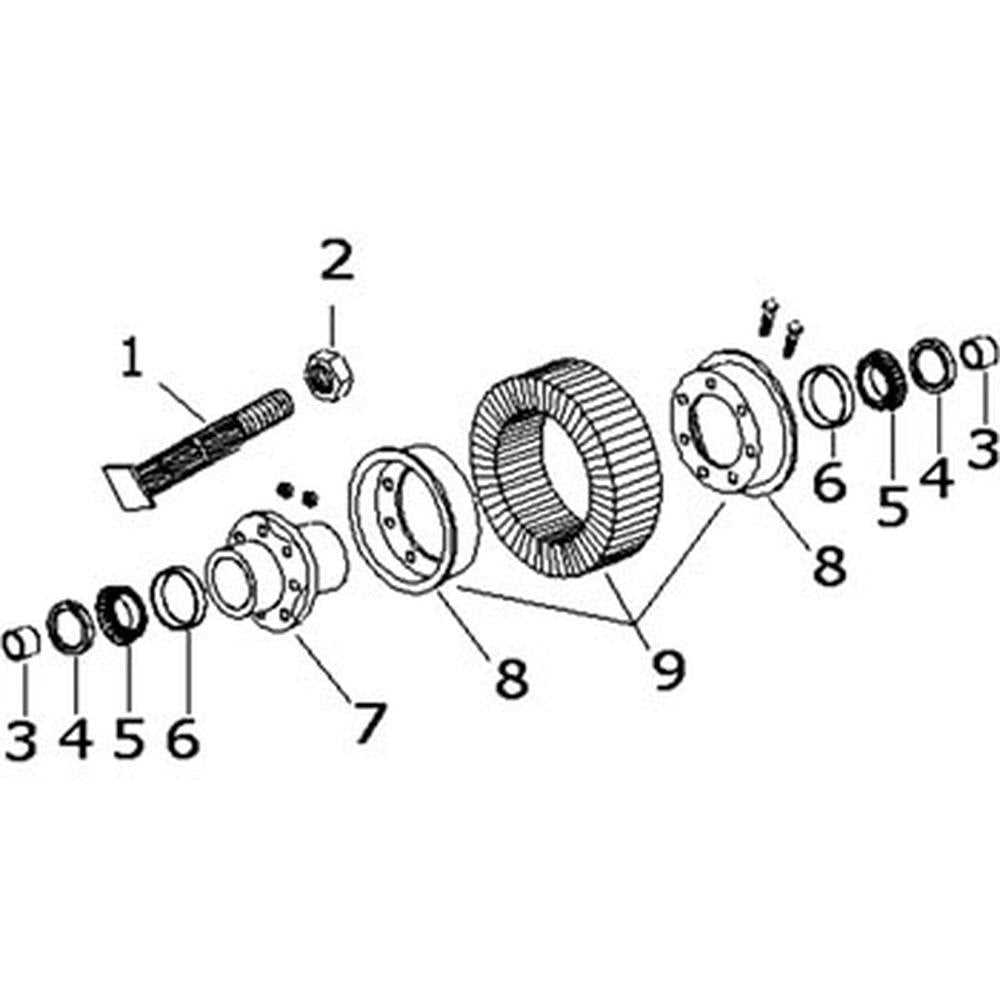

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repairs of machinery. These visuals serve as a roadmap, guiding users through the various components and their arrangements. Familiarity with these illustrations can significantly enhance the efficiency of troubleshooting and ordering necessary items.

To start, focus on the legend or key provided, which typically explains the symbols and markings used throughout the visual. Each element is often labeled with a unique identifier, making it easier to reference specific components when discussing or ordering replacements. Pay attention to any accompanying numbers or letters that indicate the sequence or groupings of parts.

Next, analyze the layout. Most visuals are organized logically, showing how pieces fit together. Observing the connections between elements can provide insight into the assembly process and help identify potential issues during maintenance. Recognizing how parts interact is crucial for effective repairs.

Lastly, don’t hesitate to consult the accompanying documentation for further clarification. Manuals often provide additional context, including installation tips and troubleshooting advice. Leveraging both the visual and textual resources will empower you to navigate the intricacies of your machinery with confidence.

Where to Find Replacement Parts

When it comes to maintaining agricultural machinery, sourcing high-quality components is crucial for optimal performance. Whether you’re in need of specific elements or accessories, there are several reliable avenues to explore for obtaining the necessary items.

Local retailers often provide a variety of components, making them a convenient option for quick replacements. Additionally, online platforms offer an extensive selection, allowing you to compare prices and specifications easily. Moreover, specialized dealerships can provide expert guidance and original equipment, ensuring compatibility with your machinery.

| Source | Description | Advantages |

|---|---|---|

| Local Stores | Physical outlets that carry a selection of components. | Immediate availability and in-person assistance. |

| Online Retailers | Websites that offer a wide range of items for various needs. | Convenience and price comparison. |

| Specialized Dealers | Authorized vendors with expertise in specific machinery. | Access to original equipment and expert advice. |

Tips for Installing New Components

Installing new elements in your machinery can significantly enhance performance and efficiency. However, achieving a seamless installation requires careful planning and attention to detail. Here are some practical suggestions to ensure a successful integration of new components.

Preparation is Key

- Review the manufacturer’s instructions thoroughly before starting the installation process.

- Gather all necessary tools and materials to avoid interruptions.

- Ensure that you have a clean and well-lit workspace to facilitate the installation.

Step-by-Step Installation

- Begin by removing any old components with caution, ensuring that no additional damage occurs.

- Inspect the new elements for defects or discrepancies before installation.

- Align the new components carefully to fit correctly into their designated positions.

- Secure all connections tightly, but avoid over-tightening to prevent damage.

- After installation, test the machinery to ensure everything functions as intended.

By following these guidelines, you can effectively enhance the functionality of your equipment while minimizing potential issues during installation.

Comparing SQ600 to Other Models

When evaluating various machinery options, it is essential to analyze the differences in functionality, design, and overall performance. This comparison provides insights into how specific models stand out or align with industry standards, helping users make informed decisions based on their unique needs.

Key Differences in Features

- Design: The layout and build quality can significantly affect durability and ease of use.

- Performance: Variations in power and efficiency impact operational effectiveness.

- Maintenance: Some models offer easier access for repairs and servicing.

Advantages of Each Model

- Model A: Known for its robust construction, making it suitable for heavy-duty tasks.

- Model B: Offers superior maneuverability, ideal for smaller or more intricate workspaces.

- Model C: Emphasizes energy efficiency, reducing long-term operational costs.

Understanding these distinctions allows operators to choose the right equipment that meets their specific requirements, enhancing productivity and ensuring satisfaction in performance.

Cost-Effective Solutions for Repairs

When it comes to maintaining and restoring equipment, finding economical options for repairs can make a significant difference. By exploring alternative methods and sourcing quality components, users can effectively manage their budgets while ensuring optimal performance of their machinery.

One practical approach is to assess the condition of existing parts before opting for replacements. Often, minor wear can be addressed through simple fixes, such as tightening connections or applying lubricants, which can extend the lifespan of the equipment without incurring high costs.

Additionally, utilizing aftermarket solutions can provide substantial savings. Many manufacturers offer compatible components that meet industry standards but at a fraction of the price of original parts. Researching reliable suppliers and reading customer reviews can guide users to reputable options.

Another effective strategy is to engage in preventive maintenance. Regular inspections and upkeep can identify potential issues early, allowing for timely interventions that prevent more extensive and costly repairs in the future. Implementing a maintenance schedule can safeguard against unexpected breakdowns and enhance overall efficiency.

Finally, community resources such as forums and repair groups can offer invaluable advice and support. Connecting with fellow users can lead to shared knowledge, tips for DIY repairs, and access to tools that might otherwise be prohibitively expensive to purchase.