In the realm of home heating, the intricate network of elements plays a crucial role in ensuring efficiency and reliability. Each component, from the ignition system to the heat exchanger, contributes to the overall functionality of the unit. Familiarity with these essential parts not only aids in troubleshooting but also enhances the ability to perform routine maintenance.

To fully grasp how these systems operate, one must visualize the arrangement and interconnections of these elements. A comprehensive representation serves as a valuable reference, making it easier to identify each section’s role. This clarity empowers homeowners and technicians alike to address issues swiftly and effectively, ultimately prolonging the lifespan of the entire heating apparatus.

Additionally, understanding the layout allows for informed decisions regarding upgrades or replacements. Knowing what each part does can facilitate better communication with service professionals and lead to more efficient repairs. By enhancing one’s knowledge of the system’s architecture, individuals can take proactive steps in maintaining a comfortable and warm environment throughout the colder months.

Understanding Burnham Boiler Components

Grasping the essential elements of a heating system is crucial for efficient operation and maintenance. Each component plays a vital role in ensuring optimal performance and energy efficiency. Familiarity with these elements allows for better troubleshooting and enhances overall system longevity.

At the core of these systems lies the combustion chamber, where fuel is ignited to generate heat. Surrounding this chamber are various sensors and valves that monitor and regulate temperature and pressure, ensuring safe and effective functionality. Additionally, the circulatory mechanisms work to distribute warmth throughout the structure, providing consistent comfort in every room.

Understanding the control mechanisms is equally important. These devices enable users to adjust settings according to specific needs, optimizing energy usage. Furthermore, the maintenance aspects cannot be overlooked, as regular inspections of these components prevent unforeseen breakdowns and extend the system’s lifespan.

Ultimately, a comprehensive understanding of these essential elements empowers users to make informed decisions regarding installation, maintenance, and upgrades, leading to improved efficiency and reduced operational costs.

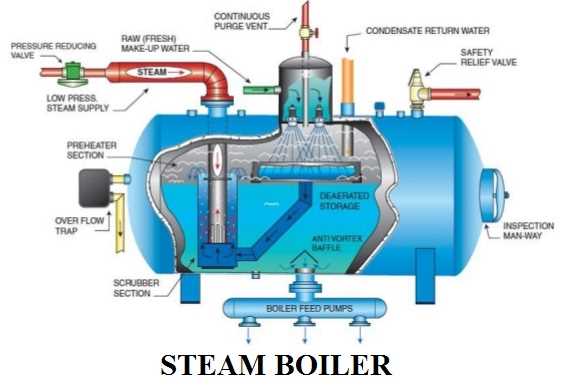

Overview of Boiler Functionality

Understanding the mechanics behind heating systems is essential for optimizing their performance and ensuring efficiency. These systems transform energy sources into heat, which is then distributed to maintain comfortable temperatures in various environments. The process involves several key components that work in unison to achieve this goal.

Energy Conversion Process

At the heart of any heating system is the conversion of energy, typically from fuels such as natural gas, oil, or electricity, into thermal energy. This transformation occurs in a central unit where fuel is ignited or heated, producing hot gases or fluids. The generated heat is then transferred to a medium, often water, which circulates through the infrastructure to deliver warmth where needed.

Distribution and Control Mechanisms

Once heated, the fluid travels through a network of pipes and radiators or other delivery methods to release warmth into the environment. To maintain the desired temperature, a control system regulates the operation of the unit, adjusting fuel flow and heat output as necessary. This ensures a consistent and efficient delivery of warmth, catering to the specific needs of the space being heated.

Regular maintenance and awareness of the system’s functionality are crucial for longevity and optimal performance. Understanding these principles allows users to make informed decisions about usage and upgrades, enhancing overall comfort and efficiency.

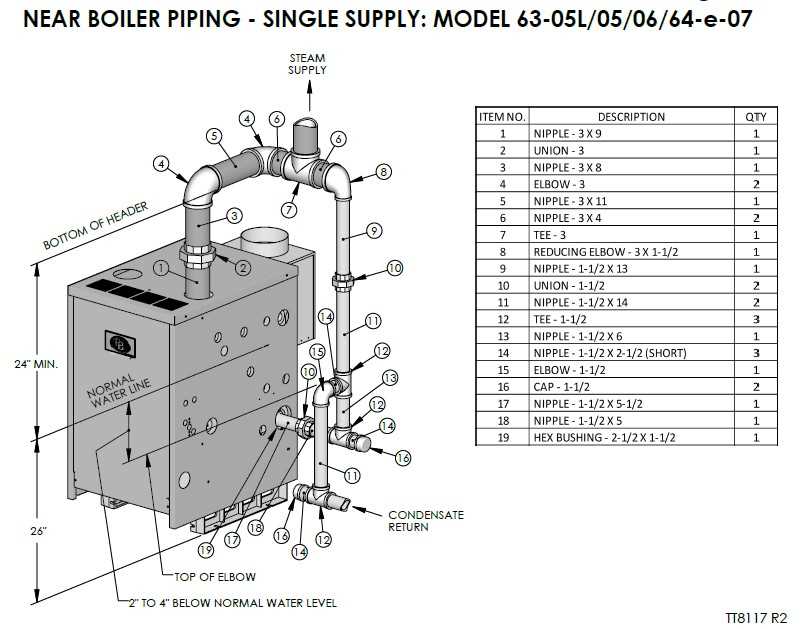

Key Parts in Burnham Models

Understanding the essential components of heating units is crucial for optimal performance and maintenance. Each model features specific elements that work together to ensure efficient operation, reliability, and safety. Identifying these key components can help users make informed decisions regarding installation, troubleshooting, and repairs.

One of the primary elements is the heat exchanger, responsible for transferring heat from the combustion process to the water or air circulating within the system. This component is vital for maintaining the desired temperature levels in residential or commercial spaces.

The control system, including thermostats and safety mechanisms, plays a significant role in regulating temperature and preventing malfunctions. This technology ensures that the unit operates within safe parameters, providing peace of mind to users.

Another important feature is the ignition system, which initiates the combustion process. This may involve electronic igniters or pilot lights, each designed to enhance efficiency and reduce energy consumption.

Lastly, the circulation pump is crucial for moving heated water throughout the system, ensuring that warmth reaches every corner of a building. Its performance directly affects the overall efficiency and comfort level of the environment.

Identifying Common Issues

Understanding the typical challenges associated with heating systems is crucial for maintaining efficiency and safety. Recognizing these problems early can prevent more significant issues and costly repairs down the line. Below are some prevalent complications you might encounter.

Common Symptoms

- Unusual noises, such as banging or hissing.

- Inconsistent heating across different rooms.

- Unexpected spikes in energy bills.

- Visible leaks or moisture around the unit.

Potential Causes

- Air trapped in the system, leading to uneven heat distribution.

- Corrosion or scale buildup affecting performance.

- Faulty components that disrupt normal operation.

- Improper settings or thermostat malfunctions.

Being aware of these indicators can help in timely interventions, ensuring the system runs smoothly and effectively.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your heating system requires regular attention and care. By following a few essential practices, you can significantly extend the lifespan of your unit while maintaining optimal performance.

- Perform regular inspections to identify any signs of wear or damage.

- Clean components regularly to prevent buildup that can hinder performance.

- Check for proper ventilation to ensure efficient operation.

In addition to routine checks, consider these vital maintenance actions:

- Schedule annual professional servicing to address complex issues.

- Monitor pressure levels consistently to avoid system stress.

- Replace filters as recommended to maintain air quality and efficiency.

By adopting these maintenance tips, you can enjoy a reliable and effective heating solution for years to come.

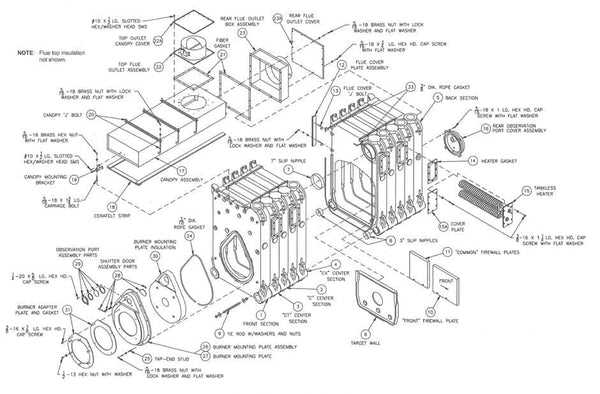

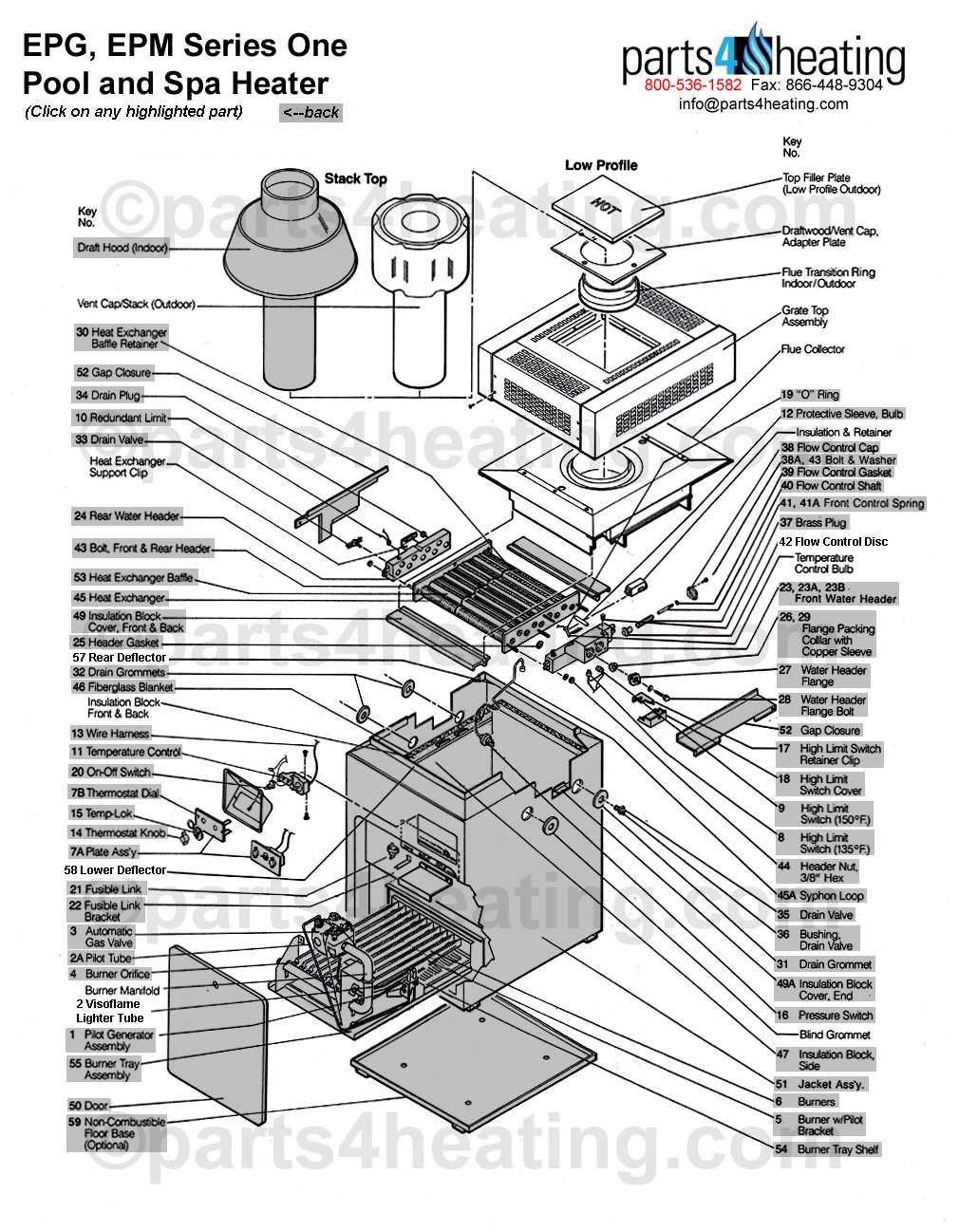

How to Read a Parts Diagram

Understanding a schematic representation is crucial for anyone involved in maintenance or repair tasks. These visual aids provide a detailed overview of components and their interconnections, helping users identify and locate specific items quickly. Familiarity with such illustrations can enhance efficiency and accuracy in troubleshooting and replacement activities.

Key Elements to Observe

Start by examining the overall layout of the illustration. Look for labels that indicate the names or numbers of each component. These identifiers are essential for cross-referencing with manuals or inventory lists. Additionally, pay attention to the connections between various elements, as these lines often signify flow paths or electrical links critical for system functionality.

Interpreting Symbols and Notations

Many schematics incorporate specific symbols to represent different types of components. Familiarizing yourself with these symbols can significantly reduce confusion. Also, be aware of any accompanying notes or legends that explain special features or unique instructions related to the illustration. This knowledge will empower you to navigate the information effectively and make informed decisions during maintenance tasks.

Replacement Options for Broken Parts

When essential components of a heating system fail, it is crucial to identify suitable alternatives to ensure optimal performance and safety. Whether due to wear and tear or unexpected malfunctions, having effective replacement options can significantly extend the lifespan of your equipment and enhance efficiency.

OEM Components are often the most reliable choice, as they are designed to meet the original specifications set by the manufacturer. These items guarantee compatibility and are typically subjected to rigorous quality testing.

Another viable route is aftermarket alternatives. While they may not come from the original manufacturer, many reputable suppliers offer components that meet or exceed the required standards. It’s essential to research the credibility of these brands to ensure you’re getting a durable and effective solution.

Rebuilt or Refurbished Options present an eco-friendly choice. These components are restored to working condition and can often be purchased at a lower cost. However, ensure that they come with a warranty and are tested for reliability before making a purchase.

Lastly, custom-made solutions can be considered for unique situations where standard replacements are not viable. Engaging with skilled technicians can lead to innovative fixes tailored to your specific needs, ensuring both functionality and safety.

In conclusion, exploring various replacement avenues can provide efficient solutions for malfunctioning elements, ultimately contributing to the seamless operation of your heating system.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance and repairs is crucial to prevent accidents and injuries. Proper measures must be taken to safeguard both the technician and the surrounding environment. Following a set of guidelines can significantly reduce risks associated with the process.

Before starting any repair work, it’s essential to familiarize yourself with the specific system you are dealing with. This includes understanding its components and operational principles. Proper training and knowledge can prevent dangerous situations.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use appropriate safety equipment, such as gloves, goggles, and ear protection, to minimize the risk of injury. |

| Disconnect Power Supply | Before beginning repairs, ensure that the power source is completely disconnected to avoid electric shocks. |

| Check for Gas Leaks | Inspect the area for any gas leaks, using soapy water to identify escaping gas, and ensure proper ventilation. |

| Use Tools Correctly | Utilize the right tools for the job, and ensure they are in good working condition to avoid accidents. |

| Follow Manufacturer Instructions | Adhere to the manufacturer’s guidelines for maintenance to ensure safe and effective repairs. |

By following these precautions, technicians can create a safer working environment, significantly minimizing the likelihood of accidents during maintenance activities.

Resources for Further Information

Accessing comprehensive resources can significantly enhance your understanding of heating systems and their components. Whether you are a professional technician or a DIY enthusiast, a variety of materials are available to help you deepen your knowledge and improve your skills.

Online Guides and Manuals

- Manufacturer websites often provide downloadable manuals and guides.

- Forums and community websites feature discussions and troubleshooting tips.

- Video tutorials on platforms like YouTube offer visual demonstrations of maintenance and repair procedures.

Books and Publications

- Technical books focusing on heating technologies can provide in-depth insights.

- Industry magazines and journals keep you updated on the latest trends and innovations.

- Local libraries may have resources related to system maintenance and repair.

Utilizing these resources will empower you with the knowledge needed to effectively manage heating systems and ensure their optimal performance.