In the world of heavy machinery, having a comprehensive understanding of each element is essential for optimal performance and maintenance. Every component plays a crucial role in the overall functionality, ensuring that the equipment operates smoothly and efficiently. This knowledge not only aids in identifying issues but also enhances the decision-making process when it comes to repairs and replacements.

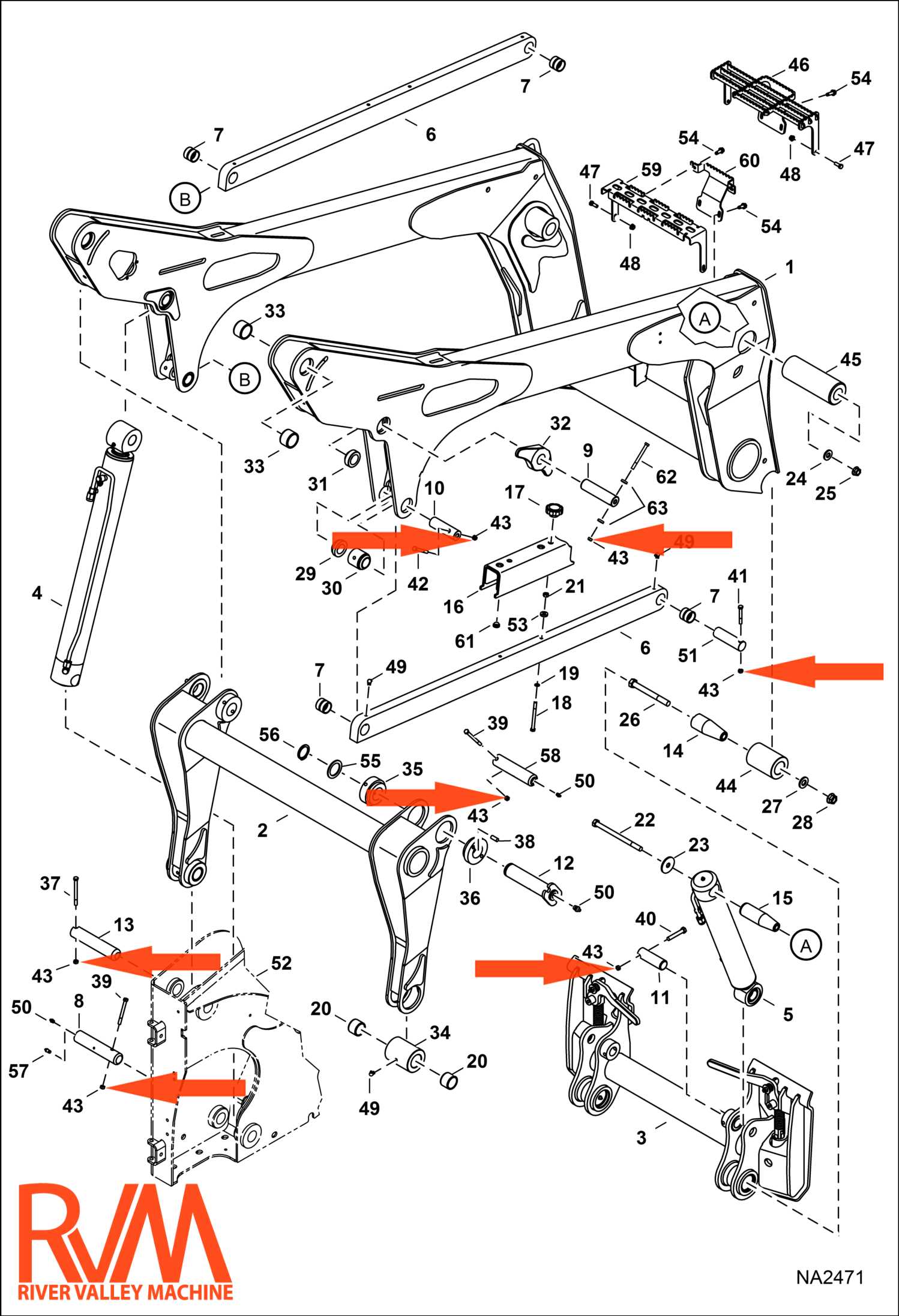

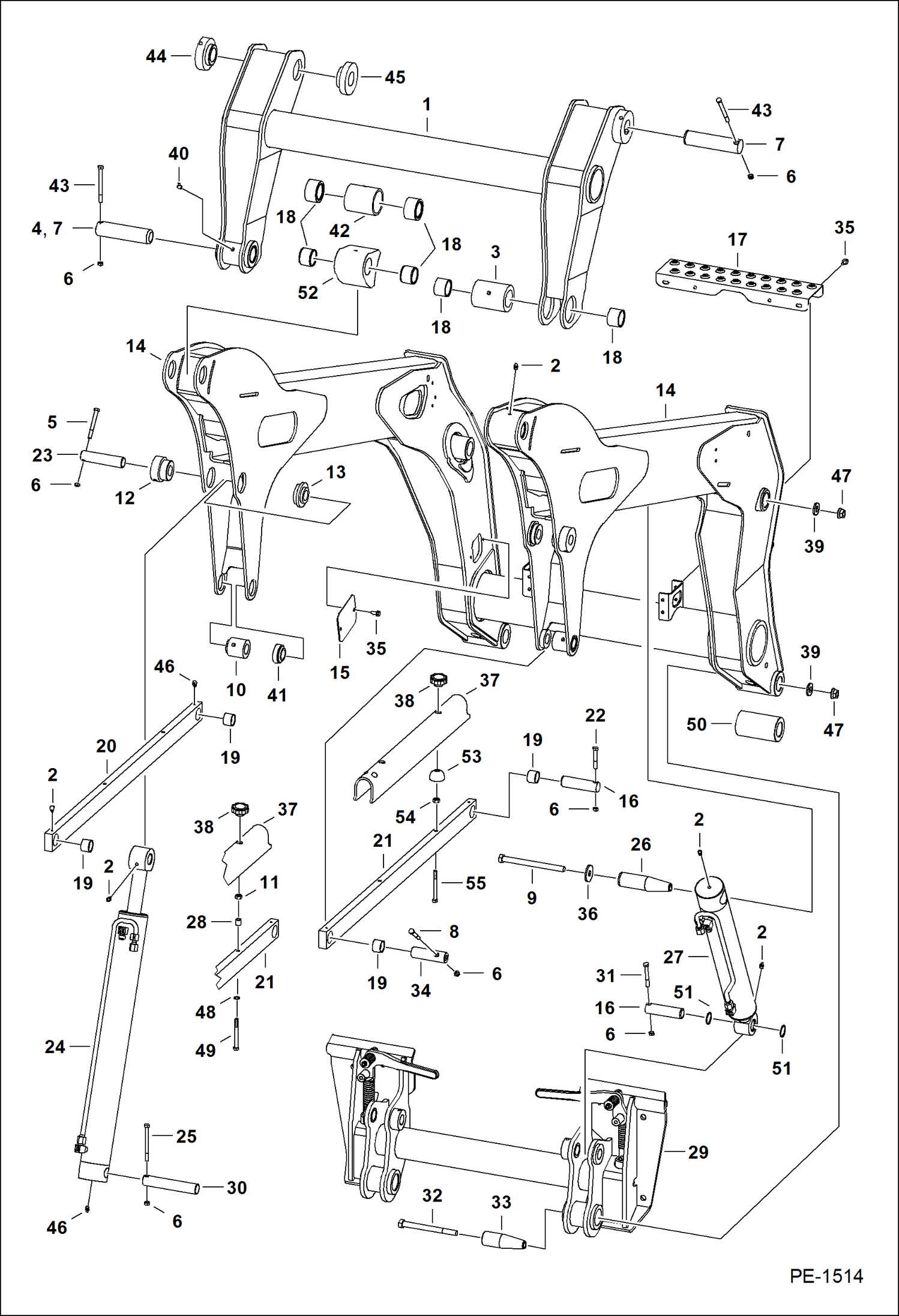

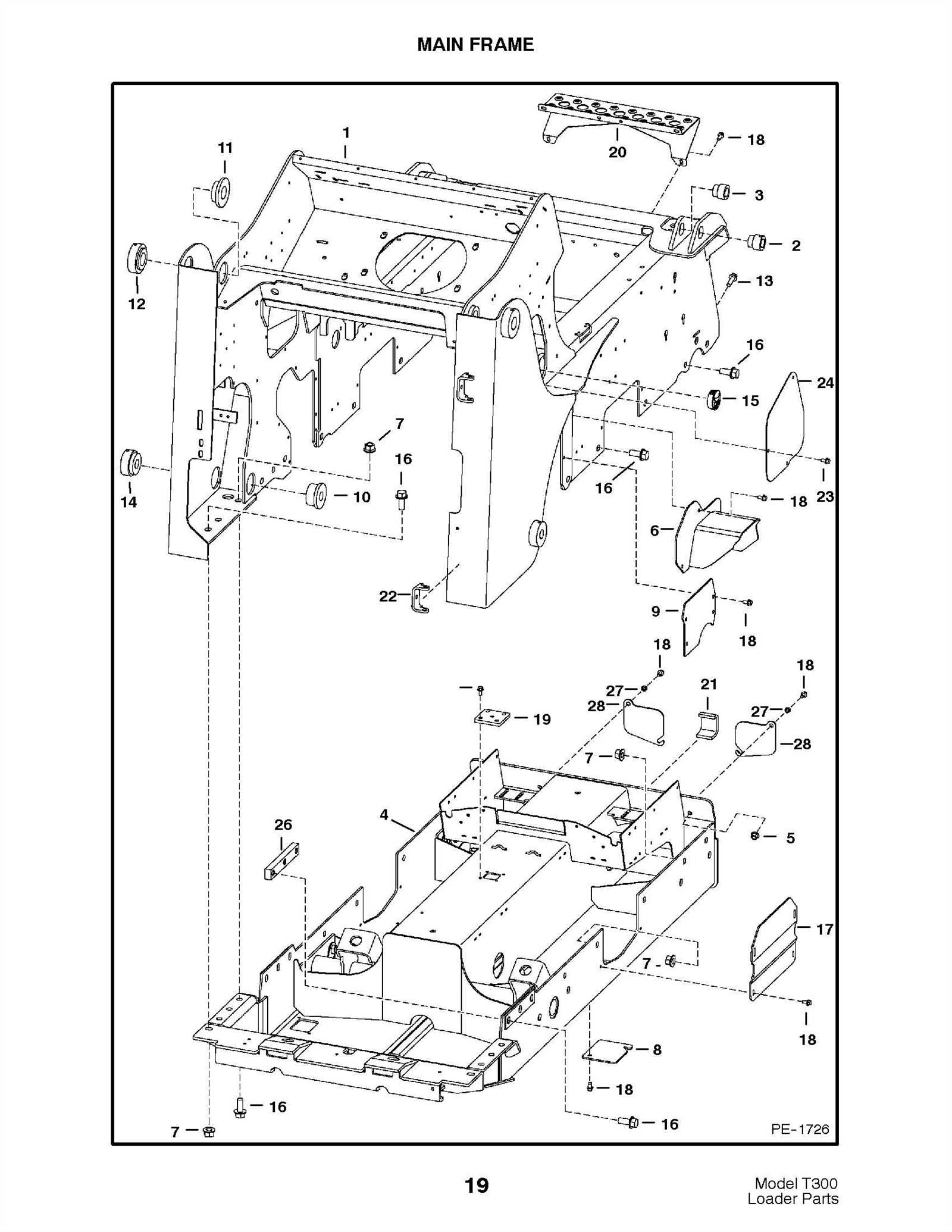

Visual representations of the individual elements allow operators and technicians to grasp the intricate relationships between various sections. By analyzing these illustrations, one can better appreciate how each part interacts within the larger system. This understanding is invaluable for troubleshooting and ensuring the longevity of the equipment.

Furthermore, being familiar with the specific layout of components can significantly reduce downtime. It empowers users to quickly locate and address potential problems, leading to increased productivity. As such, acquiring detailed insights into these essential structures becomes a fundamental aspect of effective machine management.

Exploring the Bobcat T300 Parts Diagram: A Comprehensive Guide

This section delves into the intricate layout of components and assemblies found in a particular model of compact machinery. Understanding this schematic is crucial for maintenance, troubleshooting, and overall functionality of the equipment. By familiarizing yourself with these details, you can ensure optimal performance and longevity of your machine.

Key Components Overview

Each assembly plays a vital role in the operation of the machinery. Here are some of the primary sections you will encounter:

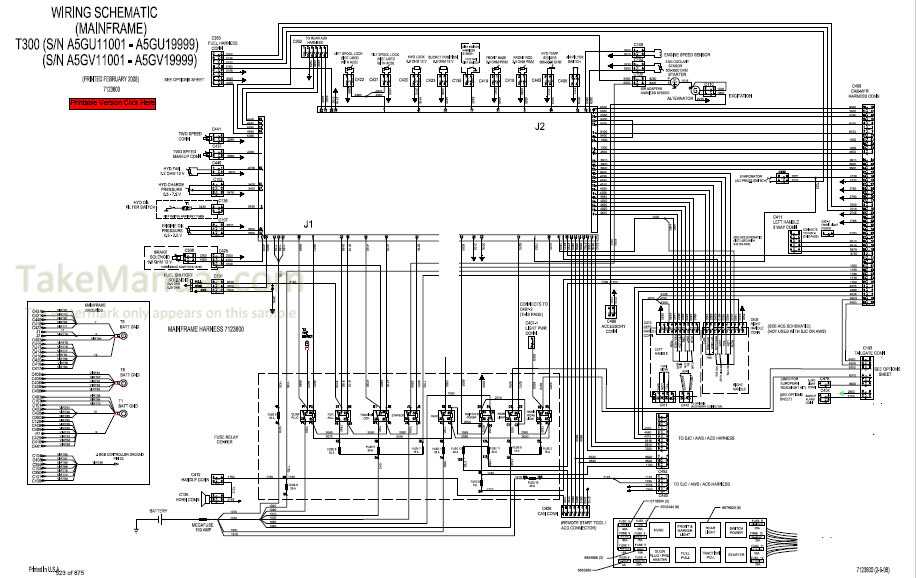

- Hydraulic System

- Engine Assembly

- Transmission

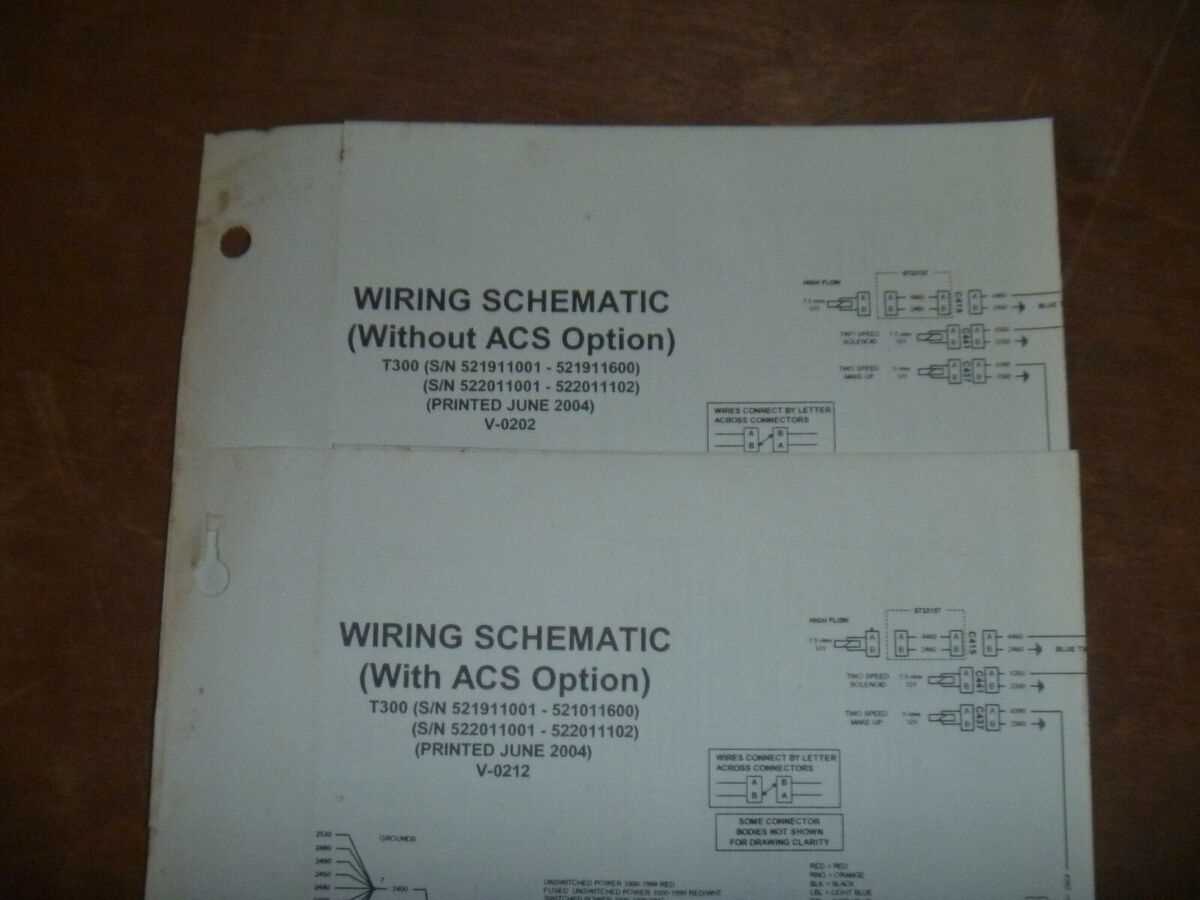

- Electrical System

- Chassis and Frame

Understanding the Layout

To effectively utilize the schematic, it’s essential to grasp the layout’s structure. Below are some tips to help navigate the components:

- Identify major assemblies and their functions.

- Look for connection points between different sections.

- Pay attention to the labels for quick reference.

- Note any specific parts that require regular maintenance.

By systematically exploring these areas, you will enhance your comprehension and ability to perform repairs or upgrades on the machinery with confidence.

Understanding the Bobcat T300: An Overview

This section provides a comprehensive look at a versatile and powerful machine designed for a variety of tasks in construction and landscaping. With its compact design and robust capabilities, this equipment is well-suited for maneuvering in tight spaces while still delivering impressive performance.

The machine features a range of functionalities that make it indispensable for professionals. Its hydraulic system allows for efficient operation of various attachments, enhancing productivity on the job site. The operator’s comfort and control are prioritized through an ergonomic design, enabling users to work for extended periods without fatigue.

Maintenance and repair are crucial for the longevity of any machinery. Understanding the components and their functions can greatly aid in troubleshooting and ensuring optimal performance. Familiarity with the essential elements of this equipment empowers operators and technicians alike, allowing them to keep the machine running smoothly and efficiently.

Importance of Familiarizing with Equipment Diagrams

Understanding machinery layouts and schematics is crucial for effective maintenance and operation. Familiarity with these visuals allows operators and technicians to identify components easily, streamline repairs, and enhance safety. By grasping how parts interact, users can prevent mishaps and optimize equipment performance.

Benefits of Understanding Visual Guides

- Efficient Troubleshooting: Quick identification of issues reduces downtime.

- Informed Repairs: Knowledge of component relationships facilitates accurate fixes.

- Safety Awareness: Recognizing potential hazards leads to safer operation practices.

Best Practices for Utilizing Equipment Schematics

- Review the guide regularly to stay updated on changes.

- Use visuals during training to enhance comprehension.

- Keep a physical or digital copy accessible for quick reference.

Key Components Highlighted in the T300 Diagram

Understanding the essential elements of machinery is crucial for effective maintenance and operation. The intricacies of each component play a vital role in ensuring optimal performance and longevity. This section delves into the significant parts illustrated in the schematic, providing insight into their functions and importance.

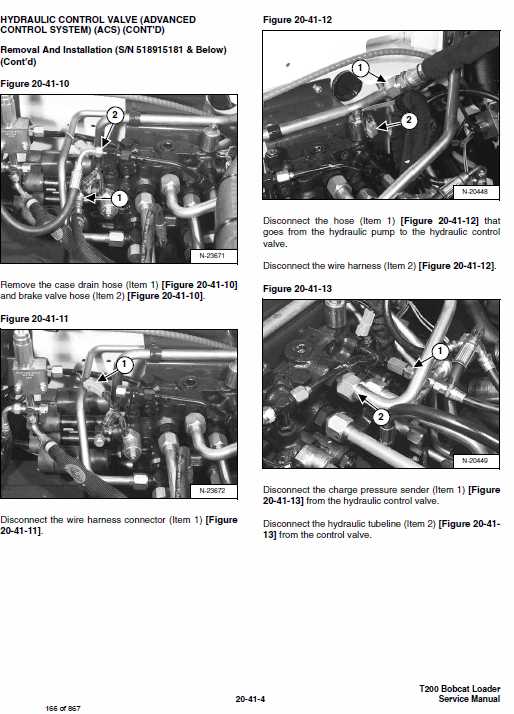

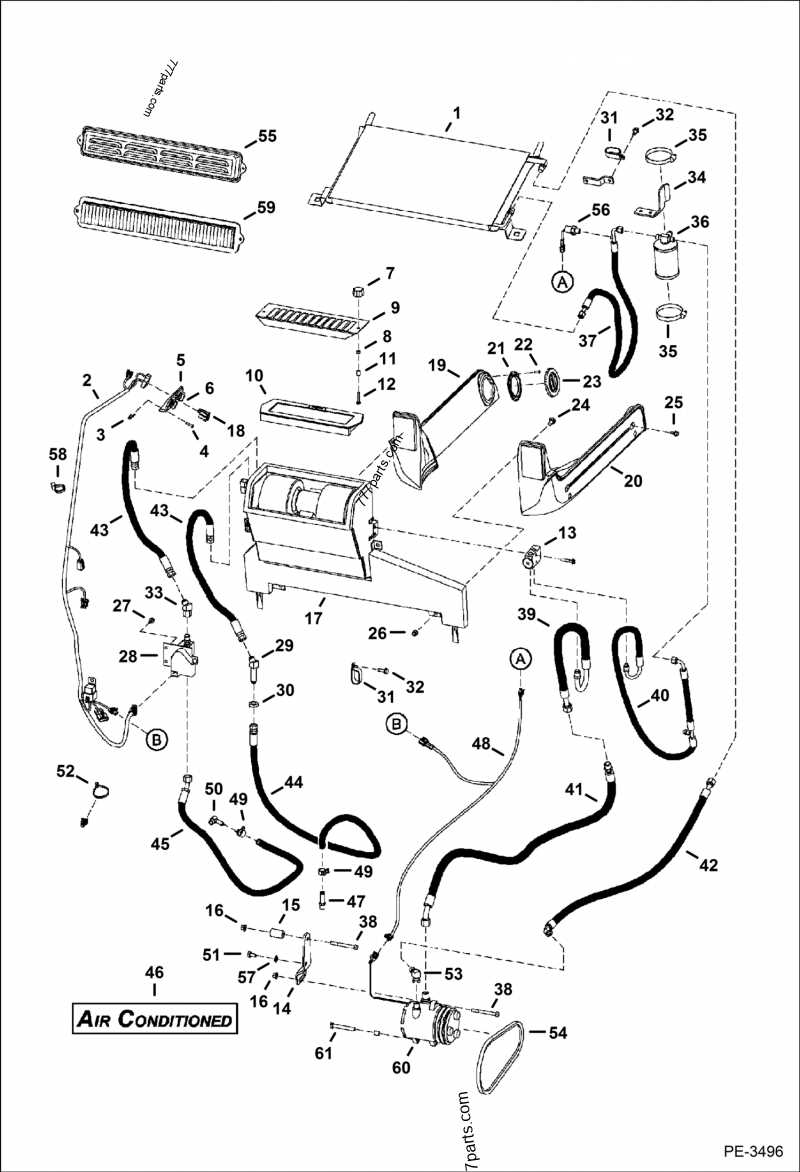

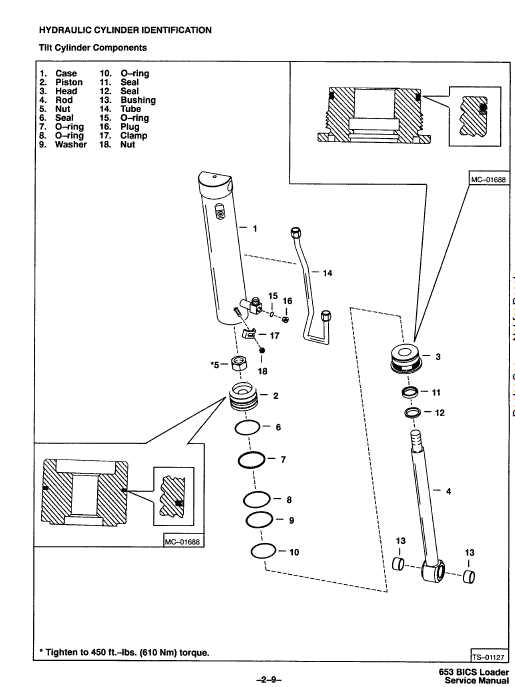

Hydraulic System

The hydraulic system is the powerhouse of the equipment, responsible for powering various functions. It consists of pumps, cylinders, and valves that work together to facilitate movement and control. A well-maintained hydraulic assembly ensures efficiency and responsiveness, making it a critical focus for operators.

Drive Train Assembly

The drive train assembly connects the engine to the wheels or tracks, translating power into motion. Key components include the transmission, axles, and differential. Understanding this assembly helps in diagnosing performance issues and is essential for ensuring smooth operation in diverse terrains.

How to Interpret and Use the Parts Diagram Effectively

Understanding the visual representation of components is essential for maintaining and repairing machinery. These illustrations serve as valuable tools for identifying individual elements and their relationships within a larger system. Mastering the interpretation of these visuals can significantly enhance your efficiency in troubleshooting and sourcing replacements.

Analyzing the Visual Representation

When examining the illustration, focus on the labeling of each component. Pay attention to numbers or letters that correlate with the accompanying list, which typically provides detailed descriptions. This method allows you to pinpoint specific items quickly and accurately. Moreover, look for any symbols or color coding that may indicate particular functions or compatibility issues.

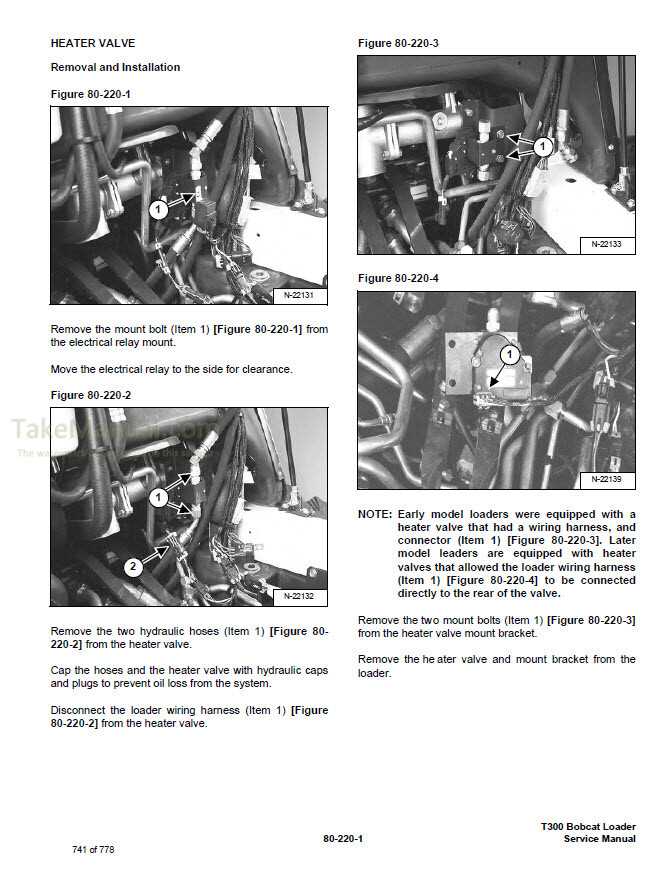

Utilizing the Information for Repairs

Once you have familiarized yourself with the illustration, use it as a reference during maintenance or repairs. Cross-reference the visual with your service manual to ensure that you are addressing the correct elements. Keeping a copy of the illustration on hand while working can streamline the process and minimize the risk of errors. By effectively utilizing this resource, you can enhance your ability to perform repairs with confidence and precision.

Common Maintenance Tasks Simplified with the Diagram

Effective upkeep of machinery is essential for optimal performance and longevity. Visual representations of components can significantly streamline routine maintenance procedures, allowing operators to quickly identify parts that require attention. This approach not only enhances efficiency but also minimizes the risk of overlooking critical elements during service.

Identifying Key Components

Having a clear visual guide aids in recognizing essential parts that may need regular inspection or replacement. By understanding the layout and function of each component, operators can systematically address potential issues. For instance, recognizing wear indicators can help schedule timely replacements, thus avoiding unexpected breakdowns.

Streamlining Maintenance Procedures

With a visual reference, the maintenance process becomes more intuitive. Operators can follow a structured approach, ensuring that no steps are missed. This method reduces downtime and promotes a more proactive stance towards equipment care. Regular checks can be integrated into the workflow, making it easier to maintain high standards of operation and safety.

In conclusion, utilizing visual aids for maintenance enhances understanding, promotes efficiency, and ultimately leads to more reliable machinery performance.

Where to Access and Use the T300 Parts Diagram

Accessing a detailed schematic of machinery components is essential for effective maintenance and repair. Such resources provide visual guidance, making it easier to identify specific elements and understand their relationships within the overall system. Whether you are a professional technician or a DIY enthusiast, having the right resources at your fingertips can significantly streamline your work process.

Online Resources: Numerous websites offer comprehensive resources for machinery schematics. Manufacturer websites often host downloadable manuals that include these essential visuals. Additionally, third-party platforms may provide forums where users can share information and insights about specific models.

Physical Manuals: Many equipment dealers and service centers provide hard copies of manuals, including detailed breakdowns of components. These printed resources can be invaluable, especially in workshop settings where internet access may be limited.

Workshops and Training Centers: Participating in training sessions at authorized service locations can also yield access to detailed schematics. These environments often equip technicians with not just the diagrams but also hands-on experience, enhancing understanding of the machinery.

Utilizing the Resource: When using a schematic, take time to familiarize yourself with the layout. Start by identifying the major components, then delve into the specifics. Mark any parts that need attention and refer to the accompanying documentation for guidance on replacements or repairs.

Tips for Troubleshooting Using the Diagram

Understanding the layout and components of your machinery is crucial for effective problem-solving. By familiarizing yourself with the visual representation of the equipment, you can pinpoint issues and implement solutions more efficiently.

Identify Common Problems

Start by recognizing frequent malfunctions. Utilize the visual guide to locate corresponding parts and assess their condition. Pay attention to wear and tear, as this can provide significant clues to underlying issues.

Systematic Approach

Adopt a methodical strategy when examining each element. Document your findings as you go along, which can help trace the root cause of the problem. This thorough examination will ultimately lead to more informed decisions regarding repairs and maintenance.

Enhancing Efficiency and Safety through Diagram Utilization

The use of visual representations in machinery maintenance and operation can significantly boost both productivity and safety standards. By providing clear and concise illustrations of components and their interrelations, these tools facilitate quicker understanding and execution of tasks. This leads to reduced downtime and more effective troubleshooting, ensuring that machinery operates at optimal levels.

Moreover, incorporating such visual aids into training programs enhances the learning experience for operators and technicians. They can easily grasp complex systems and identify critical parts, thereby minimizing the risk of errors. This proactive approach not only improves operational efficiency but also fosters a safer working environment by clearly delineating processes and potential hazards.

Ultimately, the integration of visual guides serves as a vital resource, equipping teams with the knowledge necessary to maintain equipment effectively. This promotes longevity and reliability in machinery, reflecting positively on overall project outcomes and operational success.