Maintaining heavy machinery requires not only regular care but also a clear understanding of its core mechanical structure. Each element plays a crucial role in ensuring that the equipment runs smoothly, and recognizing how these elements connect and function together is vital for preventing breakdowns and maximizing operational efficiency.

To effectively service and repair such equipment, it’s important to have a comprehensive overview of the internal and external mechanisms. Knowing the layout and functions of various assemblies can help reduce downtime and extend the life of the machine. Whether you’re replacing specific elements or conducting general upkeep, having a clear guide to the equipment’s structure is indispensable.

Comprehensive Overview of Bobcat 610 Components

The machine is composed of various key elements that work together to provide efficient functionality. Each section of the equipment plays a crucial role in ensuring optimal performance and longevity. By understanding the specific roles of these elements, operators and technicians can better maintain and troubleshoot the system, ensuring smooth operation in various tasks.

Among the main sections, the engine powers the entire system, while the hydraulic system enables precise control. The undercarriage supports the movement, and the control mechanism allows for accurate operation. Each component is interconnected, forming a reliable and durable unit capable of handling demanding workloads. Proper knowledge of these elements is essential for effective maintenance and repairs.

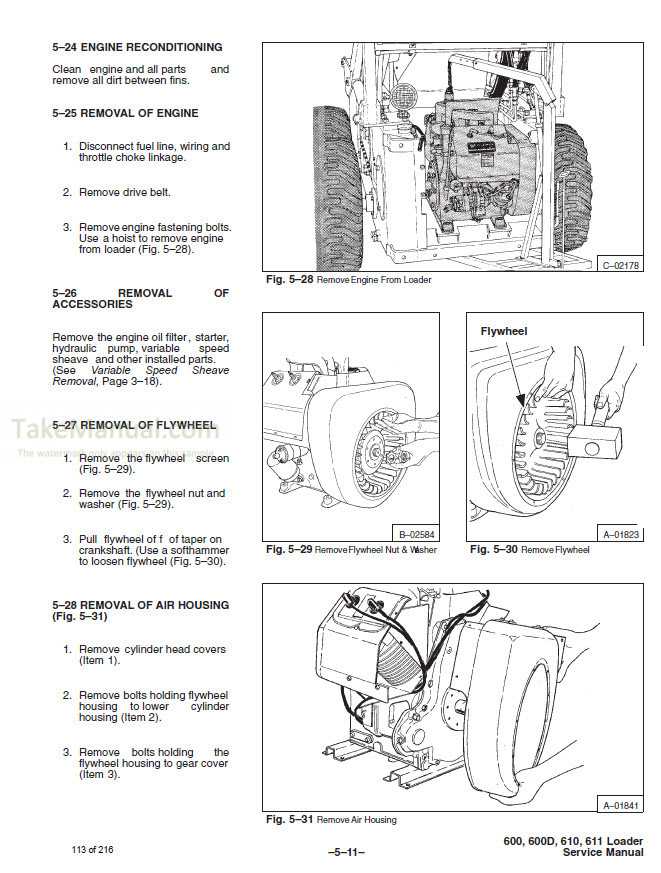

Exploring the Engine Assembly Structure

The engine assembly plays a crucial role in ensuring smooth operation, combining various interconnected components that work in harmony. Understanding the overall design and functionality of each element can help in maintaining optimal performance and ensuring durability over time.

Main Components Overview

- Cylinder block

- Pistons and crankshaft

- Camshaft and timing system

- Fuel delivery mechanisms

- Cooling and lubrication systems

Functionality and Coordination

- The pistons move within the cylinders, creating the necessary compression.

- The crankshaft converts the linear motion of the pistons into rotational energy.

- The camshaft controls the opening and closing of the valves, ensuring precise timing.

- The fuel system delivers the necessary mixture for combustion.

- The cooling system maintains a stable temperature during operation.

Understanding the Hydraulic System Layout

The hydraulic system plays a crucial role in the operation of heavy machinery, ensuring smooth and efficient performance of its key functions. Understanding how this system is arranged helps to maintain and troubleshoot it more effectively, increasing the lifespan of the equipment and reducing downtime. The layout is designed to allow power transmission through fluid, enabling mechanical parts to perform their tasks under pressure with precision and control.

Key Components of the Hydraulic System

The main elements involved in the system are responsible for generating, directing, and regulating the fluid power. These include pumps, valves, hoses, and cylinders, each contributing to the overall operation. The pump creates the necessary pressure, while valves control the flow, and hoses transport the hydraulic fluid. Cylinders convert the fluid pressure into mechanical energy, moving various parts of the machinery.

Hydraulic Flow Path

In this system, fluid is drawn from a reservoir and pushed through the pump, creating high-pressure fluid flow. This flow is then distributed to different areas via hoses and pipes, with valves guiding the direction and control of the fluid. After completing its work in the system, the fluid returns to the reservoir for recirculation, ensuring continuous operation.

| Component | Function |

|---|

| Component | Description | Function | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Wiring Harness | A bundle of cables used to transmit electrical signals across different elements. | Distributes power to various subsystems and sensors. | |||||||||

| Fuses | Protective devices that prevent overloads by breaking the circuit if necessary. | Ensures that excess current does not damage sensitive parts of the system. | |||||||||

| Relays | Switches that control the flow of electricity to high-demand components. | Activates key systems like the starter or lighting setup when required. | |||||||||

| Connectors | J

Analyzing the Drive Chain MechanismThe drive chain mechanism plays a crucial role in ensuring the smooth transfer of power within a mechanical system. By examining its structure, functionality, and interaction with other components, it becomes easier to understand how motion is efficiently transferred from one element to another. This section will explore the essential characteristics and working principles of the drive chain system. Key Components of the MechanismWithin the mechanism, several essential parts contribute to the overall performance. Chains, sprockets, and tensioners work together to maintain optimal tension and alignment, ensuring smooth operation. Proper lubrication and regular maintenance of these elements are critical to preventing wear and tear, extending the system’s lifespan. Functionality and Motion TransferThe system’s design ensures that rotational force is effectively converted into linear motion. By analyzing the interaction between the chain and sprockets, we can identify how mechanical energy is transferred, providing consistent and reliable movement. Understanding these dynamics helps improve efficiency and prolongs the life of the system under various operating conditions. Examining the Steering System ConfigurationThe steering mechanism plays a critical role in ensuring precise control and maneuverability, especially in environments that require a high level of dexterity. Understanding how the steering components interact with each other allows for improved handling and performance. This section delves into the core elements that define the steering system’s configuration, emphasizing how various linkages and controls synchronize for optimal operation. At the heart of this system are key elements responsible for transmitting motion from the operator’s inputs to the wheels. These include the central column, linkages, and gear assemblies. Each component must work in harmony to provide responsive feedback and directional stability, ensuring that even the most complex tasks are executed with accuracy. The balance between mechanical strength and smooth operation is what ultimately defines the system’s efficiency. Key Features of the Loader ArmsThe loader arms are essential components of construction machinery, designed to enhance operational efficiency and versatility. These structures are engineered to support various tasks, ranging from lifting heavy materials to executing precise maneuvers. Their design and functionality significantly impact the overall performance of the equipment, making them a crucial focus for operators and technicians alike. One of the standout characteristics of these arms is their robust construction, which allows them to withstand rigorous conditions and heavy loads. This durability is complemented by an innovative design that ensures optimal lift capacity and reach, facilitating a wide range of applications. Additionally, the geometry of the arms is tailored to provide excellent stability and control during operation.

Inspection of the Cooling System ComponentsThe effective operation of machinery relies heavily on the functionality of its cooling system. Regular evaluation of this system is crucial to prevent overheating and ensure optimal performance. Various components work together to manage temperatures and maintain the equipment’s reliability. During the inspection process, focus on several key elements, including the radiator, hoses, and coolant reservoir. The radiator serves as a heat exchanger, dissipating excess heat generated by the engine. Inspect for signs of damage, such as leaks or corrosion, which could hinder its performance. Hoses play a vital role in circulating the coolant throughout the system. Ensure they are free from cracks or wear, as compromised hoses can lead to coolant loss and subsequent overheating. Furthermore, check for proper connections to ensure a secure flow of fluid. The coolant reservoir should be adequately filled and free of contaminants. Low levels or discolored fluid may indicate leaks or the need for replacement. Additionally, examine the coolant itself for signs of degradation, as using improper or outdated fluid can negatively impact the system’s efficiency. In summary, a thorough examination of these components is essential for maintaining the integrity of the cooling system. Regular inspections can help identify potential issues before they escalate, ensuring long-term functionality and reliability of the equipment. Maintenance Tips for Bobcat 610 PartsProper upkeep of machinery components is essential for ensuring optimal performance and longevity. Regular maintenance practices not only help in identifying potential issues early but also enhance the overall efficiency of the equipment. By following a systematic approach to care, operators can minimize downtime and extend the life of their machinery. Regular InspectionConducting frequent examinations of the various elements is crucial. Check for signs of wear, loose connections, and any abnormalities that may affect functionality. By keeping a close eye on these aspects, you can address minor problems before they escalate into major repairs. Lubrication and CleaningEnsure that moving components are adequately lubricated to reduce friction and prevent premature wear. Additionally, cleaning dirt and debris from surfaces helps maintain efficiency. A clean machine operates better and is less likely to suffer from overheating or component failure. |