In the realm of machinery, grasping the intricate layout of individual elements is crucial for efficient maintenance and troubleshooting. A clear representation of how these components interconnect provides valuable insights, enabling users to navigate the complexities of their equipment with confidence. This knowledge not only enhances operational efficiency but also fosters a deeper appreciation of engineering design.

Every machine comprises a variety of essential segments, each playing a pivotal role in its overall functionality. By exploring the relationships and functions of these segments, one can gain a comprehensive understanding of how to optimize performance and ensure longevity. Whether for routine inspections or significant repairs, a well-structured visualization serves as a vital reference point.

Moreover, the accessibility of this information is paramount. Users equipped with a thorough understanding of these layouts are better prepared to tackle challenges, making informed decisions about repairs and replacements. In essence, mastering the configuration of components empowers operators and technicians alike, promoting a more efficient workflow and reducing downtime.

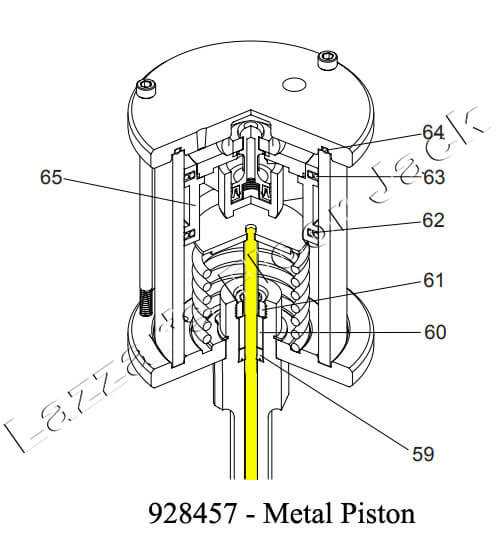

Understanding Hein-Werner Parts Diagram

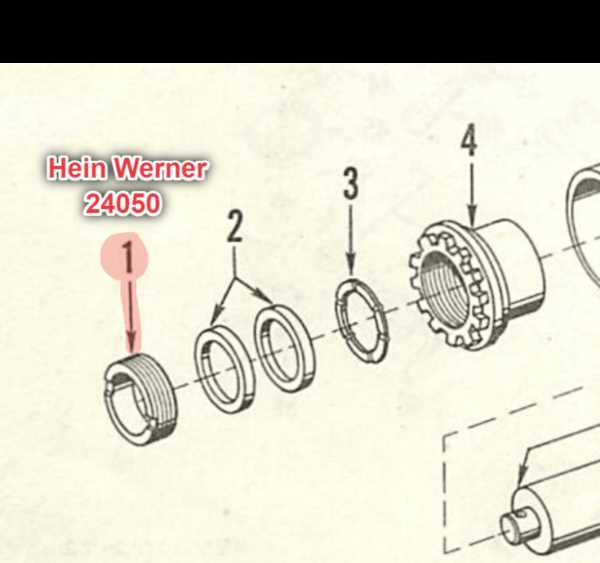

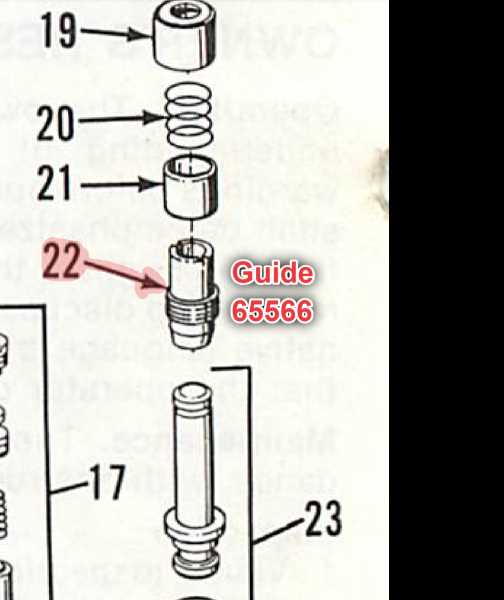

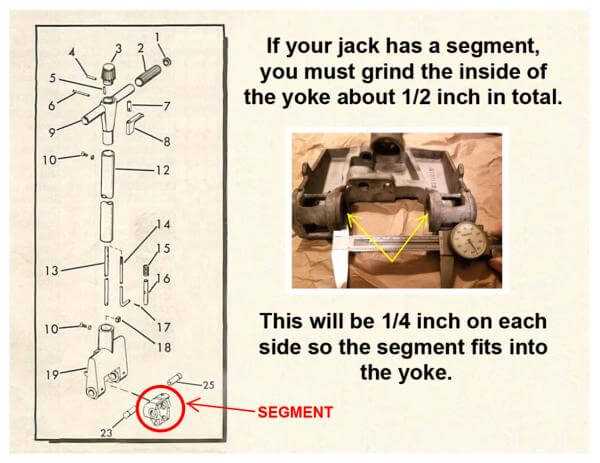

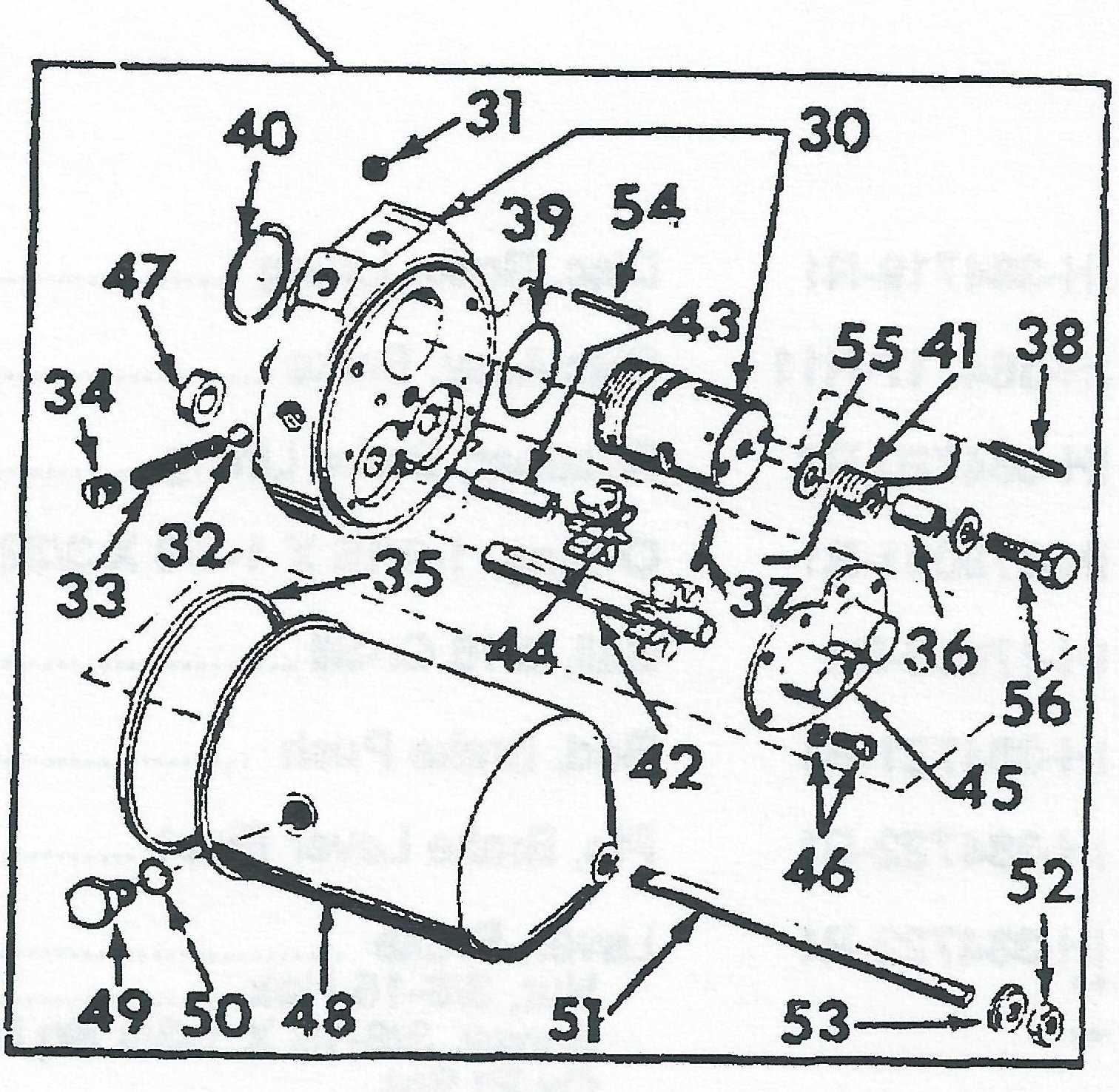

Comprehending the intricate layout of components is essential for efficient maintenance and repair of machinery. A clear representation allows users to identify essential elements, understand their interconnections, and effectively troubleshoot any issues that may arise. By grasping the visual arrangement, one can enhance their proficiency in handling equipment and ensure longevity in performance.

The visual representation typically includes various segments, each illustrating specific elements and their respective functions. Familiarity with these components not only aids in repairs but also promotes a deeper understanding of overall operational mechanics.

| Component Name | Description | Function |

|---|---|---|

| Frame | The main structure supporting the system | Provides stability and support |

| Pump | Device used to move fluids | Facilitates hydraulic functions |

| Actuator | Mechanism that converts energy into motion | Controls movement of parts |

| Control Valve | Device managing fluid flow | Regulates pressure and direction |

By studying such layouts, individuals can enhance their skills in diagnostics and repairs. The clarity provided by these visual aids ensures that even complex systems can be managed effectively, fostering both confidence and competence in operational tasks.

Importance of Accurate Parts Identification

In any mechanical or technical field, precise identification of components plays a critical role in ensuring efficiency and functionality. When individuals can accurately recognize each element, it enhances the overall process, reducing the likelihood of errors and delays. This practice not only streamlines operations but also fosters a deeper understanding of how different elements interact within a system.

Efficiency in maintenance and assembly hinges on correct recognition. When technicians can swiftly locate and identify each component, it accelerates repair and assembly tasks, minimizing downtime. This is especially crucial in environments where time is of the essence and any delay can lead to significant losses.

Moreover, effective communication among team members is facilitated by accurate identification. When everyone uses the same terminology and references, it leads to fewer misunderstandings and enhances collaboration. This clarity is vital for training new employees, ensuring that all team members are on the same page.

Additionally, correct identification contributes to safety. Misidentifying components can lead to improper installations or repairs, which may result in malfunctions or even hazardous situations. By ensuring that every part is correctly identified and understood, organizations can uphold high safety standards and protect both personnel and equipment.

Lastly, maintaining a well-organized system for identification can aid in inventory management. Accurate records and categorizations prevent unnecessary stockpiling or shortages, allowing for better planning and resource allocation. This ultimately supports the sustainability and growth of an organization.

Common Components in Hein-Werner Models

Understanding the essential elements of hydraulic lifting devices is crucial for effective maintenance and operation. Various models feature a range of components that work together to ensure reliability and efficiency. Recognizing these parts helps users troubleshoot issues and perform necessary repairs with confidence.

Key Elements

- Hydraulic Cylinder: This component is vital for lifting and lowering operations, converting fluid pressure into mechanical force.

- Pump: Responsible for generating hydraulic pressure, it facilitates the movement of fluid throughout the system.

- Control Valve: This part regulates the flow of hydraulic fluid, allowing for precise control over the lifting process.

- Frame: The structural base that supports the entire assembly, ensuring stability during operation.

- Wheels: Providing mobility, these components allow for easy maneuvering of the unit.

Additional Features

- Safety Lock: A critical feature that prevents unintended lowering of the load.

- Release Valve: Allows for controlled lowering of the lift, ensuring safety during operation.

- Rubber Pads: Enhance grip and stability, preventing slippage while lifting.

Familiarity with these components not only aids in effective usage but also ensures longevity and safe operation of hydraulic lifting systems.

How to Read a Parts Diagram

Understanding visual representations of components is essential for effective maintenance and repair. Familiarizing yourself with these illustrations allows for quick identification of elements and their relationships, streamlining the repair process.

To grasp these visuals, follow these key steps:

| Step | Description |

|---|---|

| 1 | Identify the key and symbols used in the illustration to understand their meanings. |

| 2 | Locate the main sections, which often highlight different functional areas of the assembly. |

| 3 | Trace the connections and relationships between the elements, noting how they interact. |

| 4 | Refer to accompanying documentation for detailed specifications or troubleshooting tips. |

By mastering these steps, you’ll ultimately enhance your ability to interpret these visuals accurately and efficiently.

Benefits of Using Diagram for Repairs

Utilizing a visual representation for repair tasks significantly enhances efficiency and accuracy. It serves as a crucial reference point, guiding users through complex processes and ensuring all necessary components are addressed systematically.

Improved Understanding

Visual aids facilitate better comprehension of intricate systems. By observing the layout, one can easily identify:

- Connections between components

- Placement of elements

- Sequence of assembly or disassembly

Time and Cost Efficiency

Employing a structured visual reference can lead to substantial savings in time and resources. The advantages include:

- Reduced likelihood of errors

- Quicker identification of required components

- Minimized downtime during repairs

Identifying Replacement Parts Easily

Understanding how to find the right components for your equipment can save you time and money. With the right approach, the process becomes more streamlined and efficient, allowing you to focus on what truly matters–keeping your machinery operational.

Visual aids play a crucial role in this endeavor. By utilizing clear and detailed illustrations, you can quickly pinpoint the necessary items without confusion. This not only reduces errors but also enhances your overall maintenance experience.

Additionally, organizing resources by categories or types can greatly assist in identifying the correct components. Creating a systematic method of classification enables you to navigate through options effortlessly, ensuring you always find the ultimate solution.

Finally, leveraging technology, such as mobile apps or online platforms, can further simplify your search. These tools often include comprehensive databases and user-friendly interfaces that make the task of locating replacements more accessible than ever.

Comparing Hein-Werner with Other Brands

When evaluating different manufacturers in the automotive industry, it is essential to consider various factors that distinguish them from one another. Each brand offers unique features, quality levels, and price points, influencing consumer choices. This analysis aims to highlight how one prominent manufacturer stacks up against its competitors, focusing on performance, durability, and overall value.

Performance and Reliability

In terms of performance, leading brands are often assessed based on their ability to withstand rigorous use while maintaining efficiency. The examined brand is recognized for its robust construction, providing users with confidence during heavy-duty tasks. In contrast, some competitors may offer similar specifications but fall short in long-term reliability. Thus, consumers must weigh the advantages of a trusted name against the potential benefits of lesser-known options.

Cost-effectiveness and Value

Price is a significant factor in decision-making. While some brands may present lower initial costs, they might compromise on longevity and support. On the other hand, a reputable name may require a higher investment but often delivers superior value through enhanced durability and customer service. Therefore, assessing total cost of ownership, including maintenance and lifespan, is crucial for making an informed decision.

Maintenance Tips for Hein-Werner Equipment

Proper upkeep of your lifting and repair tools is essential for ensuring their longevity and optimal performance. Regular maintenance not only enhances functionality but also prevents potential breakdowns, allowing for a safer working environment.

Regular Inspections

Conduct routine checks on all equipment to identify any wear and tear. Look for signs of damage, rust, or loose components. Addressing issues early can save time and reduce repair costs in the long run.

Lubrication and Cleaning

Keep moving parts well-lubricated to minimize friction and wear. Cleaning your tools after each use will prevent the buildup of debris and grime, ensuring smooth operation and extending their lifespan.

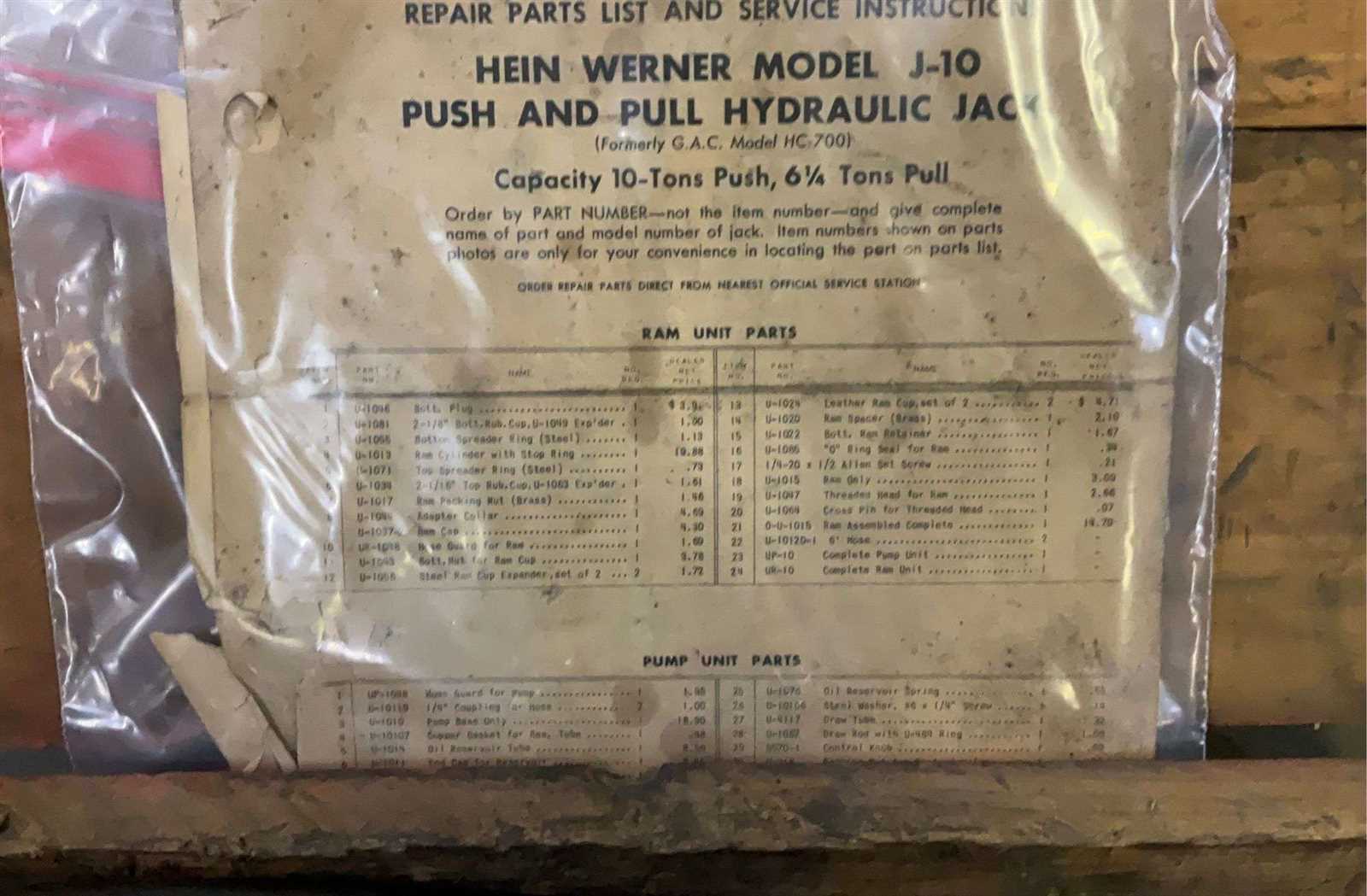

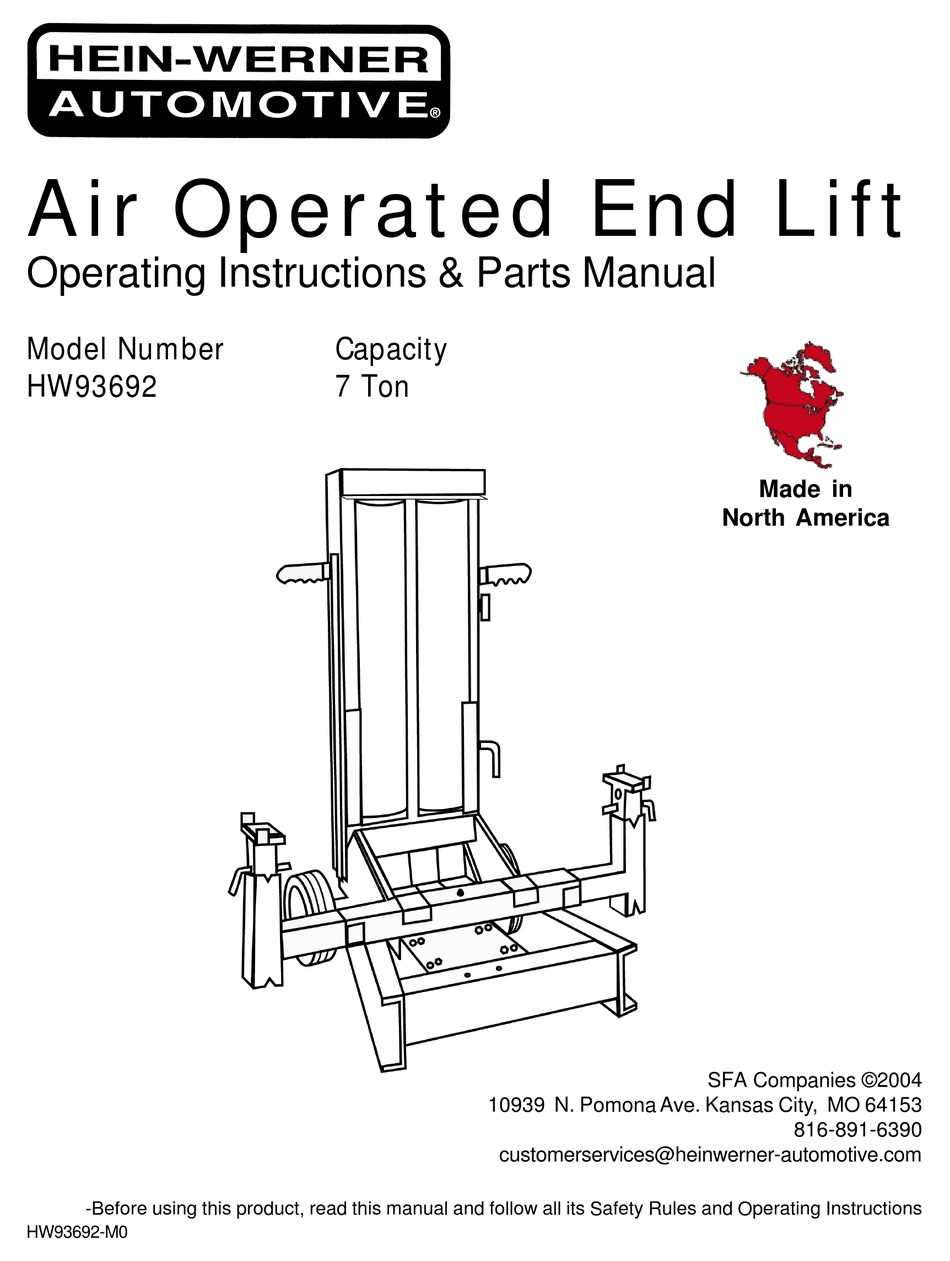

Resources for Parts and Diagrams

Accessing reliable materials and visual representations is essential for effective maintenance and repair. This section offers valuable information sources that can aid in understanding components and their configurations, ensuring optimal functionality and efficiency.

Online Platforms

Numerous websites provide comprehensive databases featuring schematics and component listings. These platforms often include user forums and expert insights, allowing for a deeper understanding of assembly and troubleshooting.

Manufacturer Manuals

Consulting official documentation from manufacturers is crucial. These manuals typically contain detailed illustrations and specifications that facilitate precise identification and sourcing of required elements. Utilizing these resources can lead to the ultimate success in any project.