In the intricate world of vehicle mechanics, the assembly that connects the wheels to the main structure is crucial for smooth operation. This section delves into the various elements that play a vital role in supporting and facilitating motion. By examining these components, we can gain insights into their functionality and significance in ensuring a vehicle’s performance and safety.

Each element within this system has a unique design and purpose, contributing to the overall efficiency of the vehicle. From the fundamental structures that provide stability to the more specialized components that enhance maneuverability, understanding these interrelations is essential for both enthusiasts and professionals alike. A comprehensive overview reveals not only how these elements interact but also their importance in the engineering of modern transportation.

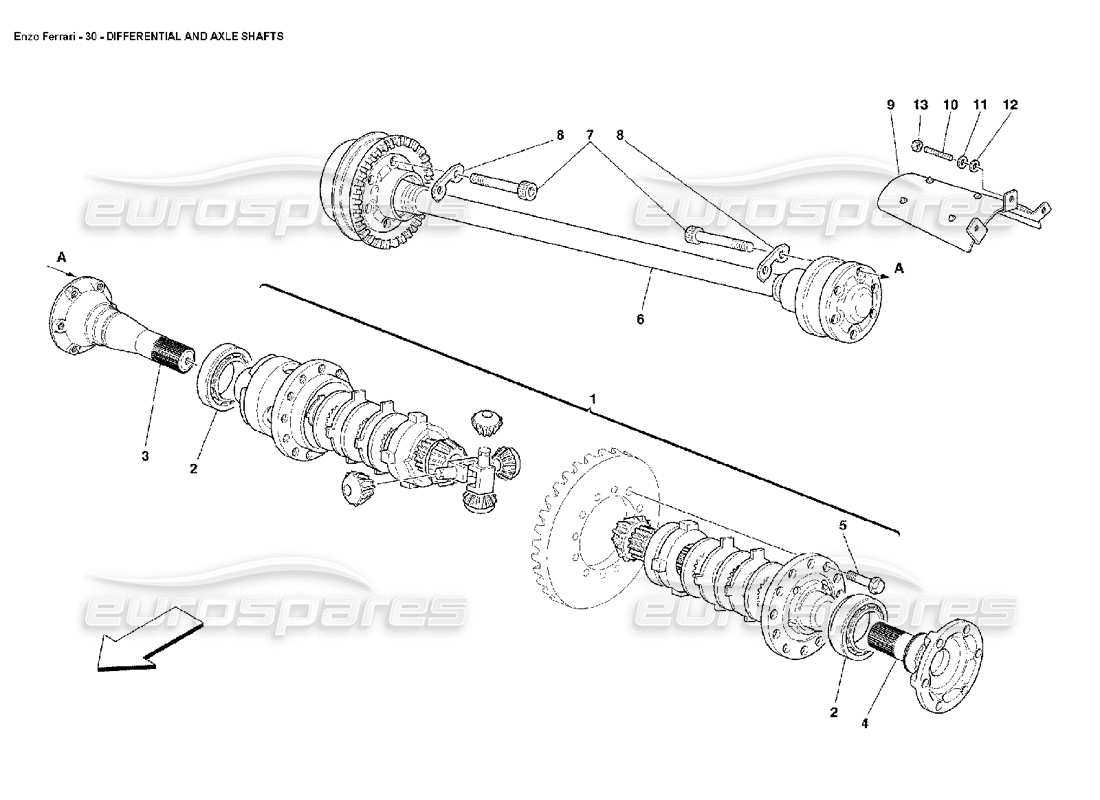

As we explore the visual representations of these components, we will uncover the relationships and configurations that define their roles. This analysis serves as a guide for anyone looking to deepen their knowledge of vehicle mechanics and maintenance. By recognizing the intricacies of each part, we can appreciate the craftsmanship and engineering that make modern vehicles reliable and efficient.

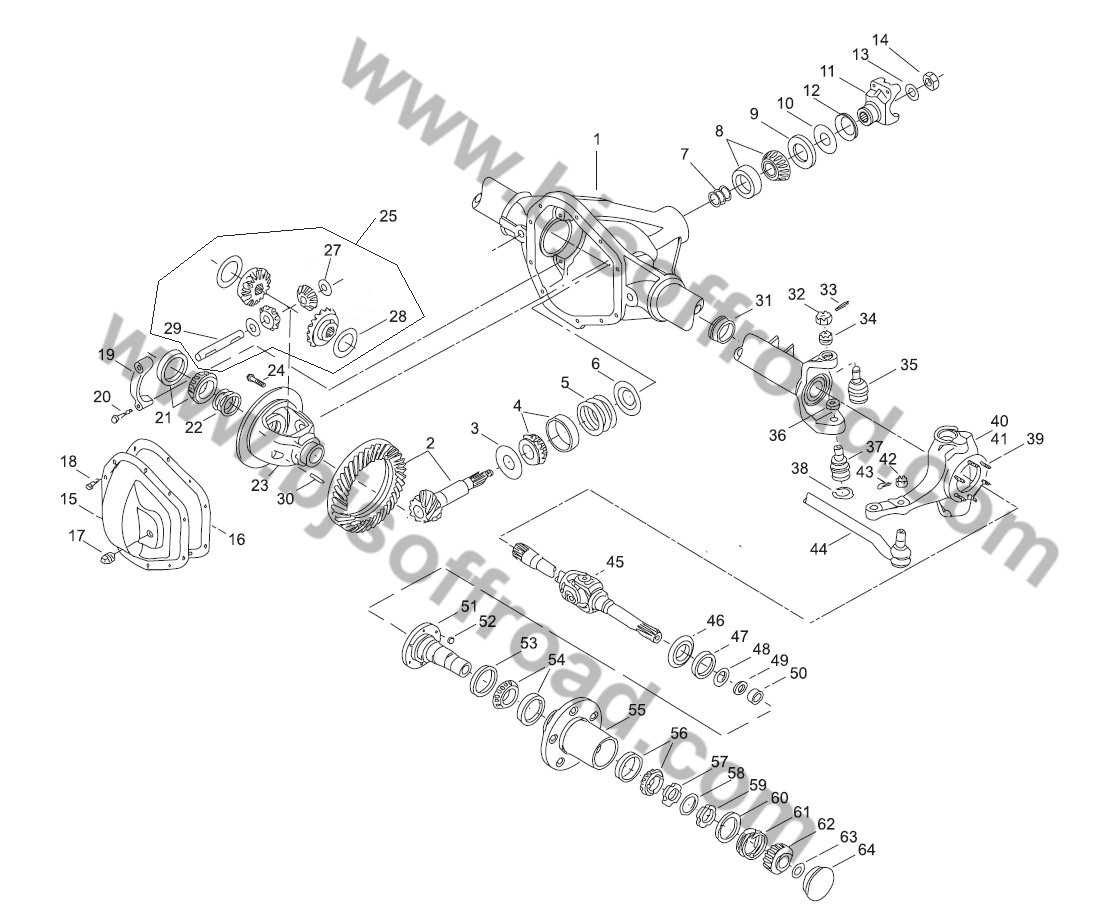

Understanding Axle Components

In the realm of automotive engineering, a comprehensive grasp of various elements that facilitate the movement and stability of vehicles is essential. These components play a pivotal role in ensuring the smooth operation and handling of any mode of transportation. Gaining insight into their functions and interrelations not only enhances one’s knowledge but also aids in effective maintenance and repair processes.

Key Elements and Their Functions

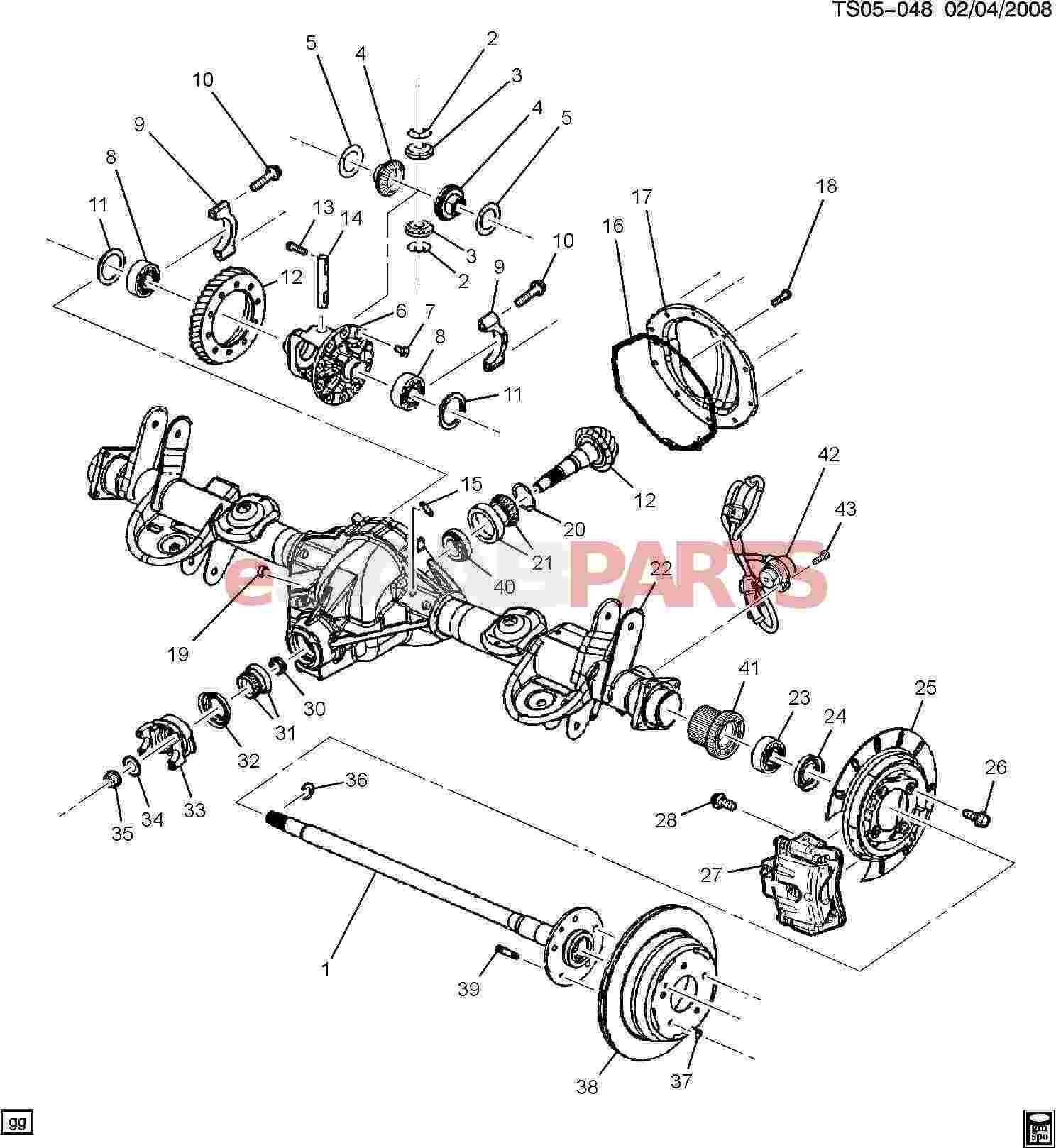

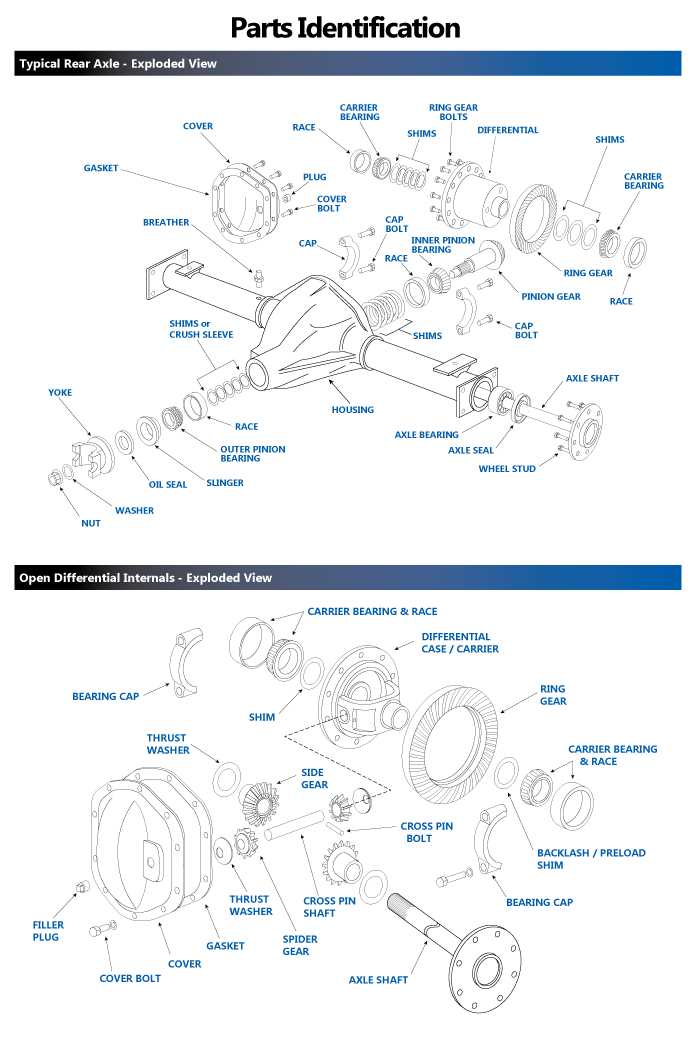

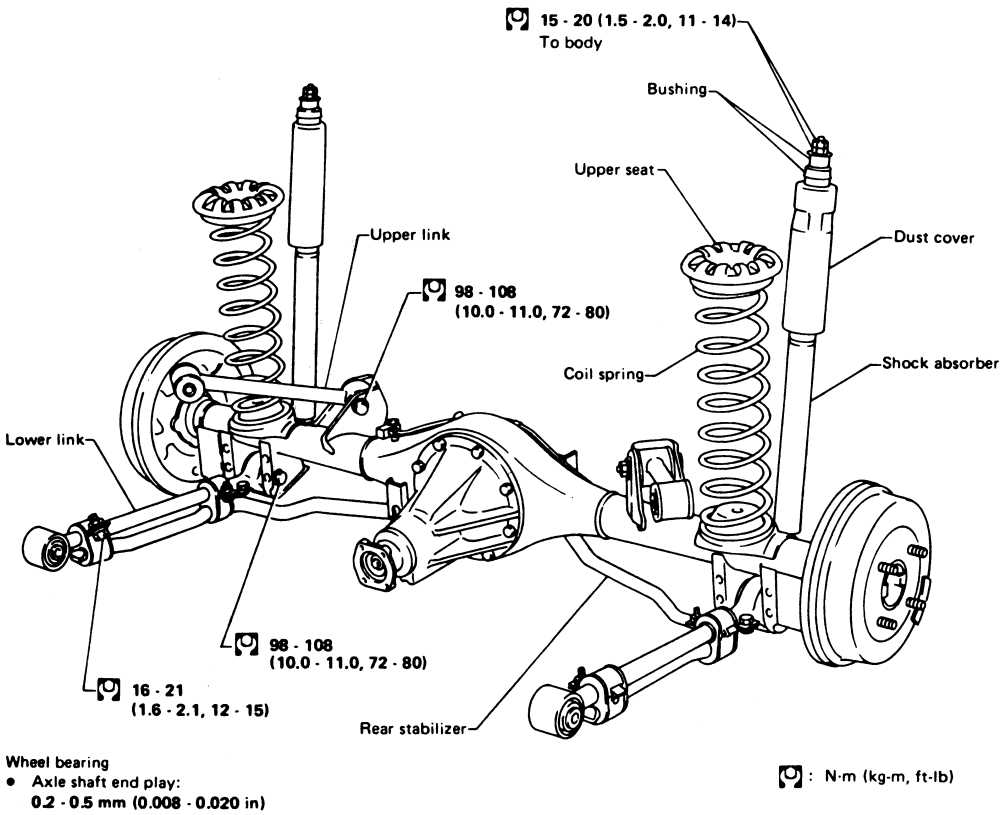

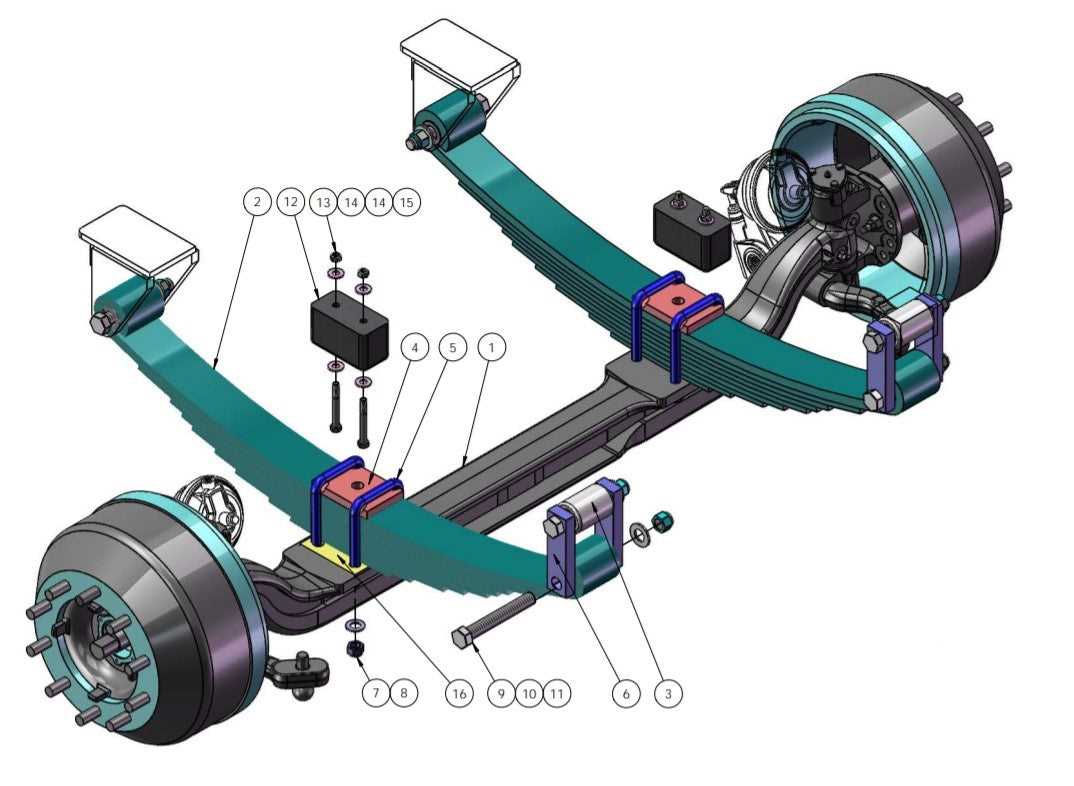

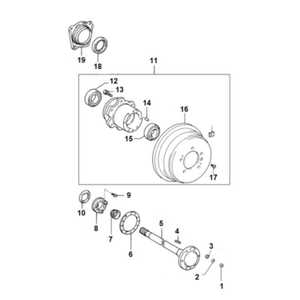

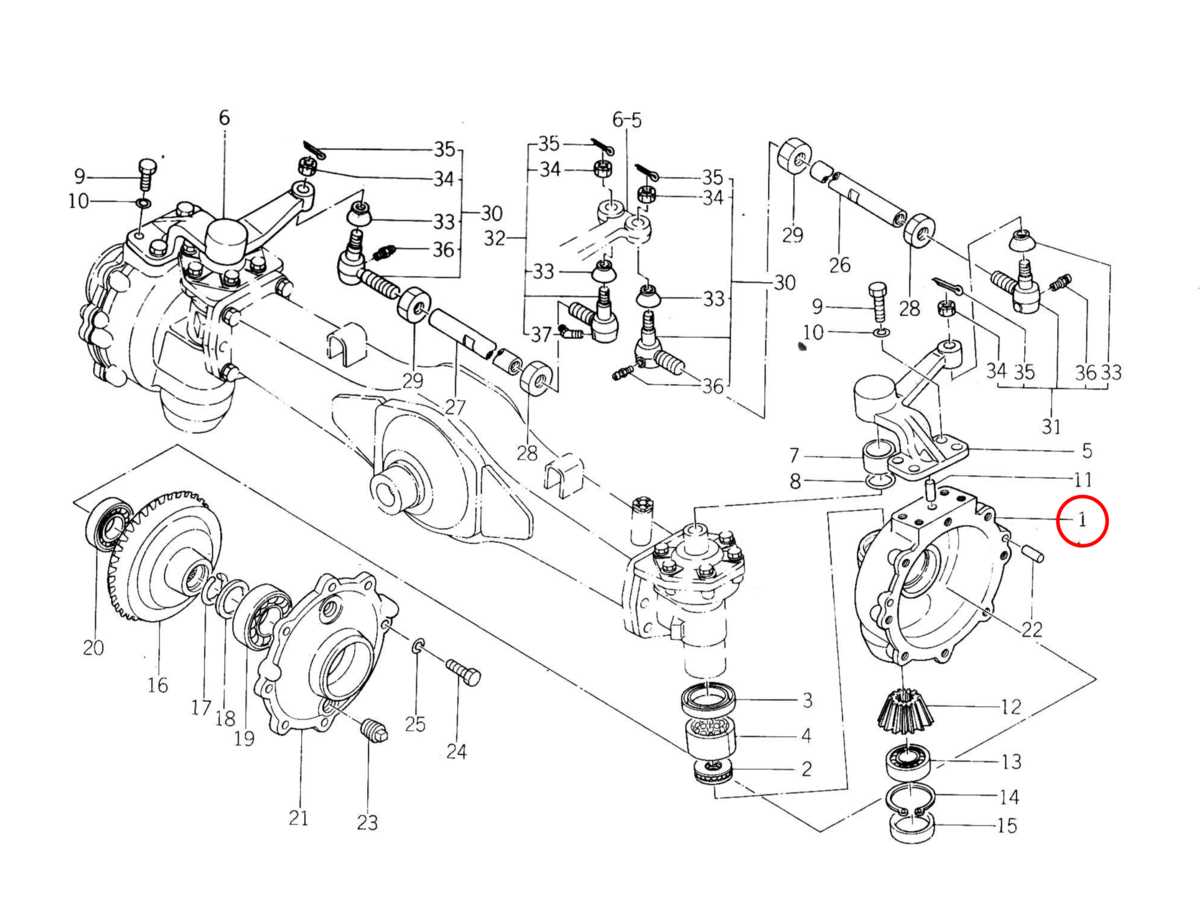

Among the primary components, the central shaft is crucial as it connects the wheels to the vehicle’s frame, allowing for rotation. Supporting elements, such as bearings, ensure smooth movement by reducing friction. Additionally, the housing encases these critical elements, protecting them from external factors while contributing to overall structural integrity. Understanding how these components interact provides a clearer picture of the overall system’s performance.

Impact on Vehicle Performance

The functionality of these essential components directly influences the vehicle’s handling, load-bearing capacity, and stability. Proper alignment and condition of each part are vital to prevent premature wear and ensure safety during operation. Regular inspections and timely replacements of worn elements can significantly enhance the longevity and reliability of the entire assembly.

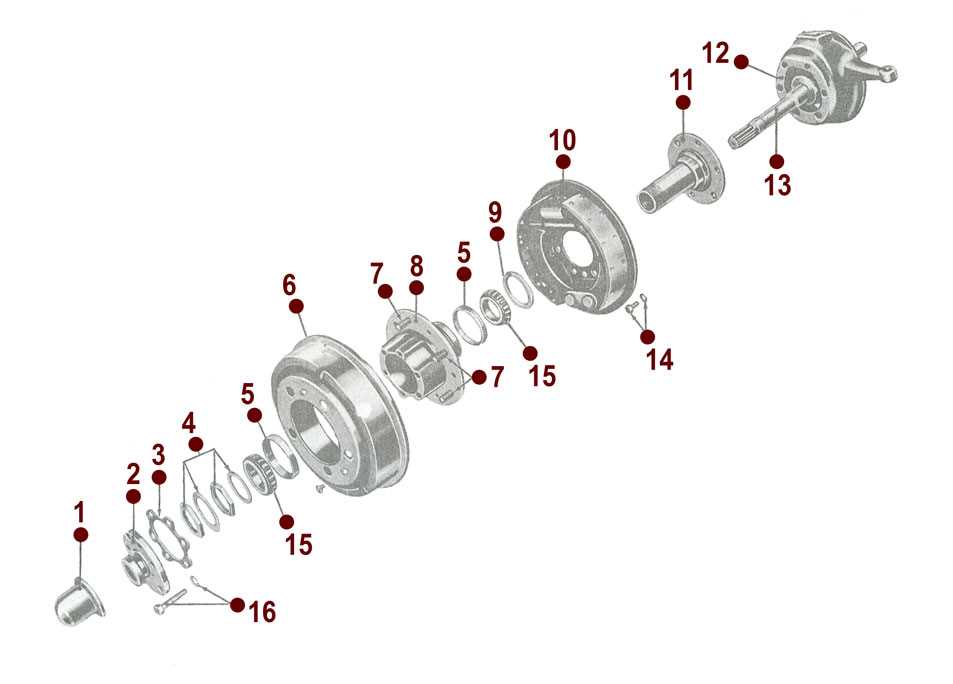

Types of Axle Parts Explained

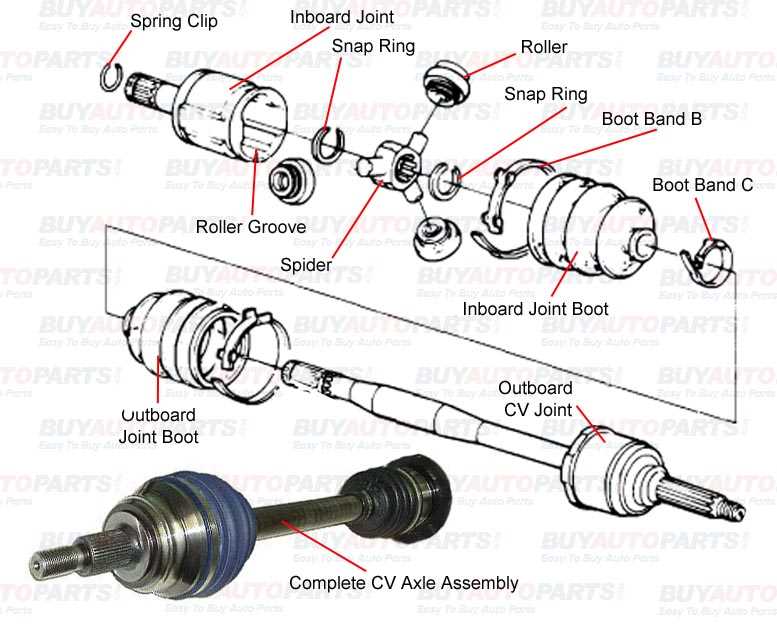

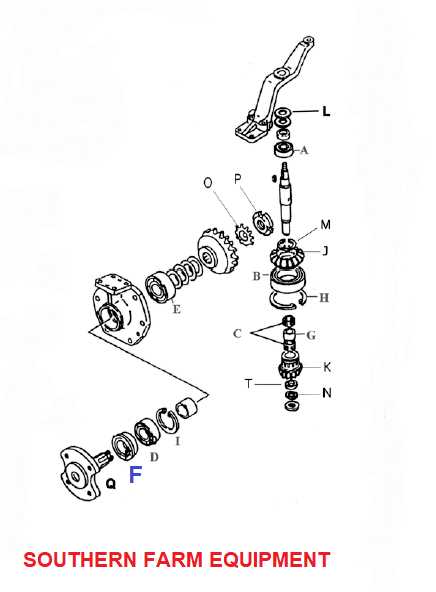

Understanding the various components associated with vehicle rotation mechanisms is essential for grasping how they contribute to overall functionality and performance. Each element plays a unique role, ensuring that motion is transmitted efficiently while maintaining stability and safety.

One crucial component is the central shaft, which serves as the primary support for rotating wheels. This structure bears significant loads and ensures smooth movement. Another important element is the bearing, which facilitates rotation by reducing friction and wear, allowing for seamless performance.

The housing, or casing, provides protection and support for the inner components, safeguarding them from external elements. Couplings are also vital, as they connect different sections, allowing for flexibility and adaptability during operation.

Finally, the suspension linkages play a significant role in maintaining proper alignment and handling characteristics, contributing to the overall driving experience. Together, these elements create a cohesive system that enhances vehicle dynamics and efficiency.

Importance of Axle Diagrams

Understanding the layout and functionality of critical components in vehicles is essential for both enthusiasts and professionals in the automotive field. Visual representations serve as a crucial resource for diagnosing issues, performing maintenance, and enhancing overall performance.

Here are several reasons why these visual aids are significant:

- Clarity: They simplify complex systems, making it easier to identify the relationships between various elements.

- Guidance: These visuals provide step-by-step instructions, ensuring that tasks are performed correctly and efficiently.

- Education: They serve as educational tools for those new to the industry, enhancing understanding of mechanical operations.

- Maintenance: Clear representations help in regular checks, ensuring that components function smoothly and reducing the likelihood of breakdowns.

In conclusion, having access to clear illustrations is invaluable for anyone working with automotive machinery, as they facilitate better comprehension and more effective maintenance practices.

Common Issues with Axle Parts

Understanding the typical challenges that arise with crucial components of a vehicle’s drivetrain is essential for maintaining optimal performance. Various factors can lead to wear and tear, affecting the functionality and safety of the vehicle. This section will explore the most frequent problems encountered, their causes, and potential solutions.

Wear and Tear

One of the most prevalent issues is the gradual degradation of components due to constant use. This wear can result from friction, exposure to harsh environmental conditions, and lack of proper maintenance. Regular inspections and timely replacements can help mitigate these effects, ensuring a smoother operation and extending the lifespan of the vehicle.

Misalignment

Misalignment of crucial elements can lead to various complications, such as uneven tire wear and compromised handling. This issue often stems from improper installation or impacts from road hazards. Addressing alignment promptly through professional assessments can significantly enhance driving safety and performance.

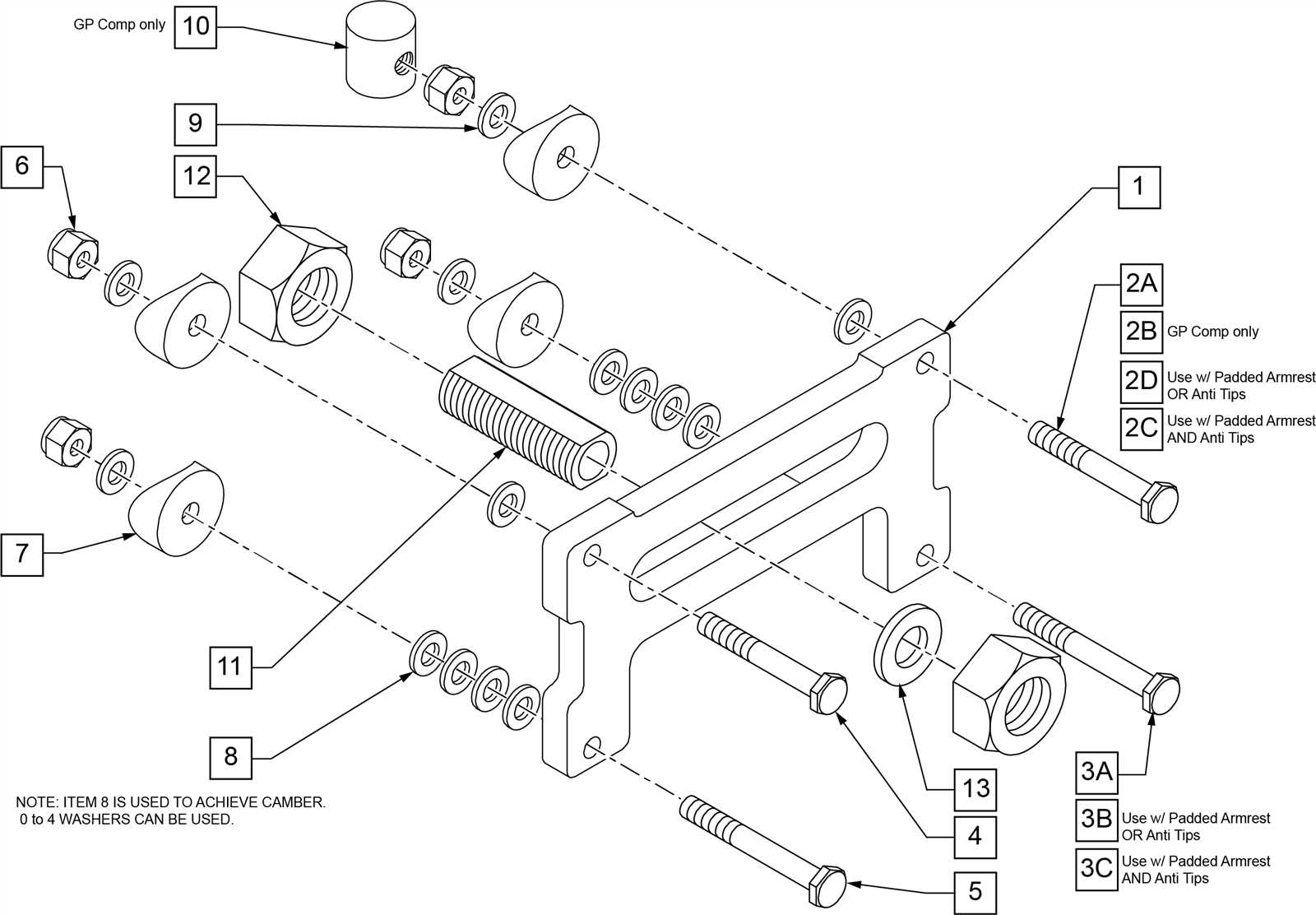

How to Read Axle Diagrams

Understanding technical illustrations related to vehicle components can be essential for maintenance and repairs. Mastering these visuals enables one to identify crucial elements and their relationships effectively.

To interpret these visuals accurately, follow these guidelines:

- Familiarize with Symbols: Learn the common symbols used to represent various components.

- Identify Key Components: Focus on the main features and their arrangement within the illustration.

- Understand Flow Directions: Note any arrows or lines indicating movement or connections.

- Review Annotations: Pay attention to any notes or labels that provide additional context.

By following these steps, you can enhance your ability to interpret complex visuals and apply that knowledge practically.

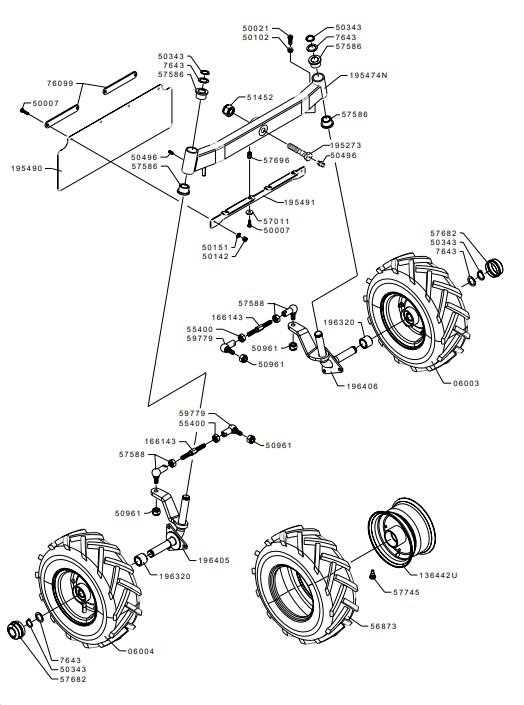

Tools for Axle Maintenance

Maintaining essential vehicle components requires a range of specialized instruments that ensure optimal performance and longevity. Proper upkeep not only enhances functionality but also prevents unexpected failures, making the right tools crucial for any automotive enthusiast or professional mechanic.

Essential Instruments

For effective maintenance, having the correct equipment is vital. Commonly used tools include wrenches, sockets, and screwdrivers, which assist in tightening and loosening fasteners. Additionally, torque wrenches are indispensable for applying the correct amount of force, preventing damage to sensitive components.

Diagnostic Tools

To identify potential issues, diagnostic equipment plays a key role. OBD-II scanners allow users to read error codes and monitor the health of various systems. Regularly using such tools can catch problems early, ensuring that repairs are made before they escalate into more significant concerns.

Replacing Axle Components Safely

When it comes to the replacement of essential vehicle components, ensuring safety during the process is paramount. This section provides crucial guidelines for conducting such maintenance tasks effectively and without risk.

Before starting any replacement procedure, consider the following steps to maintain safety:

- Always work on a level surface to prevent the vehicle from rolling.

- Utilize proper tools to avoid damaging any components or injuring yourself.

- Wear appropriate safety gear, including gloves and goggles, to protect against debris.

- Ensure the vehicle is securely lifted with jack stands, not just a jack.

Once safety measures are in place, follow these steps to replace the necessary components:

- Consult the vehicle’s manual for specific instructions related to the replacement process.

- Disconnect any relevant connections, such as brake lines or sensors, carefully.

- Remove the old component by unfastening bolts or clips, keeping track of their locations.

- Install the new component, ensuring it aligns correctly with other elements.

- Reconnect any removed connections securely to avoid future issues.

Finally, double-check all connections and fastenings before lowering the vehicle. Regular maintenance and cautious replacement of these critical elements can extend the lifespan of your vehicle and enhance safety on the road.

Innovations in Axle Technology

Recent advancements in the field of rotational support structures have led to significant improvements in efficiency, durability, and performance. These innovations are reshaping the landscape of transportation and heavy machinery, driving enhanced operational capabilities and reducing maintenance costs. As the demand for greater reliability and efficiency continues to grow, the integration of cutting-edge materials and designs becomes increasingly crucial.

Smart Materials and Design

One of the most exciting developments involves the use of smart materials, which adapt to varying conditions and loads. These materials not only enhance strength but also contribute to weight reduction, enabling vehicles and machinery to achieve better fuel efficiency and agility. Furthermore, innovative design techniques, such as topology optimization, allow for the creation of components that maximize structural integrity while minimizing unnecessary mass.

Advanced Manufacturing Techniques

The shift towards additive manufacturing has also transformed production processes. This technique enables the creation of complex geometries that traditional methods cannot easily achieve. As a result, components can be produced with improved performance characteristics, such as enhanced wear resistance and reduced friction. Additionally, this approach allows for rapid prototyping and customization, catering to specific operational needs.