For those who frequently maintain outdoor spaces, having a clear understanding of the components of your equipment is vital. Knowing how different elements come together allows you to address any issues that might arise during operation. This knowledge can help ensure the longevity of your tools and improve their efficiency over time.

In this section, we will explore the various elements that make up essential outdoor machinery, helping you recognize and understand how each piece contributes to the overall function. With this insight, you’ll be better equipped to perform repairs and adjustments, ensuring smooth and reliable operation.

Familiarity with key components can also save time and effort when it comes to maintenance. By learning how the individual pieces interact, you can quickly identify and resolve problems, minimizing downtime and maximizing performance.

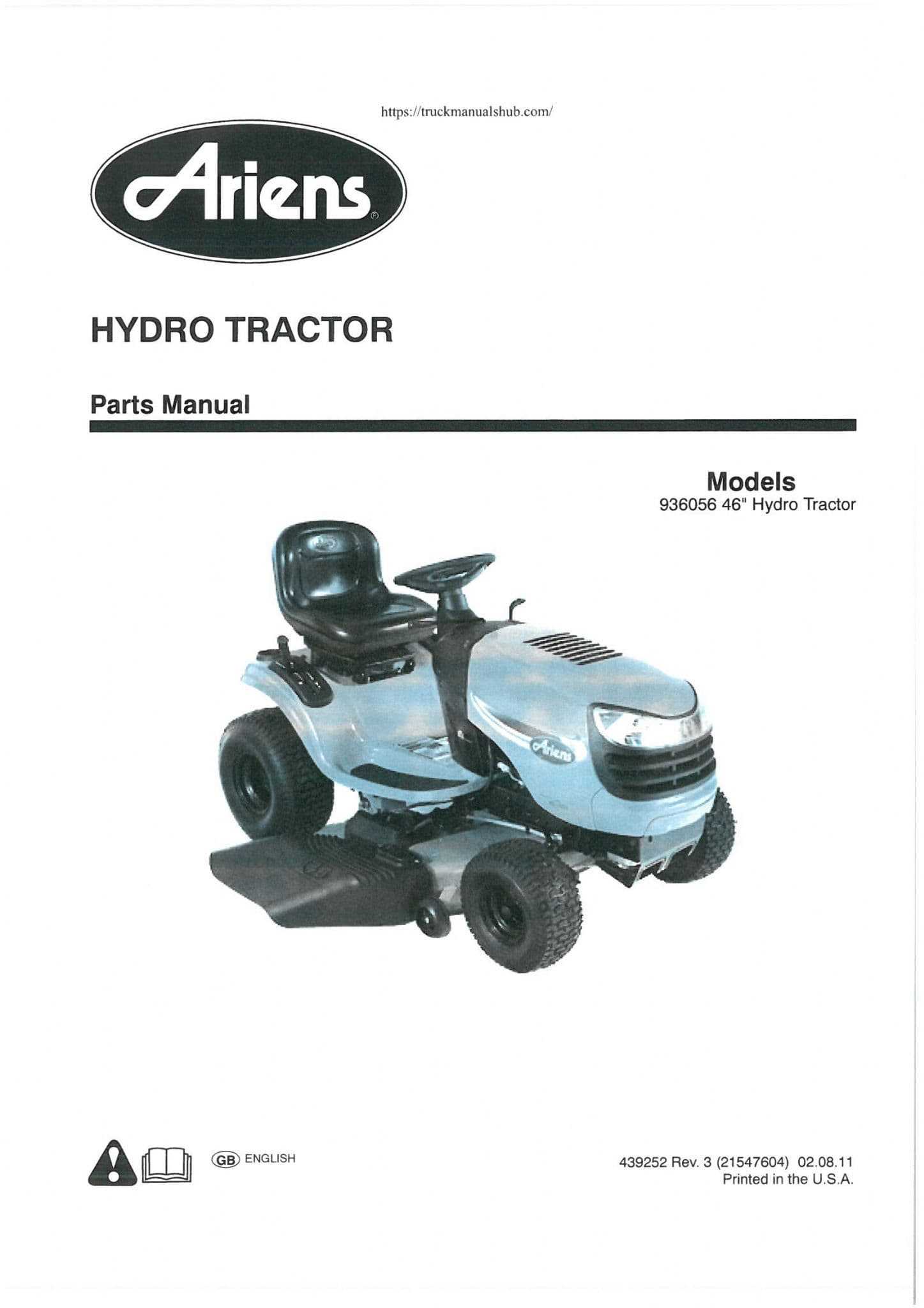

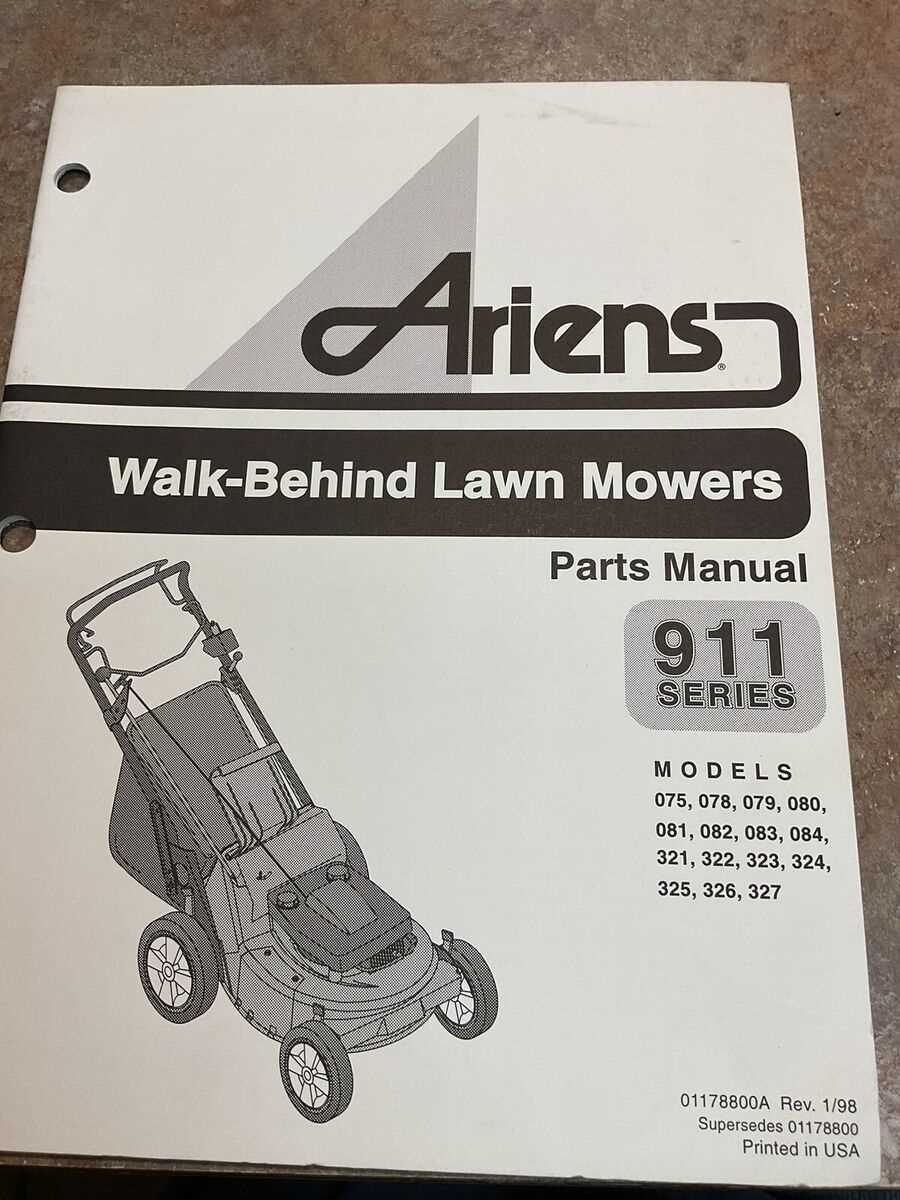

Ariens Lawn Mower Parts Diagram

When maintaining outdoor equipment, having a clear understanding of the essential components is key to ensuring smooth operation and longevity. A detailed layout of the machine’s elements can help users identify critical sections, enabling proper upkeep and repair. This guide provides insight into the core mechanical and functional aspects, aiding both experienced users and beginners in efficient troubleshooting.

Key Mechanical Elements

Each component serves a unique role in the overall performance of the equipment. Recognizing the position and purpose of these sections allows for faster diagnostics and easier replacements when necessary. Proper alignment and functioning of each element ensure smooth, uninterrupted operation.

Functional Overview

Understanding how each section contributes to the working mechanism helps users anticipate potential issues. Whether it’s the power source, cutting mechanism, or control systems, knowing the interaction between different parts facilitates preventive maintenance and extends the equipment’s lifespan.

Understanding the Main Components

To ensure proper functionality and performance, it is essential to understand the key elements that make up a standard cutting machine. Each section plays a specific role, working in harmony to deliver efficient and reliable operation. Knowing the function of these essential parts can help in maintenance and troubleshooting.

Engine and Power Source

The engine serves as the heart of the machine, generating the power needed to drive the cutting blades and move the equipment. It’s critical to keep the engine in good condition to maintain consistent performance. Regular checks of oil levels, air filters, and spark plugs ensure smooth operation.

Cutting Mechanism

The cutting mechanism is designed to slice through grass and vegetation with precision. Blades must be sharp and balanced to produce a clean cut. Ensuring the cutting height is properly adjusted allows for optimal results, while maintaining the integrity of the machine.

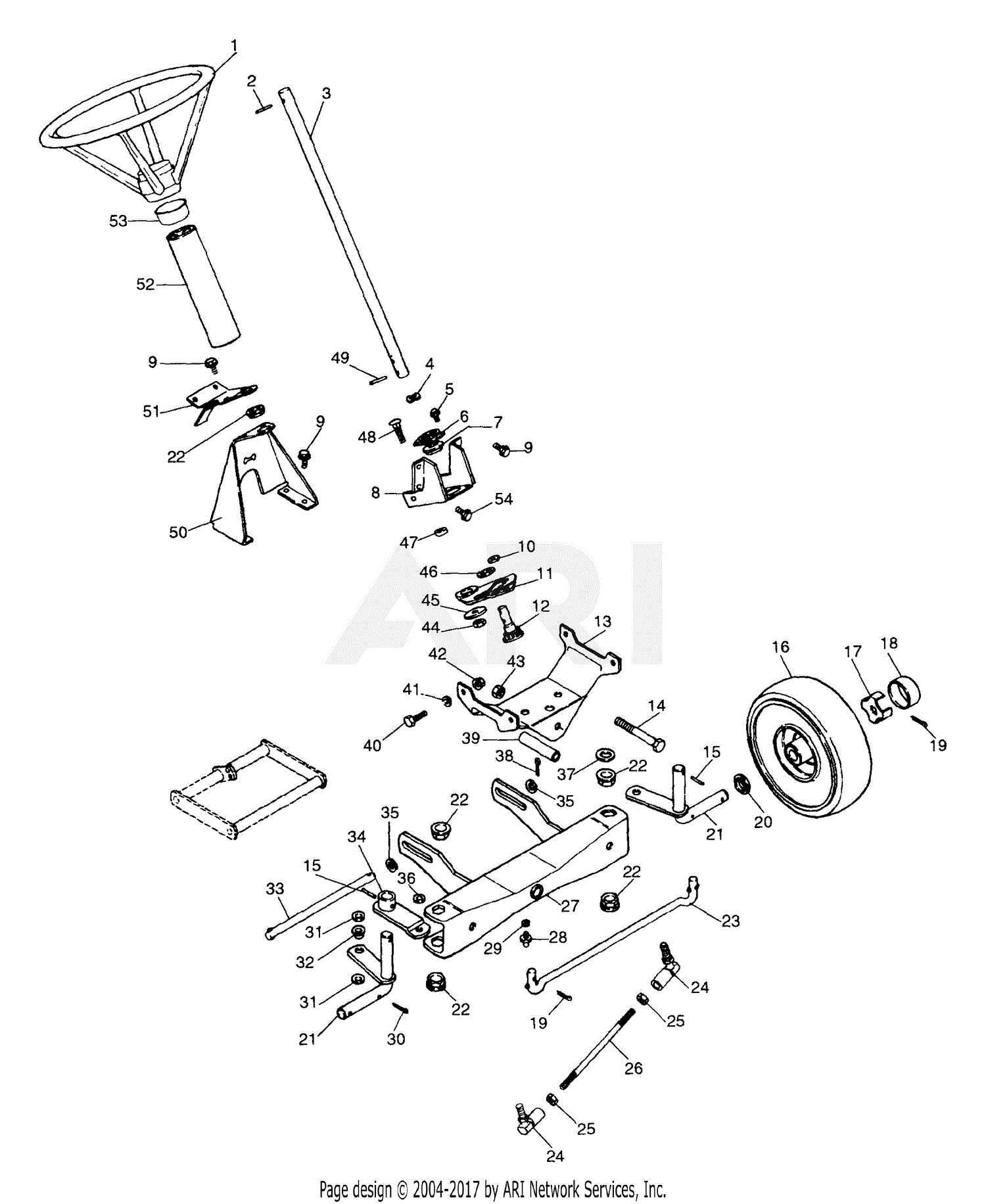

How to Read the Diagram Efficiently

Understanding a technical blueprint can greatly enhance your ability to identify various components and their relationships. By learning how to break down a schematic effectively, you can pinpoint the necessary details with ease and avoid unnecessary confusion. This process requires focus and a step-by-step approach to make the most of the information provided.

Identify Key Sections

Start by examining the overall structure of the schematic, noting any distinct areas or groupings of elements. These sections often represent different systems or subsystems, and recognizing them early helps streamline your analysis. Pay attention to labels and symbols, as they usually serve as indicators of key components.

Follow the Connections

Once you’ve identified the major sections, trace the connections between them. The lines, arrows, or pathways displayed are crucial for understanding how each part interacts with the others. Following these connections will guide you through the flow of operation, allowing you to see the bigger picture and

Identifying Engine-Related Parts

The heart of any outdoor power equipment is its motor, and understanding its components is essential for effective maintenance. Various elements work together to ensure smooth operation, from fuel delivery systems to cooling mechanisms. Properly identifying these components can help in troubleshooting issues and ensuring long-term efficiency.

Key engine elements include the fuel line, which ensures steady fuel flow, and the spark plug, which ignites the combustion process. Additionally, the air filter plays a crucial role in protecting the engine from debris, while the carburetor ensures the correct mix of air and fuel.

Recognizing these and other vital elements is the first step to successful upkeep, enabling you to address potential problems before they escalate into major repairs.

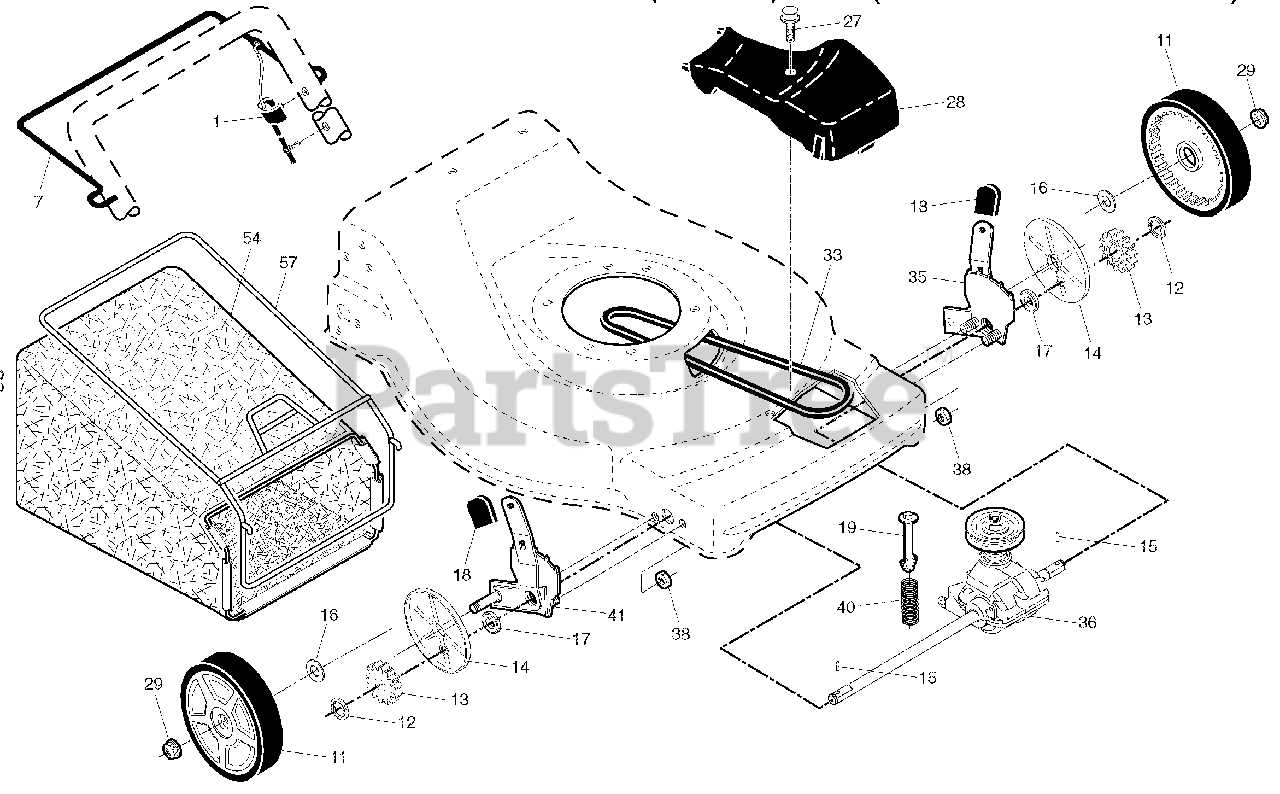

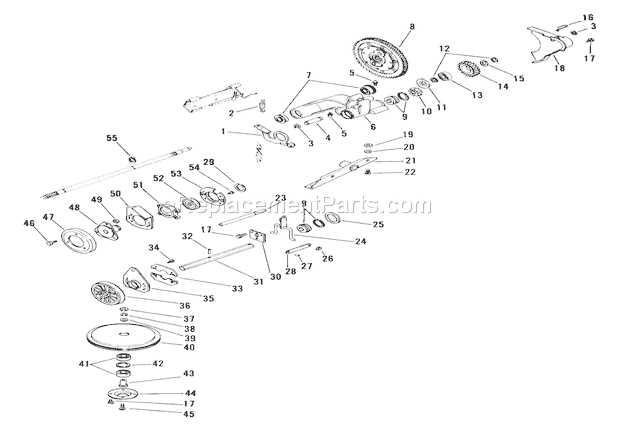

Blades and Cutting System Overview

The cutting system is a critical component responsible for the precision and quality of trimming operations. A well-designed system ensures efficient grass cutting, offering clean and consistent results. Understanding the types of blades and how they interact within the cutting mechanism helps maintain the efficiency of your equipment.

- Blade Types: Different designs offer various benefits, from standard blades for general cutting to mulching blades that finely chop grass clippings.

- Blade Maintenance: Regular sharpening and balancing are essential to avoid uneven cuts and to extend the lifespan of the system.

- Cutting Height Adjustment: Adjustable cutting height settings allow for flexibility, ensuring the system can handle various terrains and grass lengths.

Overall, maintaining the cutting system and choosing the right blades for your needs ensures optimal performance and a clean cut every time.

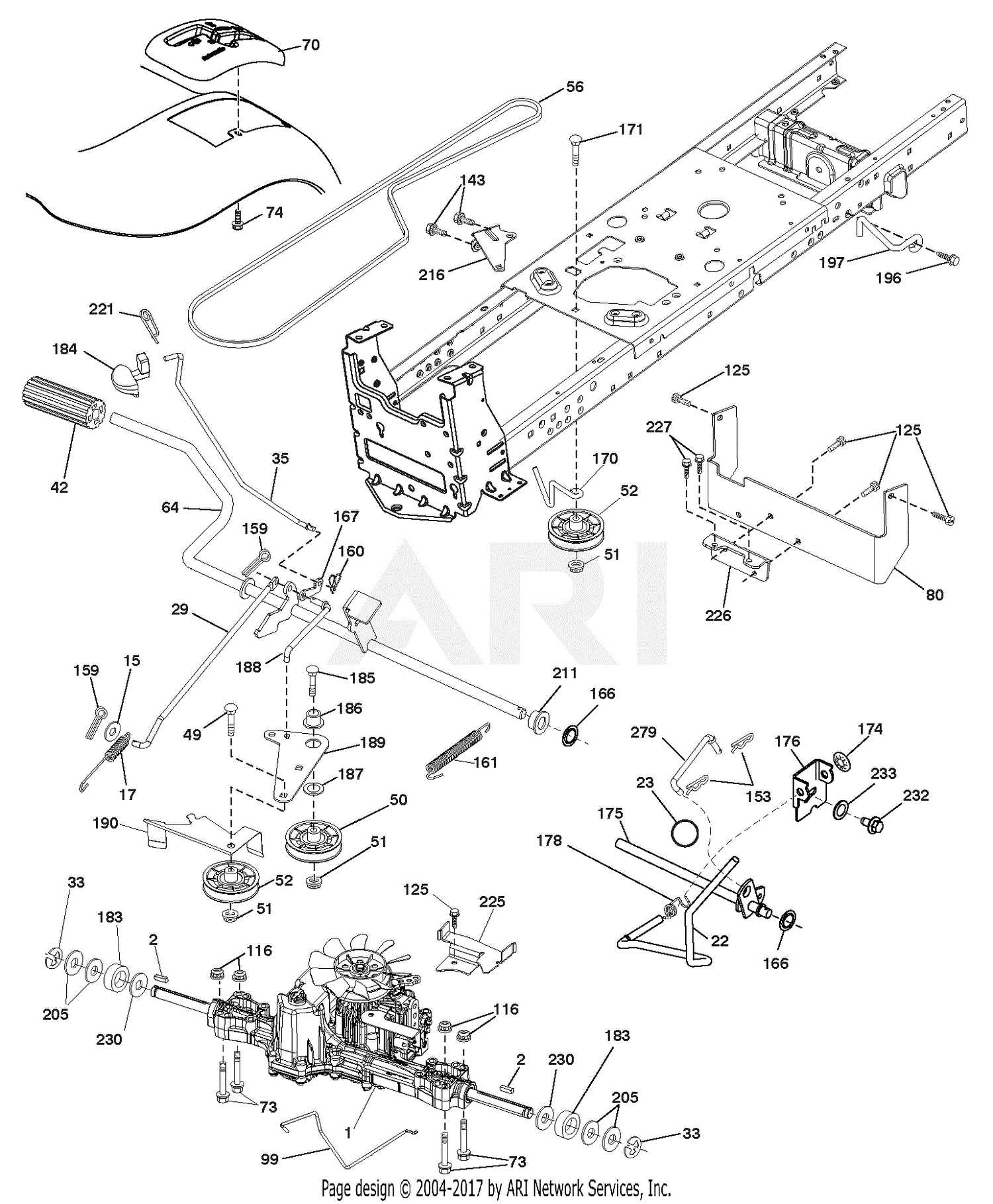

Drive and Transmission Elements

The drive and transmission components play a crucial role in the overall functionality of outdoor equipment. These elements are responsible for transferring power from the engine to the wheels, ensuring smooth operation and efficient movement. Understanding these components can help in maintaining and troubleshooting issues related to performance.

Key Components

Several vital components are involved in the drive and transmission system. Each part contributes to the effective operation and longevity of the machinery. Below is a brief overview of the key elements:

| Component | Function |

|---|---|

| Drive Belt | Transfers power from the engine to the transmission. |

| Transmission Gears | Regulates speed and torque for optimal performance. |

| Chain Drive | Provides direct power transfer between components. |

| Axles | Connects wheels to the transmission, allowing movement. |

| Clutch | Engages and disengages power transfer as needed. |

Maintenance Tips

Regular inspection and maintenance of drive and transmission elements are essential for optimal performance. It is recommended to check belts for wear, ensure proper lubrication of gears, and replace any damaged components promptly to prevent further issues.

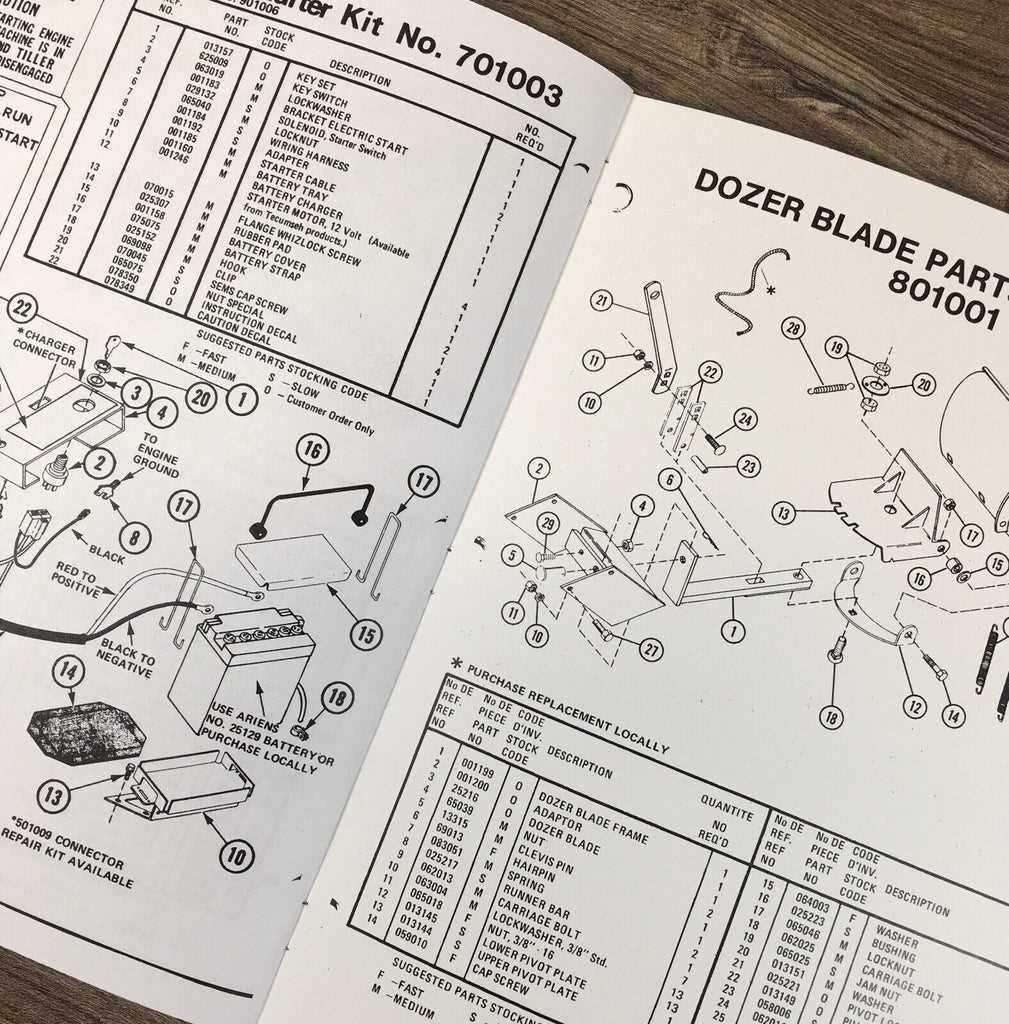

Handling Electrical and Wiring Parts

Proper management of electrical components and wiring is crucial for ensuring the smooth operation of machinery. Understanding the structure and function of these elements helps in troubleshooting issues and performing maintenance effectively. This section provides insights into the common wiring configurations and electrical components that users may encounter.

| Component | Description | Function |

|---|---|---|

| Switch | A device that opens or closes an electrical circuit. | Controls the power supply to the machine. |

| Connector | Hardware that connects wires or cables together. | Facilitates the transfer of electrical signals. |

| Fuse | A safety device that interrupts the current flow when excessive current is detected. | Protects the electrical system from damage. |

| Relay | An electromagnetic switch used to control a circuit. | Allows a low-power signal to control a higher power circuit. |

| Battery | A device that stores and provides electrical energy. | Powers the electrical components of the machinery. |

Maintenance Tips for Essential Components

Regular upkeep of critical elements in your equipment ensures optimal performance and longevity. By following a systematic approach to maintenance, you can prevent issues that may arise during operation. Below are key practices to maintain essential components effectively.

- Clean Air Filters: Ensure that air filters are free of debris. Clean or replace them as needed to maintain airflow and efficiency.

- Check and Change Oil: Regularly inspect oil levels and change the oil according to the manufacturer’s recommendations to keep the engine running smoothly.

- Inspect Blades: Keep blades sharp and free of rust. Sharpen or replace them periodically to enhance cutting performance.

- Examine Belts and Cables: Look for signs of wear or fraying. Replace damaged belts and cables to prevent operational failures.

- Lubricate Moving Parts: Regularly apply lubricant to all moving parts to reduce friction and wear, ensuring smooth operation.

Implementing these maintenance strategies will help maintain the functionality and reliability of your equipment for years to come.

Finding Replacement Parts Using Diagrams

Locating suitable components for machinery can often be a challenging task. Utilizing visual aids can greatly simplify this process. By referring to detailed illustrations, users can quickly identify the specific items they need, ensuring compatibility and efficient repairs.

Understanding the Importance of Visual References

Visual references serve as essential tools when searching for components. They provide a clear overview of each part’s placement and functionality within the equipment. This clarity helps individuals avoid errors and facilitates the selection of the correct items.

Steps to Effectively Use Illustrations

To maximize the benefits of visual aids, follow these steps:

- Study the Layout: Begin by examining the entire visual reference to grasp the overall structure.

- Identify Components: Focus on specific sections to pinpoint the required items.

- Cross-Reference: Once identified, cross-reference with supplier catalogs or websites to ensure availability.

By applying these methods, individuals can streamline their search for essential components, enhancing the repair and maintenance experience.