The intricate assembly of a vehicle is essential for its performance and longevity. Each component plays a pivotal role in ensuring smooth operation and reliability on the road. Grasping the configuration of these elements can significantly enhance one’s maintenance skills and overall comprehension of automotive engineering.

In this exploration, we will delve into the various sections that comprise a specific model’s framework, focusing on how they interact to optimize functionality. A clear visualization of these components not only aids in repairs but also in the appreciation of sophisticated automotive design.

By examining the layout of these crucial sections, enthusiasts and professionals alike can gain valuable insights. This knowledge equips them with the tools necessary for troubleshooting and upgrading, ultimately leading to a deeper connection with their vehicle.

Overview of the BMW 328i Engine

This section delves into the fundamental aspects of a well-regarded powertrain that exemplifies precision engineering and performance. The unit is celebrated for its balance of efficiency and responsiveness, catering to enthusiasts and everyday drivers alike. Its design integrates advanced technologies that enhance both power delivery and fuel economy, making it a noteworthy contender in its class.

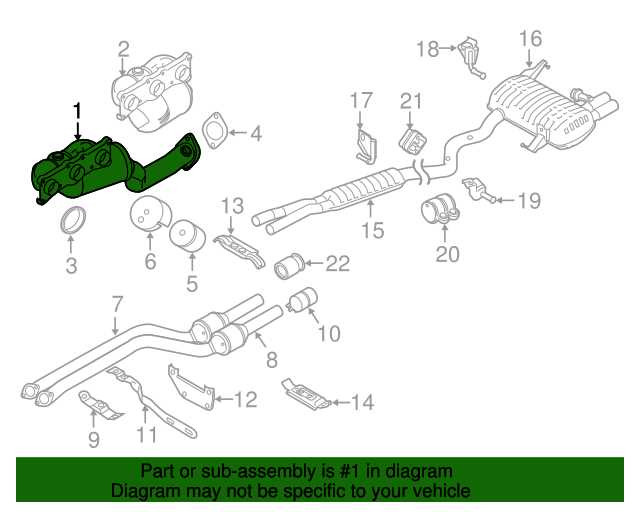

Key components of this power unit include a finely tuned combustion chamber, a robust intake system, and an efficient exhaust configuration. Each element plays a critical role in optimizing airflow and ensuring smooth operation. The incorporation of innovative features contributes to a responsive driving experience, while the overall build quality underscores reliability and durability.

Furthermore, regular maintenance and understanding of the internal workings can significantly extend the longevity of this mechanical marvel. Whether for performance upgrades or routine servicing, a thorough grasp of the intricate systems involved can aid owners in maintaining their vehicle’s peak condition.

Key Components of the Engine Assembly

The intricate system that powers a vehicle consists of several vital elements, each playing a crucial role in ensuring optimal performance and efficiency. Understanding these fundamental components allows for better maintenance and troubleshooting, ultimately leading to a smoother driving experience.

1. Cylinder Block: This is the core structure where combustion occurs, housing the cylinders that contain the pistons. It provides the necessary support and alignment for other components.

2. Pistons: These cylindrical elements move up and down within the cylinders, converting fuel combustion into mechanical energy. Their motion drives the crankshaft, which ultimately powers the wheels.

3. Crankshaft: This pivotal shaft transforms the linear motion of the pistons into rotational energy. It is crucial for transferring power to the transmission system.

4. Camshaft: Responsible for controlling the timing of valve openings and closings, this component plays a significant role in regulating airflow into and out of the combustion chamber.

5. Valves: These elements allow the intake of air and fuel while enabling exhaust gases to exit. Proper functioning of the valves is essential for efficient combustion.

6. Timing Chain or Belt: This component synchronizes the rotation of the crankshaft and camshaft, ensuring that the opening and closing of valves occur at the correct intervals for optimal performance.

7. Oil Pan: This reservoir collects and stores lubricating oil, which is critical for reducing friction among moving parts, thereby enhancing longevity and efficiency.

Each of these components is essential for the seamless operation of the vehicle’s propulsion system. Regular inspection and maintenance of these parts can lead to improved reliability and performance on the road.

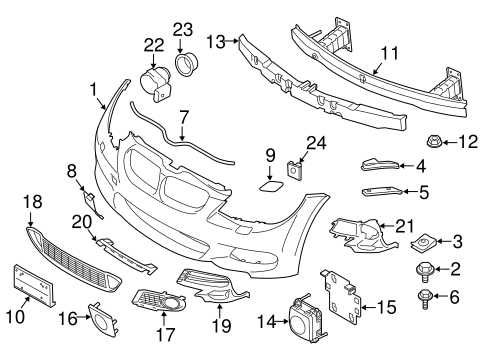

Understanding Engine Diagrams Explained

Comprehending technical illustrations related to mechanical systems can greatly enhance one’s understanding of how these intricate machines operate. Such visual representations serve as vital tools for both novices and experienced individuals, facilitating the identification and function of various components.

The Importance of Visual Aids

Visual aids provide clarity and simplify complex concepts. Here are a few reasons why they are essential:

- Enhances learning by providing a clear picture of relationships between components.

- Assists in troubleshooting by highlighting potential issues within the assembly.

- Aids in maintenance by outlining the locations of essential elements.

Key Elements of Mechanical Illustrations

Understanding the key elements in these illustrations is crucial. Consider the following components:

- Labels: Indicate the names and functions of different elements.

- Connections: Show how components interact and are linked together.

- Flow Arrows: Demonstrate the direction of movement or processes.

By familiarizing oneself with these aspects, individuals can better navigate the complexities of mechanical systems and enhance their proficiency in handling related tasks.

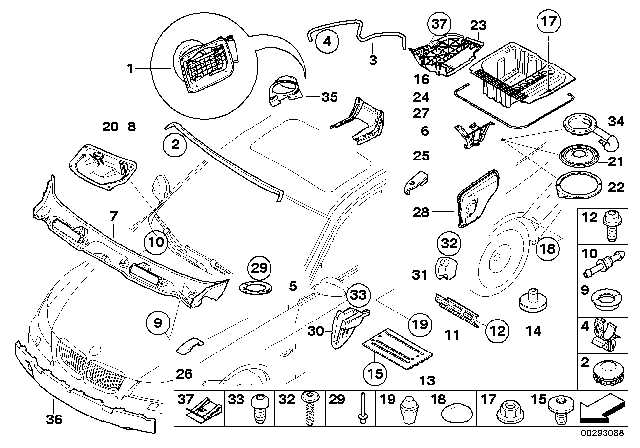

Importance of Engine Part Identification

Recognizing individual components within a mechanical system is crucial for effective maintenance and troubleshooting. Proper identification not only facilitates timely repairs but also enhances overall performance and longevity. Understanding each element’s role ensures that any issues can be swiftly addressed, minimizing downtime and potential damage.

Benefits of Accurate Recognition

Accurate identification of components leads to informed decisions regarding repairs and replacements. This knowledge empowers technicians to select the right tools and materials, ensuring optimal functionality. Furthermore, it fosters a deeper understanding of how each element interacts within the assembly, promoting a holistic approach to mechanical care.

Enhancing Diagnostic Skills

Familiarity with specific elements enhances diagnostic capabilities. When individuals can pinpoint components efficiently, they can quickly ascertain faults and implement solutions. This skill is invaluable in preventing minor issues from escalating into major complications, ultimately saving time and resources.

Common Issues with BMW 328i Engines

The performance of any vehicle’s power unit is crucial for optimal operation and longevity. Several common complications can arise in this model’s propulsion system, impacting both efficiency and reliability. Understanding these issues is essential for maintenance and repair strategies.

One prevalent problem involves oil leaks, which can stem from various gaskets and seals deteriorating over time. Addressing these leaks promptly is vital to prevent further damage and ensure the smooth functioning of the entire system.

Another concern relates to overheating, often caused by a malfunctioning thermostat or a failing water pump. Overheating can lead to severe damage, making it imperative for owners to monitor coolant levels and system performance regularly.

Fuel delivery issues can also emerge, particularly with the injectors becoming clogged or the fuel pump experiencing failures. These challenges can lead to misfires and decreased acceleration, necessitating immediate attention.

Finally, electrical system failures can pose significant hurdles, including faulty sensors or wiring issues that disrupt communication between components. Regular diagnostics can help identify and resolve these electrical anomalies before they escalate.

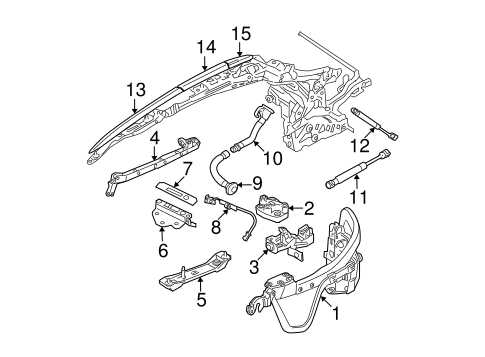

Replacing Parts: A Step-by-Step Guide

Maintaining your vehicle’s performance often requires the replacement of various components. This guide will provide you with a clear, methodical approach to ensuring that you can efficiently swap out any necessary elements, enhancing the longevity and reliability of your automobile.

Preparation Steps

Before beginning the replacement process, gather the necessary tools and materials. A well-organized workspace will streamline your efforts. Ensure that you have the following items ready:

| Tools | Materials |

|---|---|

| Wrenches | Replacement component |

| Screwdrivers | Gaskets (if required) |

| Torque wrench | Lubricants |

| Pliers | Cleaning supplies |

Replacement Process

Start by disconnecting the power source to ensure safety during the procedure. Next, carefully remove the component that needs to be replaced, taking note of how it is connected. Documenting the arrangement can be helpful for reinstallation. Once the old part is removed, prepare the new one by ensuring it is clean and free of debris. Finally, install the new component by reversing the removal steps, making sure all connections are secure and properly torqued.

Aftermarket vs. OEM Engine Components

When it comes to vehicle maintenance and repairs, enthusiasts often face a crucial decision regarding component sourcing. Understanding the distinctions between manufacturer-sourced offerings and alternative options can greatly influence both performance and longevity.

Quality and Performance

Original components are typically engineered to meet specific standards set by the manufacturer, ensuring a precise fit and reliable performance. In contrast, aftermarket options may vary in quality, with some providing enhanced performance while others might fall short, leading to potential issues down the line.

Cost and Availability

While factory components often come with a higher price tag, they can provide peace of mind through their reliability. Aftermarket selections, on the other hand, usually offer a wider range of prices and availability, making them an attractive option for budget-conscious individuals. Balancing cost and quality is key to making an informed decision.

Maintenance Tips for Longevity

Ensuring the extended lifespan of a vehicle requires a proactive approach to upkeep and care. Regular attention to various components not only enhances performance but also prevents costly repairs down the line. By adopting consistent maintenance practices, you can keep your automobile in optimal condition for years to come.

Regular Inspections

- Conduct routine checks on fluid levels, including oil, coolant, and brake fluid.

- Examine belts and hoses for signs of wear or cracking.

- Inspect tires for proper inflation and tread depth.

Scheduled Services

- Follow the manufacturer’s recommended service intervals for oil changes and filter replacements.

- Schedule periodic brake inspections and replacements as needed.

- Consider timing belt or chain replacements at the advised mileage to prevent potential failures.

By implementing these practices, you can enhance the reliability and efficiency of your vehicle, ultimately contributing to its longevity and your overall driving experience.