When it comes to maintaining and repairing your vehicle, having a solid grasp of how the key mechanical elements work together is crucial. Every system in a car plays an integral role, and knowing the layout of the primary components can help with diagnostics and repairs. In this guide, we will explore the various crucial mechanisms that contribute to your vehicle’s performance, from the core propulsion system to the peripheral systems that support it.

Understanding the configuration of these systems allows you to better identify potential issues and apply effective solutions. Whether you’re a seasoned mechanic or a DIY enthusiast, familiarizing yourself with the essential assemblies of your vehicle can prevent costly mistakes and improve your confidence when tackling repairs. The following information will provide you with a clear visual representation of how everything fits together, highlighting the most important sections for ease of reference.

By examining these detailed layouts, you can pinpoint the specific areas that may require attention or replacement. The interplay between different elements is often what keeps the entire system running smoothly. With this knowledge, you can approach your vehicle’s maintenance tasks with a more informed perspective and a greater level of precision.

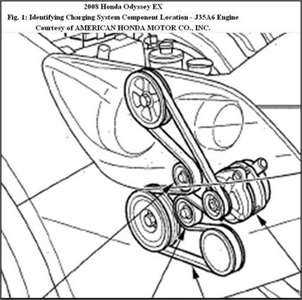

Understanding the 2007 Honda Odyssey Engine

The heart of any vehicle is its powertrain, the intricate system that transforms fuel into motion. In this model, the mechanics work together to provide smooth performance, optimal efficiency, and reliability. By exploring the key components of this system, drivers can gain a deeper understanding of how the vehicle operates under various conditions.

Key Components of the Powertrain

At the core of the system lies the vital mechanism that converts fuel into power, responsible for propelling the vehicle. Surrounding this are essential elements like the intake and exhaust systems, which regulate airflow and emissions. The interaction of these components ensures a harmonious balance between performance and environmental consideration. Additionally, the cooling system plays a crucial role, maintaining optimal temperature to prevent overheating.

Maintenance Considerations

Regular maintenance of these core systems is crucial for ensuring long-term reliability and preventing costly repairs. Regular checks on fluid levels, belts, and hoses can prevent malfunctions. Understanding how these systems work together will help owners recognize early signs of wear and tear, ultimately extending the lifespan of their vehicle.

Key Components of the Engine System

The heart of any vehicle consists of a complex network of elements working in harmony to generate power and ensure smooth operation. Understanding the main components responsible for these functions is crucial for maintaining optimal performance. Each part plays a specific role in controlling the flow of air, fuel, and exhaust, as well as maintaining proper cooling and lubrication.

Here are the essential components involved in the propulsion system:

- Fuel Delivery System – Responsible for supplying the correct mixture of fuel and air to the combustion chamber for efficient power generation.

- Ignition System – Generates the spark necessary to ignite the air-fuel mixture, initiating the combustion process.

- Timing Mechanism – Coordinates the opening and closing of valves, ensuring proper air intake and exhaust expulsion at the right intervals.

- Cooling System – Prevents overheating by circulating coolant to absorb and dissipate heat from critical engine components.

- Lubrication System – Reduces friction between moving parts, ensuring smooth operation and preventing wear and tear on metal surfaces.

- Exhaust System – Directs harmful gases away from the combustion process and helps reduce emissions, contributing to better environmental performance.

Each of these components is designed to contribute to the overall efficiency and longevity of the powertrain. Understanding how they interact can help in diagnosing issues and ensuring proper maintenance of the vehicle’s propulsion system.

Common Engine Issues and Solutions

Vehicles can experience a variety of problems over time, especially in their power units. Understanding the most common issues can help identify them early, preventing costly repairs or breakdowns. Each component plays a vital role, so when a malfunction occurs, the entire system may be affected. In this section, we will explore some frequent challenges and their possible solutions.

Overheating Problems

One of the most common issues in any vehicle is overheating. If the temperature rises beyond the recommended range, it can lead to serious damage if not addressed. The main culprits for overheating can include:

- Faulty radiator

- Leaking coolant

- Broken water pump

- Clogged cooling system

- Faulty thermostat

Solution: To prevent overheating, always ensure that the coolant levels are adequate and that there are no leaks. Regularly inspect the radiator and replace any worn-out components, such as the thermostat or water pump.

Poor Performance and Power Loss

When a vehicle begins to lose power or performs sluggishly, it can be a sign of various underlying issues. These may include:

- Clogged air filters

- Worn spark plugs

- Fuel delivery problems

- Dirty fuel injectors

- Faulty ignition coils

Solution: Regular maintenance, such as replacing air filters and spark plugs, is crucial for maintaining optimal performance. If there are persistent power issues, professional diagnostics may be necessary to examine fuel injectors and ignition systems.

Unusual Noises and Vibrations

Any strange noise or vibration from the power unit can indicate a malfunctioning part. Common causes include:

- Loose or damaged belts

- Worn bearings or pulleys

- Faulty tensioners

- Exhaust system leaks

Solution: If you notice abnormal sounds, inspect the belts and pulleys for any wear or damage. Replacing these components can prevent further damage and ensure the smooth operation of the vehicle.

Importance of Regular Maintenance Practices

Consistent upkeep of any vehicle is essential to ensure its longevity and optimal performance. Regular attention to key systems and components helps prevent unnecessary wear and tear, reducing the risk of major breakdowns. By adhering to a planned maintenance schedule, owners can address potential issues early, ensuring smoother operation and avoiding expensive repairs down the road.

Benefits of Routine Maintenance

- Increases the lifespan of the vehicle by addressing small issues before they escalate.

- Improves fuel efficiency, as components that are regularly checked and maintained function more effectively.

- Enhances overall safety by ensuring that all critical systems, such as brakes and suspension, are working properly.

- Preserves the resale value of the vehicle by keeping it in good running condition.

Key Areas for Regular Attention

- Transmission and fluid levels should be checked frequently to ensure smooth gear shifts and optimal operation.

- Battery and electrical systems should be tested regularly to avoid unexpected power issues.

- Braking system, including pads and rotors, should be inspected to maintain reliable stopping power.

- Cooling systems, such as radiators and hoses, help prevent overheating, especially in warmer climates.

Following a proactive maintenance routine not only reduces the likelihood of emergency repairs but also contributes to a more efficient and enjoyable driving experience. By taking these preventive steps, owners can maximize the performance and reliability of their vehicles.

Tools Needed for Engine Repairs

Performing maintenance and repairs on a vehicle requires a specific set of tools to ensure efficiency and accuracy. Having the right equipment not only makes the process smoother but also helps in avoiding potential damage to components. Whether you’re a seasoned mechanic or a DIY enthusiast, understanding the necessary tools is essential for successful repairs.

Basic Tool Kit

A comprehensive toolkit is fundamental for any repair job. Essential items include wrenches, screwdrivers, and ratchets. These tools allow for the loosening and tightening of fasteners with ease. Additionally, pliers and socket sets can assist in accessing hard-to-reach areas and securing components effectively.

Specialized Equipment

In some cases, more advanced tools are required. Diagnostic scanners help identify issues within the system by reading error codes. For tasks that involve intricate parts, torque wrenches ensure that connections are fastened to the manufacturer’s specifications. Lastly, having a reliable oil filter wrench can simplify fluid changes and contribute to overall vehicle health.

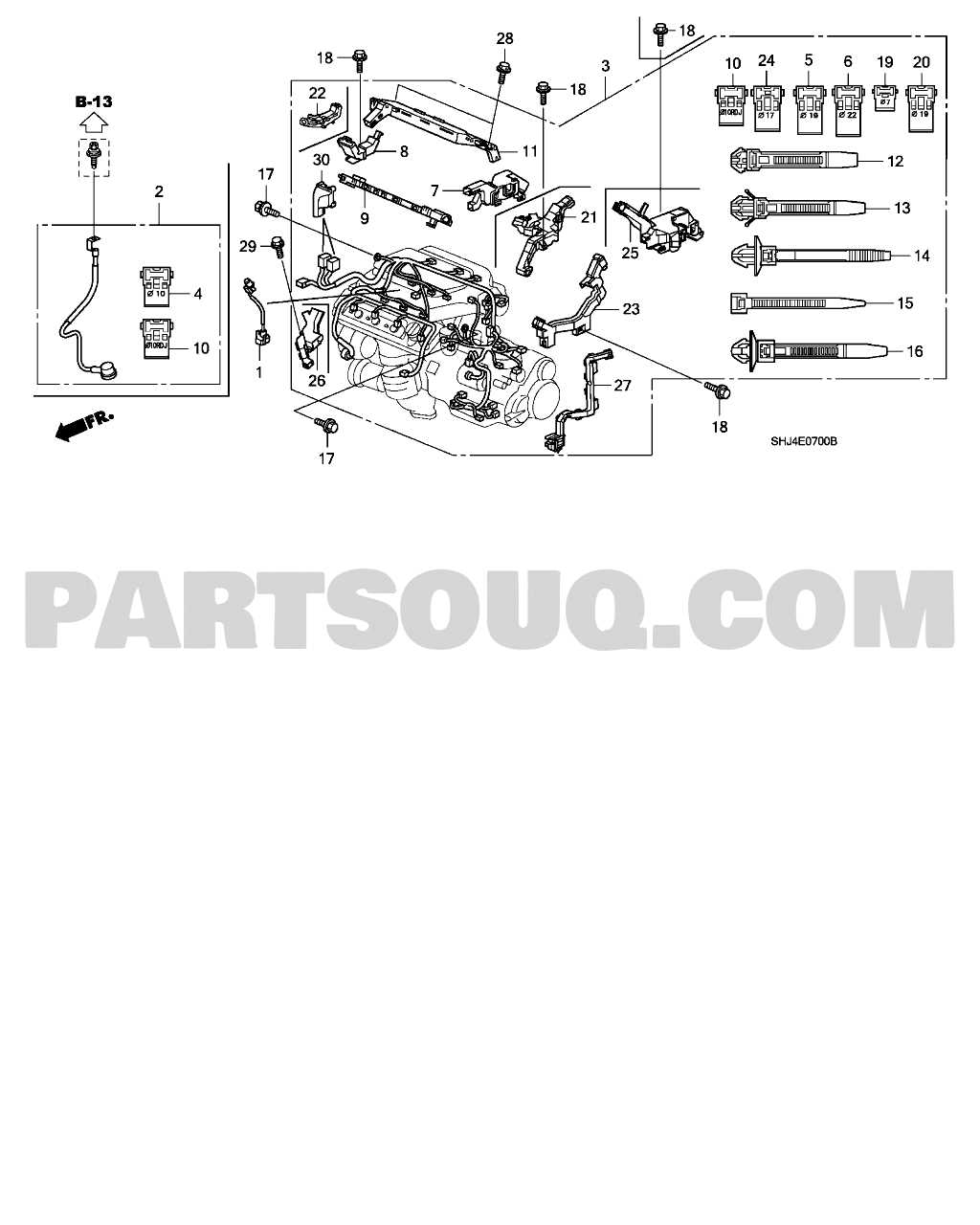

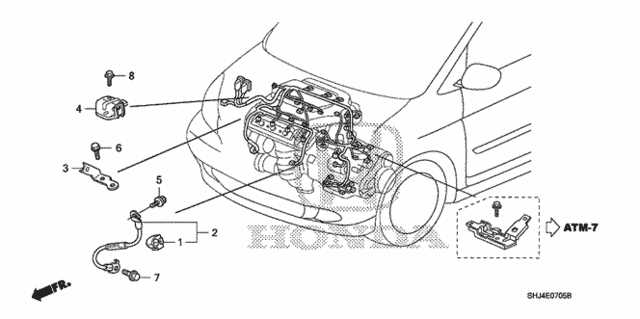

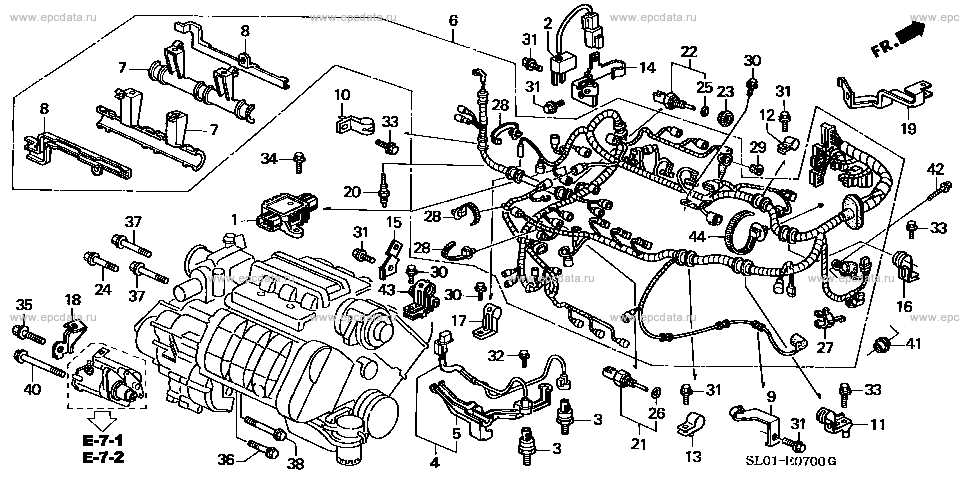

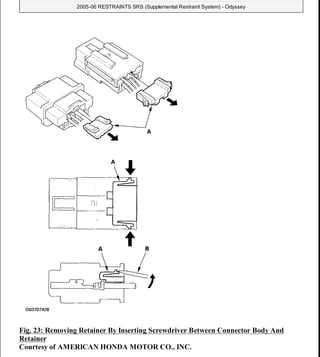

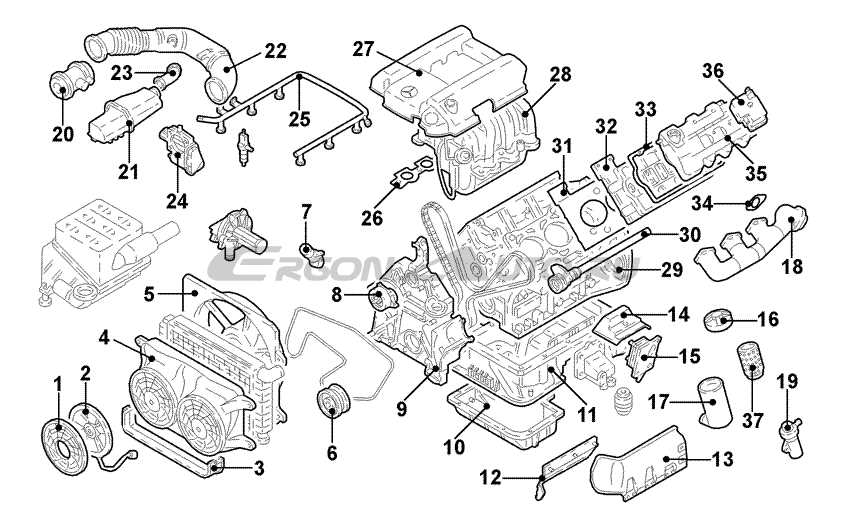

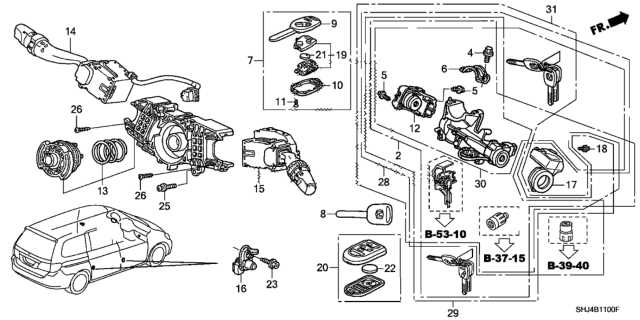

How to Read Engine Parts Diagrams

Understanding mechanical schematics is essential for anyone involved in vehicle maintenance or repair. These visual representations provide a detailed map of various components, their relationships, and their placement within a system. While these illustrations may seem complex at first glance, breaking them down into manageable sections can make them easier to interpret and use effectively.

Step one in reading these diagrams is identifying the key symbols used for different elements. Most diagrams will include standard notations that represent specific parts like valves, pistons, and belts. These symbols are universally recognized within the automotive industry, so once you become familiar with them, you’ll find it easier to interpret.

Step two is understanding how the components are connected. Lines or arrows in the visual guide indicate how parts are linked or how they move in relation to each other. By following these connections, you can grasp how the entire system functions as a cohesive unit. It’s crucial to pay attention to the flow of power, air, or fluids between the various components.

Step three is using the diagram to troubleshoot or plan for repairs. Once you know the layout of each component, you can locate malfunctioning areas or check for wear. The schematic often includes numerical or alphabetical labels, which correspond to specific specifications or technical data, making the process of diagnosis more accurate.

In summary, becoming proficient at reading these visual representations requires practice, but understanding them empowers you to diagnose and repair issues more effectively. With time, you’ll be able to analyze the layout and function of each element within the system, leading to better decision-making during maintenance or repairs.

Aftermarket vs. OEM Engine Parts

The choice between different sources for components can significantly influence vehicle performance and longevity. Understanding the nuances of these options is essential for informed decision-making.

Quality and Performance

Quality can vary widely between alternatives. Here are some points to consider:

- OEM components are manufactured by the original creator, ensuring compatibility and reliability.

- Aftermarket alternatives often promise enhanced features or better pricing, but may lack quality assurance.

- Some aftermarket options are designed to outperform originals, but this can lead to unforeseen issues.

Cost Considerations

Budget is a crucial factor in the decision-making process:

- OEM items typically come with a higher price tag but guarantee a specific standard.

- Aftermarket choices can be more affordable, providing potential savings for consumers.

- Weighing long-term value against initial cost is vital for making the best selection.

Visual Guide to Engine Assembly

Understanding the layout and organization of critical components within a vehicle’s power unit is essential for both mechanics and enthusiasts. This section provides a comprehensive overview of how the various mechanical elements interact and come together to form a complete system. A clear understanding of these assemblies will aid in diagnostics, repairs, and general maintenance.

Visualizing the key components can significantly simplify the process of troubleshooting or upgrading. Each element, from the intake system to the exhaust manifold, plays an integral role in the unit’s overall performance. By examining these elements, one can identify their functions, how they connect, and their contribution to optimal functionality.

Component location and positioning are critical in ensuring proper assembly. For example, the arrangement of pistons, timing mechanisms, and camshafts must follow precise specifications to maintain balance and efficiency. Incorrect placement or misalignment can lead to poor operation or even damage.

Focusing on the spatial relationships between different sections is crucial. By following a logical sequence from the base to the top of the structure, it becomes easier to identify connections and understand the order in which assembly occurs.

Resources for Engine Troubleshooting

When facing issues with a vehicle’s power source, having access to the right resources can significantly streamline the diagnostic process. A variety of tools and references can aid in identifying problems effectively, ensuring a smoother resolution and restoring optimal performance.

Online Forums and Communities

Engaging with dedicated online forums can provide invaluable insights. Enthusiasts and experts often share their experiences, solutions, and troubleshooting tips. These platforms facilitate knowledge exchange and can help pinpoint specific challenges based on similar situations faced by others.

Service Manuals and Guides

Comprehensive manuals are crucial for understanding the intricacies of your vehicle’s mechanics. They typically include step-by-step instructions, specifications, and diagrams that clarify various components. Accessing these resources can simplify repair processes and enhance your understanding of potential issues.

| Resource Type | Description | Example |

|---|---|---|

| Online Forums | Community-driven platforms for sharing experiences and solutions. | Reddit, Car Forums |

| Service Manuals | Detailed guides that outline repairs and specifications. | Haynes, Chilton |

| Troubleshooting Apps | Mobile applications providing diagnostic support and tips. | OBD-II Scanner Apps |

| Video Tutorials | Visual aids that demonstrate repair processes. | YouTube Channels |