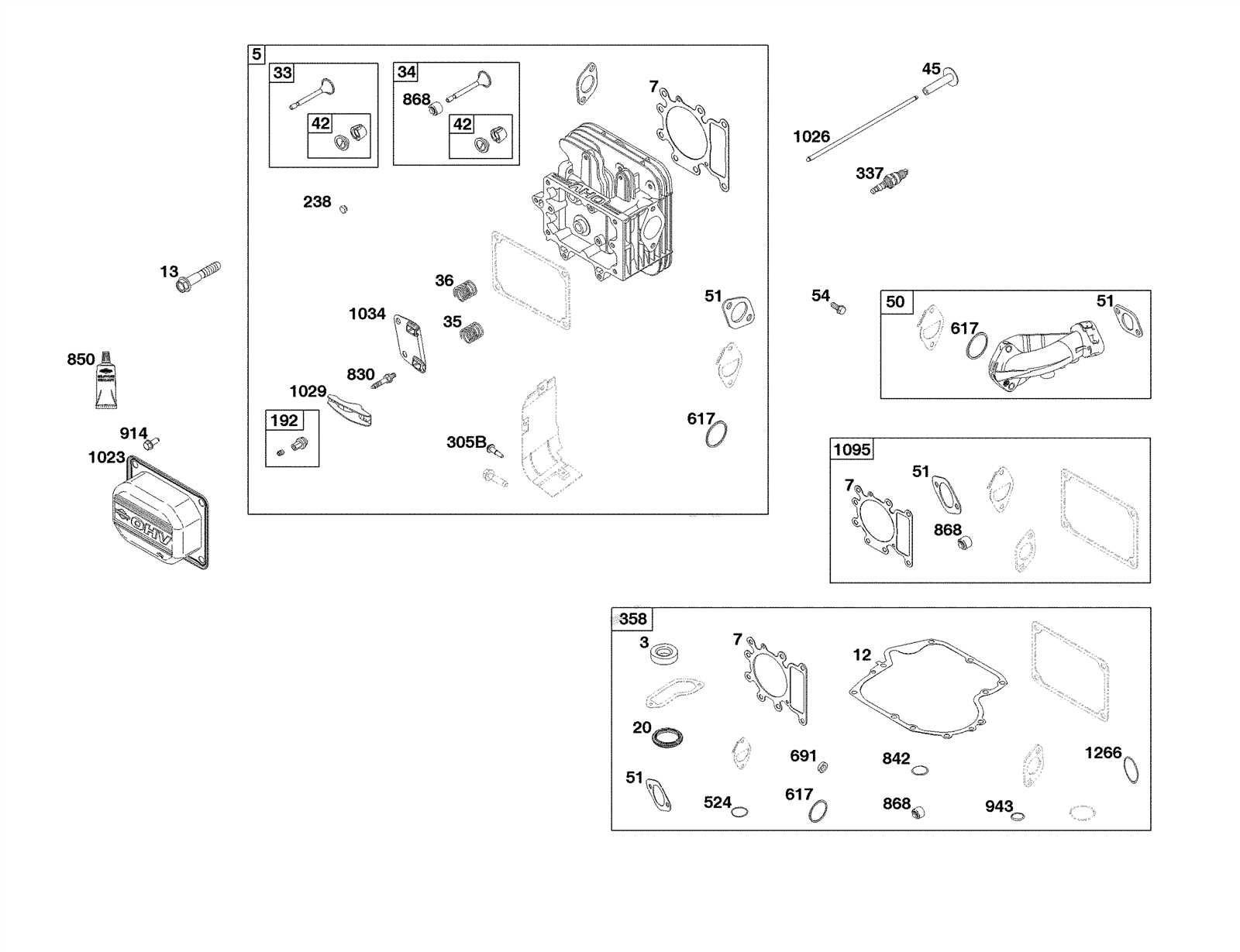

Understanding the layout and arrangement of various mechanical elements is essential for ensuring smooth operation and effective maintenance. Each element is strategically placed to serve a specific function, contributing to the overall efficiency of the machinery.

By examining the detailed structure, one can gain insights into the connections between these elements and how they interact to form a cohesive system. This understanding is key when it comes to troubleshooting or replacing individual segments.

The following breakdown offers a clear depiction of each element’s role and its positioning within the system, making it easier to navigate and maintain.

13an77xs093 Parts Overview

The focus of this section is to provide a comprehensive understanding of the individual components that make up the equipment. Each element plays a vital role in ensuring proper functionality and performance.

- Engine Block: The central power source, crucial for driving the machinery.

- Transmission System: Responsible for controlling the speed and power distribution throughout the device.

- Cutting Mechanism: Ensures precision in the machine’s primary function, optimizing the end result.

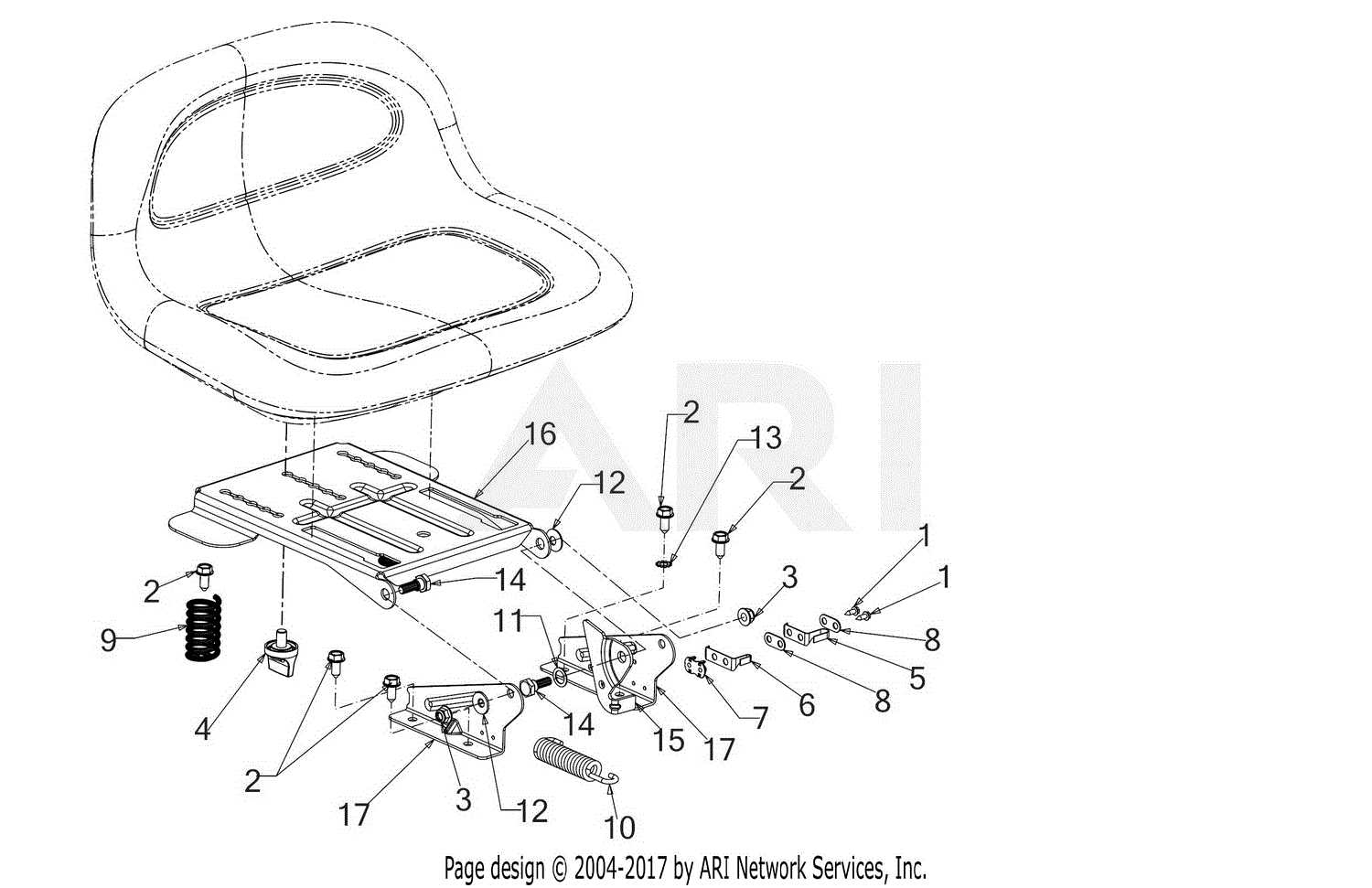

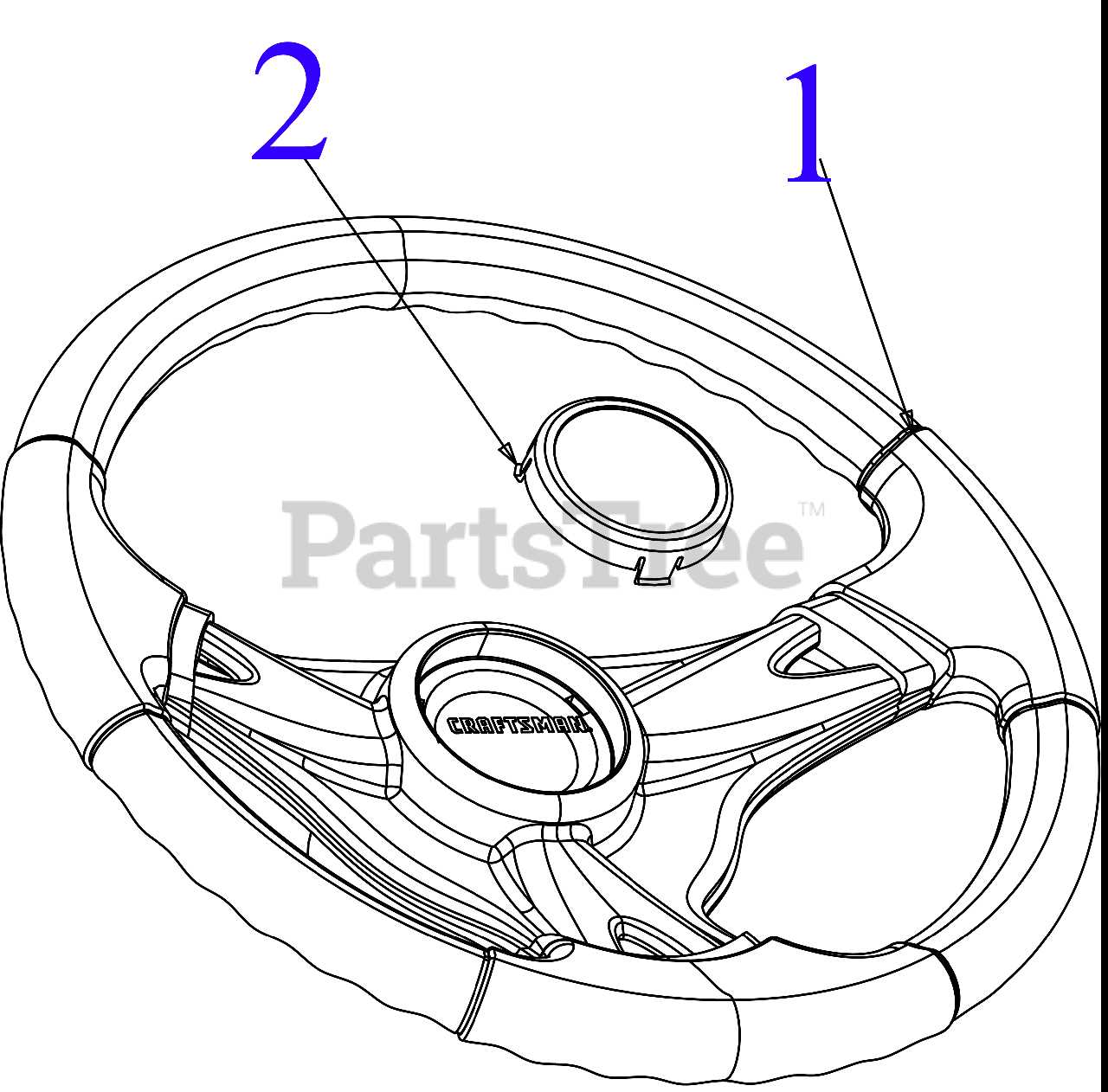

- Steering Assembly: Allows for smooth navigation and accurate control during operation.

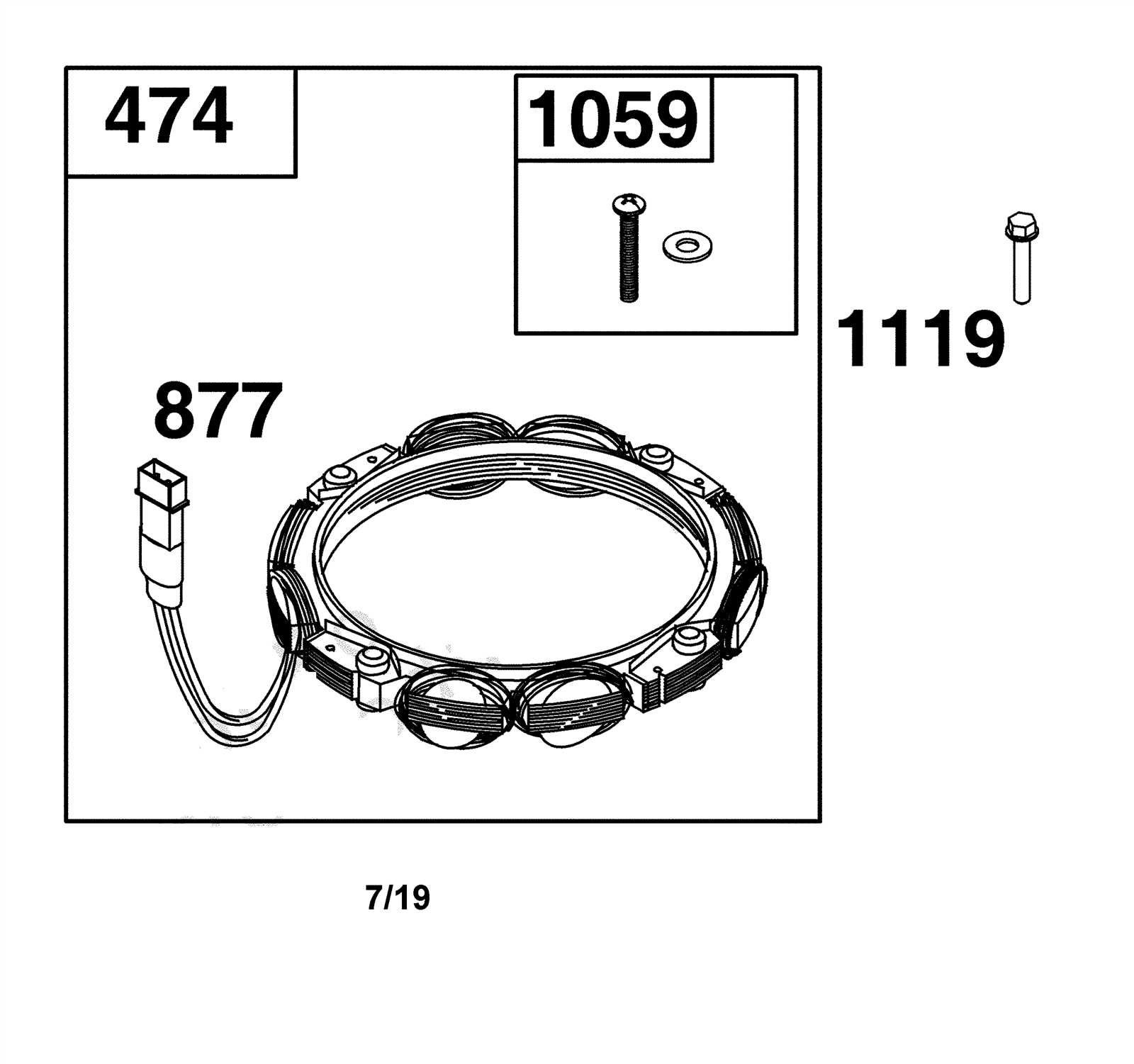

- Electrical Wiring: Connects various elements to enable seamless communication between parts.

- Safety Mechanisms: Integral to protecting the operator and preventing accidents.

These key elements work in harmony, ensuring optimal efficiency and safety throughout the device’s use.

Component Breakdown for the Model

The model consists of various essential elements that work together to ensure optimal performance. Each element plays a specific role in the overall functioning, making it crucial to understand their individual contributions and how they interact.

Main Structural Elements

The key structural components include the frame, which provides stability and support, and the internal mechanisms that ensure the model operates smoothly. These elements are designed to fit seamlessly, contributing to the model’s durability and efficiency.

Functional Modules

Beyond the structural base, the model features several functional modules that enable its advanced operations. These include

Key Features and Specifications

This section provides an overview of the most important characteristics and technical details, offering insight into the capabilities and strengths of the model. These attributes ensure high performance and efficiency, making the equipment reliable and versatile in various scenarios.

Core Capabilities

The device comes equipped with advanced functionality that enhances user experience. Its design prioritizes both ease of use and adaptability, allowing it to seamlessly integrate with different systems and environments. Durability and precision are core aspects of its construction, ensuring long-term performance.

Technical Specifications

Among the most notable technical details are the device’s compatibility with various

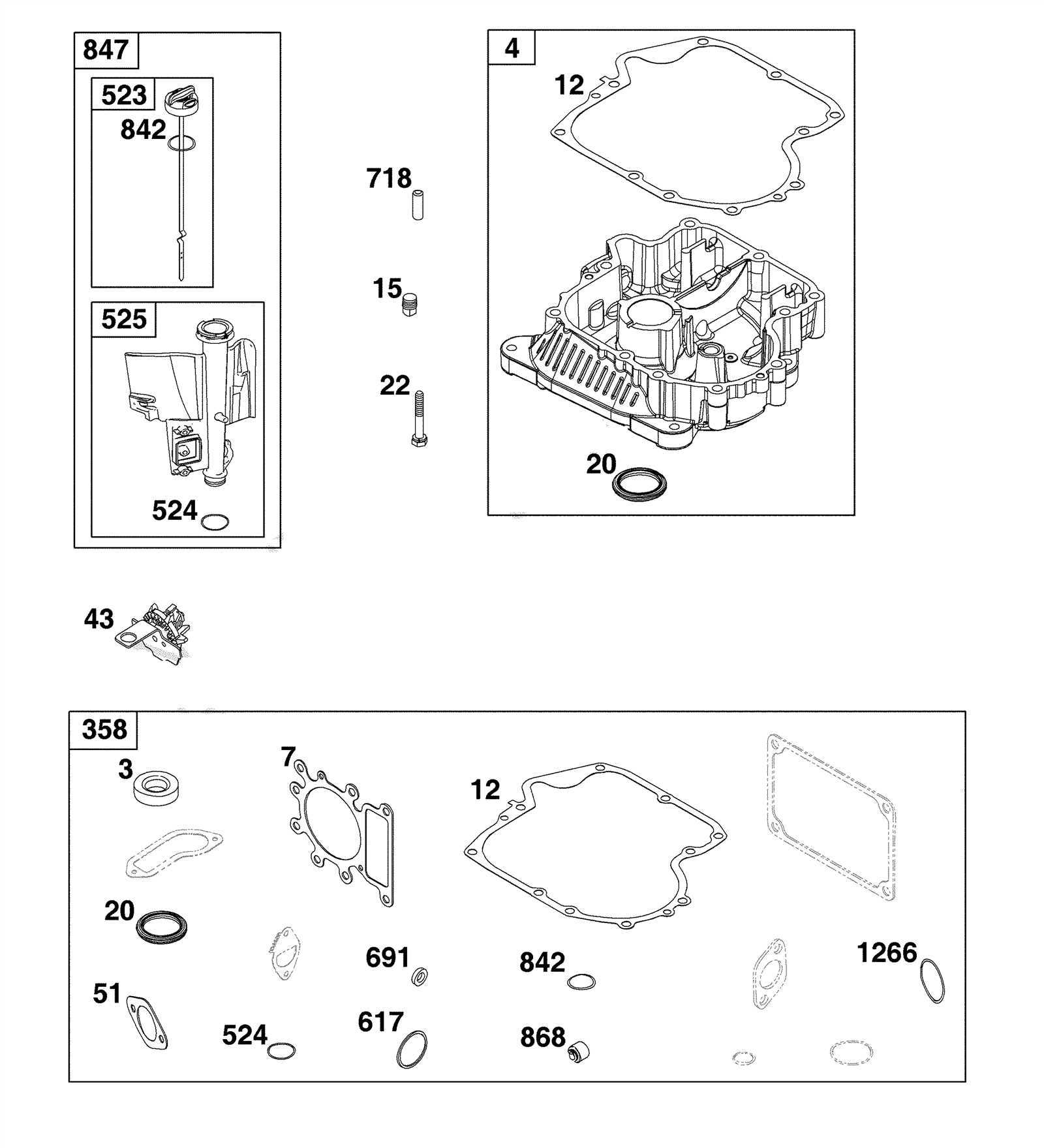

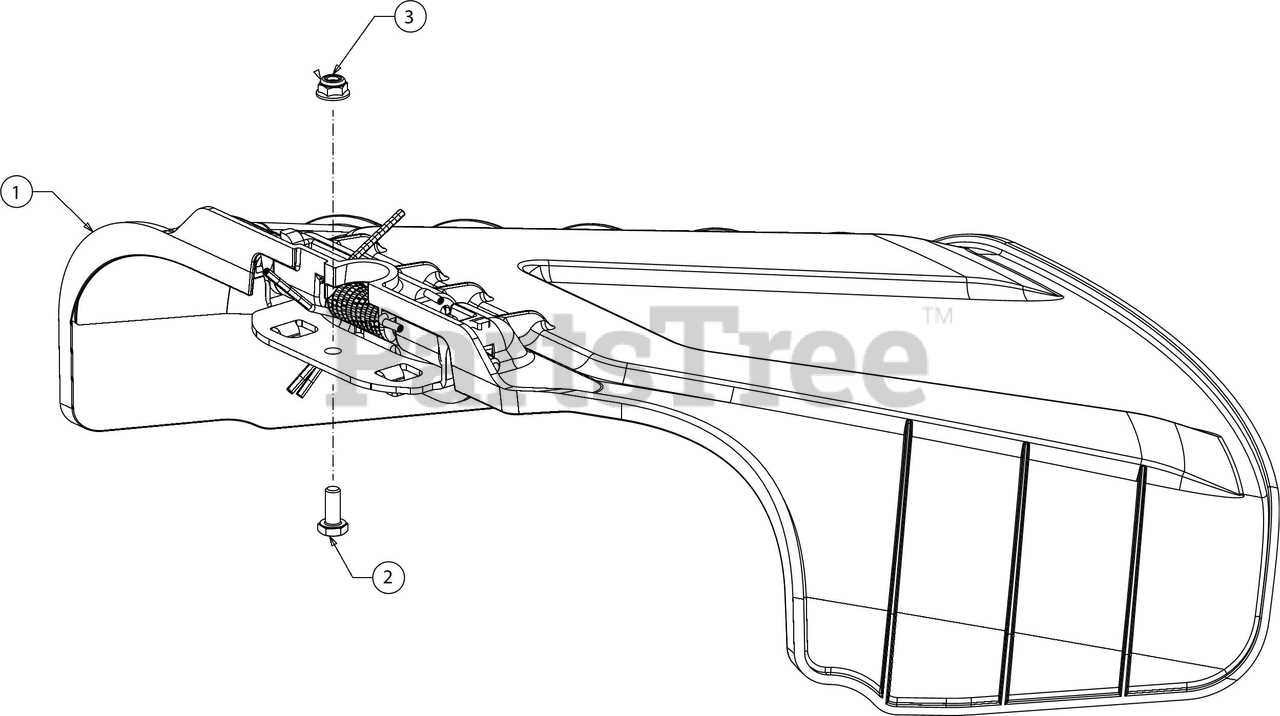

Common Replacement Parts Explained

Over time, some components of equipment can wear out or become damaged, making it necessary to replace them. Understanding which elements may need replacement and why they fail can help extend the lifespan of your device. Regular maintenance and timely replacements ensure efficient performance and prevent more significant issues.

Blades and Belts are frequently replaced due to wear and tear from daily use. Blades can become dull, affecting their functionality, while belts can stretch or crack, leading to a decrease in efficiency.

Filters and batteries are other common components that require regular attention. Filters can become clogged over time, reducing airflow or efficiency, while batteries lose their capacity after many charging cycles.

Maintenance Tips for Longevity

To ensure your equipment operates efficiently over an extended period, consistent upkeep is essential. Regular care helps in preventing wear and tear, allowing each component to function smoothly, and minimizes unexpected issues.

Regular Cleaning

Dust and debris can accumulate over time, affecting the performance of your machine. It’s crucial to clean all accessible areas, paying attention to surfaces prone to buildup. Use a soft brush or compressed air to remove particles from delicate sections.

Lubrication and Adjustment

Maintaining proper lubrication in moving parts is vital for reducing friction and extending the lifespan of your equipment. Check for any signs of stiffness and apply the appropriate grease or oil where necessary. Also, ensure all moving elements are correctly aligned to avoid strain.

Consistent monitoring and minor adjustments

Installation Process for New Components

When integrating new elements into a system, it is crucial to follow a structured approach to ensure seamless functionality. This section outlines essential steps and considerations that can facilitate the installation, enhancing both efficiency and reliability in operation.

Preparation Steps

- Gather all necessary tools and components required for the installation.

- Review the technical specifications and guidelines for each element.

- Ensure the workspace is clean and organized to prevent any mishaps during the process.

Installation Procedure

- Begin by turning off the system to ensure safety during the installation.

- Carefully remove the existing components that need replacement, taking note of their arrangement for reference.

- Install the new components by following the manufacturer’s instructions, ensuring a secure fit.

- Double-check all connections and fittings for stability and alignment.

- Once the installation is complete, power on the system and conduct a functionality test to verify proper operation.

Identifying Wear and Tear

Recognizing signs of degradation in machinery is essential for maintaining optimal performance and longevity. Various components can exhibit symptoms that indicate they are reaching the end of their useful life. Early detection of these issues can prevent more significant failures and costly repairs.

Common Indicators of Degradation

- Unusual Noises: Any strange sounds during operation may suggest misalignment or damaged parts.

- Vibrations: Excessive shaking can indicate imbalance or wear on moving elements.

- Fluid Leaks: Presence of liquids can signify seal degradation or cracks in housing.

- Inconsistent Performance: Fluctuations in efficiency or output may point to underlying issues.

Visual Inspections

Regular visual inspections can help identify potential problems before they escalate. Look for:

- Cracks or signs of corrosion on surfaces.

- Worn or frayed belts and hoses.

- Loose or missing fasteners that can compromise stability.

By paying attention to these factors, you can ensure the reliability of your equipment and extend its operational lifespan.

Where to Source Spare Parts

Finding reliable sources for replacement components is crucial for maintaining the functionality of your equipment. Various avenues exist to obtain these essential items, ensuring that you can keep your machinery running smoothly.

Local Retailers: Check with nearby hardware stores or specialized shops that cater to your specific needs. These establishments often carry a range of components that may suit your requirements.

Online Marketplaces: Numerous websites provide a vast selection of items for sale, allowing you to compare prices and availability. Popular e-commerce platforms can be a valuable resource for sourcing what you need from the comfort of your home.

Manufacturer Direct: Reaching out to the original manufacturer can be a reliable option. They often have the most accurate information regarding compatible items and may offer them for sale directly.

Forums and Community Groups: Engaging with online forums and communities can connect you with individuals who have faced similar challenges. Members often share tips on where to find specific items and might even have recommendations for trusted sellers.

Upgrading Options for Enhanced Performance

Enhancing the efficiency of your machinery can significantly boost its overall functionality and longevity. Various strategies exist to improve performance, allowing users to tailor their equipment to better suit their specific needs. By considering different enhancement techniques, operators can ensure their devices operate at optimal levels, meeting the demands of various tasks.

One effective method for upgrading involves replacing outdated components with modern equivalents. This not only increases efficiency but also improves reliability. Additionally, integrating advanced technologies can provide enhanced features, offering greater control and precision during operation. Regular maintenance checks and timely updates are also crucial in maintaining high performance.

Ultimately, the choice of upgrades will depend on the individual requirements and operational conditions. Careful assessment of available options can lead to informed decisions, ensuring that your machinery remains competitive and efficient in an ever-evolving environment.