The marine propulsion system plays a crucial role in ensuring smooth navigation through water. Each element within this mechanism is designed to work in harmony, delivering the necessary thrust and control to guide vessels efficiently. The system is a combination of multiple key pieces that need to be understood in order to keep the boat performing optimally.

When examining this type of propulsion technology, it’s essential to know how the various sections interact with each other. Whether focusing on the drive mechanisms or the hydraulic components, having a clear picture of their layout and functions helps in maintenance and troubleshooting. This understanding is not only beneficial for repairs but also for upgrades and modifications, allowing enthusiasts to get the most out of their setup.

In the following section, we will delve deeper into the main elements of this propulsion technology, providing a clearer view of how they are connected. By grasping the structure and purpose of each component, users can ensure long-lasting performance and a safer experience on the water.

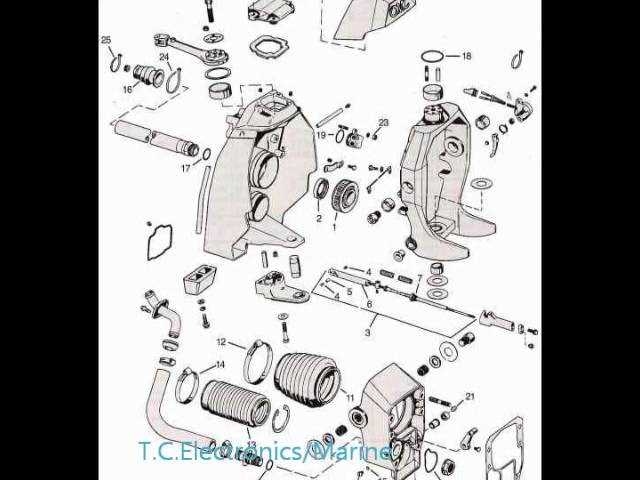

Understanding the OMC Cobra Outdrive Assembly

The propulsion mechanism is a crucial component for marine vessels, ensuring smooth movement through the water. It consists of various interconnected parts that function together to provide power, steering, and stability. Knowing how these elements interact helps maintain optimal performance and avoid potential mechanical issues.

Main Elements of the Propulsion Mechanism

- Drive Gear System: This set of gears transfers power from the engine to the propeller, ensuring proper rotation and speed control.

- Steering Components: These parts manage the direction of the boat, allowing smooth turns and maneuverability on water.

- Trim and Tilt Functions: These systems adjust the angle of the propeller, optimizing efficiency depending on speed and water conditions.

Maintenance Tips for Longevity

- Regularly inspect the gear system for any signs of wear or damage to prevent malfunctions.

- Ensure all steering components are well-lubricated to maintain easy and responsive control.

- Check and clean the propeller area frequently to avoid debris buildup that can impact performance.

Key Components of the OMC Cobra Outdrive

The propulsion system of a boat relies on an intricate assembly of mechanical elements that work together to ensure smooth operation and control. Understanding the essential parts of this mechanism helps with maintenance, repair, and overall performance optimization. Below is a look at some of the crucial components that make this system function effectively.

| Component | Description | |||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Propeller | Responsible for converting engine power into thrust, enabling movement through the water. | |||||||||||||||||||||||

| Gimbal Bearing | Provides support for the drive shaft, ensuring smooth rotation and reducing vibration. | |||||||||||||||||||||||

| Shift Cable | Connects to the control system, allowing seamless shifting between gears for better handling. | |||||||||||||||||||||||

| Water Pump | Ensures proper engine cooling by circulating water through the cooling system. | |||||||||||||||||||||||

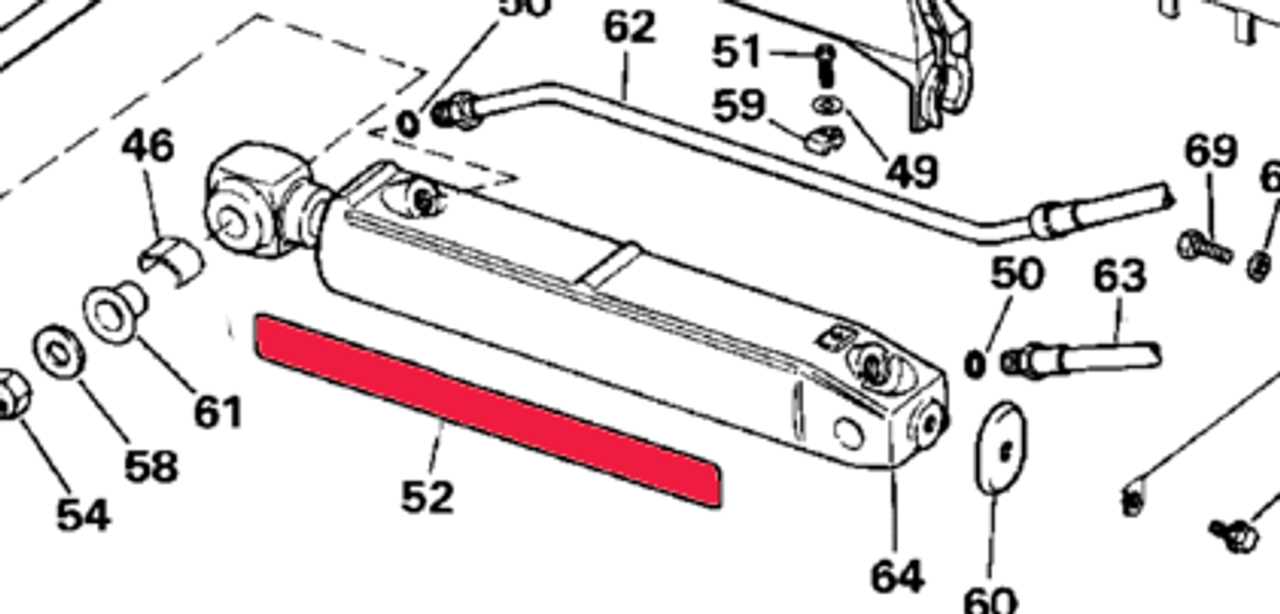

Trim Cylinder

How the OMC Cobra Shift System Works

The shift mechanism plays a crucial role in the smooth and efficient functioning of marine propulsion systems. It ensures a seamless transition between different modes of operation, allowing the vessel to move forward, reverse, or remain in neutral. Understanding how this intricate system functions can help troubleshoot common issues and improve overall performance. Key Components Involved in ShiftingAt the core of the system is a combination of levers, cables, and gears. These elements work together to engage or disengage propulsion, depending on the chosen mode. Each movement of the control lever triggers a series of actions within the internal structure, shifting the drive from one gear to another. The Shifting ProcessWhen the operator moves the lever, the system uses a synchronizing mechanism to align the gears correctly, preventing any sudden or harsh engagement. This synchronized movement is essential for avoiding mechanical stress and ensuring the engine runs smoothly across various speeds and conditions. Identifying the Main Seals and GasketsWhen it comes to ensuring the proper functioning of your propulsion system, recognizing and maintaining the crucial seals and gaskets is key. These components play a vital role in preventing leaks, maintaining pressure, and ensuring smooth operation, making them essential for the longevity and performance of any marine setup. Understanding their function and location will help prevent potential malfunctions and extend the service life of the entire mechanism. Key Seals to Focus OnThe primary seals work by keeping vital fluids in while blocking contaminants from entering sensitive areas. These include the larger shaft seals and smaller ones that encase critical moving parts. Regular inspection of these seals helps avoid fluid loss and ensures that all elements within the assembly are well-lubricated and protected from water or debris intrusion. Important Gaskets to Monitor

Gaskets act as the final defense between two connected surfaces, preventing fluid or gas leaks. Common areas to find these components are around gear housings, water pumps, and other key junctions. Worn-out gaskets can lead The Importance of the OMC Cobra PropellerThe propeller is one of the most crucial components for any marine vessel. It plays a vital role in transforming engine power into movement through the water, ensuring smooth navigation and optimal speed. A well-chosen propeller enhances efficiency, reducing strain on the motor, while also maximizing fuel economy. Its proper function is key to maintaining the vessel’s performance and handling in various water conditions. Understanding the impact of the right propeller on a boat’s overall performance can’t be overstated. From acceleration to steering control, every aspect of the boat’s dynamics is influenced by this component. Below is a table summarizing its main functions:

|