In the realm of outdoor machinery, comprehending the intricate layout of components is essential for effective maintenance and operation. Having a clear visual reference can significantly enhance your ability to troubleshoot and ensure the longevity of your equipment. This guide aims to provide an insightful look into the structural organization of key elements, facilitating a smoother user experience.

Utilizing a detailed representation not only aids in identifying each segment but also empowers operators to perform necessary upkeep with confidence. Whether you are a seasoned professional or a novice enthusiast, familiarity with the configuration can streamline repairs and adjustments, ultimately optimizing performance. Understanding how everything fits together is vital in maximizing the efficiency and reliability of your machinery.

As you delve into this topic, you will discover various insights that will enrich your knowledge and support your hands-on efforts. With the right information at your fingertips, navigating the complexities of your equipment becomes a more manageable and rewarding endeavor.

Understanding the John Deere L110

This section provides insights into a popular lawn care machine known for its efficiency and reliability. Designed for residential use, it offers an array of features that simplify the maintenance of outdoor spaces. Users appreciate its intuitive design and the performance it delivers, making it a favored choice among homeowners.

Key Features

Among the many attributes of this equipment, several stand out, enhancing its appeal and functionality. These include a robust engine, user-friendly controls, and a versatile cutting deck. Such characteristics enable users to navigate various terrains with ease, ensuring a well-manicured lawn.

Specifications Overview

| Attribute | Description |

|---|---|

| Engine Type | Air-cooled, single-cylinder |

| Cutting Width | 42 inches |

| Transmission | Automatic, variable speed |

| Fuel Capacity | 1.5 gallons |

| Weight | Approx. 450 lbs |

Understanding the specifications helps users optimize their experience and maintain the machine effectively, ensuring longevity and peak performance.

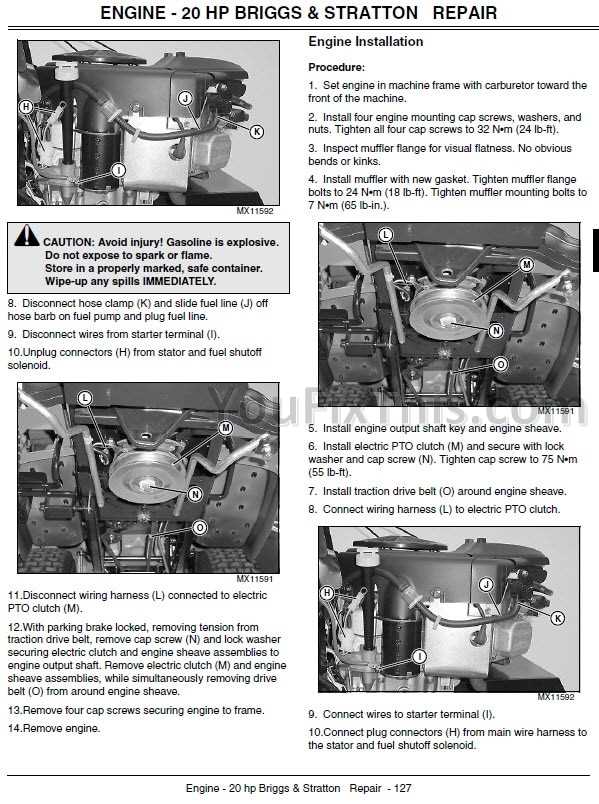

Importance of Parts Diagrams

Visual representations are crucial in understanding the structure and functionality of complex machinery. They provide clarity, allowing users to grasp the arrangement and relationship between various components, which is essential for effective maintenance and repair.

These illustrations serve as invaluable references, enabling technicians and operators to quickly identify the necessary elements during troubleshooting. By having a clear view of how each piece fits together, users can streamline their efforts and reduce the likelihood of errors.

Moreover, such visual aids enhance communication among team members, ensuring everyone is on the same page regarding assembly and disassembly tasks. This collaborative approach ultimately leads to increased efficiency and productivity.

In addition, utilizing these resources can prolong the lifespan of equipment, as proper understanding encourages timely interventions and preventative measures. Thus, visual guides are not just helpful but essential for optimal performance.

Key Components of the L110

This section explores essential elements that contribute to the functionality and efficiency of the machine. Understanding these key features helps in appreciating the overall design and performance capabilities.

| Component | Description |

|---|---|

| Engine | Powerful motor providing the necessary force for operation. |

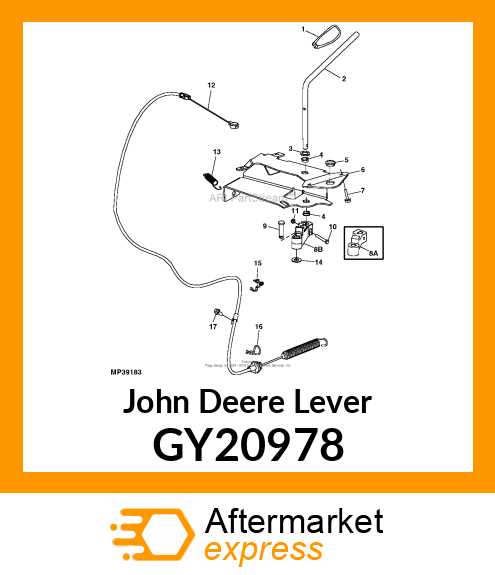

| Transmission | System enabling smooth gear shifting and speed control. |

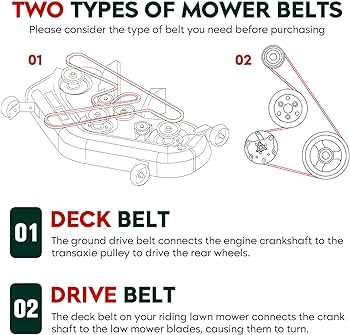

| Deck | Durable platform housing cutting blades for efficient grass trimming. |

| Wheels | Robust tires ensuring stability and traction on various terrains. |

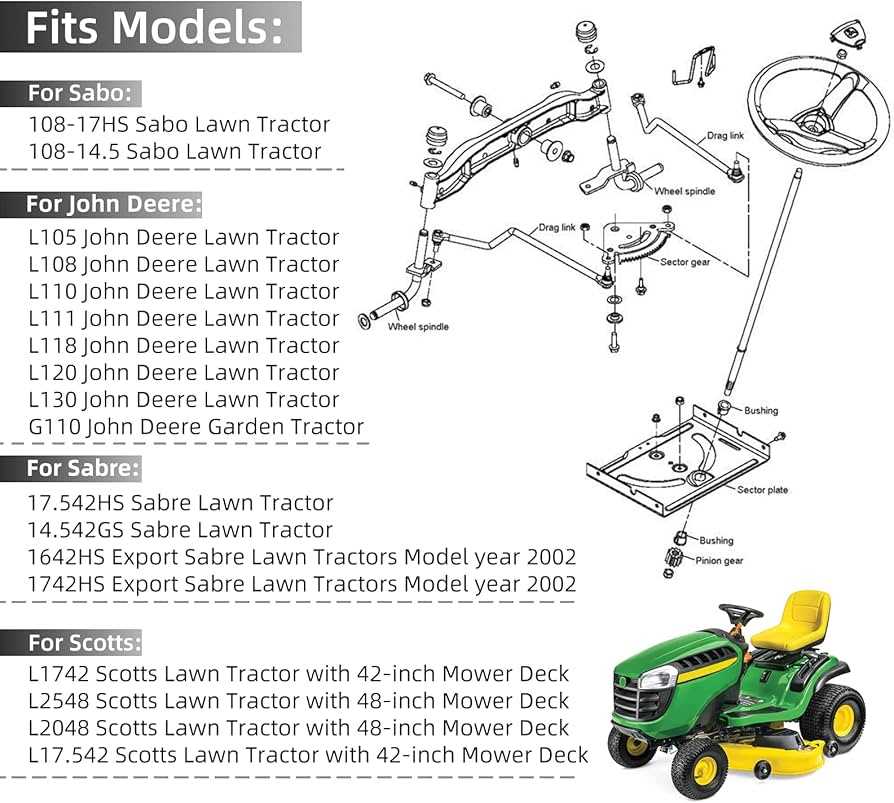

| Steering System | Mechanism allowing precise maneuverability and control. |

How to Read a Parts Diagram

Understanding technical illustrations is essential for effective maintenance and repairs. These visuals provide a detailed representation of components and their relationships, aiding in identification and assembly. By familiarizing yourself with the layout, you can navigate through the elements with confidence.

Start by examining the key: Symbols and labels indicate various elements. Familiarize yourself with these markings to grasp their meanings quickly.

Next, observe the layout: Components are often grouped logically, allowing you to follow the assembly process. Pay attention to connections and orientations.

Finally, take note of part numbers: These identifiers are crucial for ordering replacements. Ensure you record them accurately to avoid confusion during procurement.

Common Issues with L110 Parts

Many users encounter various challenges when dealing with components of their equipment. Understanding these common problems can significantly enhance the maintenance process and extend the lifespan of the machinery.

Wear and Tear: Over time, certain elements may deteriorate due to regular use. This can lead to reduced efficiency and increased risk of malfunction.

Incorrect Installation: Mistakes during assembly can result in operational issues. Ensuring proper fitting is essential for optimal functionality.

Compatibility Concerns: Using incompatible replacements can cause serious problems. Always verify that components meet specifications before installation.

Routine Maintenance Neglect: Skipping regular checks and maintenance can exacerbate existing issues. Consistent upkeep is crucial to prevent larger complications.

Addressing these common concerns proactively can ensure a smoother experience and enhance the overall performance of the equipment.

Where to Find Replacement Parts

Finding the right components for your equipment can significantly enhance its performance and longevity. Whether you’re looking to replace a worn-out piece or upgrade your machine, there are several avenues you can explore to acquire what you need.

Online Retailers: Numerous websites specialize in selling various components. Major e-commerce platforms often have a wide selection, allowing you to compare prices and read customer reviews before making a purchase.

Authorized Dealers: Visiting an authorized dealer is a reliable way to ensure you receive high-quality components that meet the manufacturer’s specifications. They can also provide expert advice and assistance in selecting the correct items.

Local Repair Shops: Local mechanics or repair shops often have a range of components on hand or can order specific items for you. Establishing a relationship with a trusted shop can be beneficial for future maintenance needs.

Salvage Yards: Salvage yards can be treasure troves for those seeking economical solutions. You might find gently used components that are in good condition, allowing you to save money while maintaining functionality.

Manufacturer’s Website: Many manufacturers offer online catalogs or stores where you can find components tailored specifically for your model. This ensures compatibility and often provides detailed information about each item.

Maintenance Tips for L110 Owners

Proper upkeep is essential for ensuring optimal performance and longevity of your machine. Regular attention to its components can prevent unexpected issues and enhance its efficiency. Below are some helpful suggestions to keep your equipment in excellent condition.

- Regular Cleaning: Keep the exterior and undercarriage free of debris. Dirt and grass buildup can cause overheating and affect performance.

- Check Fluids: Regularly inspect oil, fuel, and coolant levels. Ensure they are filled to the recommended levels to avoid damage.

- Inspect Blades: Sharpen and clean the cutting blades to maintain a clean cut. Dull blades can strain the engine and produce uneven results.

- Tire Maintenance: Check tire pressure frequently. Properly inflated tires enhance maneuverability and reduce wear.

- Belt Examination: Inspect belts for wear and tension. Replace any frayed or damaged belts to ensure smooth operation.

By incorporating these practices into your routine, you can significantly extend the lifespan of your equipment while ensuring its optimal performance throughout the seasons.

Upgrading Components for Better Performance

Enhancing the functionality of your equipment can significantly improve efficiency and longevity. By focusing on specific elements, users can achieve smoother operation and greater output. Evaluating current features and identifying areas for improvement is crucial in this process.

One effective strategy involves upgrading the engine components. A more powerful engine can lead to improved speed and better handling under various conditions. Additionally, better fuel efficiency can be a notable benefit, allowing for longer operational periods without frequent refueling.

Another key area is the transmission system. Implementing advanced transmission options can enhance the responsiveness and adaptability of the machine, making it more versatile for different tasks. This improvement often translates to increased productivity, especially in challenging terrains.

Moreover, investing in high-quality tires can provide superior traction and stability. Upgraded tires ensure that the equipment maintains control in diverse environments, minimizing the risk of slippage and enhancing overall safety.

Lastly, considering enhancements in the control systems can lead to a more user-friendly experience. Modernized controls not only improve accuracy but also reduce the learning curve for new operators, allowing for a quicker transition and more efficient use.