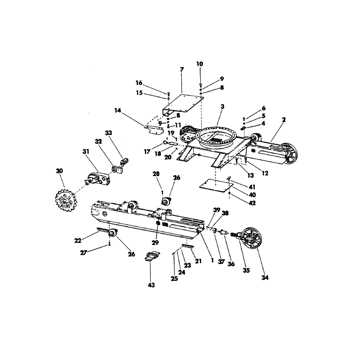

Maintaining outdoor equipment requires a comprehensive understanding of its structure and individual components. When faced with repairs or upgrades, having a clear visual representation can greatly simplify the process. This section aims to provide insights into the arrangement of parts for specific machinery, helping users navigate their maintenance tasks with confidence.

In the world of heavy-duty machinery, recognizing each element’s role and placement is crucial for optimal performance. Whether you’re a seasoned technician or a novice user, grasping the nuances of the layout can lead to more efficient repairs and a longer lifespan for the equipment. Clear visual guides serve as invaluable resources, making it easier to identify issues and implement solutions swiftly.

By exploring the intricate design of these systems, operators can enhance their troubleshooting skills and reduce downtime. This knowledge not only empowers users to address common problems but also fosters a deeper appreciation for the engineering behind these robust machines. Emphasizing the importance of understanding these layouts encourages proactive maintenance and ultimately leads to improved functionality.

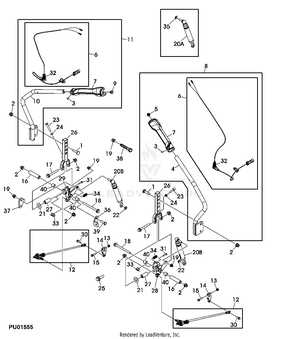

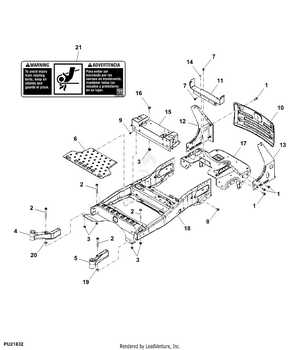

Understanding the Z520A Components

In this section, we will explore the essential elements that make up a specific model of a popular lawn care machine. Each component plays a crucial role in ensuring optimal performance and efficiency, contributing to the overall functionality and reliability of the equipment.

Key Elements of the Equipment

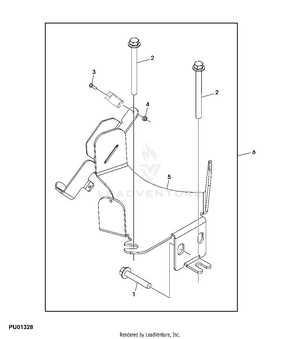

The primary parts include the engine, transmission, and cutting deck. The engine serves as the powerhouse, providing the necessary energy for operation, while the transmission facilitates smooth movement across various terrains. The cutting deck, a vital feature, determines the quality of the grass cut and is often adjustable to achieve different mowing heights.

Maintenance and Performance

Regular upkeep of these components is essential for maintaining peak performance. Identifying wear and tear early can prevent costly repairs and extend the lifespan of the machine. Understanding the functionality of each part allows users to delve into maintenance practices effectively, ensuring that the equipment operates at its ultimate capacity.

Key Features of the Z520A Model

This exceptional mower stands out in the landscape care industry due to its innovative design and advanced technology. With a combination of performance and user-friendly features, it caters to both residential and commercial needs, ensuring efficient grass management.

Powerful Engine: At the heart of this machine is a robust engine that delivers exceptional torque and speed. This ensures quick mowing and the ability to tackle even the toughest terrains with ease.

Precision Cutting: The cutting deck is engineered for optimal performance, allowing for precise grass trimming. This feature minimizes uncut areas and promotes a well-manicured appearance for any lawn.

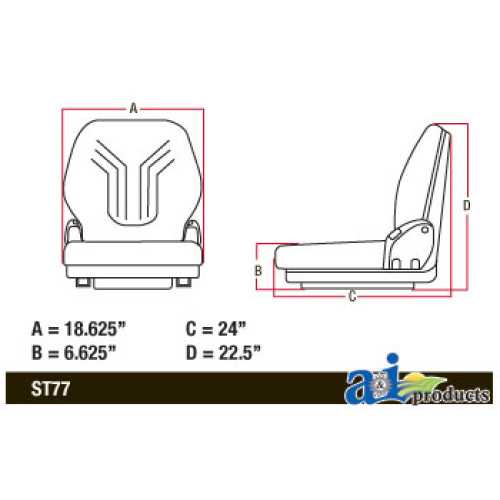

Comfort and Ergonomics: Designed with the operator in mind, the seating and control layout provide maximum comfort during extended use. Adjustable elements accommodate various user preferences, enhancing overall experience.

Durability: Constructed with high-quality materials, this model is built to withstand rigorous conditions. Its resilience ensures a long lifespan, making it a reliable choice for frequent use.

Ease of Maintenance: Routine upkeep is straightforward, with accessible components designed for quick inspections and repairs. This practicality helps users maintain peak performance without hassle.

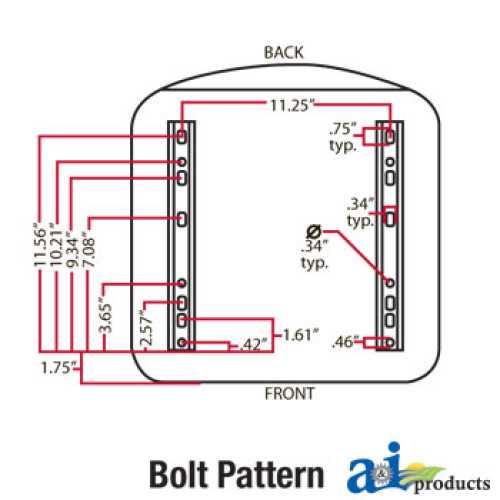

Identifying Replacement Parts Easily

Finding the right components for your equipment can often be a daunting task. With numerous options and variations available, knowing how to accurately identify the necessary items is crucial for effective maintenance and repairs. Utilizing reliable resources and systematic approaches can simplify this process significantly.

Utilizing Manufacturer Resources

One of the most effective ways to locate the correct components is to refer to the manufacturer’s official materials. These resources typically include detailed catalogs, user manuals, and online databases that provide specific information about the items you need. By cross-referencing your equipment model with these resources, you can ensure that you select the appropriate replacements.

Visual Identification Techniques

Employing visual identification methods can also aid in recognizing the required components. Carefully examining the existing items for part numbers, shapes, and sizes will help you match them with available options. Taking photos of the components can be beneficial when consulting with suppliers or experts, ensuring that you communicate your needs effectively.

Importance of Regular Maintenance

In addition to improving functionality, routine maintenance can contribute significantly to safety. Well-maintained equipment reduces the likelihood of accidents caused by mechanical failures. Moreover, adhering to a systematic maintenance schedule can uphold the value of the machinery, making it a wise investment over time.

| Benefits of Regular Maintenance | Description |

|---|---|

| Enhanced Performance | Regular checks ensure all components function optimally, leading to better efficiency. |

| Cost Savings | Early detection of issues can prevent costly repairs or replacements. |

| Increased Safety | Properly maintained equipment reduces the risk of accidents and injuries. |

| Extended Lifespan | Routine care can significantly prolong the useful life of the machinery. |

| Value Retention | Well-maintained equipment retains its market value better than neglected machinery. |

Common Issues and Solutions

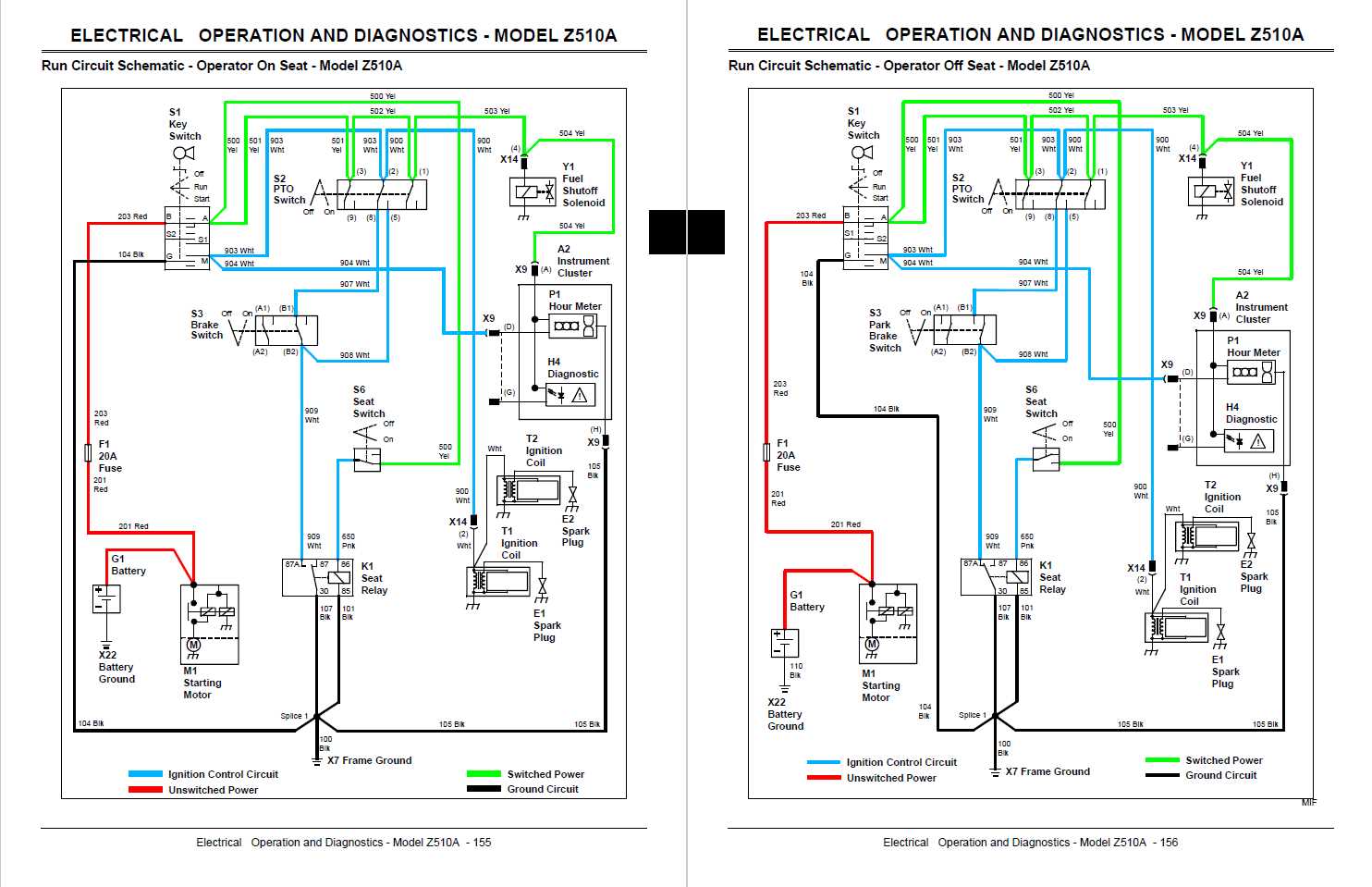

In the world of lawn care equipment, encountering problems is not uncommon. Understanding frequent challenges and their remedies can significantly enhance performance and longevity. Below are some prevalent issues along with effective solutions to address them.

- Engine Starting Problems:

Difficulty in starting the engine is a frequent concern. Possible causes include:

- Empty fuel tank.

- Clogged fuel filter.

- Faulty spark plug.

Solution: Check fuel levels, replace the fuel filter, and inspect the spark plug for damage.

- Uneven Cutting:

An uneven cutting pattern can lead to an unsightly lawn. This issue may arise from:

- Worn blades.

- Incorrect deck height.

- Unbalanced mower deck.

Solution: Sharpen or replace blades, adjust the cutting height, and ensure the deck is level.

- Excessive Vibration:

Unusual vibrations during operation can indicate underlying issues such as:

- Loose components.

- Imbalanced blades.

- Worn bearings.

Solution: Tighten loose parts, balance the blades, and replace worn bearings as needed.

- Overheating:

Overheating can result in severe damage. Common causes include:

- Dirty air filters.

- Blocked cooling fins.

- Low oil levels.

Solution: Clean or replace air filters, remove debris from cooling fins, and check oil levels regularly.

Addressing these common issues promptly can ensure smooth operation and prolong the life of your lawn care equipment. Regular maintenance is essential to prevent many of these problems from arising in the first place.

Where to Find Authentic Parts

Locating genuine components for your equipment is crucial for maintaining performance and longevity. Authentic replacements ensure compatibility and reliability, helping you avoid issues associated with substandard alternatives. To secure these essential items, it is important to know where to search.

Official Dealerships are often the most reliable source. They provide direct access to manufacturer-approved items, ensuring that you receive the exact specifications needed for your machinery. Additionally, many dealerships offer expert advice and support to assist with your selections.

Online Retailers specializing in machinery can also be a valuable resource. Look for reputable websites that guarantee authenticity and offer a wide selection. Always check reviews and ratings to ensure the credibility of the seller.

Manufacturer Websites often have sections dedicated to replacement components. Visiting these sites can help you find detailed information and official listings of available products, allowing you to make informed choices.

Local Repair Shops that focus on your type of equipment may carry genuine replacements or can help order them. Building a relationship with a trusted mechanic can provide you with insights and recommendations for sourcing authentic items.

In conclusion, prioritizing genuine components from verified sources will enhance the efficiency and durability of your machinery, ensuring optimal performance for years to come.

Assembly and Disassembly Tips

When working on any machinery, proper techniques for putting together and taking apart components are crucial for efficiency and safety. Understanding how to carefully manage each stage of the process can significantly reduce the risk of damage and ensure that everything functions as intended once reassembled. These strategies will help streamline your workflow and maintain the integrity of your equipment.

Preparation is Key

Before starting the assembly or disassembly, make sure to gather all necessary tools and components. Organize your workspace to avoid any unnecessary clutter, which can lead to misplaced parts. It’s also advisable to label components and fasteners as you remove them, ensuring that reassembly is straightforward. Keeping a detailed log of steps taken during disassembly can also aid in a smoother assembly process.

Step-by-Step Approach

Take a methodical approach when assembling or disassembling parts. Work through each component systematically, paying attention to the order in which pieces are connected. This not only minimizes the chances of losing small parts but also helps in identifying any discrepancies during reassembly. Always refer to your reference materials to verify correct positioning and alignment for optimal functionality.

Comparing Z520A with Other Models

This section explores the differences and similarities between a specific model and its counterparts in the same category. Understanding these variations can help potential users make informed decisions based on their unique needs and preferences.

One of the key aspects to consider is the engine performance. While some models boast higher horsepower, others may excel in fuel efficiency, offering a balance that suits different users. Additionally, the cutting technology varies, with certain machines featuring advanced mulching capabilities, while others prioritize speed and precision in mowing.

Another important factor is the comfort and usability of each unit. Ergonomics play a significant role in user experience, with features like adjustable seats and intuitive controls differing across models. This can greatly impact the ease of operation during extended periods of use.

Lastly, maintenance and durability are crucial elements to compare. Some machines are designed for easy access to components, making routine upkeep simpler, while others may require more effort and specialized knowledge. Evaluating these aspects can provide insights into long-term investment value.