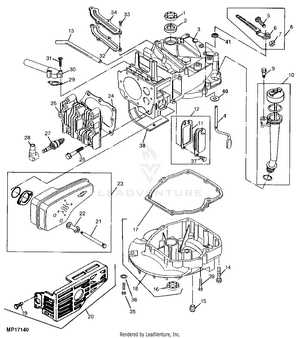

Understanding the arrangement and structure of various mechanical elements is crucial for ensuring optimal performance and longevity. A clear visualization of the internal and external configurations helps users and technicians to perform adjustments and replacements with greater precision.

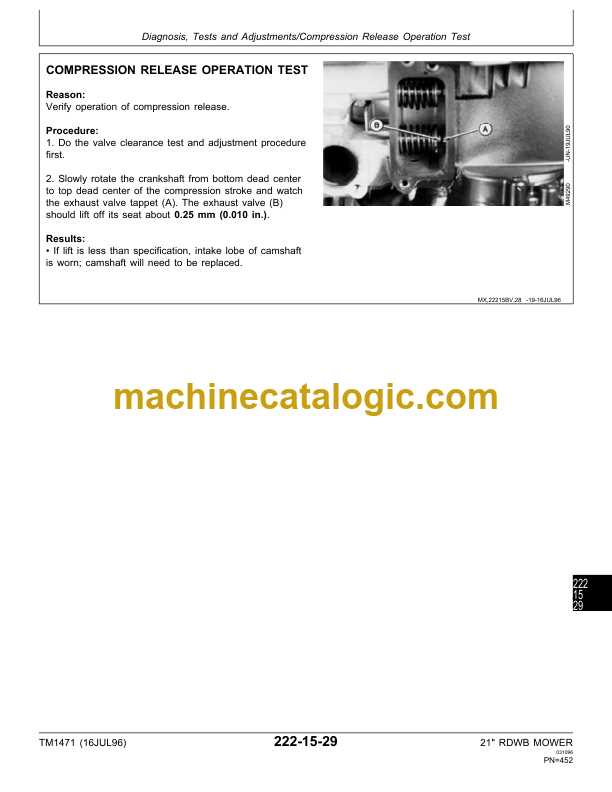

Detailed schematics provide valuable insights into how each element interacts within a larger system. Such guidance is essential for both routine maintenance and troubleshooting, allowing users to identify potential issues before they escalate.

For those who aim to deepen their knowledge, these illustrations act as a roadmap for assembling and disassembling key components. With an organized approach, it becomes easier to maintain and repair even the most intricate mechanisms.

John Deere SB14 Components Overview

This section explores the various mechanical and structural elements that form a robust and efficient agricultural device. Each part plays a crucial role in maintaining optimal functionality, ensuring seamless operation during field tasks.

Key Structural Elements

The machinery is built with durable materials, featuring a reinforced frame that supports its overall stability. The integration of a balanced weight system helps in maintaining steady performance even in demanding conditions, providing a reliable solution for diverse tasks.

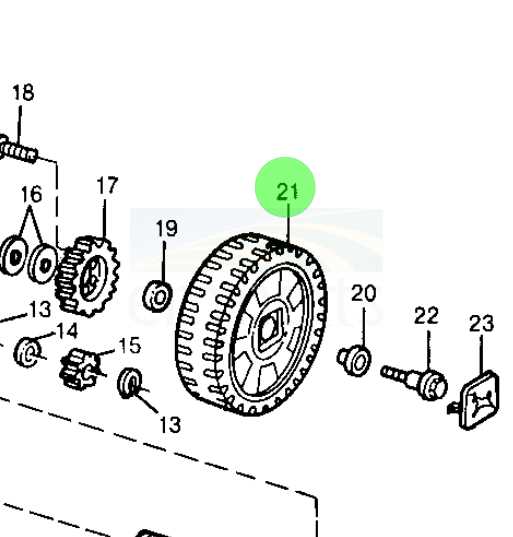

Operational Mechanisms

The device is equipped with a set of intricate mechanisms that work together to ensure smooth operations. These include transmission systems for effective power transfer, as well as adjustable settings that allow users to customize performance based on specific needs.

| Component | Description | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine System | Provides the necessary power for efficient fieldwork, optimized for energy consumption. | ||||||||||||||

| Chassis Structure | Offers support and stability, designed to endure tough environmental conditions. | ||||||||||||||

| Control Unit |

| Issue | Description | Solution |

|---|---|---|

| Engine Misfire | Unexpected stops or irregular engine performance. | Check spark plugs and ignition system; replace faulty components. |

| Overheating | Machine running hotter than normal, risking damage. | Inspect cooling system, clean radiator, and ensure proper fluid levels. |

| Poor Traction | Difficulty maintaining grip on surfaces, leading to inefficiency. | Examine tire condition and air pressure; adjust as necessary. |

| Hydraulic Leak | Fluid loss affecting operation and performance. | Identify and replace damaged hoses or seals to stop leaks. |

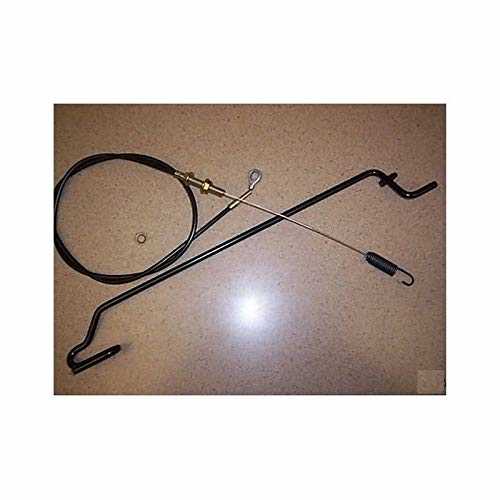

Upgrading Parts for Better Performance

Enhancing the efficiency of machinery can significantly impact productivity and overall functionality. By opting for superior components, operators can achieve not only improved performance but also increased longevity of the equipment. It is essential to consider various factors when selecting new elements to ensure compatibility and effectiveness.

Choosing Quality Components

Investing in high-quality replacements is crucial. Components made from durable materials can withstand wear and tear, leading to fewer breakdowns and maintenance needs. This choice results in smoother operation and enhanced output, making tasks easier and more efficient.

Compatibility and Installation

When upgrading, verifying that new elements align with existing systems is vital. Proper installation ensures that enhancements function as intended. Utilizing professional services can aid in achieving optimal results, minimizing the risk of complications during the upgrade process.

Understanding the Functionality of Each Element

Grasping the roles of various components in agricultural machinery is essential for optimal operation and maintenance. Each part contributes significantly to the overall efficiency and performance, ensuring that the equipment functions smoothly and effectively. A thorough comprehension of these elements aids users in troubleshooting and enhancing the longevity of the machine.

The following are key components commonly found in such machinery, along with their primary functions:

- Engine: Powers the entire system, converting fuel into mechanical energy.

- Transmission: Transfers power from the engine to the wheels, enabling movement and speed adjustments.

- Hydraulic System: Utilizes fluid to facilitate movement and control of attachments, enhancing versatility.

- Frame: Provides structural integrity and support for all other components, ensuring stability during operation.

- Wheels: Enable mobility and traction, allowing the equipment to navigate various terrains effectively.

- Attachments: Specialized tools or implements that enhance functionality for specific tasks, such as tilling or mowing.

By familiarizing oneself with these elements, users can better understand how to operate and maintain their machinery, ensuring efficient and effective performance in the field.

Where to Find Replacement Parts

Locating suitable components for your equipment can be essential for maintaining its optimal performance. Several reliable sources can help you acquire the necessary items efficiently.

Authorized Dealers

One of the most dependable options is to visit authorized dealerships. These establishments often stock original items and can provide expert advice on compatibility and installation. Benefits of purchasing from authorized dealers include:

- Access to genuine components

- Professional support and guidance

- Warranty options for peace of mind

Online Retailers

The internet offers a vast array of options for finding the right components. Many online retailers specialize in equipment supplies and can deliver directly to your doorstep. When shopping online, consider the following:

- Check customer reviews and ratings for reliability

- Compare prices across different platforms

- Ensure the website has a clear return policy

Compatibility with Other Models

The versatility of equipment components can significantly enhance operational efficiency. Understanding the compatibility of these elements with various models is crucial for optimal performance and maintenance. This section explores how different machinery configurations can work seamlessly together.

Commonly Compatible Models

Many configurations share similar attributes, allowing for interchangeable use across a range of machinery. When selecting components, it is essential to consider models that utilize comparable specifications. This ensures a reliable fit and performance, reducing potential issues during operation.

Benefits of Cross-Model Compatibility

Utilizing components that are compatible with multiple models offers several advantages. Flexibility in maintenance allows operators to keep fewer spare parts on hand, while cost-effectiveness is achieved by reducing the need for specific replacements. Additionally, having a diverse range of compatible options enables more efficient repairs and upgrades.