Understanding the layout and structure of agricultural equipment is essential for efficient maintenance and operation. The ability to identify and recognize various mechanisms allows operators to address issues promptly, ensuring long-term functionality and reducing downtime.

Detailed knowledge of how different mechanisms work together provides clarity, helping users keep their machinery in peak condition. Regular inspection and care are key factors in preventing malfunctions and ensuring that the equipment remains reliable over time.

Identifying essential components and their relationships within complex machinery can significantly enhance overall performance and longevity. This section will provide insights into the assembly and functionality of key systems involved in fieldwork.

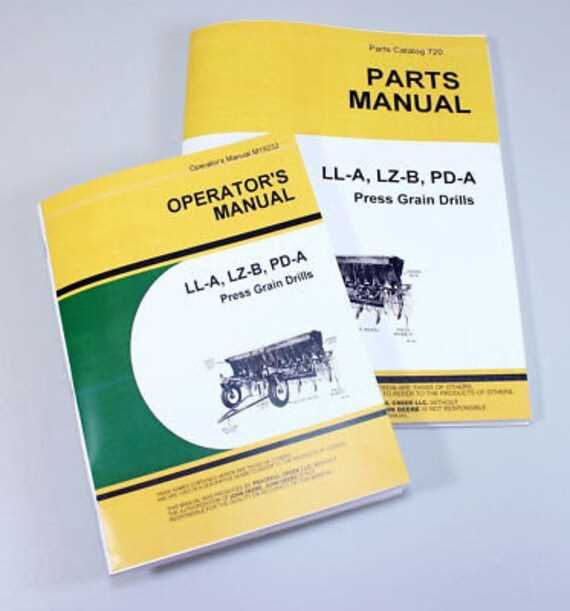

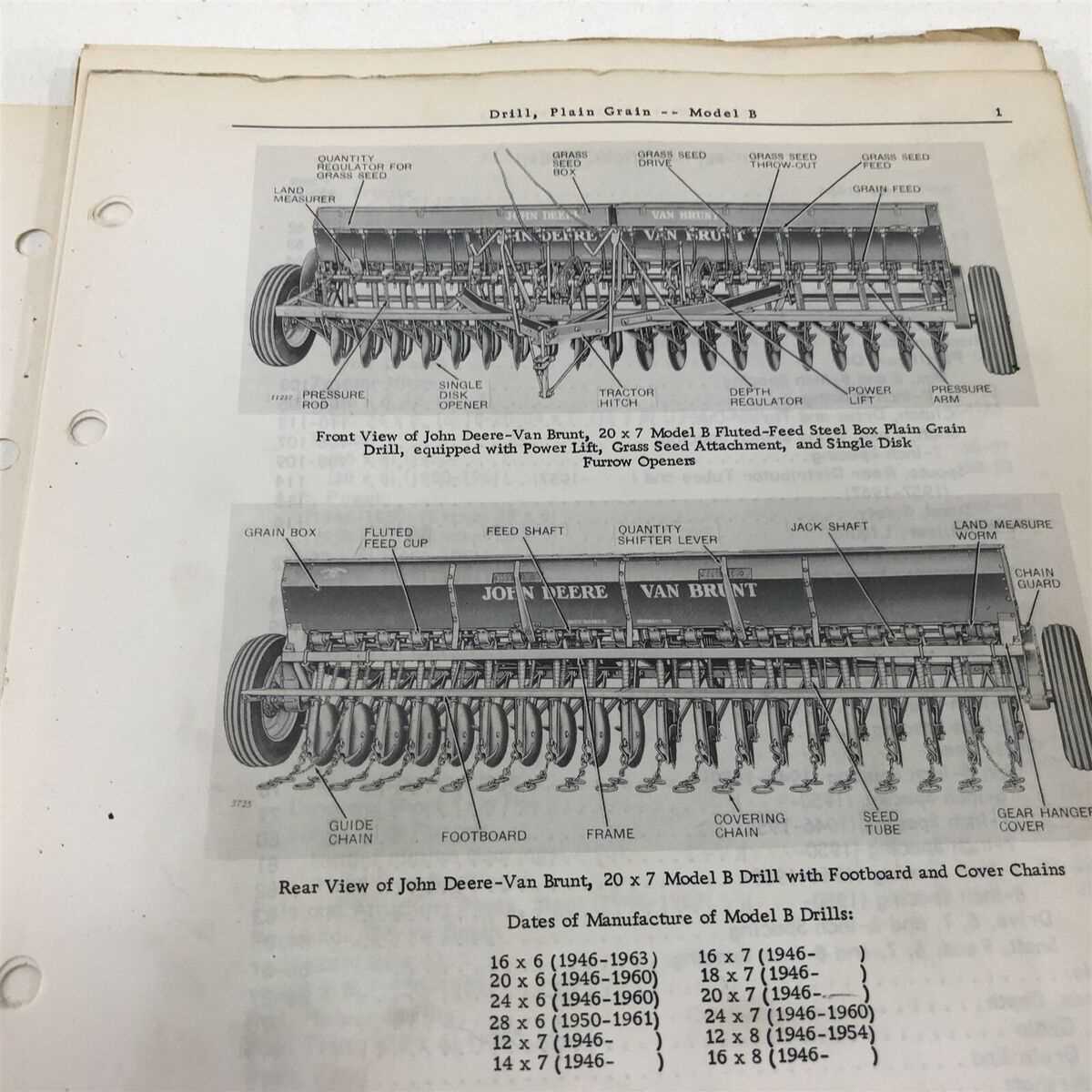

Overview of the John Deere Model B Drill

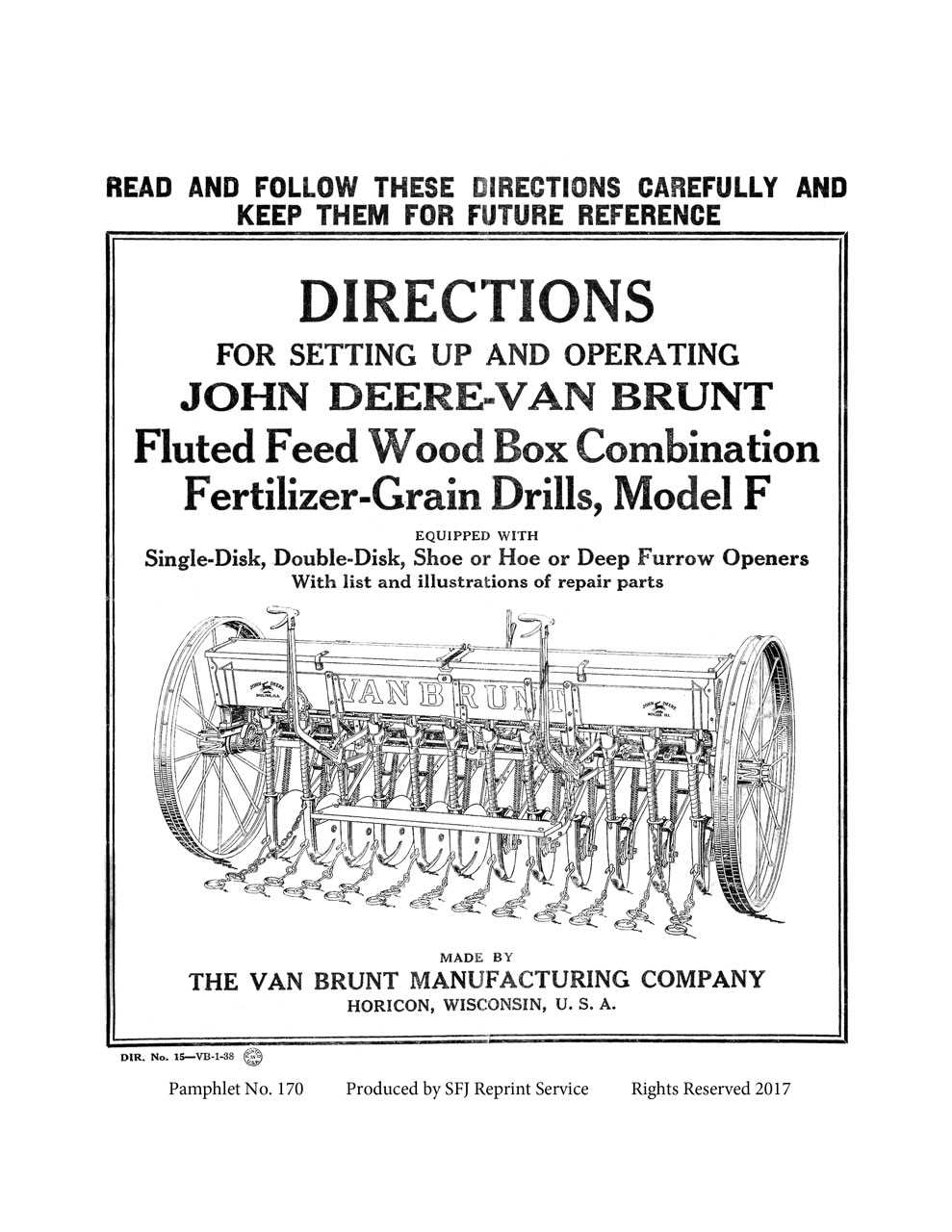

The agricultural implement in focus is a versatile seeding tool, known for its efficiency in planting a variety of crops. It is widely appreciated by farmers due to its reliable performance and the ability to handle different field conditions. This machine, originally developed for large-scale use, stands out for its durability and adaptability in various soil types, ensuring consistent planting results.

Key Features and Functionality

One of the standout features of this seeding equipment is its ability to uniformly distribute seeds, which contributes to optimal crop growth. The tool offers adjustable settings that allow for precise seed placement, enhancing the effectiveness of planting. Additionally, it comes equipped with mechanisms that ensure easy maintenance, making it a practical choice for long-term agricultural use.

Benefits in Modern Agriculture

In modern farming practices, this tool provides several advantages. Its robust construction ensures long-lasting performance, while its user-friendly controls simplify the operation. Farmers value its efficiency in improving crop yields, especially when dealing with expansive fields. The equipment’s design allows it to be used in various agricultural environments, ensuring versatility and high productivity.

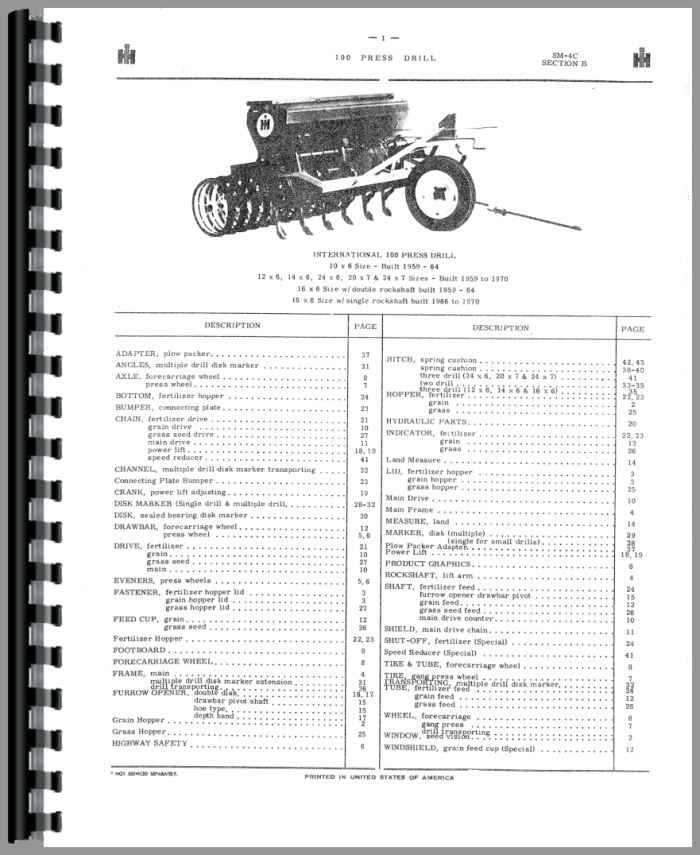

Main Components of the Grain Drill

The seeding equipment is designed with several crucial elements that ensure efficient sowing and soil preparation. Each part plays a significant role in achieving uniform seed distribution and proper depth placement. Understanding these components can help improve the operation and maintenance of agricultural machinery.

Seed box: The container where seeds are stored before being distributed to the soil. It is constructed to maintain an even flow, allowing seeds to pass smoothly through the system.

Seed metering system: This mechanism regulates the quantity of seeds released, ensuring precise control over the amount being planted. Accuracy in this process is essential for optimal crop growth.

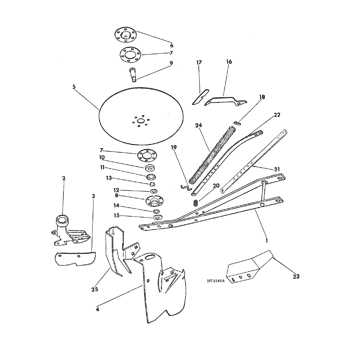

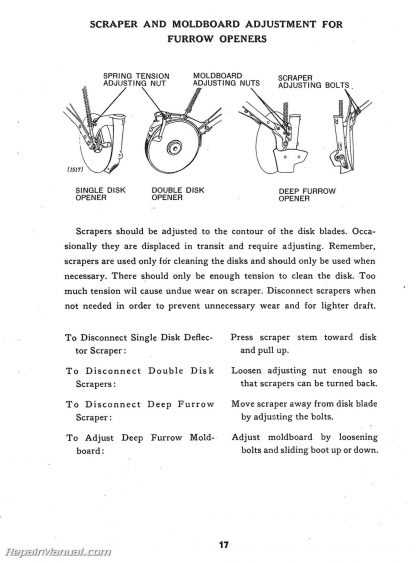

Opener assemblies: These tools create furrows in the soil where seeds are placed. They come in various shapes and sizes, each designed to suit different soil types and conditions.

Press wheels: Positioned behind the openers, these wheels press the soil down over the seeds, ensuring they are securely covered and positioned at the correct depth for germination.

Understanding these essential elements helps to maximize efficiency and ensures the equipment operates at its full potential during planting seasons.

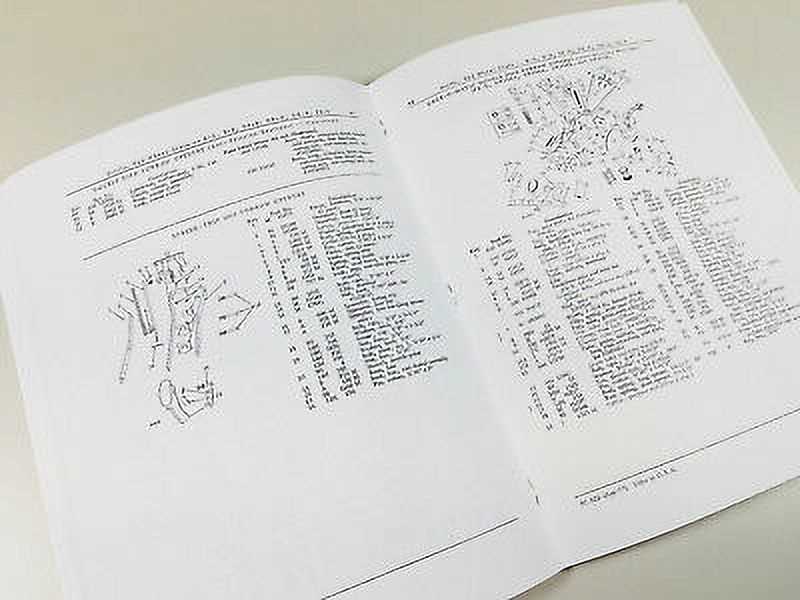

Diagram of the Seed Delivery System

The seed delivery system is designed to ensure the accurate and consistent distribution of seeds during the planting process. This mechanism carefully manages the flow of seeds from the storage area to the soil, providing even spacing and depth. Understanding the components of this system can help optimize planting efficiency and improve crop yield.

| Component | Function |

|---|---|

| Seed Hopper | Holds the seeds and feeds them into the distribution system. |

| Seed Metering Unit | Regulates the flow of seeds to ensure uniform planting. |

| Seed Tubes | Transfers seeds from the metering unit to the soil. |

| Opener | Creates furrows in the soil for precise seed placement. |

| Press Wheels | Ensure proper seed-to-soil contact by pressing the seeds into the ground. |

Understanding the Gear Mechanism

The gear system plays a critical role in ensuring smooth operation by transmitting motion effectively between components. Understanding how the gears interact within the machinery can help users maintain and troubleshoot potential issues, ensuring optimal performance. This section will explore the function of gears and their influence on overall machine operation.

| Component | Function | ||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Main Gear | Transfers rotational force to other elements within the system. | ||||||||||||||||||||||||||||||

| Pinion Gear | Engages with the larger gears to control speed and direction. | ||||||||||||||||||||||||||||||

| Adjustment Levers | Allow fine-tuning of the gear settings for specific tasks. | ||||||||||||||||||||||||||||||

| Drive Chain | Connects various gears, ensuring synchronized motio

Maintaining the Seed HopperProper care and regular upkeep of the seed storage unit are essential to ensure smooth operation and consistent performance. This component is critical for evenly distributing seeds during planting, and any malfunction can affect the overall planting efficiency. Routine inspection and cleaning help to prevent clogs, wear, and other issues that could hinder its functionality. One of the key tasks in maintenance is regularly checking for any blockages or debris that may accumulate over time. This can be done by inspecting the hopper thoroughly and ensuring that all passageways remain clear. Additionally, monitoring the condition of seals and gaskets is vital to maintain a tight seal, preventing seed spillage or contamination. Another important aspect of maintenance involves lubrication of the moving parts within the seed storage unit. Proper lubrication reduces friction and wear, ensuring that the unit operates smoothly and extends its lifespan. Regularly checking the hopper’s structure for any signs of rust or corrosion is also crucial, as these can affect the integrity and efficiency of the system. Role of the Coulter Assembly

The coulter assembly plays a crucial role in ensuring the proper functioning of soil preparation equipment. It is responsible for cutting through the soil, creating a path for the following components to work efficiently. This part enhances the overall performance by preparing the ground for optimal seed placement. Functions of the Coulter Assembly

Components of the Assembly

Lubrication Points for Optimal Performance

Proper lubrication is essential for ensuring the longevity and efficiency of agricultural machinery. Regularly servicing the moving components and keeping them well-oiled minimizes wear and tear, reducing the risk of costly repairs and downtime. Identifying the correct lubrication points helps maintain smooth operation under various working conditions.

Replacing Worn Parts in the Drill

Maintaining optimal functionality in your seeding equipment requires regular attention to components that have experienced wear and tear. Over time, certain elements may degrade, affecting the overall performance. Timely replacement of these worn components ensures the equipment continues to operate smoothly and efficiently. Below, we explore the steps for identifying and replacing those key components that are most likely to wear out during use.

|