In the world of lawn maintenance machinery, comprehending the arrangement of various elements is crucial for efficient operation and repair. A detailed exploration of these layouts can enhance your knowledge, allowing for better upkeep and troubleshooting of your equipment.

Each section of a machine plays a pivotal role in its functionality. By delving into the specifics of each unit, users can gain insights into how components interact and contribute to overall performance.

Moreover, having access to visual representations can be the ultimate guide for enthusiasts and professionals alike. These illustrations serve as valuable resources, simplifying complex tasks and ensuring that maintenance is performed accurately and effectively.

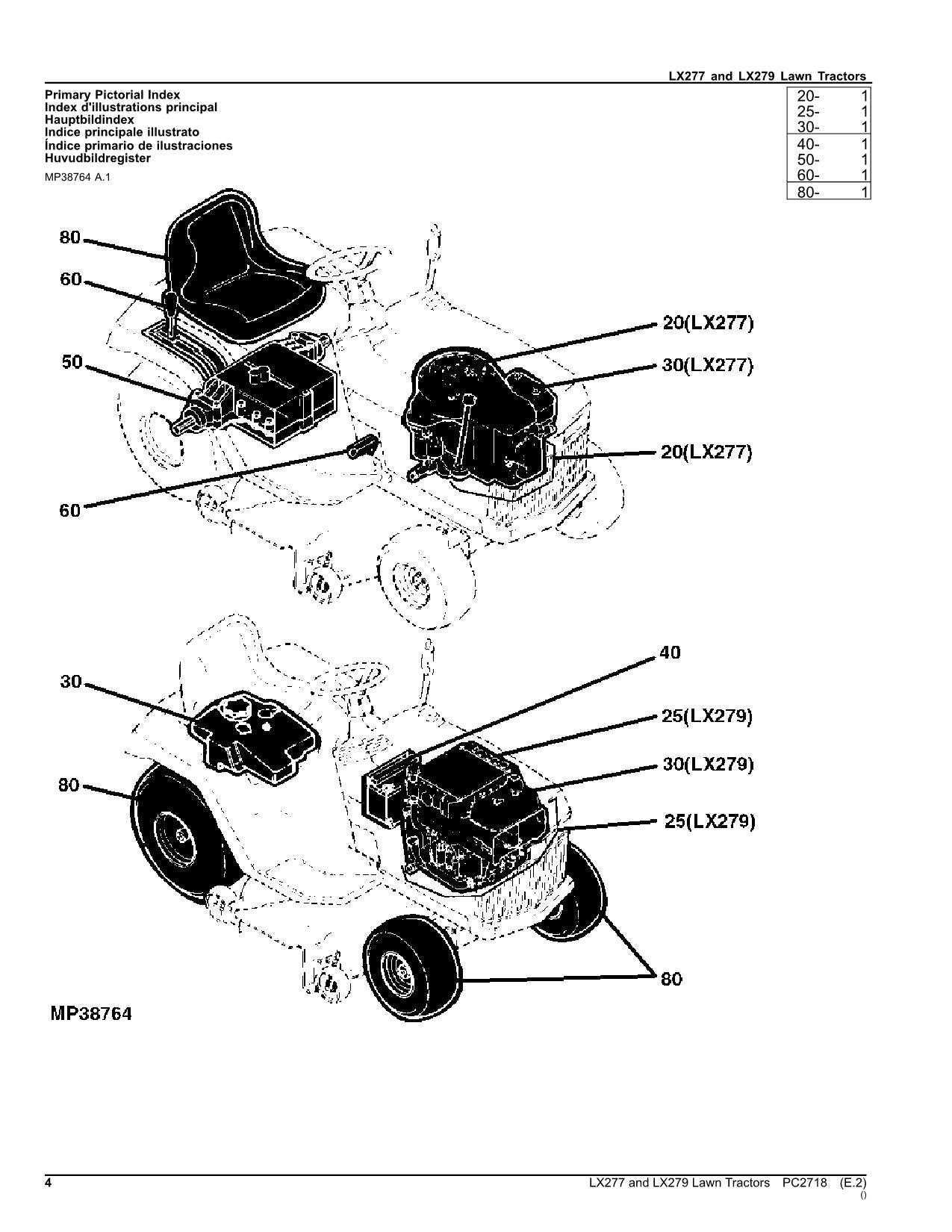

Understanding the LX277 Parts Diagram

Grasping the intricacies of an assembly layout is essential for effective maintenance and repair of machinery. Familiarity with each component’s placement and function enables users to troubleshoot issues more efficiently and perform necessary replacements with confidence.

Key Components Overview

Focusing on critical elements within the layout can simplify the repair process. Here are some fundamental categories to consider:

- Engine: Vital for powering the unit, understanding its components ensures proper functionality.

- Transmission: This system transmits power from the engine to the wheels, making its mechanics crucial for movement.

- Chassis: The framework that supports all other elements, ensuring stability and durability.

- Electrical System: Involves wiring and connections that control various functions, including ignition and lights.

Benefits of Familiarization

Recognizing the layout serves multiple purposes:

- Improved troubleshooting skills lead to quicker repairs.

- Better understanding of assembly helps in the identification of wear and tear.

- Enhanced ability to perform preventative maintenance prolongs the lifespan of the machinery.

By taking the time to study the layout, operators can ensure their equipment remains in optimal condition, ready for any task at hand.

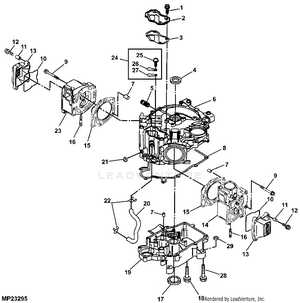

Key Components of John Deere LX277

This section explores the essential elements that contribute to the efficiency and functionality of a specific lawn maintenance machine. Understanding these components is crucial for effective operation and maintenance.

Core Elements

- Engine: Provides the necessary power for operation.

- Transmission: Ensures smooth movement and speed control.

- Cutting Deck: Responsible for achieving a clean and even cut.

Additional Features

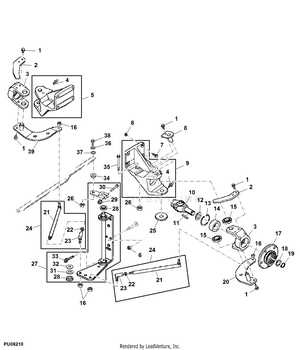

- Steering System: Offers maneuverability and precision handling.

- Wheels: Enhances stability and traction on various terrains.

- Controls: Facilitates user interaction and operational adjustments.

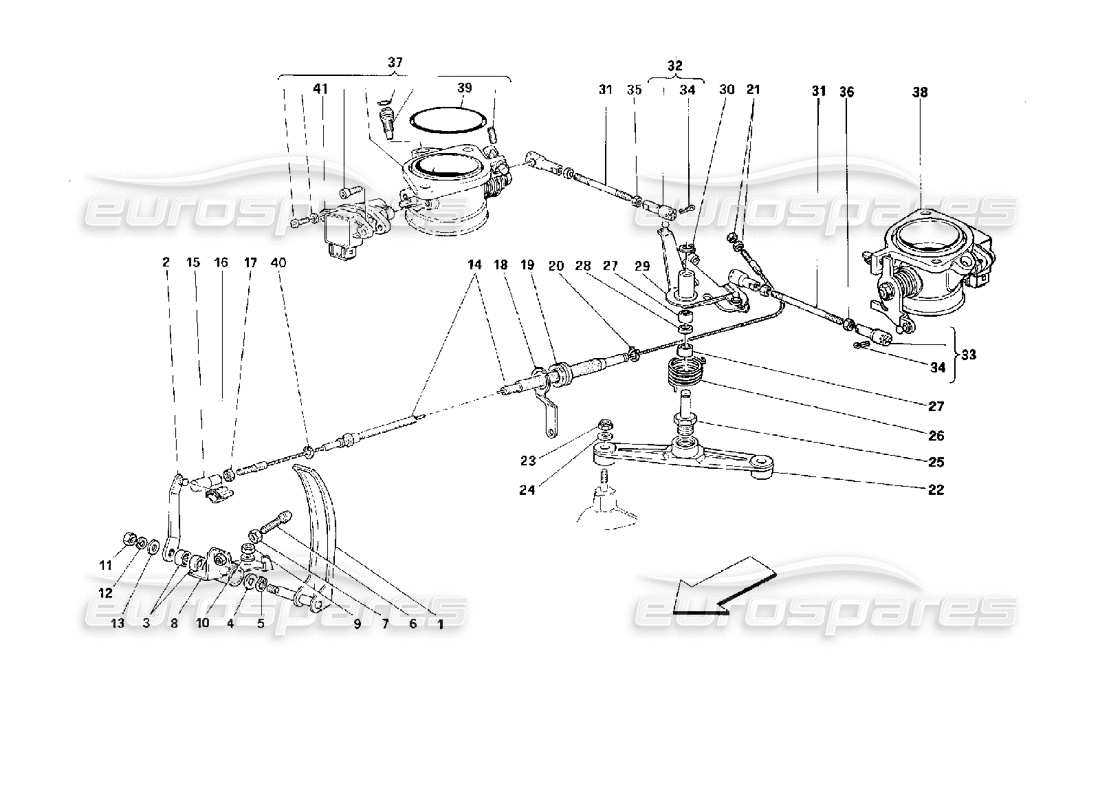

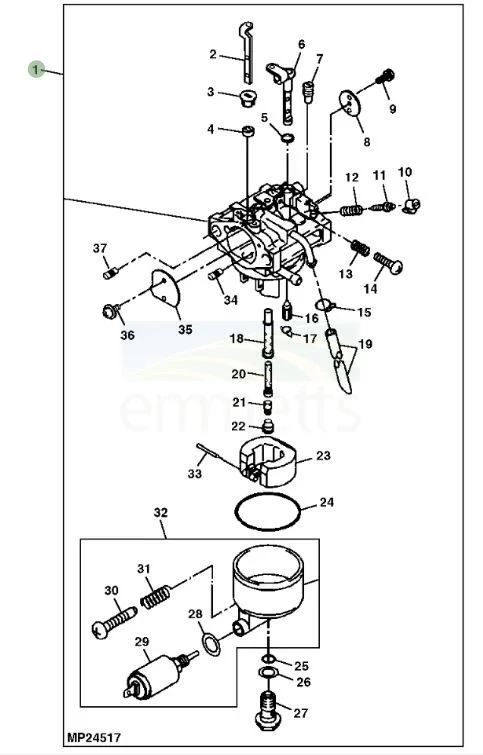

How to Read the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repairs. These illustrations provide a detailed overview of various elements, making it easier to identify and locate specific pieces needed for your machinery. By familiarizing yourself with the layout and symbols used, you can streamline the process of troubleshooting and replacement.

Step 1: Begin by examining the overall layout. Typically, components are grouped based on their functionality, allowing you to quickly find what you need. Look for sections that categorize parts by their roles, such as engine components, electrical systems, or chassis elements.

Step 2: Pay attention to the labeling. Each component usually has a corresponding number or letter that references a detailed list. This list will provide specifications, part numbers, and other critical information for ordering replacements.

Step 3: Familiarize yourself with common symbols and lines. Dashed lines often indicate connections, while solid lines may represent physical boundaries of parts. Understanding these can help clarify how components interact within the system.

Step 4: Take note of any additional notes or legends that may accompany the illustration. These can provide vital insights into assembly order or specific installation instructions, ensuring you perform repairs correctly and safely.

By mastering the interpretation of these visuals, you enhance your ability to manage equipment effectively, leading to improved performance and longevity.

Common Replacement Parts for LX277

When maintaining a lawn care machine, understanding essential components that may need replacement is crucial for ensuring optimal performance. Regular wear and tear can affect efficiency, so identifying the most frequently needed items can help users keep their equipment running smoothly.

Engine Components

One of the most vital areas to focus on includes engine elements. Items such as air filters and oil filters play significant roles in maintaining engine health. Regular replacement of these components can lead to improved performance and longevity, ensuring that the machine operates effectively during all seasons.

Cutting Deck Essentials

The cutting deck is another critical section where replacements are often necessary. Blades, belts, and spindles are among the most commonly replaced elements. Keeping these components in good condition ensures a clean cut and enhances the overall mowing experience, allowing for a well-maintained lawn.

Maintenance Tips for Your Lawn Tractor

Regular upkeep of your lawn care equipment is essential for ensuring optimal performance and longevity. By implementing a few straightforward practices, you can keep your machine in top shape and ready for the task at hand.

Routine Checks

- Fluid Levels: Regularly inspect and replenish oil, fuel, and coolant to avoid engine strain.

- Air Filter: Clean or replace the air filter periodically to maintain airflow and efficiency.

- Tires: Check tire pressure and tread depth to ensure stability and traction.

Seasonal Maintenance

- Blades: Sharpen or replace mower blades at the start of each season for a clean cut.

- Batteries: Test battery health before winter storage and keep terminals clean.

- Cleaning: Remove grass clippings and debris from under the deck to prevent rust and improve performance.

Identifying Faulty Parts in LX277

Recognizing malfunctioning components is crucial for maintaining the efficiency and longevity of your equipment. Timely detection of these issues can prevent further damage and ensure optimal performance. This section will guide you through common signs of wear and methods to identify problematic elements.

Common Symptoms of Malfunction

Several indicators can help you pinpoint failing components:

- Unusual noises during operation

- Decreased power or performance

- Vibrations that were not previously present

- Visible wear or damage on external parts

- Difficulty in starting the machine

Steps to Diagnose Issues

To effectively assess the condition of your equipment, follow these steps:

- Perform a visual inspection for any signs of damage.

- Listen for irregular sounds while the machine is in use.

- Check for leaks or fluid loss in hydraulic systems.

- Test the operation of moving parts for smoothness and responsiveness.

- Consult the manual for specific troubleshooting guidelines related to suspected components.

By understanding these symptoms and following systematic diagnostic steps, you can effectively identify and address issues, ensuring your equipment operates reliably for years to come.

Where to Find Genuine Parts

Locating authentic components for your equipment is crucial for maintaining its performance and longevity. Opting for original pieces ensures compatibility and reliability, which is vital for effective operation. Here are some reliable sources to consider when seeking quality replacements.

Official Dealers

Authorized retailers are often the best source for obtaining original components. These dealers provide assurance of quality and can offer expert advice tailored to your specific model. Moreover, they may have access to exclusive products and promotional offers.

Online Marketplaces

Reputable e-commerce platforms frequently host a wide range of genuine items. When using these sites, verify the seller’s credibility by checking reviews and ratings. Additionally, look for listings that explicitly state authenticity to avoid counterfeit alternatives.

In conclusion, sourcing authentic components from trustworthy dealers or online platforms ensures that your machinery continues to operate efficiently and effectively.

Cost Considerations for Replacements

When evaluating the financial implications of component replacements for outdoor machinery, several factors come into play. Understanding these elements can help in making informed decisions that balance performance with budget constraints.

First, the quality of replacement items significantly influences the overall expense. Higher-quality components often come with a premium price but can result in longer lifespan and improved efficiency. On the other hand, opting for cheaper alternatives may lead to increased maintenance costs over time, negating initial savings.

Another aspect to consider is the availability of parts. Commonly found components may be less expensive due to competition among suppliers, whereas rare or specialized items could carry a hefty price tag. Researching multiple sources can uncover better deals and ensure the best value.

Labor costs also play a crucial role. If a professional is required for installation, this can add to the total expenditure. Some individuals may choose to perform replacements themselves, which can save money but requires time and a certain level of skill.

Lastly, warranty coverage is an essential consideration. Parts that come with a warranty may have a higher upfront cost, but they can provide peace of mind and potential savings if issues arise shortly after installation. Balancing these factors can lead to more strategic financial planning regarding equipment upkeep.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers several advantages that enhance the performance and longevity of machinery. These products are designed specifically for particular models, ensuring a perfect fit and compatibility. This precision translates into optimal efficiency and reliability, reducing the likelihood of malfunctions.

Quality Assurance

OEM components undergo rigorous testing and meet strict quality standards. This commitment to excellence ensures that each piece functions as intended, minimizing the risk of failure during operation. When you choose these items, you are investing in the durability and effectiveness of your equipment.

Warranty Protection

Many manufacturers provide warranties for their original components, offering peace of mind to users. Should any issues arise, these guarantees can save you time and money, as repairs or replacements may be covered. In contrast, aftermarket alternatives often lack such protection, potentially leading to increased costs down the line.