In the world of outdoor machinery, having a clear understanding of the individual components is essential for effective maintenance and repairs. This section aims to provide a comprehensive overview of the various elements that make up these machines, focusing on their functions, relationships, and the importance of each part in ensuring optimal performance.

Whether you are a seasoned operator or a newcomer to machinery, familiarizing yourself with the intricate details of your equipment can significantly enhance your efficiency. By delving into the intricate layout of the mechanical parts, you can better diagnose issues, plan for replacements, and maintain the longevity of your machinery. Knowledge of how these components fit together is crucial for any maintenance project.

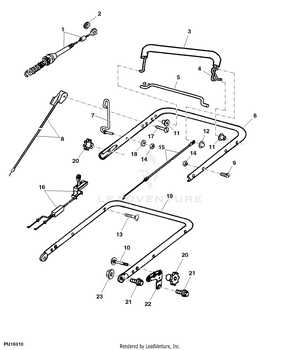

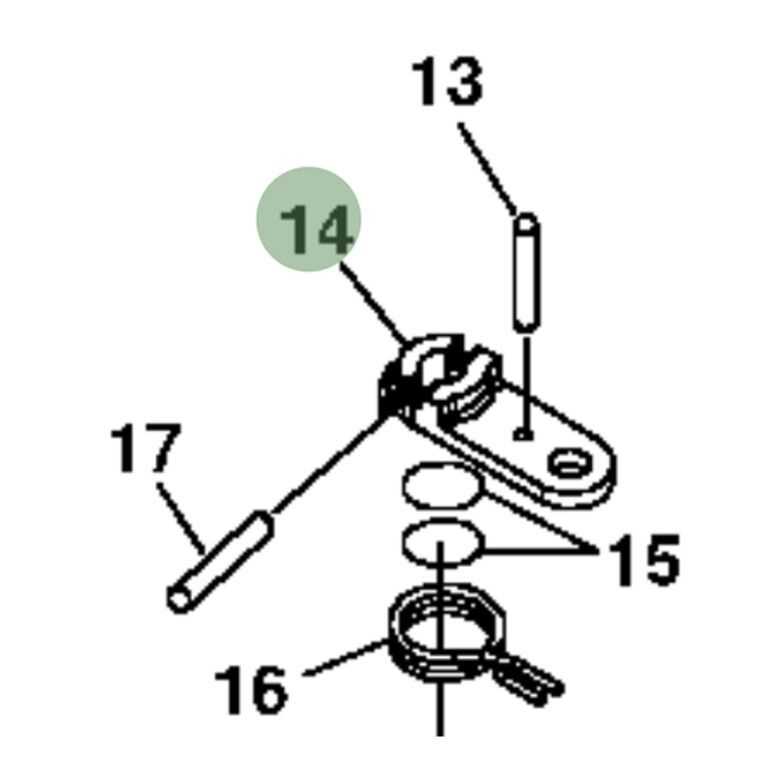

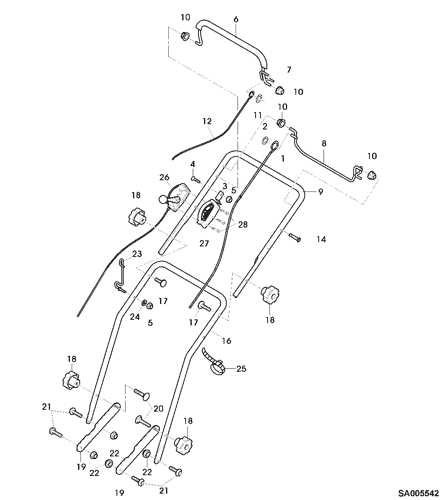

To facilitate this understanding, we will explore a visual representation that illustrates the assembly of these crucial elements. This visual guide serves as an invaluable resource, allowing users to identify each part with ease and recognize its role within the larger system. With this knowledge, operators can tackle repairs and maintenance tasks with confidence, ultimately leading to improved performance and reduced downtime.

Overview of John Deere JS63C

This section provides a comprehensive look at a specific model designed for optimal performance in lawn maintenance. It highlights key features, functionalities, and essential components that contribute to its efficiency and reliability.

Key Features

This model is equipped with a powerful engine that ensures a robust cutting capability, allowing users to tackle various grass types and terrains with ease. Additionally, the ergonomic design enhances user comfort, making prolonged use manageable. A durable build guarantees longevity, which is critical for maintaining landscapes over time.

Specifications and Components

Understanding the specifications and components of this equipment is vital for proper maintenance and troubleshooting. Below is a table summarizing some of the essential attributes:

| Specification | Details |

|---|---|

| Engine Type | Four-stroke gasoline engine |

| Cutting Width | 21 inches |

| Weight | Approximately 70 lbs |

| Drive Type | Self-propelled |

| Deck Material | Steel |

Importance of Parts Diagrams

Understanding the intricacies of machinery maintenance and repair is essential for ensuring optimal performance and longevity. Visual representations of components provide clarity on assembly and disassembly processes, aiding technicians in identifying and addressing issues effectively. Such illustrations serve as a critical resource for anyone involved in the upkeep of complex equipment.

These visual aids enhance the efficiency of repairs by simplifying the identification of individual elements and their functions within a system. By providing a clear reference, they minimize the likelihood of errors during maintenance tasks. Furthermore, these representations contribute to a deeper comprehension of how different components interact, fostering better decision-making when it comes to upgrades or replacements.

Utilizing these graphical resources can lead to significant time savings and increased productivity in workshops. When technicians can quickly locate and understand the role of each segment, they can expedite troubleshooting processes, ensuring that machinery remains operational with minimal downtime. Overall, the use of such visual resources is indispensable for effective machinery management.

Common Issues with JS63C Models

Understanding the frequent challenges associated with these specific lawn care machines can enhance the maintenance and operation experience for users. While designed for efficiency and durability, certain factors may lead to performance issues over time. Identifying and addressing these problems early can help ensure optimal functionality.

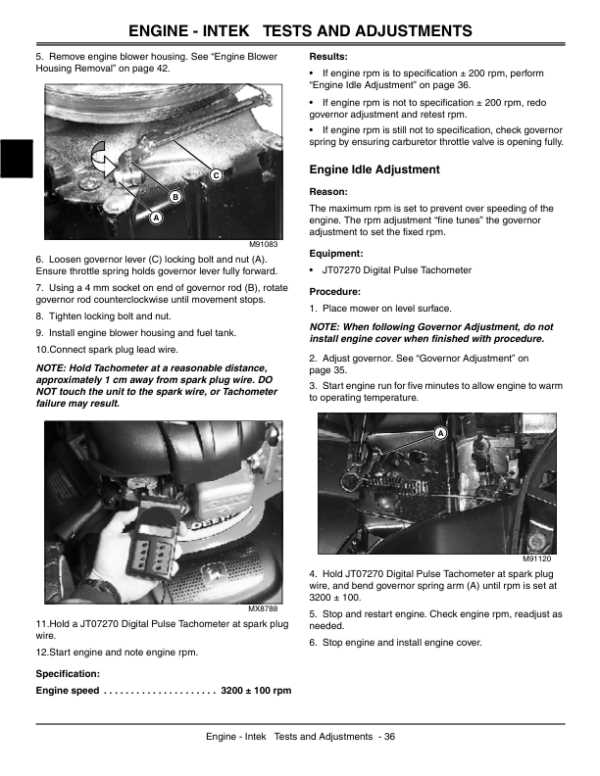

One prevalent concern involves the engine’s starting difficulties. Users may experience issues with ignition or fuel delivery, resulting in a lack of responsiveness when attempting to start the machine. Regular checks of the battery, spark plug, and fuel system can mitigate this issue.

Another common problem is related to the cutting mechanism. Blades may become dull or damaged due to regular wear and tear or encountering hard debris. Ensuring that the cutting components are regularly sharpened and inspected can prevent uneven cuts and enhance overall efficiency.

Additionally, users often report issues with the drive system. This may manifest as reduced speed or a complete failure to engage. Inspecting the drive belt and pulleys for wear and ensuring proper tension can help resolve these concerns.

Finally, electrical problems can arise, impacting the machine’s operation. Faulty wiring, blown fuses, or malfunctioning switches can disrupt the functionality. Regular maintenance and prompt replacement of any damaged components can help maintain reliable performance.

How to Interpret Parts Diagrams

Understanding assembly illustrations is crucial for effective maintenance and repair. These visual representations provide a clear breakdown of components and their relationships within a machine. By familiarizing yourself with these resources, you can identify specific elements needed for repairs and ensure proper assembly.

First, familiarize yourself with the layout. Most illustrations are organized into sections, often grouped by functionality. Take note of any labels or numbers that correspond to individual components, as these can guide you in locating the necessary pieces.

Next, pay attention to the legends. Many visual guides include a key that explains the symbols used. Recognizing these symbols will help you understand the functions of each part and how they interact with one another.

Finally, refer to the accompanying documentation. Often, illustrations are supplemented by manuals that provide additional context, such as installation instructions or specifications. Cross-referencing these resources will enhance your comprehension and improve your ability to execute repairs accurately.

Key Components of JS63C Lawn Mower

The effective operation of a lawn care machine relies on several essential elements that work together to ensure optimal performance and durability. Understanding these vital components can aid in maintenance and troubleshooting, allowing users to extend the lifespan of their equipment.

- Engine: The heart of the mower, responsible for generating power to drive the blades and propel the machine forward. Its efficiency significantly influences overall performance.

- Blades: Sharp cutting instruments that slice through grass, providing a clean and even cut. The quality and condition of the blades directly affect the appearance of the lawn.

- Deck: The structure housing the blades, designed to optimize airflow and cutting efficiency. A well-maintained deck ensures uniform grass height and reduces clumping.

- Wheels: Essential for maneuverability, the wheels must provide stability and traction on various terrains. Their size and tread pattern can impact the ease of navigation.

- Chassis: The frame that supports all components, providing strength and durability. A robust chassis contributes to the machine’s ability to withstand wear and tear.

Regular maintenance and timely replacement of these components can enhance performance, reduce breakdowns, and ensure a well-kept lawn throughout the season.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of any machinery. By adhering to a systematic maintenance schedule, operators can significantly enhance performance, reduce the likelihood of unexpected breakdowns, and extend the life of their equipment. Below are some practical suggestions for maintaining your machine effectively.

| Task | Frequency | Tips |

|---|---|---|

| Oil Change | Every 50 hours | Use high-quality oil and check levels regularly. |

| Blade Sharpening | As needed | Keep blades sharp for optimal cutting performance. |

| Air Filter Cleaning | Every 25 hours | Ensure proper airflow by keeping the filter clean. |

| Belt Inspection | Monthly | Look for wear and tear; replace if frayed. |

| Tire Pressure Check | Every week | Maintain correct pressure for stability and performance. |

By following these maintenance tips, you can ensure that your machinery operates at its best, providing reliable performance and minimizing downtime. Consistent attention to these details will pay off in the long run.

Finding Replacement Parts Online

Locating necessary components for machinery has become significantly easier with the advent of online resources. This digital approach offers a vast selection of options, making it possible for users to find specific items without the constraints of geographical limitations. Online platforms can provide detailed information and support to ensure that the right selections are made for maintenance or repair tasks.

When searching for components, consider the following strategies:

- Utilize Manufacturer Websites: Most manufacturers offer official platforms where users can explore a comprehensive inventory of available items tailored to their equipment.

- Online Marketplaces: Sites like eBay and Amazon host a wide range of options from various sellers, often providing competitive pricing and user reviews.

- Specialty Retailers: Numerous online stores specialize in specific categories, offering expertise and assistance in finding the exact items needed for your machinery.

- Forums and Community Groups: Engaging with online communities can yield recommendations and insights from other users who have faced similar repair challenges.

Once you have identified potential sources, ensure that you:

- Check compatibility with your specific equipment model.

- Read product descriptions carefully to understand the features and specifications.

- Review seller ratings and customer feedback to gauge reliability.

- Compare prices across multiple platforms to ensure you are getting the best deal.

By following these steps, you can navigate the online marketplace effectively, ensuring that you secure the components you need for your machinery efficiently and reliably.

Warranty and Support Information

This section provides essential details regarding the coverage and assistance available for your equipment. Understanding the terms of the warranty and the support options ensures that users can maximize the performance and longevity of their machinery.

Each unit is backed by a comprehensive warranty that safeguards against defects in materials and workmanship. The specifics of the warranty period and the components covered may vary, so it is crucial to consult the official documentation or authorized representatives for precise information.

In addition to warranty coverage, users have access to a dedicated support team trained to assist with inquiries and troubleshooting. Contacting customer service or visiting the official website can provide valuable resources, including manuals, maintenance tips, and expert advice to address any concerns effectively.

For those seeking replacement components or upgrades, authorized dealers are available to ensure compatibility and quality. Utilizing genuine replacements will help maintain the integrity and efficiency of your equipment, prolonging its service life.