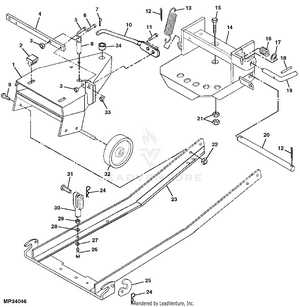

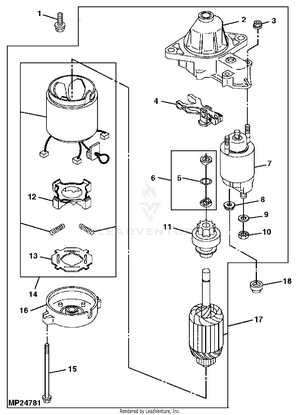

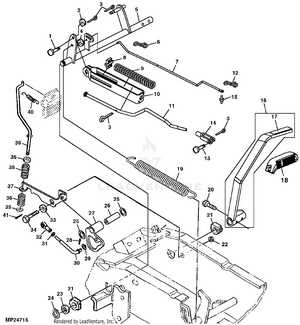

Maintaining and repairing machinery is an essential part of ensuring optimal performance and longevity. Knowledge of the various components and their arrangements can significantly simplify the troubleshooting process. A clear visual representation of the intricate elements involved can be invaluable for both seasoned professionals and newcomers alike.

In this section, we will explore a detailed illustration that provides insights into the various components of a specific model. This resource serves as a guide to help users identify parts, understand their functions, and assist in making informed decisions during maintenance or repairs. Whether you are looking to replace a worn-out piece or simply wish to familiarize yourself with the equipment, having a visual reference can greatly enhance your understanding.

Utilizing such resources can lead to more efficient repairs and maintenance routines. By knowing the layout and connections of different parts, users can approach their tasks with greater confidence and accuracy. This not only saves time but also minimizes the risk of errors during service, ensuring that your machinery remains in top condition for years to come.

Understanding John Deere GX345 Components

Grasping the intricacies of machinery is essential for effective maintenance and operation. This section aims to explore the various elements that contribute to the functionality of a specific model, offering insights into their roles and interconnections.

Key Elements

- Engine: The powerhouse that drives the entire system.

- Transmission: Responsible for the transfer of power and speed.

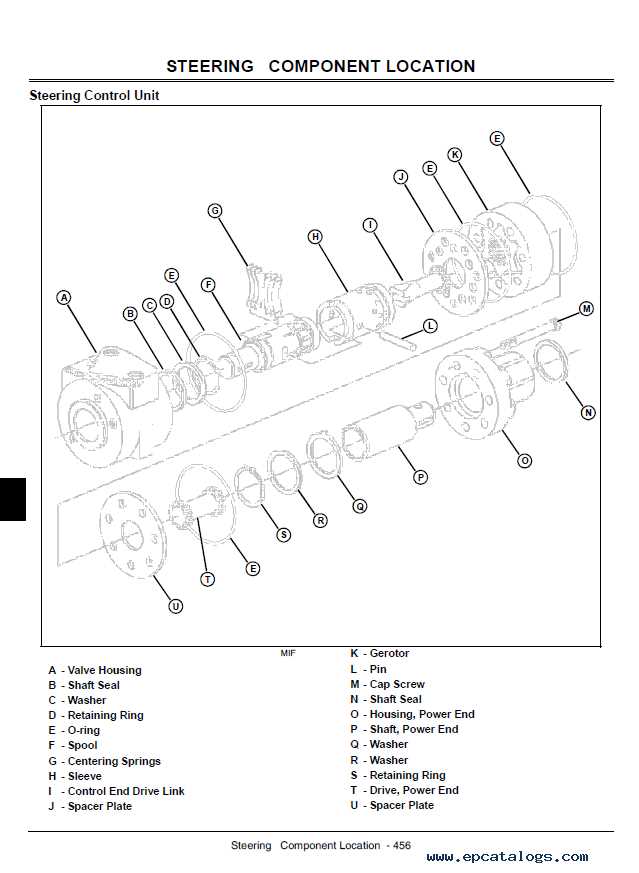

- Steering Mechanism: Ensures maneuverability and control.

- Chassis: Provides structural support and stability.

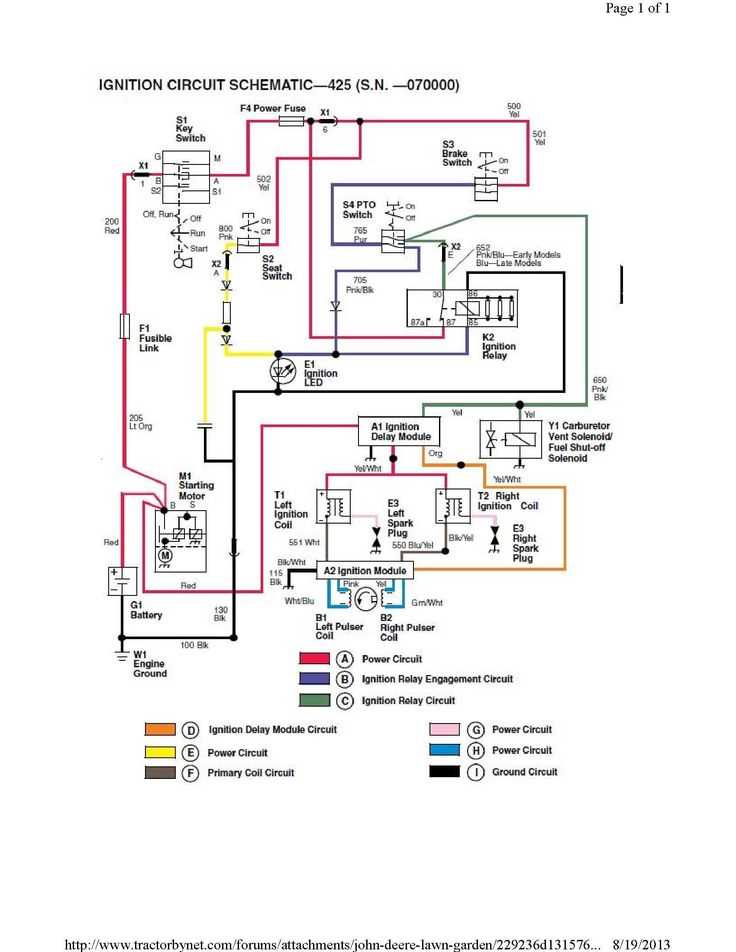

- Electrical System: Powers all electronic components and accessories.

Maintenance Tips

- Regularly check fluid levels to ensure optimal performance.

- Inspect belts and hoses for signs of wear or damage.

- Keep components clean to prevent debris buildup.

- Follow the manufacturer’s guidelines for servicing.

- Replace worn parts promptly to maintain efficiency.

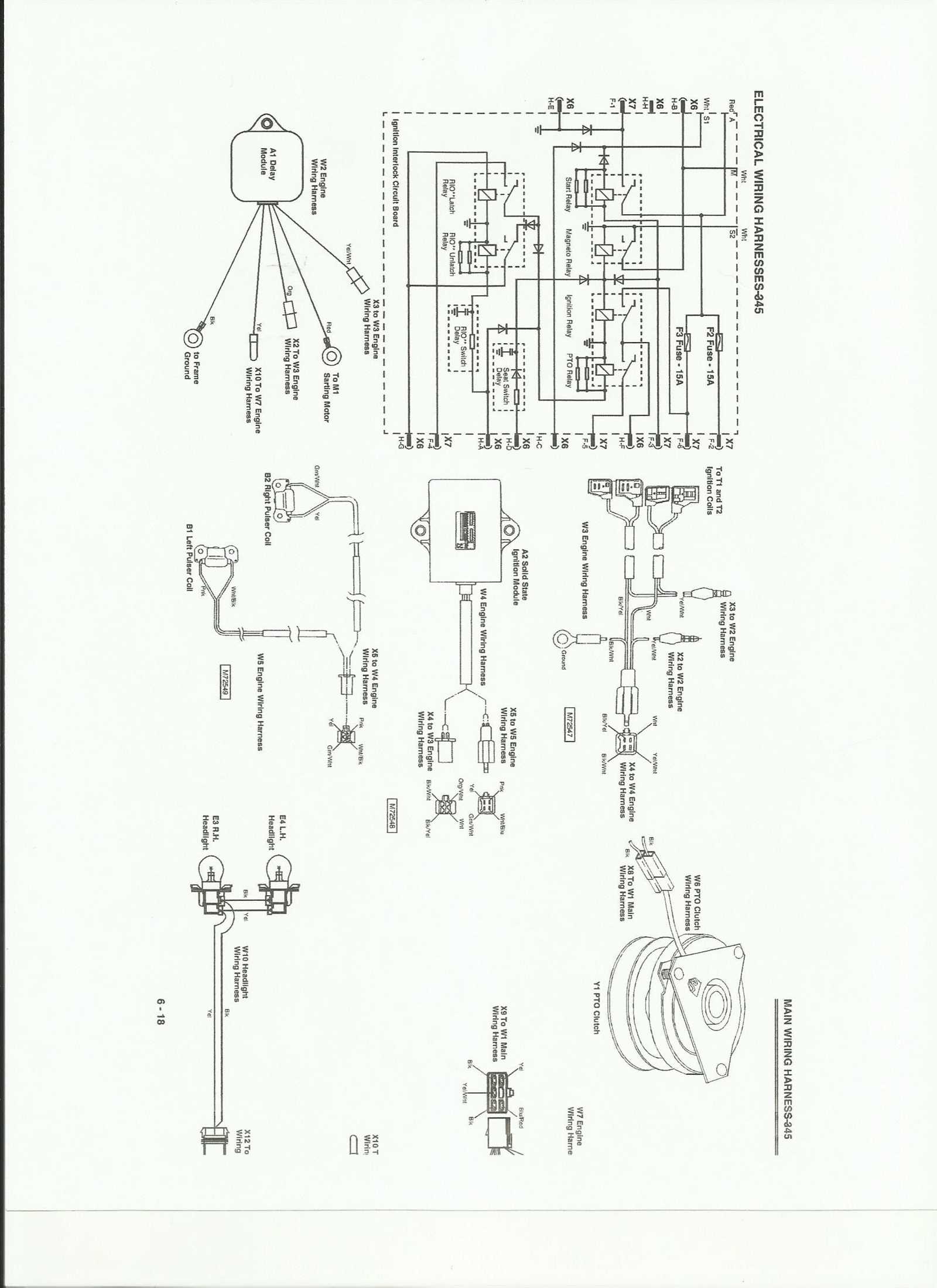

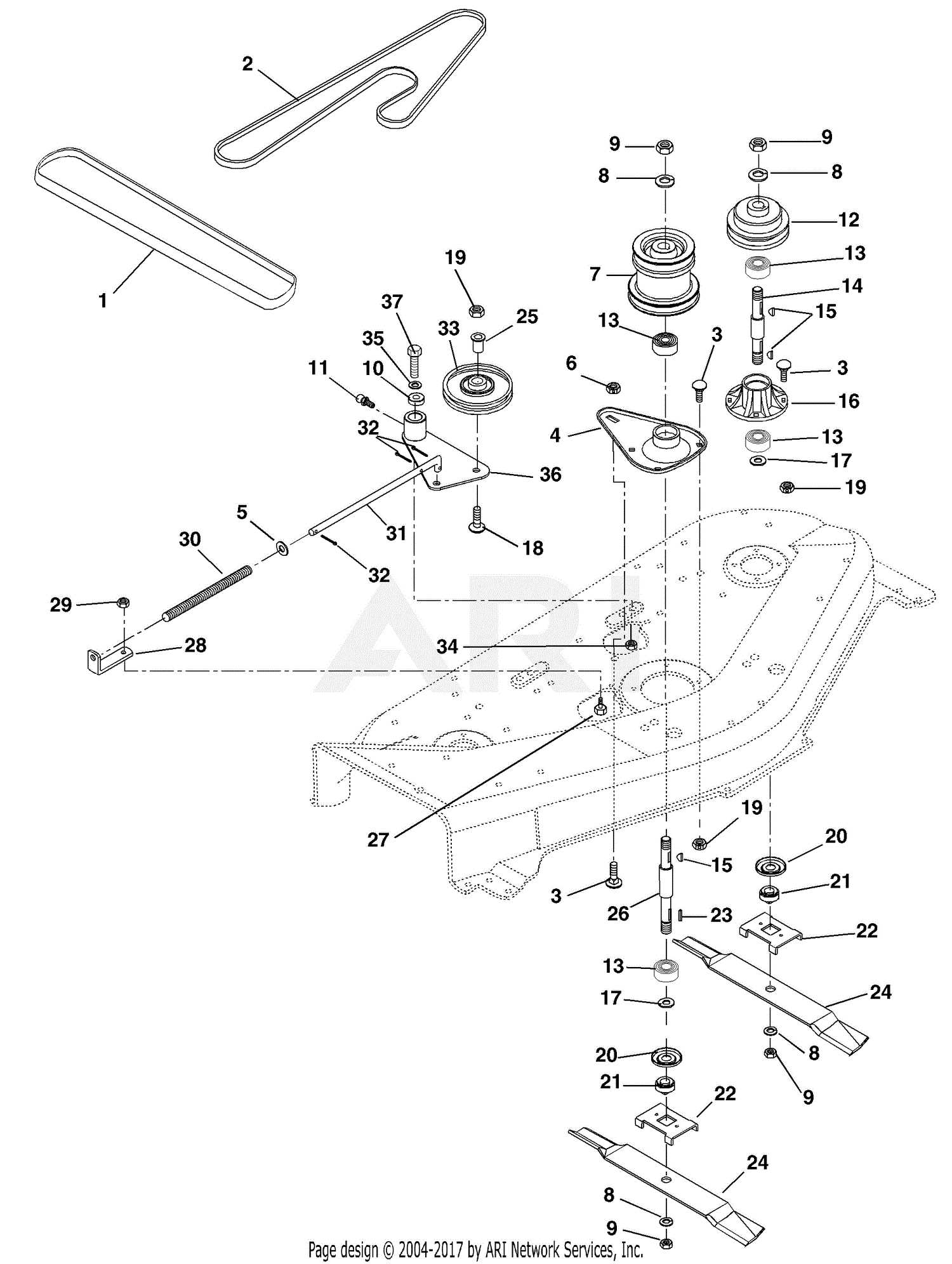

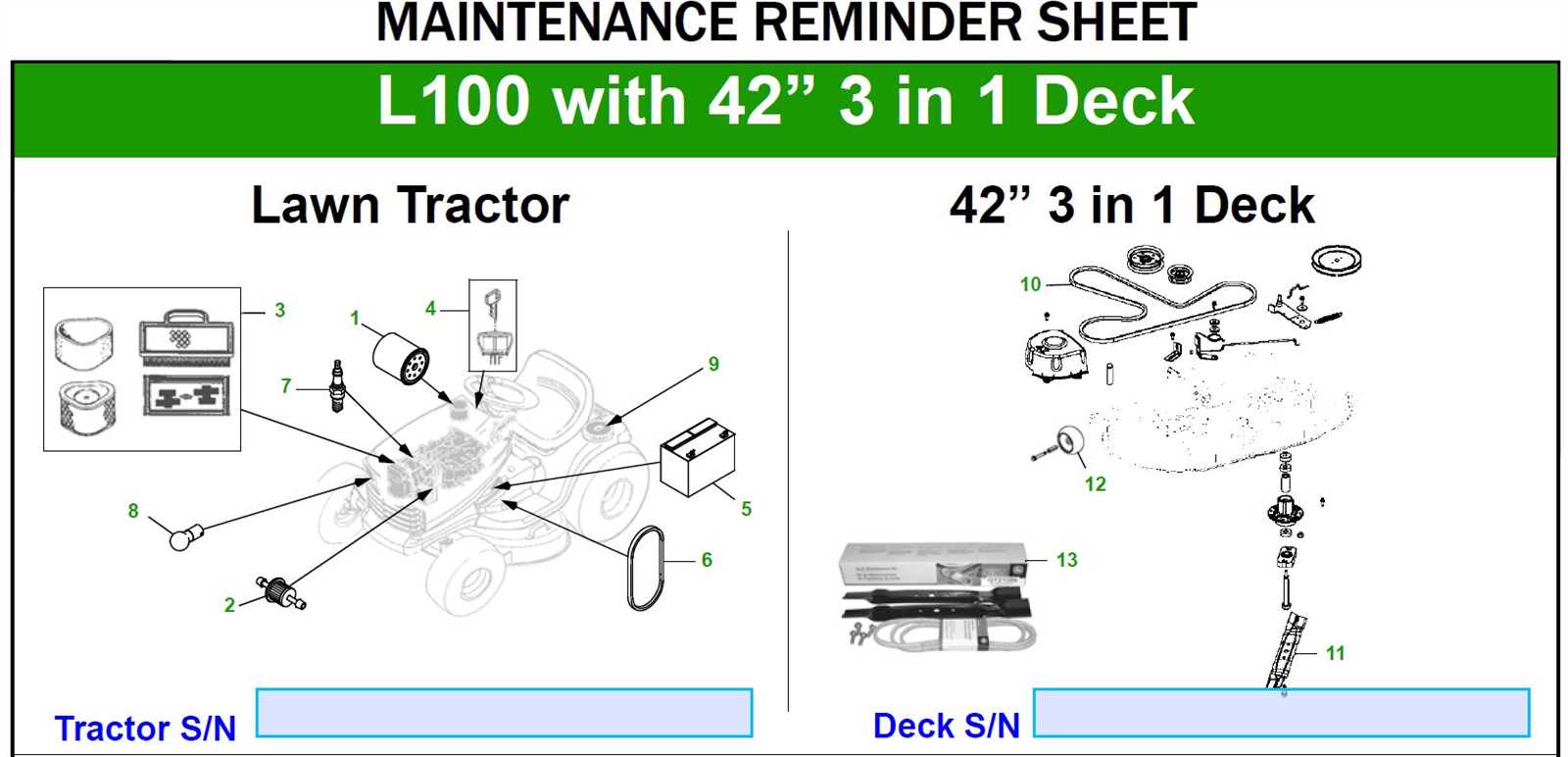

Importance of Parts Diagrams

Understanding the various components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools for both novice and experienced technicians, allowing them to identify specific elements and their functions within a complex system.

Clarity is one of the primary benefits of these visual aids. They provide a clear and concise layout, enabling users to quickly locate and understand each component’s placement and relationship to others. This ease of use minimizes confusion and speeds up the repair process.

Moreover, enhanced communication is another significant advantage. When discussing repairs or replacements, having a visual reference helps ensure everyone involved is on the same page. This shared understanding reduces the likelihood of errors and misinterpretations during discussions.

Finally, utilizing these resources can lead to cost efficiency. By clearly identifying parts that need replacement, users can avoid unnecessary purchases and focus only on what is required for restoration, ultimately saving both time and money.

Common Issues with GX345 Parts

When dealing with lawn maintenance equipment, certain challenges frequently arise that can affect performance and longevity. Understanding these typical concerns can help in proactive maintenance and timely repairs, ensuring that the machinery operates efficiently.

Wear and Tear: Over time, components can degrade due to continuous usage. This can lead to decreased efficiency and potential breakdowns. Regular inspections are crucial to identify signs of wear before they escalate into larger issues.

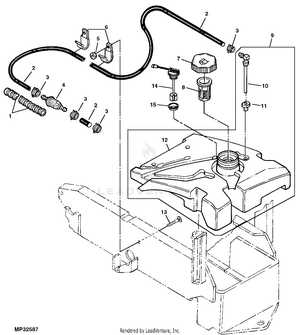

Fuel System Problems: Clogs or leaks in the fuel delivery system can disrupt operation. Ensuring that filters are clean and lines are intact can help prevent these disruptions and maintain optimal performance.

Electrical Failures: Electrical systems are often prone to issues such as faulty connections or battery failures. Routine checks of wiring and connections can mitigate these risks, ensuring reliable starts and operations.

Cooling System Issues: An effective cooling mechanism is essential to prevent overheating. Accumulation of debris in cooling fins or low coolant levels can lead to overheating, which can damage the engine. Regular cleaning and monitoring are recommended.

Transmission Troubles: Shifting problems or unusual noises from the transmission can signal underlying issues. Regular maintenance and fluid checks can help keep this critical system functioning smoothly.

By being aware of these common issues and implementing preventive measures, users can significantly enhance the performance and lifespan of their equipment.

Where to Find Replacement Parts

Finding the right components for your machinery can be crucial for its performance and longevity. There are several avenues you can explore to locate quality replacements that fit your needs.

- Authorized Dealers: Visiting an authorized dealer ensures that you receive original and high-quality components. They often have a wide range of items available and can provide expert advice.

- Online Retailers: Numerous websites specialize in selling machinery components. Some popular options include:

- eBay

- Amazonspecialty stores

- Dedicated machinery supply sites

- Local Repair Shops: Many local repair facilities have access to parts and can often order what you need. They can also assist with installation and offer guidance on maintenance.

- Aftermarket Suppliers: There are various suppliers that provide high-quality alternatives to original components at potentially lower prices. Researching customer reviews can help ensure reliability.

- Community Forums: Online forums and communities dedicated to machinery enthusiasts can be invaluable resources. Members often share recommendations for sourcing components and may offer second-hand items.

By exploring these options, you can effectively find the necessary components to keep your equipment running smoothly.

Maintenance Tips for GX345 Owners

Proper upkeep is essential for maximizing the performance and lifespan of your equipment. Regular maintenance not only ensures efficient operation but also prevents costly repairs down the line. Following a consistent maintenance schedule can enhance your machine’s reliability and effectiveness.

Routine Checks

Performing routine inspections is crucial. Check fluid levels, belts, and tires to ensure everything is in optimal condition. A quick glance can often reveal issues before they escalate.

| Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 50 hours | Use high-quality oil for best results. |

| Air Filter Inspection | Every 25 hours | Clean or replace as needed. |

| Tire Pressure Check | Monthly | Maintain proper inflation for optimal performance. |

Seasonal Maintenance

As seasons change, so do maintenance needs. Preparing your machine for varying weather conditions is key. During winter, consider using a fuel stabilizer and storing the equipment in a sheltered area. In warmer months, focus on cooling system maintenance and cleaning grass buildup to prevent overheating.

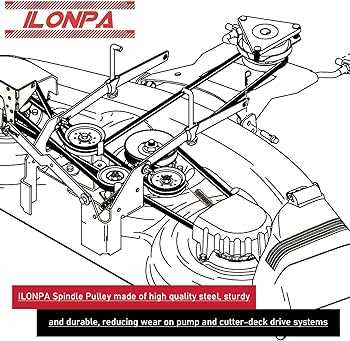

Upgrading Your GX345 Equipment

Enhancing your outdoor machinery can significantly improve performance and longevity. By selecting high-quality components and modern accessories, you can elevate the efficiency of your equipment. This guide outlines key considerations and options for upgrading your machinery, ensuring it meets your evolving needs.

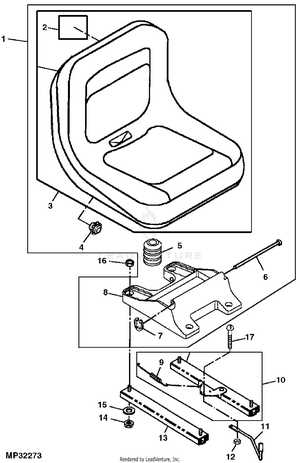

When contemplating upgrades, it’s essential to assess the areas that can benefit most. Consider factors such as power output, comfort, and usability. The right enhancements can transform your experience, making tasks easier and more enjoyable.

| Upgrade Type | Description | Benefits |

|---|---|---|

| Engine Enhancements | Improved air filters, exhaust systems, and fuel injectors. | Increased power and fuel efficiency. |

| Comfort Additions | Upgraded seating, steering wheels, and controls. | Enhanced ergonomics and reduced operator fatigue. |

| Cutting Deck Upgrades | Replacement blades, reinforced decks, and mulching kits. | Superior cutting performance and grass management. |

| Attachment Options | New implements such as snow plows, trailers, or tillers. | Increased versatility for various tasks. |

By thoughtfully selecting upgrades, you can ensure your machinery remains reliable and effective, ready to tackle any challenge. Consider investing in quality replacements and enhancements to maximize your equipment’s potential.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair of machinery. These illustrations serve as guides to identify various elements, ensuring that users can easily locate and comprehend the necessary items for their tasks. Mastering the ability to interpret these visuals can significantly enhance your efficiency in handling equipment issues.

Key Elements to Observe

When examining these visual references, it’s important to focus on specific details that can help in identifying parts. Pay attention to the labeling, color coding, and overall layout. Here are some critical aspects to consider:

| Element | Description |

|---|---|

| Labels | Identify components with corresponding numbers or letters for easy reference. |

| Color Coding | Different colors may indicate various categories or statuses of parts. |

| Grouping | Related items are often clustered together to simplify navigation. |

Tips for Effective Navigation

To maximize your understanding of these visuals, consider the following strategies:

- Familiarize yourself with the overall layout before diving into specifics.

- Take notes on frequently referenced components to build your knowledge base.

- Consult additional resources or manuals for clarification on complex elements.

Tools Needed for Repairs

Proper maintenance requires a set of essential instruments to ensure efficiency and effectiveness. Utilizing the right tools not only simplifies the repair process but also enhances safety and accuracy.

Essential Tools

- Wrenches

- Screwdrivers

- Pliers

- Socket set

- Torque wrench

Additional Equipment

- Jack and jack stands

- Oil filter wrench

- Multimeter

- Safety goggles

- Gloves

Customer Reviews and Experiences

This section highlights the diverse feedback and encounters shared by users regarding their machinery. Insights from customers can reveal the reliability, efficiency, and overall satisfaction levels associated with their equipment. By examining these reviews, potential buyers can make informed decisions and understand what to expect from their investments.

User Feedback

Many owners appreciate the robust construction and ease of use. One user noted, “The performance has exceeded my expectations; it’s a workhorse that handles tough tasks effortlessly.” This sentiment is echoed by others who commend its durability and versatility.

While the majority of experiences are positive, some users have encountered issues. A common concern mentioned is the availability of specific components. One reviewer remarked, “Finding the right replacements can be a bit tricky, but the support team was helpful.” This highlights the importance of customer service in resolving potential hurdles.