In the world of outdoor machinery, comprehending the intricate arrangement of elements is essential for effective maintenance and repair. A thorough grasp of how various sections fit together enhances efficiency and prolongs the lifespan of your equipment. This knowledge not only empowers operators but also minimizes downtime by facilitating quick fixes and replacements.

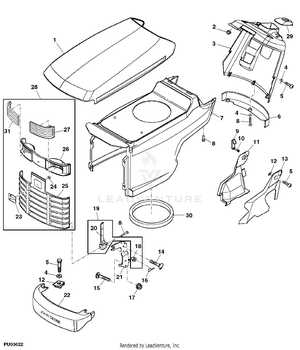

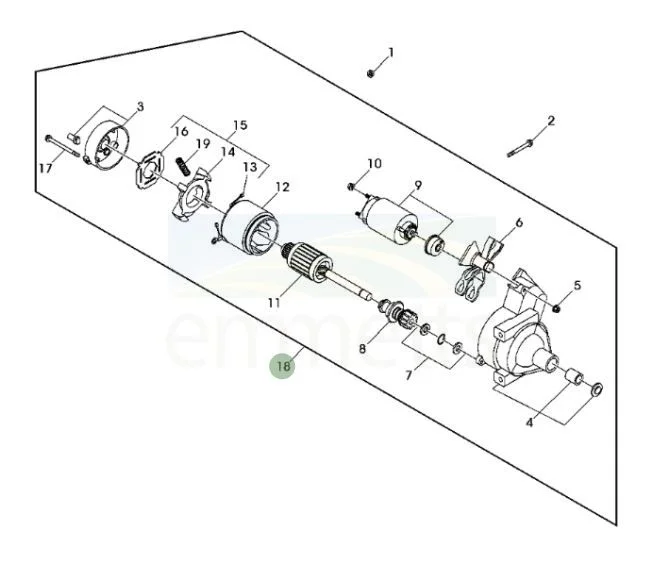

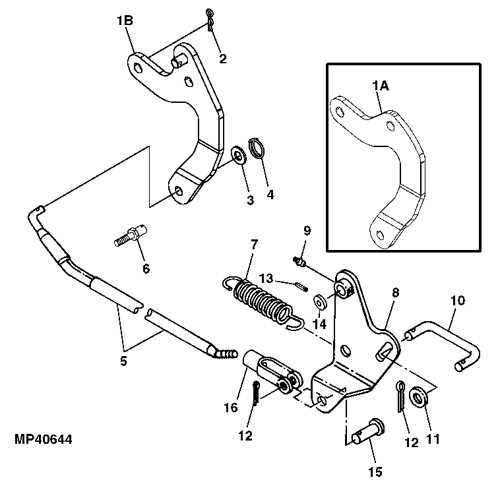

The examination of these mechanisms involves detailed illustrations that depict each segment and its connection to others. Such visual guides serve as invaluable resources, providing clarity and insight into the functionality of the entire system. Whether you’re a seasoned technician or a novice user, being familiar with these layouts can greatly simplify troubleshooting processes.

Furthermore, understanding the specific roles of individual components allows for informed decision-making when it comes to upgrades or replacements. It fosters a proactive approach to maintenance, ensuring that every aspect of your machinery is in optimal condition. By delving into these illustrations, one can unlock the full potential of their outdoor equipment.

Understanding John Deere GT225 Components

Exploring the intricate elements of garden machinery can enhance maintenance and repair efforts. Recognizing how each segment contributes to overall functionality allows for better troubleshooting and informed decisions regarding upgrades or replacements.

Key Elements of the Machine

Several crucial components work together to ensure smooth operation. Understanding these can lead to improved performance and longevity:

- Engine Assembly

- Transmission System

- Steering Mechanism

- Electrical System

- Cutting Deck

Maintenance Considerations

Regular upkeep of each part is vital for optimal performance. Here are some maintenance tips:

- Inspect the engine regularly for any signs of wear or leaks.

- Check the transmission fluid and ensure it is at the recommended level.

- Keep the steering system lubricated to prevent stiffness.

- Examine electrical connections for corrosion or loose wires.

- Clean the cutting deck after each use to maintain efficiency.

By understanding these components and their maintenance needs, operators can enhance the functionality and lifespan of their equipment.

Common Issues with GT225 Parts

Maintenance challenges can arise in various machinery, often due to wear and tear or improper usage. Understanding these typical problems is essential for effective upkeep and longevity of the equipment.

One frequent concern involves the engine not starting or running inconsistently. This may stem from fuel issues, ignition system failures, or air filter blockages.

Another issue is with the transmission, which can exhibit slipping or difficulty in shifting gears. This often results from low fluid levels or worn components that require timely attention.

Finally, blades may suffer from dullness or damage, impacting cutting efficiency. Regular inspection and sharpening are crucial for optimal performance.

How to Access the Parts Diagram

Gaining access to the schematic representation of components is crucial for effective maintenance and repair of machinery. Understanding how to find and utilize these visual guides can significantly enhance your ability to service your equipment efficiently. Below are steps to help you navigate through the resources available for this purpose.

Utilizing Online Resources

One of the easiest ways to locate the schematic is through official websites and authorized dealers. Many manufacturers provide comprehensive digital libraries where you can search for your specific model. By entering relevant details, you can quickly access the necessary illustrations and part numbers.

Consulting Manuals and Documentation

If you prefer physical materials, check the user manual that came with your machinery. Often, these guides include detailed drawings along with parts listings. Additionally, if you have access to any repair books or maintenance documentation, they can serve as excellent references for understanding the layout of components.

Tip: Always ensure you have the correct model information handy to facilitate a smooth search process.

Remember, a thorough understanding of the components involved will empower you to handle repairs more confidently and effectively.

Benefits of Using Original Parts

Utilizing authentic components for machinery maintenance offers numerous advantages that enhance performance, reliability, and longevity. These elements are specifically designed to fit seamlessly, ensuring optimal functionality and reducing the likelihood of malfunction. When quality is paramount, original elements stand out as the preferred choice.

| Advantage | Description |

|---|---|

| Enhanced Performance | Original components are engineered to meet precise specifications, ensuring your equipment operates at its best. |

| Increased Longevity | Using genuine elements can extend the lifespan of your machinery by minimizing wear and tear. |

| Improved Safety | Authentic parts undergo rigorous testing, contributing to safer operation and reducing the risk of failure. |

| Warranty Protection | Utilizing original components often preserves manufacturer warranties, safeguarding your investment. |

| Better Resale Value | Machines maintained with genuine parts tend to retain higher resale value, appealing to future buyers. |

In summary, choosing authentic components is a strategic decision that promotes efficiency and reliability while safeguarding your machinery’s overall health.

Maintenance Tips for GT225 Owners

Proper upkeep is essential for maximizing the performance and longevity of your machinery. Regular attention to key components ensures optimal functioning and minimizes the likelihood of unexpected breakdowns. By following a systematic maintenance routine, owners can maintain their equipment in peak condition, enhancing both efficiency and safety.

Regular Inspection

Frequent checks are vital to identify wear and tear before they escalate into serious issues. Focus on the following areas during your inspections:

| Component | Inspection Frequency | Key Points |

|---|---|---|

| Oil Level | Every 5 hours | Ensure adequate levels and check for contamination. |

| Air Filter | Every 10 hours | Clean or replace to prevent engine strain. |

| Blades | Every 20 hours | Sharpen or replace to maintain cutting efficiency. |

Seasonal Maintenance Tasks

Seasonal care can greatly improve performance. Consider the following tasks as part of your routine:

- Change oil and filter at the beginning of each season.

- Check battery condition and clean terminals.

- Inspect belts and cables for signs of wear or fraying.

Identifying Replacement Part Numbers

Understanding how to pinpoint the correct identifiers for components is crucial for efficient maintenance and repair of outdoor machinery. Whether you are replacing a worn-out item or upgrading to a new feature, knowing the exact specifications can save time and prevent costly mistakes. This section will guide you through the process of identifying the necessary identifiers for your equipment.

| Component Description | Replacement Identifier |

|---|---|

| Engine Filter | EF12345 |

| Drive Belt | DB67890 |

| Blade Assembly | BA54321 |

| Fuel Pump | FP98765 |

When searching for the right identifiers, consider consulting official manuals or trusted online resources. These tools can provide valuable insights into the specifications needed for your specific model. Always verify the numbers before purchasing to ensure compatibility with your machinery.

Tools Needed for GT225 Repairs

Maintaining and fixing outdoor equipment requires the right set of tools to ensure efficiency and safety. Having a well-organized toolkit is essential for anyone looking to perform repairs effectively. The following are essential implements that will facilitate a smooth repair process.

Essential Hand Tools

Start with basic hand tools, as they are fundamental for most repair tasks. A set of wrenches and screwdrivers are crucial for loosening and tightening various components. Additionally, pliers can be useful for gripping and bending materials. A socket set is also recommended for dealing with bolts that require more torque.

Power Tools and Safety Equipment

Incorporating power tools can significantly reduce the time needed for repairs. A drill is invaluable for making holes or driving screws quickly. Furthermore, always prioritize safety by wearing protective gear such as gloves and goggles to prevent injuries. A workbench or a sturdy surface can also enhance efficiency and safety during repairs.

Comparing Aftermarket vs. OEM Parts

When maintaining equipment, the choice between alternative and original components can significantly impact performance and longevity. Understanding the differences can help in making informed decisions that align with both budget and quality expectations.

Advantages of OEM Components

- Guaranteed compatibility with your equipment.

- Manufactured to meet strict quality standards.

- Often come with a warranty for added peace of mind.

Benefits of Aftermarket Components

- Typically more affordable than their original counterparts.

- Wide variety of options available to suit different needs.

- Some products may offer enhanced performance features.

Ultimately, weighing the pros and cons of each type will enable better choices tailored to individual requirements.

Where to Buy GT225 Parts Online

Finding high-quality components for your outdoor equipment can significantly enhance its performance and longevity. Fortunately, there are several reliable online platforms where you can source these essential items. In this section, we will explore some of the best options for purchasing these crucial elements, ensuring you get the right fit for your machinery.

Top Online Retailers

| Retailer | Website | Special Features |

|---|---|---|

| Manufacturer’s Store | manufacturerstore.com | Directly sourced items, warranty options |

| Specialty Parts Retailer | specialtyparts.com | Wide selection, expert customer service |

| Online Marketplaces | marketplace.com | User reviews, competitive pricing |

Considerations for Purchase

When selecting a vendor, consider the availability of customer support, shipping options, and return policies. Additionally, checking for user feedback can provide insights into the reliability of both the components and the retailer. By taking these factors into account, you can make an informed decision and ensure a seamless shopping experience.