The maintenance and operation of any outdoor machinery depend heavily on a clear comprehension of its individual components. For enthusiasts and operators alike, knowing how these parts interconnect and function is crucial for optimal performance. Whether you’re a seasoned professional or a casual user, a thorough grasp of the inner workings can enhance both efficiency and longevity.

In the realm of garden equipment, there exists a wide array of models, each featuring unique assemblies that serve specific purposes. Familiarizing yourself with the structure of these machines not only aids in troubleshooting but also empowers users to undertake repairs and upgrades confidently. This knowledge can transform the way you interact with your equipment, making tasks more manageable and reducing downtime.

To assist in this endeavor, visual representations of machinery layouts offer invaluable insights. By examining these schematics, you can pinpoint locations of essential components, identify compatible replacements, and ensure that every part is in its rightful place. Armed with this information, you’re better equipped to maintain your equipment, leading to enhanced functionality and a more satisfying gardening experience.

Understanding John Deere E170 Components

Grasping the essential elements of a lawn tractor is crucial for effective maintenance and operation. Each part plays a significant role in ensuring optimal performance, contributing to the overall functionality of the machine. Familiarizing oneself with these components can lead to better care and enhanced longevity.

Key Elements to Recognize

Understanding the various parts can help users troubleshoot issues and perform regular upkeep. Below are some critical components:

- Engine: The powerhouse that drives the entire system.

- Transmission: Responsible for power distribution and speed control.

- Deck: The cutting mechanism that determines the quality of the lawn finish.

- Wheels: Ensure mobility and stability on various terrains.

- Battery: Provides the necessary power to start the engine and operate electrical systems.

Maintenance Tips

Proper care of these components can significantly enhance performance:

- Regularly check and change the oil to ensure smooth engine operation.

- Inspect the blades for sharpness and replace them as needed for effective cutting.

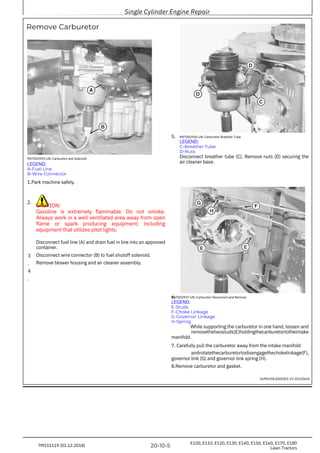

- Keep the air filter clean to maintain engine efficiency.

- Monitor tire pressure to ensure optimal traction and handling.

- Examine the battery terminals for corrosion to prevent starting issues.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding and maintaining complex machinery. They provide clarity and help users identify each element’s position and function within the system. By offering a detailed view, these illustrations streamline the repair process and enhance overall efficiency.

- Enhanced Understanding: Clear visuals aid in grasping how different components interact.

- Streamlined Maintenance: Quick reference guides allow for faster identification of issues.

- Effective Communication: Shared images facilitate better dialogue between technicians and customers.

- Training Tool: New users benefit from visual aids, making learning more accessible.

In summary, utilizing such visuals not only simplifies repairs but also fosters a more knowledgeable user base, ultimately contributing to longer-lasting equipment.

Common Issues with E170 Parts

When dealing with outdoor equipment, certain components often present challenges that can hinder performance and efficiency. Understanding these common complications can help in timely maintenance and replacement, ensuring optimal functionality.

Frequent Malfunctions

Many users encounter specific malfunctions that require attention. These can stem from wear and tear, improper installation, or lack of maintenance.

| Component | Common Issues |

|---|---|

| Battery | Short lifespan, poor charging |

| Belts | Fraying, slipping |

| Blades | Dulling, bending |

Maintenance Tips

Regular inspections and prompt replacements are essential. Keeping components clean and properly lubricated can significantly extend their lifespan and prevent major failures.

Where to Find Replacement Parts

Locating components for your outdoor machinery can often seem challenging, but several reliable sources can simplify the process. Understanding where to search for high-quality substitutes is essential for maintaining optimal performance and longevity of your equipment.

Online Retailers offer a vast selection of components at competitive prices. Websites dedicated to outdoor machinery often provide detailed catalogs and user-friendly interfaces to help you find the exact item you need.

Local Dealers are another excellent resource. Visiting a nearby store not only allows you to obtain the necessary components quickly but also gives you the advantage of expert advice from knowledgeable staff who can assist you in making the right choice.

Salvage Yards can be a hidden gem for finding used parts at a fraction of the original cost. These facilities often have a variety of components that are still in good condition, providing a sustainable option for maintenance.

Manufacturer Websites frequently offer direct access to genuine components. Checking the official site ensures that you are purchasing high-quality items that are compatible with your machinery.

Lastly, Online Marketplaces such as auction sites can provide opportunities to find rare or hard-to-find components. Just be sure to check seller ratings and reviews to ensure a positive purchasing experience.

Maintenance Tips for E170 Owners

Proper upkeep is essential for ensuring the longevity and efficiency of your equipment. Regular attention to specific areas can enhance performance and prevent costly repairs. Here are some practical recommendations for maintaining your machine.

- Regular Inspections: Conduct routine checks for wear and tear. Look for signs of damage or corrosion that could affect functionality.

- Fluid Levels: Monitor oil and coolant levels consistently. Keeping these at optimal levels helps prevent overheating and mechanical failures.

- Air Filter Maintenance: Clean or replace the air filter periodically. A clean filter improves engine performance and fuel efficiency.

Following a structured maintenance schedule can significantly reduce the likelihood of breakdowns. Utilize the manufacturer’s guidelines for service intervals and recommended procedures.

- Change the oil and oil filter as specified in the maintenance schedule.

- Sharpen or replace blades to ensure effective cutting performance.

- Check tire pressure regularly to ensure safe operation and prevent uneven wear.

Staying proactive with these tips will not only extend the lifespan of your equipment but also enhance your overall experience. Make maintenance a priority to enjoy smooth and efficient operation throughout the seasons.

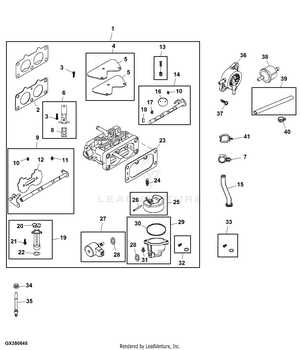

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair tasks. These illustrations serve as valuable tools, providing a clear overview of how various elements fit together and function within a machine. By familiarizing yourself with the layout and symbols used in these visuals, you can enhance your ability to identify specific items and comprehend their relationships.

Start by examining the overall layout. Typically, these visuals are organized in a logical manner, grouping related components together. Pay attention to labels, as they often indicate the names or functions of the parts depicted. This labeling is crucial for determining which pieces you may need to replace or service.

Next, look for reference numbers or codes associated with each element. These identifiers can be cross-referenced with catalogs or manuals to find detailed information about the specifications and compatibility of the components. This step is vital for ensuring that you select the correct items during procurement.

Additionally, note the different types of lines and symbols used. Solid lines may represent physical connections, while dashed lines could indicate functional relationships or potential movement. Familiarizing yourself with these conventions will deepen your understanding of the overall assembly and its operations.

Finally, practice makes perfect. The more you engage with these illustrations, the more intuitive reading them will become. Over time, you’ll develop the skills needed to quickly interpret the visuals, allowing you to tackle maintenance tasks with confidence and efficiency.

Upgrading John Deere E170 Features

Enhancing the functionality and performance of your lawn care equipment can significantly improve its efficiency and lifespan. By focusing on key areas for improvement, you can transform your machine into a more powerful and user-friendly tool for maintaining your landscape.

Consider the following upgrades to maximize the potential of your equipment:

- Engine Performance: Upgrading the engine or tuning it for better fuel efficiency can lead to noticeable improvements in power and reliability.

- Cutting Deck: Installing a higher-quality or wider cutting deck can enhance mowing speed and reduce the number of passes needed, saving time.

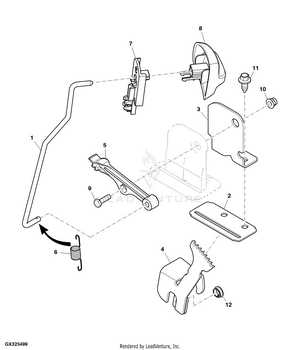

- Transmission System: An improved transmission system can provide smoother operation and better control on varied terrain.

- Comfort Features: Adding ergonomic seats and adjustable controls can make long mowing sessions much more comfortable.

Each of these enhancements contributes to a more efficient and enjoyable mowing experience, allowing you to tackle your lawn maintenance tasks with greater ease.

Additionally, consider integrating advanced technology options:

- GPS Navigation: This feature can assist in planning mowing routes, ensuring comprehensive coverage.

- Smart Sensors: Installing sensors for detecting obstacles can enhance safety and prevent accidental damage.

- Bluetooth Connectivity: This allows for convenient monitoring and control of equipment settings via mobile devices.

Investing in these upgrades not only boosts performance but also increases the overall enjoyment of your outdoor projects.

Comparing E170 with Other Models

This section explores the differences and similarities between a specific lawn tractor and its counterparts. By examining various features, performance metrics, and design elements, we aim to provide a comprehensive understanding of how these machines stack up against one another.

Performance and Efficiency

When evaluating performance, it’s essential to consider the engine power and cutting efficiency. Some models offer enhanced horsepower, allowing for faster mowing and better handling of tough terrains. Additionally, fuel efficiency varies, which can impact long-term operational costs. Choosing the right machine often depends on the specific needs of the user.

Design and Usability

The usability of each tractor is influenced by its design features. Ergonomic controls, seat comfort, and ease of access to maintenance points play significant roles in user experience. Models with advanced technology, such as integrated displays, provide more information at a glance, making operation smoother and more intuitive. Ultimately, the choice between models should reflect personal preferences and intended use.