Exploring the intricate design of agricultural equipment is essential for optimizing performance and longevity. Each element of these machines plays a crucial role in their overall functionality, ensuring efficiency in various tasks. A comprehensive understanding of these components can significantly enhance maintenance practices and operational effectiveness.

In this section, we delve into the essential building blocks that comprise a specific rotary cutting apparatus. By examining the layout and interconnections of each part, users can gain valuable insights into their equipment’s mechanics. This knowledge not only aids in troubleshooting but also empowers operators to make informed decisions regarding repairs and upgrades.

Whether you are a seasoned professional or a novice in the field, having a clear visual representation of the assembly will enhance your comprehension. Recognizing how each segment interacts within the larger framework allows for better management of resources and improved functionality in agricultural tasks.

Overview of John Deere 350 Mower

This section provides an insight into a well-known agricultural implement designed for efficient cutting and harvesting. Its robust construction and innovative features make it a preferred choice for many farmers and landscapers.

Key Features

- Durability: Built to withstand tough conditions.

- Efficiency: Designed for optimal cutting performance.

- Versatility: Suitable for various applications in agriculture and landscaping.

Benefits

- Enhanced productivity through faster operation.

- Lower maintenance costs due to quality materials.

- Improved ease of use with user-friendly controls.

Overall, this implement represents a reliable choice for those looking to enhance their cutting capabilities while maintaining efficiency and durability in their operations.

Key Features of the Sickle Mower

This segment highlights the essential characteristics that make this agricultural implement an indispensable tool for effective grass and crop management. Understanding these features can enhance efficiency and improve overall performance during operations.

Durability and Construction

The robustness of the design ensures longevity, making it suitable for various terrains and weather conditions. Key elements include:

- High-quality materials that resist wear and tear.

- Reinforced components to handle heavy usage.

- Weather-resistant finishes to prevent rust and corrosion.

Operational Efficiency

Enhancements in functionality allow for seamless operation and improved productivity. Important aspects include:

- Adjustable cutting heights for customized performance.

- Sharp blades that provide clean cuts, reducing the need for multiple passes.

- Easy attachment and detachment for quick setup and storage.

These features contribute to the overall effectiveness of the implement, ensuring optimal results in various agricultural tasks.

Common Issues with John Deere 350

When operating any piece of agricultural machinery, it is essential to be aware of potential challenges that may arise. This specific model, known for its efficiency, can encounter several recurring problems that users should monitor closely to ensure optimal performance and longevity.

One frequent issue involves the cutting mechanism. Over time, wear and tear can lead to a decrease in cutting efficiency, resulting in uneven grass or crop cutting. Regular inspections and timely replacements of worn components can mitigate this problem.

Another common challenge pertains to the drive system. Users often report difficulties with the belts and pulleys, which can wear out or misalign, leading to reduced power transfer. Keeping these parts properly adjusted and lubricated is crucial for maintaining functionality.

Hydraulic system leaks are also a noted concern. These can occur due to aging seals or loose connections, causing a drop in operational pressure. Routine checks and maintenance can help identify and rectify these leaks before they escalate into more significant issues.

Lastly, electrical problems may arise, particularly with wiring and connections. Corrosion or fraying can lead to intermittent functionality. Ensuring that electrical components are clean and securely connected is vital for reliable operation.

Essential Replacement Parts Explained

Understanding the fundamental components necessary for maintaining agricultural machinery is crucial for optimal performance and longevity. Each element plays a significant role in ensuring that the equipment operates efficiently, minimizing downtime and enhancing productivity in the field.

One of the most critical elements is the cutting blade, which requires regular inspection and timely replacement to ensure clean and effective operation. Dull or damaged blades can lead to poor performance and increased strain on the entire system.

Another vital component is the drive mechanism. This system facilitates the transfer of power from the engine to the cutting mechanism. Any wear and tear in this area can result in decreased efficiency and potential breakdowns, making it essential to monitor and replace any worn components promptly.

Additionally, belts and pulleys are integral to the overall functionality. They ensure smooth operation and proper alignment of moving parts. Regular checks for signs of fraying or damage can prevent unexpected failures and extend the lifespan of the machinery.

Lastly, bearings and bushings are often overlooked but are essential for reducing friction between moving parts. Keeping these elements in good condition is vital for smooth operation and preventing excessive wear on other components.

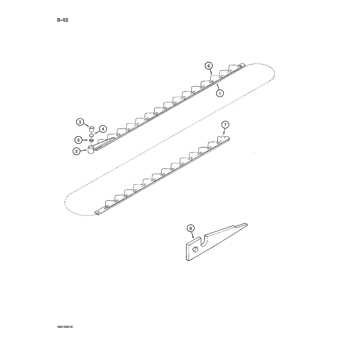

How to Read a Parts Diagram

Understanding a schematic can greatly enhance your ability to identify and source components for machinery. This knowledge is essential for effective maintenance and repair, allowing users to locate specific items quickly and accurately.

Here are some key elements to consider when interpreting a schematic:

- Legend: Familiarize yourself with the legend or key provided. This section typically explains symbols and color codes used throughout the illustration.

- Sectioning: Diagrams are often divided into sections. Each area may represent a different assembly or component group, making it easier to focus on specific parts.

- Numbering: Components are usually numbered sequentially. This numbering system helps you correlate the items with accompanying lists or catalogs.

- Connections: Pay attention to the lines and arrows indicating how parts connect or interact with each other. Understanding these relationships is crucial for assembly and disassembly.

By following these guidelines, you can navigate schematics with greater confidence, ensuring that you locate and manage components effectively.

Where to Find Quality Parts

Finding reliable components for your agricultural equipment can be challenging but rewarding. Ensuring that you have access to high-quality replacements is essential for maintaining optimal performance and longevity. Here are some effective sources to consider when searching for top-notch supplies.

- Manufacturer Websites: Directly visiting the official websites of manufacturers can provide access to original equipment and specifications.

- Authorized Dealers: Connecting with local authorized dealers ensures you receive authentic items along with professional support.

- Online Marketplaces: Popular e-commerce platforms often feature a wide range of options, allowing for price comparisons and reviews.

- Specialty Retailers: Dedicated agricultural supply stores often stock a variety of equipment components, catering to specific needs.

- Salvage Yards: Checking out salvage yards can lead to discovering used but functional components at a lower cost.

- Online Forums and Communities: Engaging with online communities can provide recommendations and insights from fellow equipment owners.

By exploring these avenues, you can enhance your chances of locating durable and efficient items that meet your operational requirements.

Maintenance Tips for Longevity

Ensuring the long-term functionality of your agricultural equipment requires regular attention and care. By following essential maintenance practices, you can enhance performance and extend the lifespan of your machinery. Implementing these tips will help you avoid costly repairs and ensure optimal operation.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect cutting blades | Before each use | Sharpen or replace as needed to ensure clean cuts. |

| Check lubrication | Weekly | Use the recommended oil type for all moving parts. |

| Clean debris | After each use | Remove grass and dirt to prevent rust and wear. |

| Inspect belts and cables | Monthly | Look for signs of wear or damage; replace if necessary. |

| Check tire pressure | Monthly | Maintain proper inflation for better handling and performance. |

| Store properly | Seasonally | Keep in a dry, sheltered area to avoid corrosion. |

By adhering to these recommendations, you can significantly improve the reliability and durability of your equipment, ensuring that it remains an effective tool in your agricultural endeavors.

Upgrades for Enhanced Performance

Improving equipment efficiency can significantly boost productivity and extend the lifespan of machinery. By integrating advanced components and technologies, users can achieve optimal results in their tasks. This section explores several enhancements that can elevate the performance of your agricultural implement.

Recommended Enhancements

Several key modifications can be made to enhance the functionality and efficiency of your equipment. Below is a table summarizing these potential upgrades:

| Upgrade | Description | Benefits |

|---|---|---|

| High-Performance Blades | Reinforced and sharper cutting edges. | Improved cutting efficiency and reduced wear. |

| Advanced Drive Systems | Upgraded belts and pulleys for smoother operation. | Enhanced power transmission and reduced slippage. |

| Precision Alignment Tools | Tools to ensure accurate setup and alignment. | Improved cutting accuracy and reduced downtime. |

| Upgraded Gearbox | High-efficiency gearbox for better torque. | Increased power delivery and reduced fuel consumption. |

Implementation Considerations

When planning upgrades, it’s essential to assess compatibility with existing systems and to consult with professionals when necessary. Proper installation and maintenance of these enhancements will ensure that your equipment performs at its best for years to come.