The efficient operation of construction and excavation machinery depends on the intricate arrangement of various mechanical elements. These systems are built with precision, allowing each part to work in harmony to achieve optimal performance. Understanding the structure and the role of each component can greatly benefit those who maintain and operate such equipment.

Exploring the layout of these elements helps in identifying how each segment contributes to the overall functionality. Whether dealing with hydraulics, mechanical linkages, or other crucial sections, recognizing their connections aids in smoother repairs and routine upkeep. This knowledge is key for ensuring that every piece functions seamlessly within the larger assembly.

Accurate knowledge of the machinery’s setup can make the difference when troubleshooting or carrying out routine checks. A clear grasp of how different components are interlinked is essential for maintaining the longevity and efficiency of the equipment. By focusing on the technical arrangement, operators and technicians can ensure the machinery remains in top condition, ready for any task.

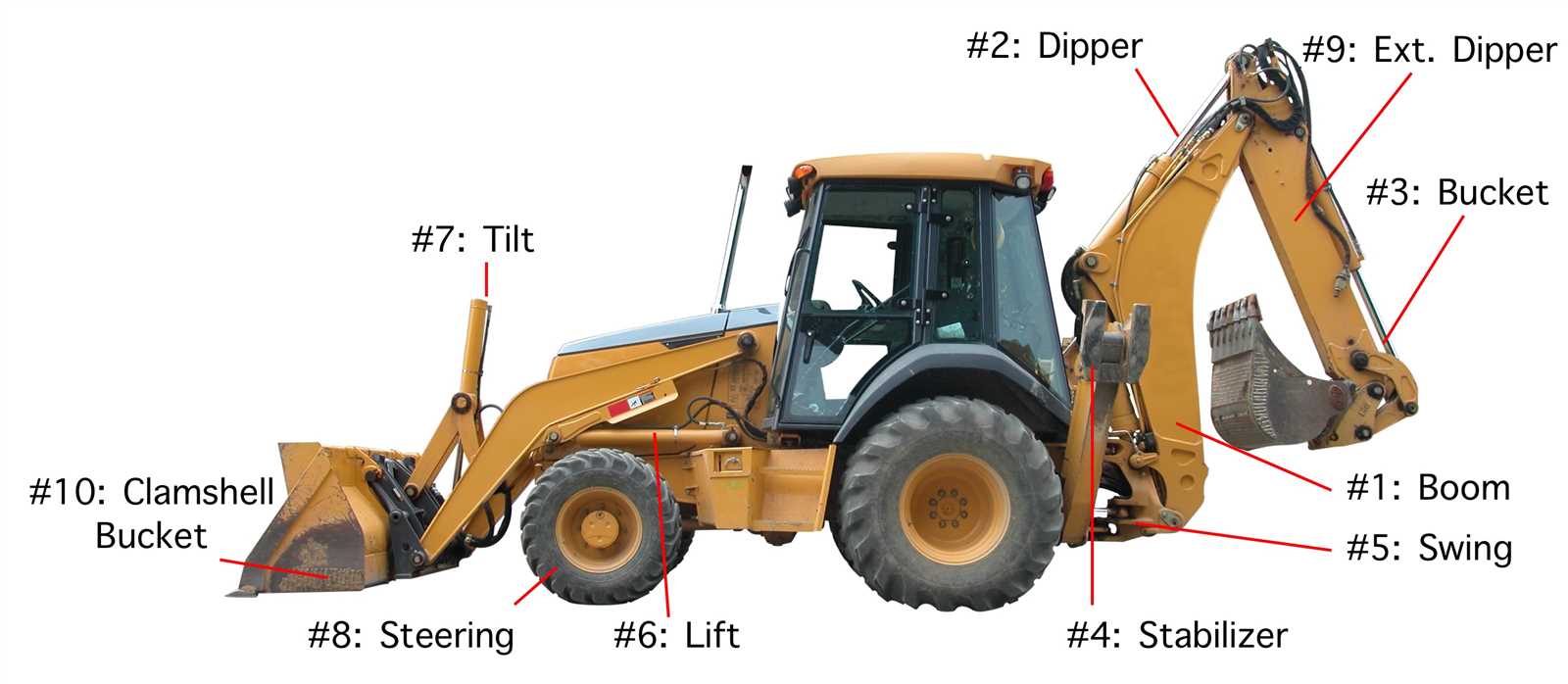

Understanding the Components of a Backhoe

When it comes to operating heavy machinery, knowing the different elements that make up the equipment is crucial for efficient use and maintenance. This type of machinery consists of various interconnected parts that each serve specific roles in its operation. Understanding how these elements work together helps in maximizing performance and prolonging the lifespan of the equipment.

Main Structural Elements

The core structure includes a robust frame that serves as the foundation for the rest of the machine. Attached to this are lifting arms and a sturdy attachment, allowing for various types of movement and digging capabilities. The design is focused on providing balance and strength, ensuring the machine can handle heavy loads and tough conditions.

Hydraulic System and Controls

A key feature of this machinery is its hydraulic system, which powers movements such as lifting, digging, and rotating. The system consists of pumps, cylinders, and fluid reservoirs, all working together to ensure smooth operation. Operators use a set of levers and pedals to control these movements, making it possible to execute precise actions with minimal effort.

Exploring Key Parts of Heavy Machinery

Understanding the essential components of large construction equipment is crucial for ensuring smooth operation and maintenance. Each element of these robust machines plays a vital role, contributing to their overall efficiency and durability. Familiarity with these components can help operators maximize the equipment’s potential and address issues before they escalate.

Vital Structural Elements

The core framework of these machines supports all primary functions, providing stability and strength during intense operations. Frames and chassis form the backbone, allowing the equipment to withstand heavy loads and challenging terrains. This robust structure ensures that the machinery remains reliable even under demanding conditions, enabling continuous productivity.

Hydraulic and Mechanical Systems

Hydraulics are the driving force behind the powerful movements of construction equipment, allowing precise control of lifting and digging mechanisms. Pumps and cylinders convert hydraulic energy into mechanical force, enabling smooth operation of various attachments. Efficient hydraulic systems ensure that the equipment performs complex tasks with accuracy, enhancing overall performance.

Essential Elements of Construction Equipment

Construction machinery plays a crucial role in various projects, offering the power and precision needed to handle diverse tasks. These machines are designed to provide efficient solutions for lifting, digging, and transporting materials across construction sites. Understanding the fundamental components of such equipment helps in ensuring smooth operations and longevity.

Hydraulic Systems are at the core of many machines, enabling precise movements and control. These systems use pressurized fluids to generate force, allowing equipment to lift heavy loads and perform intricate maneuvers. The durability and maintenance of these systems directly impact the overall performance of the machinery.

Engine Performance is another critical aspect, as it dictates the power output and fuel efficiency of the equipment. A reliable power source ensures that the machinery can operate for extended periods without interruptions, even in challenging conditions. Regular checks and upkeep are essential to maintain optimal engine functionality.

The chassis and frame provide structural support, ensuring stability and safety during operations. A well-designed frame distributes weight evenly, reducing wear and tear on other components. Additionally, reinforced frames are vital for maintaining balance, especially when handling uneven terrains or heavy materials.

Proper control systems enhance the user experience b

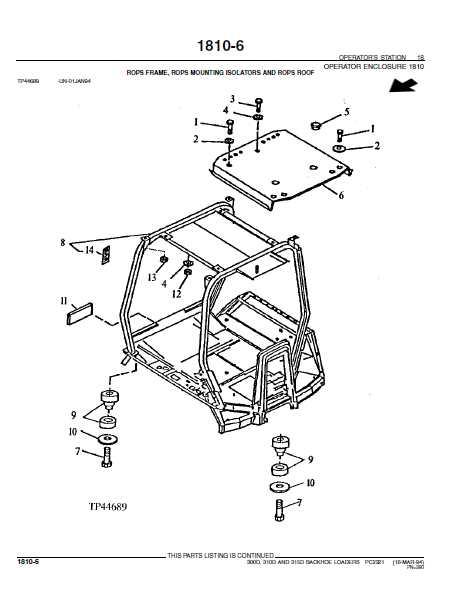

Detailed Breakdown of Backhoe Mechanisms

This section provides a comprehensive overview of the intricate systems and components that enable a versatile digging machine to perform various tasks efficiently. Each mechanism works in harmony to deliver precision, power, and flexibility for a range of operations, from excavation to lifting.

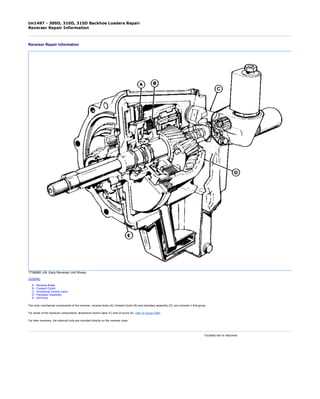

Hydraulic System Overview

The hydraulic system is the powerhouse that drives many of the machine’s functions. This network of fluid-filled pipes, pumps, and valves generates the necessary force for smooth and controlled movements.

- Pump: Generates pressure, supplying energy for different components.

- Control Valves: Direct the flow of hydraulic fluid, allowing for precise movement control.

- Cylinders: Transform hydraulic pressure into mechanical movement, enabling arm and attachment motion.

Stabilization and Balance Systems

Maintaining stability is crucial during operation, especially when working on uneven surfaces or lifting heavy materials. The stabilization system ensures that the equipment remains balanced, minimizing the risk of tipping.

- Outriggers: Extendable supports that increase stability during digging or lifting tasks.

- Weight Distribution: The machine is designed to balance weight evenly across its frame for secure

Guide to Backhoe Maintenance Essentials

Proper upkeep is crucial for ensuring the longevity and smooth operation of construction machinery. Regular attention to various components helps to prevent unexpected issues, reduce downtime, and extend the equipment’s lifespan. Understanding the key areas that require routine care can make a significant difference in performance.

One of the primary focuses should be on the hydraulic system. Keeping this system in optimal condition ensures smooth movements and efficient power delivery. Checking fluid levels, inspecting hoses for wear, and replacing any damaged parts are essential steps in maintaining the hydraulic mechanisms.

Another vital aspect is maintaining the engine. Regularly checking oil levels, air filters, and coolant can prevent overheating and ensure consistent power output. It’s also important to schedule routine inspections to identify potential issues before they become major problems.

Tire care is equally important, as it ensures stability and traction during operations. Monitoring tire pressure and inspecting for any wear or damage can help maintain safe and efficient operation. Timely replacement of worn-out tires is necessary for maintaining optimal grip and maneuverability.

Lastly, don’t overlook the electrical system. Inspecting wiring connections, testing battery health, and replacing any faulty fuses or lights

Identifying Critical Backhoe Attachments

Understanding essential attachments for excavation machinery is crucial for maximizing efficiency and performance. Various tools play a significant role in enhancing the versatility and functionality of the equipment. By recognizing these critical implements, operators can tailor their machines to specific tasks, ultimately improving productivity and effectiveness on the job site.

Commonly Used Attachments

Several widely utilized implements are integral to successful excavation operations. Each attachment serves a unique purpose, making it vital to choose the right tool for the task at hand. Below is a summary of common attachments and their functionalities:

Attachment Type Functionality Bucket Used for digging, lifting, and transporting materials. Auger Ideal for drilling holes in the ground for posts and foundations. Hydraulic Thumb Enhances the ability to grasp and manipulate objects. Ripper Designed for breaking through hard soil or pavement. Grading Blade Used for leveling and smoothing surfaces. Choosing the Right Implement

Selecting the appropriate attachment depends on the specific requirements of the project. Factors such as soil type, project scale, and desired outcomes should guide the decision-making process. Properly assessing the task can lead to more effective and efficient operation, allowing operators to accomplish their goals with greater ease.

Overview of Hydraulic System in Machinery

The hydraulic system plays a crucial role in the functionality of various types of equipment, enabling the effective transfer of power and movement through the use of fluid. This system is designed to convert mechanical energy into hydraulic energy, facilitating the operation of various components within the machinery. Understanding its structure and function is essential for maintaining optimal performance and efficiency.

Typically, a hydraulic system comprises several key components:

- Hydraulic Fluid: The medium that transmits power and lubricates the system.

- Pump: Responsible for generating flow and pressure, allowing the fluid to circulate through the system.

- Actuators: Devices such as cylinders or motors that convert hydraulic energy into mechanical energy.

- Valves: Control the direction and flow rate of the hydraulic fluid, ensuring precise movement and operation.

- Reservoir: A storage unit for the hydraulic fluid, allowing for proper circulation and cooling.

The efficiency of the hydraulic system significantly impacts the overall performance of machinery. Regular maintenance and timely inspection of the components are essential to prevent malfunctions and ensure smooth operation.

In summary, the hydraulic system is a vital aspect of modern machinery, enabling powerful and efficient operation across various applications. Familiarity with its components and functionality can greatly enhance the ability to troubleshoot and maintain equipment.

Replacing and Upgrading Machine Components

Maintaining and enhancing the functionality of machinery is essential for optimal performance and longevity. Regularly assessing and updating various components can significantly improve efficiency, reduce downtime, and extend the life of the equipment. This section delves into effective strategies for component replacement and upgrades, ensuring your machine operates at peak performance.

When considering upgrades, it is crucial to evaluate the specific needs of your equipment and identify which elements may benefit from enhancements. Factors such as compatibility, functionality, and overall performance should guide your decision-making process.

Component Upgrade Options Benefits Hydraulic System High-efficiency pumps Increased power and speed Transmission Enhanced gearsets Smoother operation and better torque Control Panel Digital displays Improved monitoring and ease of use Engine Performance-tuned components Greater fuel efficiency and power Ultimately, investing time and resources into replacing and upgrading essential components can yield significant returns in productivity and reliability. Stay proactive in managing your equipment to ensure its optimal functioning over the long term.

Common Issues with Backhoe Equipment

Excavation machinery is vital for various construction and landscaping tasks. However, like any complex equipment, it can encounter a range of challenges that affect its performance and reliability. Understanding these common issues can help operators maintain their machinery effectively and minimize downtime.

One prevalent concern is hydraulic system failures. Leaks or pressure drops can lead to inefficient operation, making it difficult to perform tasks accurately. Regular checks of hydraulic fluid levels and inspecting hoses for wear can prevent such problems.

Engine performance issues are another frequent complication. Factors such as fuel quality, air filter cleanliness, and regular maintenance play crucial roles in ensuring optimal operation. Neglecting these aspects can lead to decreased power and efficiency.

Additionally, electrical malfunctions may arise due to faulty wiring or connections. Monitoring the electrical system and addressing any signs of wear can mitigate these risks. Operators should also be aware of tire wear and track conditions, as these can significantly impact maneuverability and overall performance.

By staying informed about these potential issues and implementing proactive maintenance strategies, users can enhance the longevity and reliability of their excavation machinery.