When it comes to maintaining and operating a versatile machinery unit, a comprehensive grasp of its various elements is essential. The intricacies involved in these compact machines necessitate a clear understanding of how each component works in unison. This knowledge not only enhances operational efficiency but also aids in effective troubleshooting and repairs.

Visual aids play a crucial role in this learning process, offering a detailed representation of the equipment’s structure. By examining these illustrations, operators can easily identify where each element is situated and how they interact. Such clarity empowers users to tackle maintenance tasks with confidence and precision.

Furthermore, familiarity with the different mechanisms can lead to improved performance and longevity of the machinery. Understanding how each section contributes to the overall functionality ensures that users can maximize their investment while minimizing downtime. This article aims to provide an insightful overview of the various components involved, illustrating their significance in the realm of compact loaders.

Understanding John Deere 240 Skid Steer

This section explores the essential features and functionalities of a popular compact machinery model. With a focus on operational efficiency and versatility, it caters to various tasks, making it a vital asset in the construction and landscaping industries.

Key Features

The machine boasts an impressive lift capacity and maneuverability, enabling it to tackle diverse projects. Its robust design ensures durability, while user-friendly controls enhance the overall experience for operators.

Maintenance and Upkeep

Regular maintenance is crucial for longevity. Familiarizing oneself with the various components can lead to better care, ensuring optimal performance over time. Investing in quality replacements can significantly affect operational efficiency.

Essential Components Overview

This section highlights the fundamental elements that contribute to the efficient functioning of compact machinery. Understanding these components is crucial for maintenance and operational efficiency.

- Engine: Powers the entire machine, ensuring adequate performance.

- Hydraulic System: Enables lifting and movement through fluid power.

- Transmission: Facilitates power transfer and speed adjustments.

- Chassis: Provides structural integrity and stability during operation.

- Electrical System: Powers controls and lighting for enhanced usability.

Each of these parts plays a vital role, and regular inspection can prevent unexpected downtime.

Importance of Accurate Parts Diagrams

Detailed schematics play a crucial role in the maintenance and repair of machinery. They serve as visual guides, ensuring that technicians can identify components and understand how they fit together. This clarity enhances efficiency and minimizes the risk of errors during servicing.

When working with complex equipment, precision is vital. Accurate representations enable users to quickly locate specific elements, which can expedite repairs and reduce downtime. Moreover, they facilitate effective communication among team members, ensuring everyone is on the same page regarding maintenance tasks.

| Benefit | Description |

|---|---|

| Efficiency | Speeds up the repair process by providing clear visuals. |

| Accuracy | Reduces mistakes by ensuring proper identification of components. |

| Communication | Enhances collaboration among team members working on repairs. |

| Cost-Effectiveness | Minimizes unnecessary expenditures by avoiding misdiagnoses. |

Common Issues with Skid Steer Parts

When operating compact machinery, several frequent challenges can arise, affecting performance and efficiency. Identifying these issues early can save time and reduce repair costs, ensuring that the equipment functions optimally throughout its lifespan.

Frequent Mechanical Failures

Mechanical components can wear out or fail due to prolonged use or inadequate maintenance. Common failures include hydraulic leaks, worn tracks, and damaged buckets, which can significantly impact productivity.

Electrical System Glitches

Electrical issues are another prevalent concern, often leading to malfunctions in controls or starting systems. Problems may stem from faulty wiring, dead batteries, or malfunctioning sensors.

| Issue Type | Description |

|---|---|

| Hydraulic Leaks | Loss of fluid leading to reduced lifting capacity. |

| Worn Tracks | Decreased traction affecting maneuverability. |

| Electrical Malfunctions | Issues with starting or control systems. |

How to Read Parts Diagrams

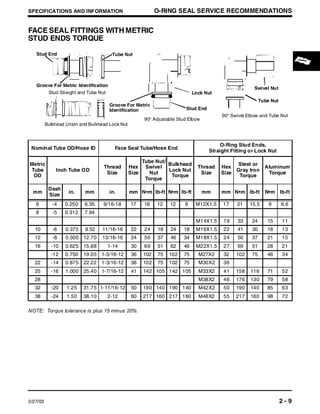

Understanding technical illustrations is essential for effective maintenance and repair tasks. These visual representations help users identify components and their relationships within machinery, enabling informed decisions when sourcing replacements or conducting repairs.

Key Elements of Visual Representations

Familiarizing yourself with common features in these illustrations can simplify the process. Each illustration typically includes labeled sections, part numbers, and references to accompanying manuals. Recognizing these elements will enhance your ability to navigate the visual information efficiently.

Utilizing the Information

Once you understand the basic structure, you can effectively utilize the information to locate specific components. When analyzing the illustration, pay attention to the following:

| Element | Description |

|---|---|

| Labels | Indicate the names of various elements within the system. |

| Part Numbers | Unique identifiers that allow you to order or reference specific items. |

| Connection Lines | Show how different components interact or are assembled. |

| Legend | A guide that explains symbols and notations used in the illustration. |

By leveraging this knowledge, you can effectively navigate and interpret technical illustrations, ensuring you have the right components for your repair tasks.

Finding Replacement Parts Easily

Locating suitable components for machinery can often feel like a daunting task. However, with the right approach and resources, you can streamline the process significantly. Understanding where to search and what to look for can save time and ensure that you acquire the correct items for your equipment.

Utilizing Online Resources

The internet is a treasure trove of information when it comes to sourcing equipment components. Websites specializing in heavy machinery often provide comprehensive catalogs, enabling users to search by model or category. Additionally, forums and community groups can be invaluable for recommendations and insights from fellow operators.

Consulting Local Dealers and Suppliers

While online options are convenient, local dealers can offer immediate access to necessary components. Establishing a relationship with nearby suppliers allows for personalized assistance, ensuring that you receive quality items tailored to your specific needs. Furthermore, these dealers often have in-depth knowledge about compatibility and can help identify any alternative options.

Maintenance Tips for Optimal Performance

Ensuring peak efficiency in your machinery requires regular attention and care. By implementing a consistent maintenance routine, you can extend the lifespan of your equipment and prevent unexpected breakdowns. This section outlines essential practices to enhance functionality and reliability.

1. Regular Inspections: Conduct routine checks on all critical components. Look for signs of wear and tear, leaks, or loose fittings, as early detection can save time and resources.

2. Cleanliness is Key: Keeping your equipment clean not only improves aesthetics but also prevents dirt buildup that can hinder performance. Regularly wash exterior surfaces and ensure internal areas are free of debris.

3. Fluid Levels: Maintain proper fluid levels for hydraulic systems, engine oil, and coolant. Regularly check and replace fluids as needed to ensure optimal functioning and prevent overheating.

4. Filter Replacement: Change air and oil filters according to manufacturer recommendations. Clean filters enhance airflow and lubrication, contributing to overall efficiency.

5. Tire and Track Maintenance: Regularly inspect tires or tracks for wear. Proper inflation and alignment can significantly affect traction and fuel efficiency.

6. Operator Training: Ensure that operators are well-trained in the use of the machinery. Proper techniques can prevent unnecessary wear and enhance overall productivity.

7. Scheduled Servicing: Adhere to a scheduled maintenance plan based on usage hours. Professional servicing can identify underlying issues before they escalate.

Implementing these practices will lead to reliable operation and longevity, ultimately safeguarding your investment.

Resources for Parts and Manuals

Accessing reliable resources for components and documentation is essential for maintaining machinery efficiently. This section provides valuable avenues for acquiring necessary information and items, ensuring that operators can keep their equipment in optimal condition.

Online Retailers: Numerous e-commerce platforms specialize in offering a wide selection of machinery components. These sites often provide detailed descriptions, making it easier to find the exact item needed.

Manufacturer Websites: Visiting the official site of the equipment manufacturer can yield comprehensive manuals and guides. These resources often include troubleshooting tips and maintenance schedules.

Forums and Community Groups: Engaging with online forums dedicated to machinery can be beneficial. Users frequently share insights, experiences, and recommendations for sourcing components and manuals.

Local Dealers: Establishing a relationship with nearby dealers can provide access to genuine items and expert advice. Many dealers also offer repair services and consultation.

Technical Documentation Libraries: Libraries that focus on industrial equipment often house a wealth of manuals and schematics. These can be invaluable for in-depth understanding and repair strategies.